Soft-water cooling pipeline control method for blast furnace

A soft water cooling and control method technology, applied in blast furnaces, cooling devices, blast furnace details, etc., can solve problems such as difficult adjustment of water volume, complex pipeline design, and reduced cooling intensity, so as to achieve convenient water volume adjustment, less equipment investment, and improved safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

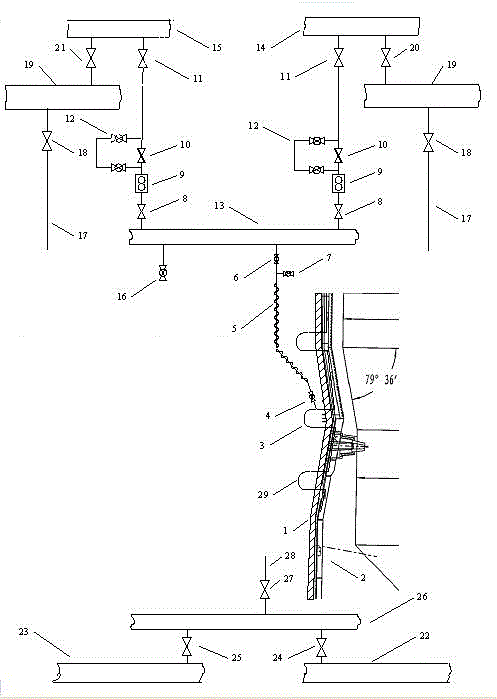

[0027] TISCO 3# Blast Furnace Overhaul Project, namely 1800m 3 The blast furnace is designed by the Shougang Design Institute. The cooling of the blast furnace body adopts the structure of full stave and thin fireplace lining. The cooling water pipeline is connected in series from the furnace bottom section to the furnace throat. Each section is composed of 40 staves. Each stave is equipped with 4 standpipe cooling channels, the water velocity in the channel is 2.5m / s, and the tuyere area is the fifth section of the stave, in the bosh, furnace waist, and lower part of the furnace body (6~9 sections, a total of four sections of copper cooling wall) using copper stave technology.

[0028] figure 1 As shown, the blast furnace soft water cooling pipeline control method is: the blast furnace soft water cooling pipeline includes a soft water cooling pipeline and a soft water branch pipeline.

[0029] Connection of soft water cooling lines:

[0030] 1# soft water inlet main pipe 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com