Heat pipe type electromagnetic deironing device

A technology of electromagnetic iron remover and heat pipe type, which is applied in transformer/inductor cooling, magnetic separation, chemical instruments and methods, etc., can solve the problems of complex overall structure, unsuitability for large-scale development of electromagnetic iron remover, poor heat dissipation effect, etc. Achieve good heat transfer effect, superior performance, and reduce the effect of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

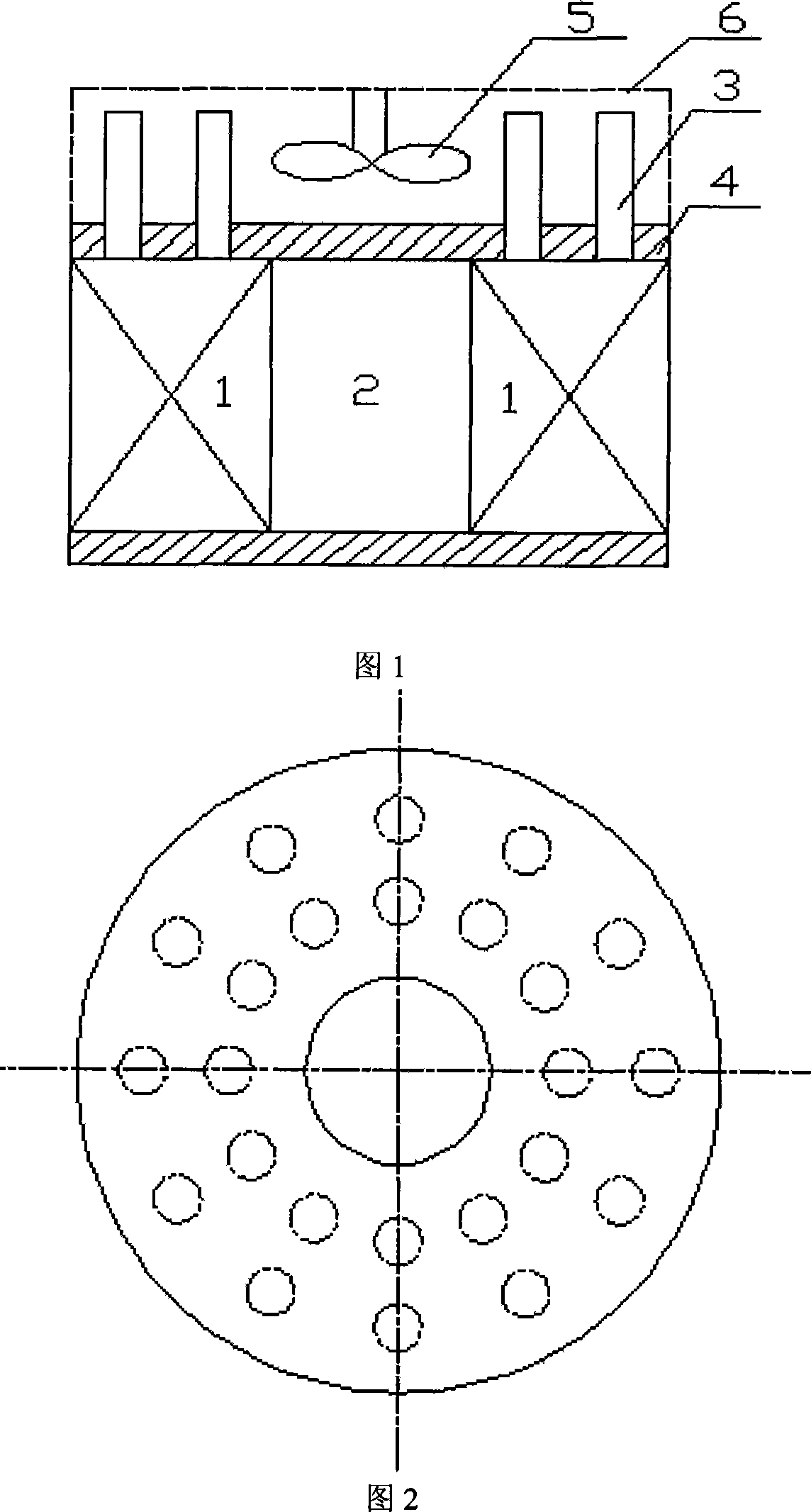

[0012] As shown in the figure, 1 is an annular cavity for placing electromagnetic coils, which is made of ordinary carbon steel plates. A magnetic core 2 is placed in the ring of the circular cavity. After putting the electromagnetic coil into the cavity, cover the middle partition 4, and determine the quantity and arrangement of the aluminum heat pipe condensing section 3 according to the heat dissipation mode and heat dissipation power. Aluminum material is selected for heat pipe condensing section 3, firstly because aluminum has a large heat dissipation coefficient and can dissipate heat in time, and secondly because aluminum material has a relatively low density, which can effectively reduce the weight of the electromagnetic separator. The cooling medium of the heat pipe is added into the annular cavity, and the cooling medium needs to have satisfactory thermal performance and good insulation performance. At present, R-113 or HFC- can be selected as the cooling medium of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com