Patents

Literature

48results about How to "Lower the furnace temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

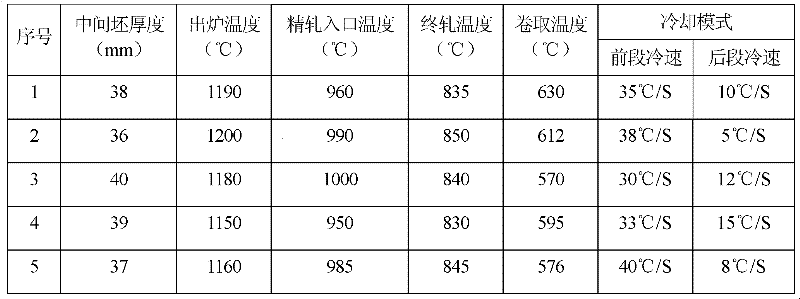

Preparation method for reducing scales generated on surfaces of hot-rolled steel plates

InactiveCN101947557ALower the furnace temperatureReduce the number of spawnsTemperature control deviceWork treatment devicesChemical compositionSheet steel

The invention belongs to the technical field of hot-rolled strips and relates to a method for controlling the surface quality of hot-rolled steel plates, namely a preparation method for reducing scales generated on the surfaces of the hot-rolled steel plates. The chemical components of the steel in the method have wider application range and are especially suitable for the hot-rolled steel platescontaining such microalloying elements as Nb, V, Mn and Si. The hot-rolled steel plates have the following chemical components by weight: not less than 0.05% and not more than 0.20% of C, not more than 0.70% of Si, not less than 0.20% and not more than 2.00% of Mn, not less than 0.02% and not more than 0.10% of Nb, not less than 0.03% and not more than 0.15% of V, not more than 0.12% of Ti, not more than 0.040% of P, not more than 0.030% of S and the balance Fe and inevitable impurities. The control method dispenses with improvement of existing equipment, is simple and controllable in processconditions, realizes the aim of reducing the scales by controlling the slab tapping temperature, the finish rolling, initial rolling and final rolling temperature, the coiling temperature and the cooling method and has the advantages of low energy consumption, low cost and wide applicable scope.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

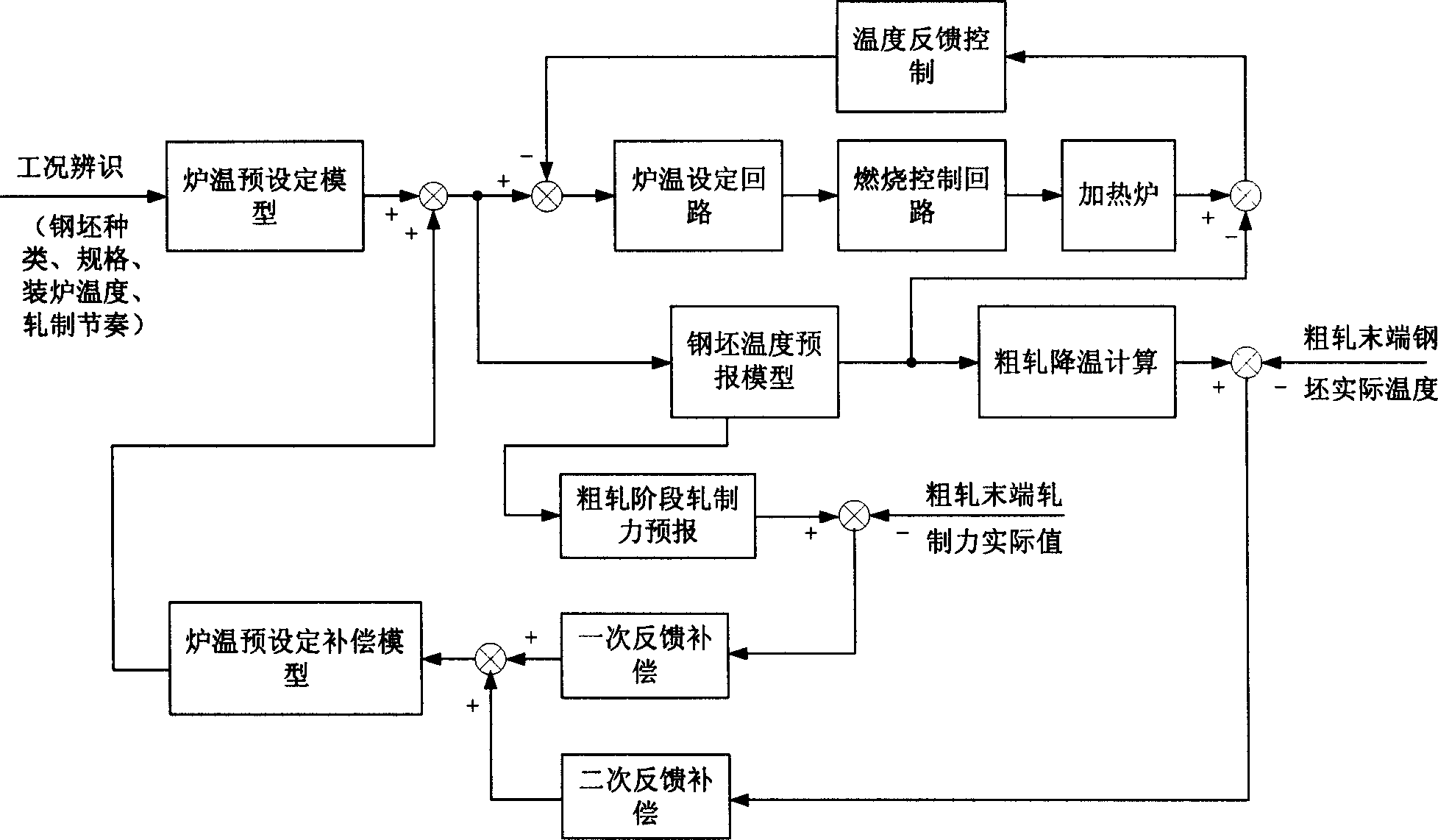

Heating furnace comprehensive optimizing controlling system designing and controlling method for hot rolling process

InactiveCN1644257AReduce the total energy consumption of productionAchieve optimal controlTemperature control deviceAdaptive controlProduction lineControl system design

A design and control method for the optimizing control system of intermediate rolling mill and heating furnace in order to improve the heating quality of billet in the heating furnace and save energy features that the heating furnace and intermediate rolling mill constitute a closed loop system, the information (rolling force, temp, etc) is fed back to heating furnace for dynamically changing the heating temp, and the optimizing control strategy and control algorithm are used in the billet heating process.

Owner:DALIAN UNIV OF TECH

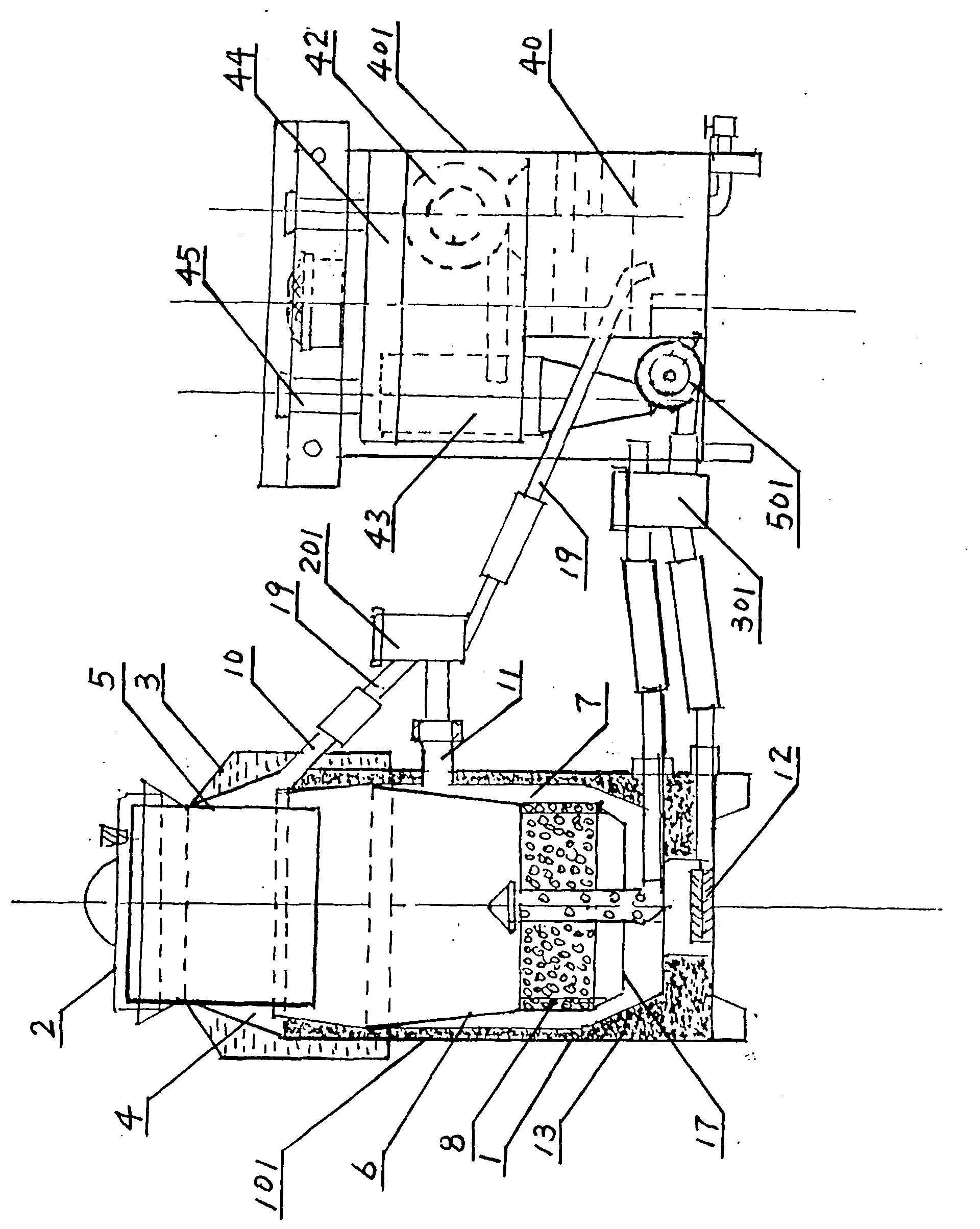

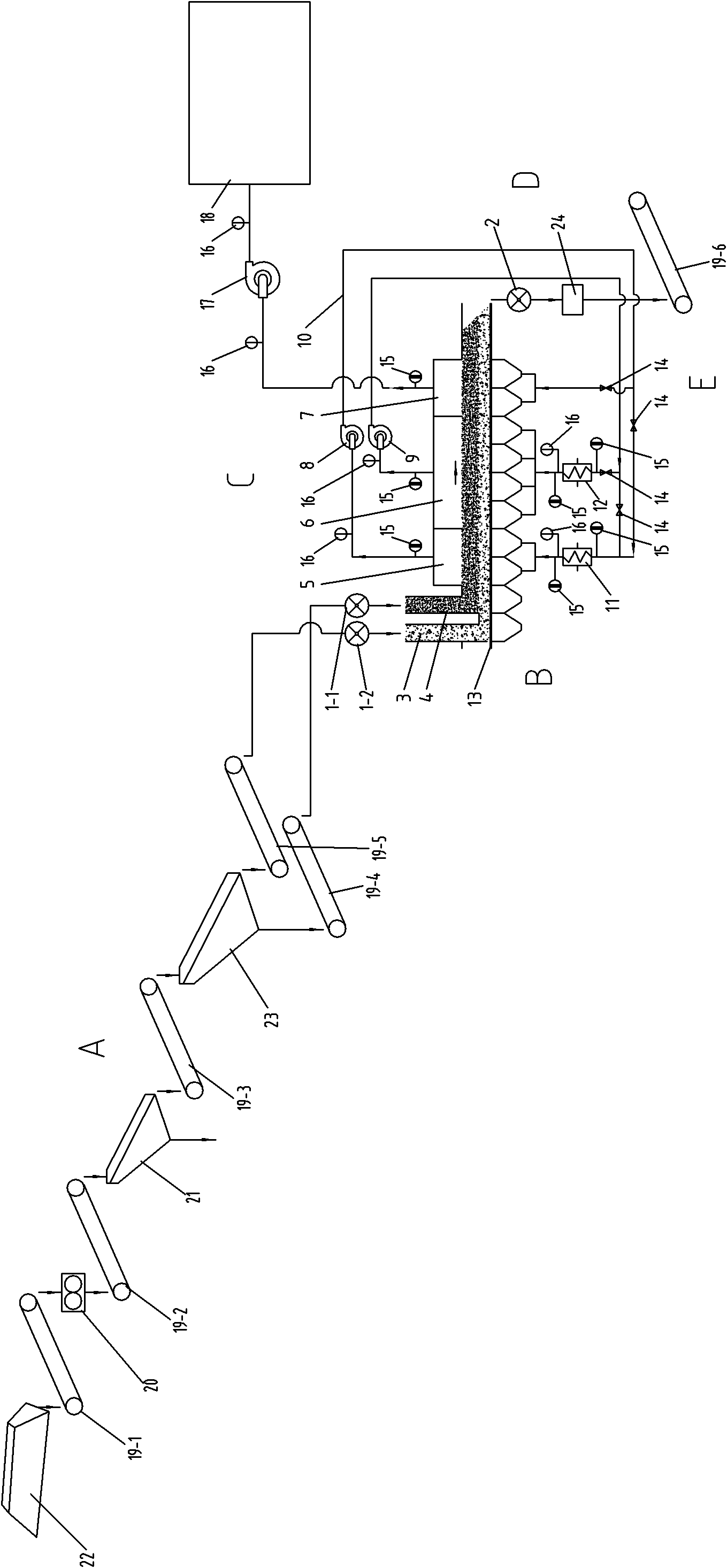

Double-flow biomass gasified gas purification device

InactiveCN102079998AHigh calorific valueIncrease contact areaBulk chemical productionCombustible gas productionReaction temperatureMoisture

The invention relates to a gasified gas purification device, in particular to a double-flow biomass gasified gas purification device, which solves the problems of low reaction temperature of a gasification furnace, abundant generated tar and wastewater, low gas-producing efficiency and abundant impurities and low heat value of output gas, resulted from unscientific structure of the gasification furnace. The gasified gas purification device comprises a gasification furnace, a gas flow control valve, a vortex flow oxidation-assisted control valve, a gas purifier and a fan. The gasified gas purification device provided by the invention has the advantages of increasing the reaction temperature of the furnace, wherein the temperature in oxidation, reduction and pyrolysis cylinders is between 1,300 and 1,600 DEG; increasing the gasification intensity; being capable of quickly separating moisture in biomass combustible gas so that gas quality is better; ensuring greatly reduced tar content in the combustible gas, less wastewater generated, high gas-producing efficiency and low environmental pollution due to the adoption of a mesh-type catalytic cracking device; and removing tar, moisture and ash in the gas through the gas purifier so that the heat value of the gas is improved. The gasified gas purification device is widely applied in industrial and civil fields.

Owner:林口信安建材板业有限公司

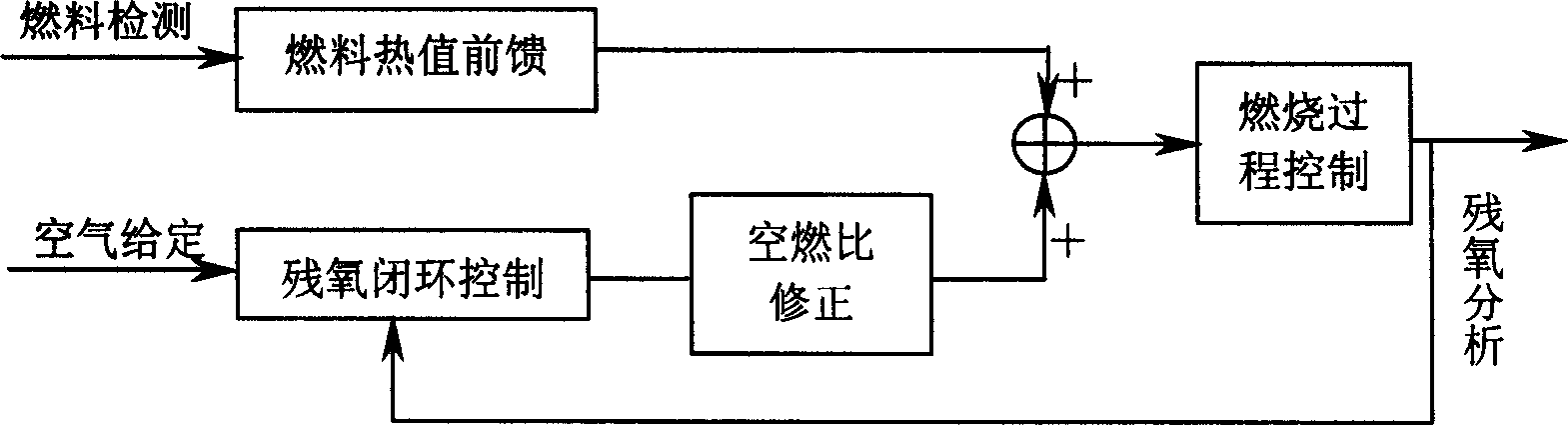

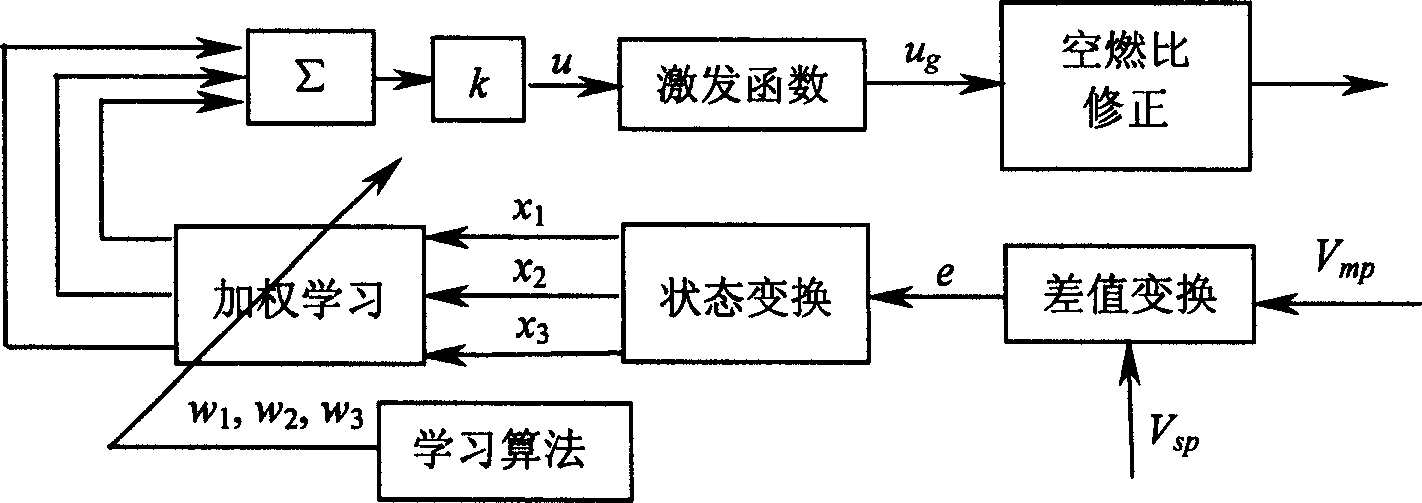

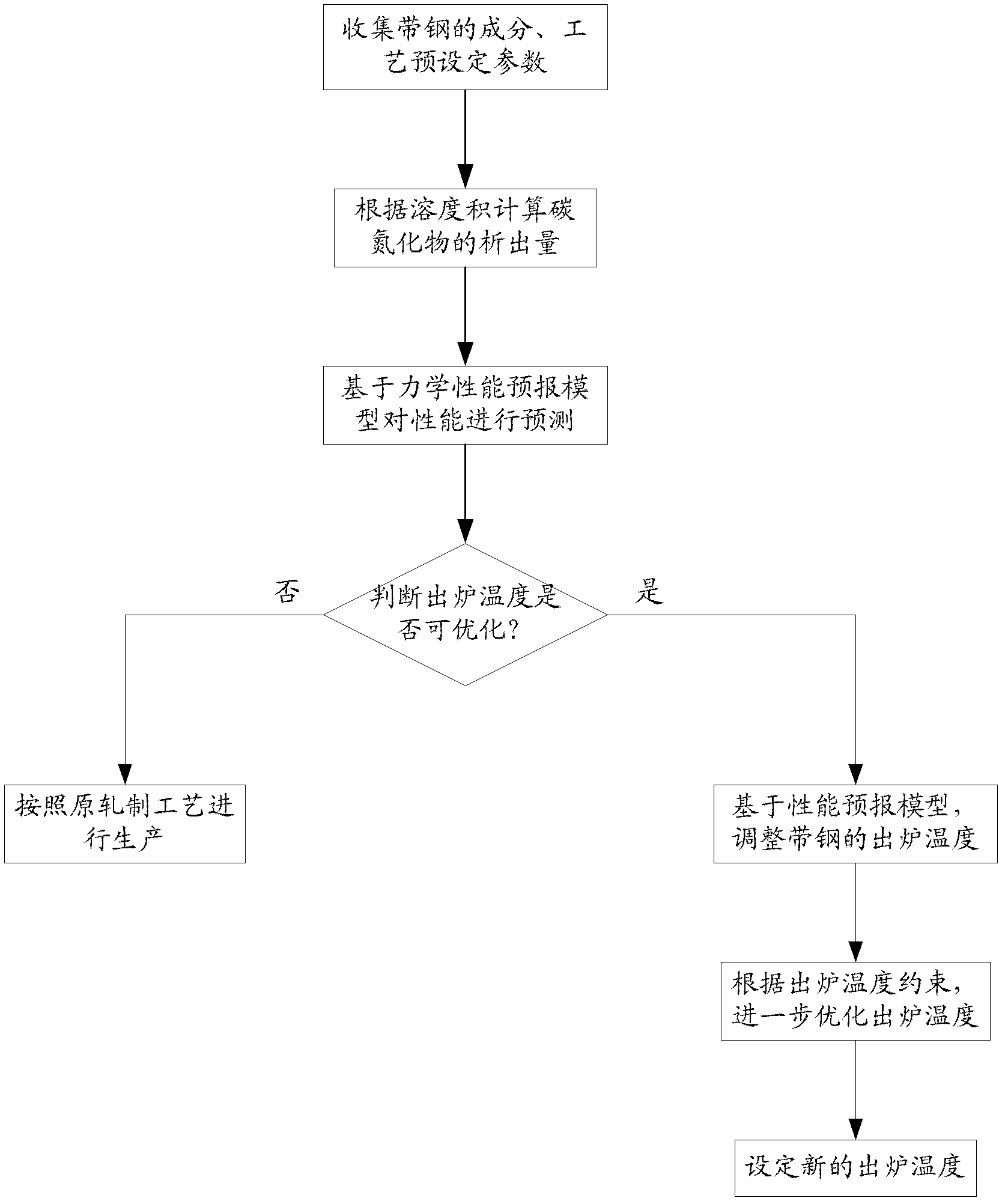

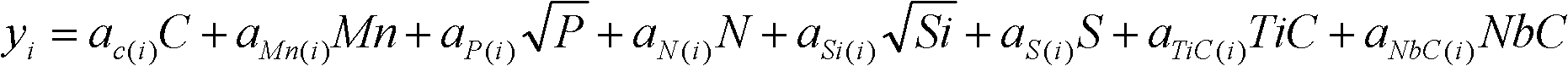

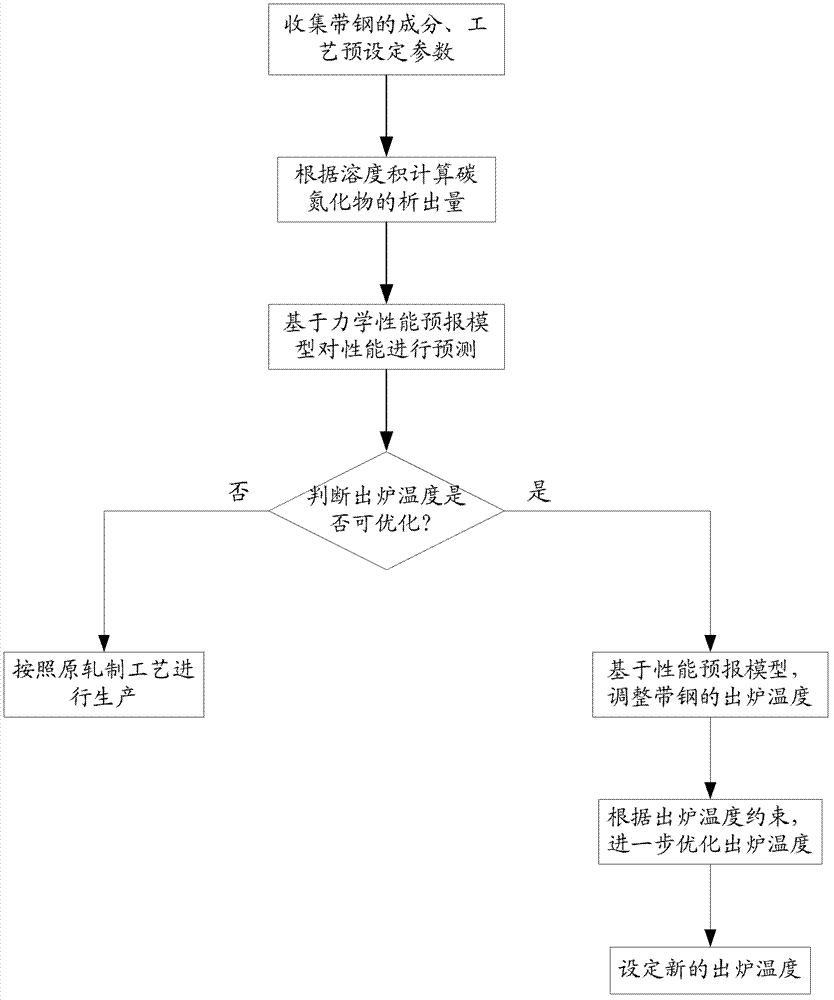

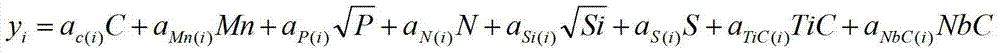

Heating furnace energy-saving control method based on strip steel mechanical property forecasting model

ActiveCN102560081AProcess temperature optimization controlRealize energy saving and consumption reductionFurnace typesHeat treatment process controlFurnace temperatureMechanical property

A heating furnace energy-saving control method based on a strip steel mechanical property forecasting model belongs to the field of process control and comprises the following steps: controlling the furnace temperature of a heating furnace on the basis of a process control computer, and establishing an industrial forecasting model for mechanical properties of a hot-rolled strip steel; before an ingot blank enters the heating furnace, forecasting the mechanical properties of the rolled strip steel according to chemical components and preset technical parameters; if the forecasted values of the mechanical properties are greater than the target values of the mechanical properties, optimizing the strip steel discharging technical temperature; and on the premise of ensuring the mechanical properties of the strip steel and not going against other necessary constraints, reducing the fuel gas consumption of the heating furnace by reducing the discharging temperature, so that the strip steel discharging technical temperature is optimized and controlled, and the fuel gas consumption of the heating furnace or the energy consumption of a unit product is reduced. The control method has a wide steel variety adapting range and can be widely applied to the field of temperature control of heating furnaces in slab blank hot rolling production lines.

Owner:BAOSHAN IRON & STEEL CO LTD

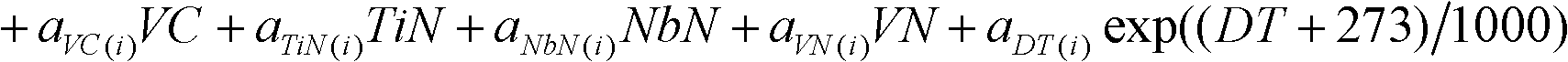

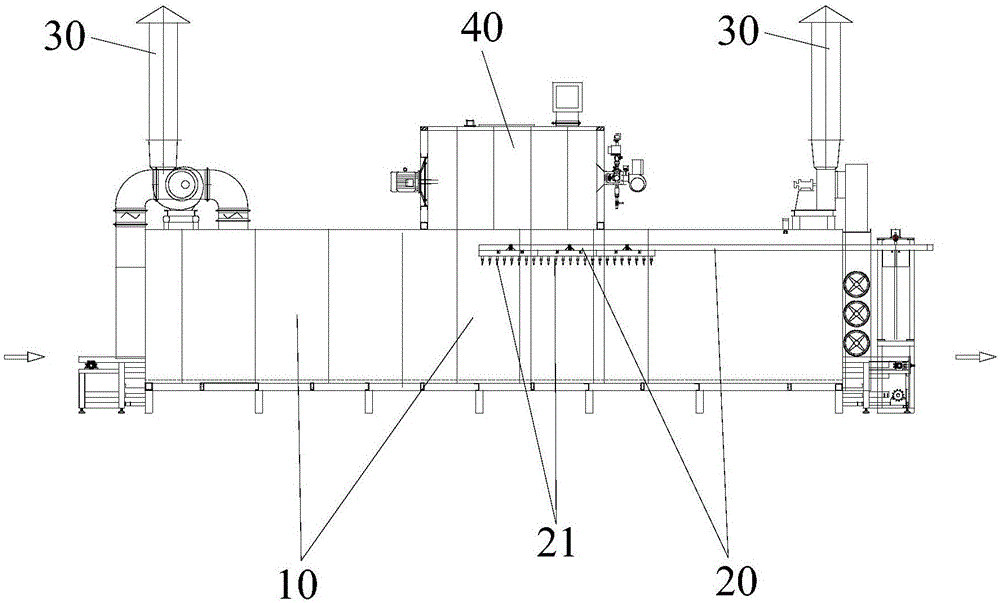

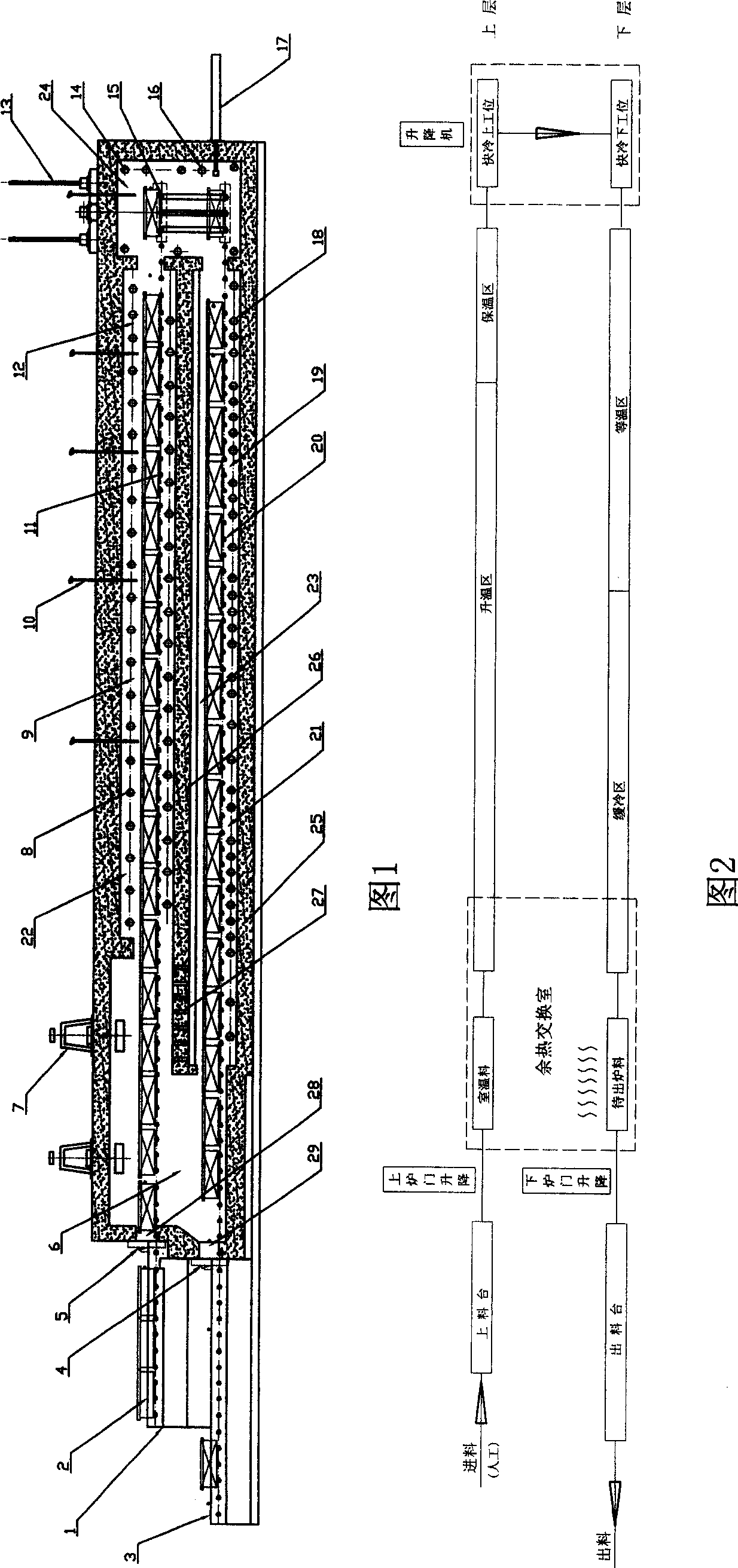

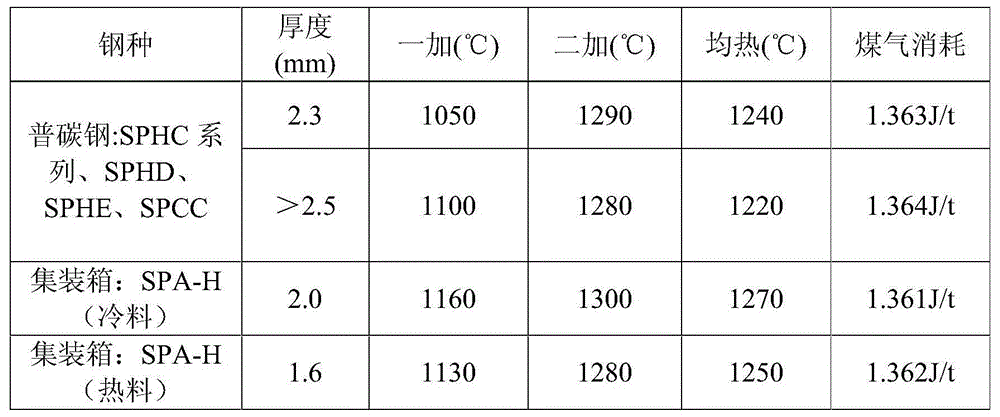

Double layer roller bottom type continuous spheroidizing annealing furnace

ActiveCN1908203AGood for healthEasy and reliable annealing transferFurnace typesHeat treatment furnacesCooling chamberHearth

the invention discloses a double-layer roll-bottom continuous-balling annealing furnace, which contains furnace, wherein the hearth consists of upper hearth and lower hearth, whose inlet and outlet are set on one end of furnace; the residual heat exchanging chamber is set near the furnace; the sealing rapid-cooling chamber is set in the furnace far away from inlet and outlet, which interconnects upper and lower furnaces; the upper driving roll is set on the upper furnace; the lower driving roll is set in the lower furnace; the elevator and pushing rod are set in the sealing rapid-cooling chamber; the upper heater and heat coupler are set in the upper furnace and lower heater is set in the lower furnace.

Owner:杭州骏马轴承有限公司

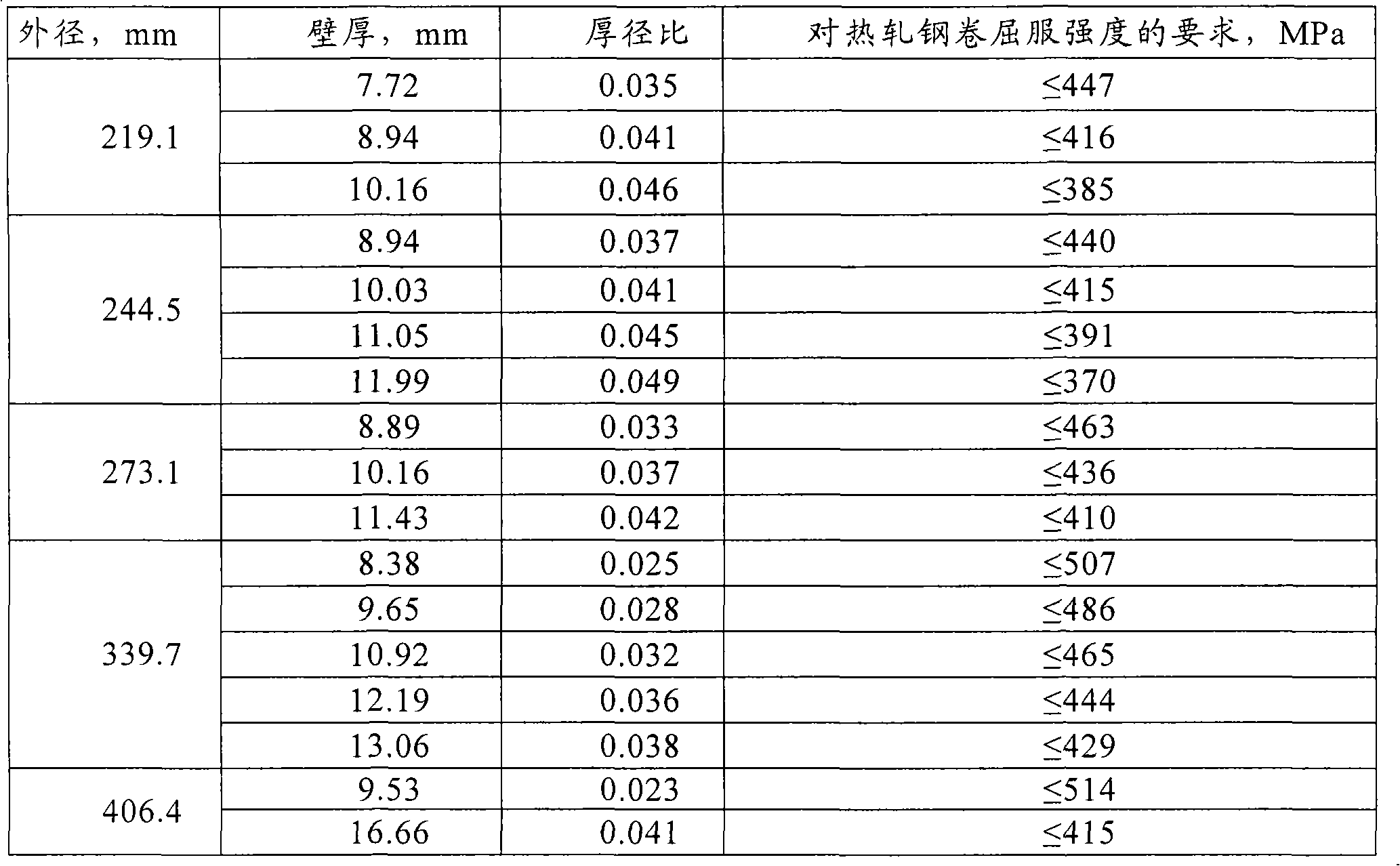

Petroleum sleeve steel and manufacturing method thereof

ActiveCN101845583AReduce formationHigh tensile strengthDrilling rodsTemperature control deviceMolten steelThermal treatment

The invention provides petroleum sleeve steel which comprises the following components in mass percent: 0.31-0.35 of C, 0.1-0.45 of Si, 0.8-1.5 of Mn, not more than 0.02 of P, not more than 0.01 of S, not more than 0.024 of Al, not more than 0.1 of V, not more than 0.35 part of Mo, and the balance Fe and inevitable impurities. The invention further provides a manufacturing method of the petroleum sleeve steel. The manufacturing method comprises the following steps: smelting molten steel by a converter or an electric furnace, and then casting the smelted molten steel into board blank; heating the board blank to the temperature of 1190-1260 DEG C, and then primarily rolling into board bands; conveying the primarily rolled board bands and then finally rolling through a final roller, wherein, the temperature for final rolling is 820-920 DEG C; and cooling the finally rolled board bands, and then rolling up the bands into steel coils at the temperature of not less than 610 DEG C. In the invention, the steel coils produced by the manufacturing method can meet the requirements of the steel with all specifications (i.e. the ratio of radius to thickness is not more than 0.049) for a non-integral pipe thermal-treatment straight welding petroleum sleeve API K55 on the hot-rolled steel coils.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for controlling aluminum component in steel

InactiveCN102021276AReduce entryReduce deoxygenation burdenProcess efficiency improvementMolten steelMolten slag

The invention belongs to the technical field of ferrous metallurgy and relates to a method for controlling an aluminum component in steel. In order to solve technical problems, the invention provides the method for precisely and stably controlling the aluminum component in steel, particularly the aluminum component in low-carbon aluminium steel. The control method comprises the following steps of: A, smelting in an electric furnace or a converter, wherein the primarily smelted molten steel is deoxidized by aluminum after the molten steel is discharged; B, low-frequency (LF) refining; and C, continuous casting. The control method is characterized in that: in the LF refining process, the adding amount of slag is 12 to 14Kg per ton of steel during slagging; and based on 100 weight parts, the slag mainly comprises the following components in part by weight: 60 to 68 parts of CaO, 15 to 20 parts of Al203, more than zero part and less than or equal to 5.0 parts of SiO2, more than zero part and less than or equal to 3.0 parts of MgO and 10 to 15 parts of CaF2. When the control method is used, the activity of SiO2 in the slag can be reduced, and the probability of reaction between aluminum in the steel and SiO2 in the slag can be reduced, so that the aluminum component in the molten steel is precisely controlled and the desulfurization rate of the molten slag is also improved at the same time.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

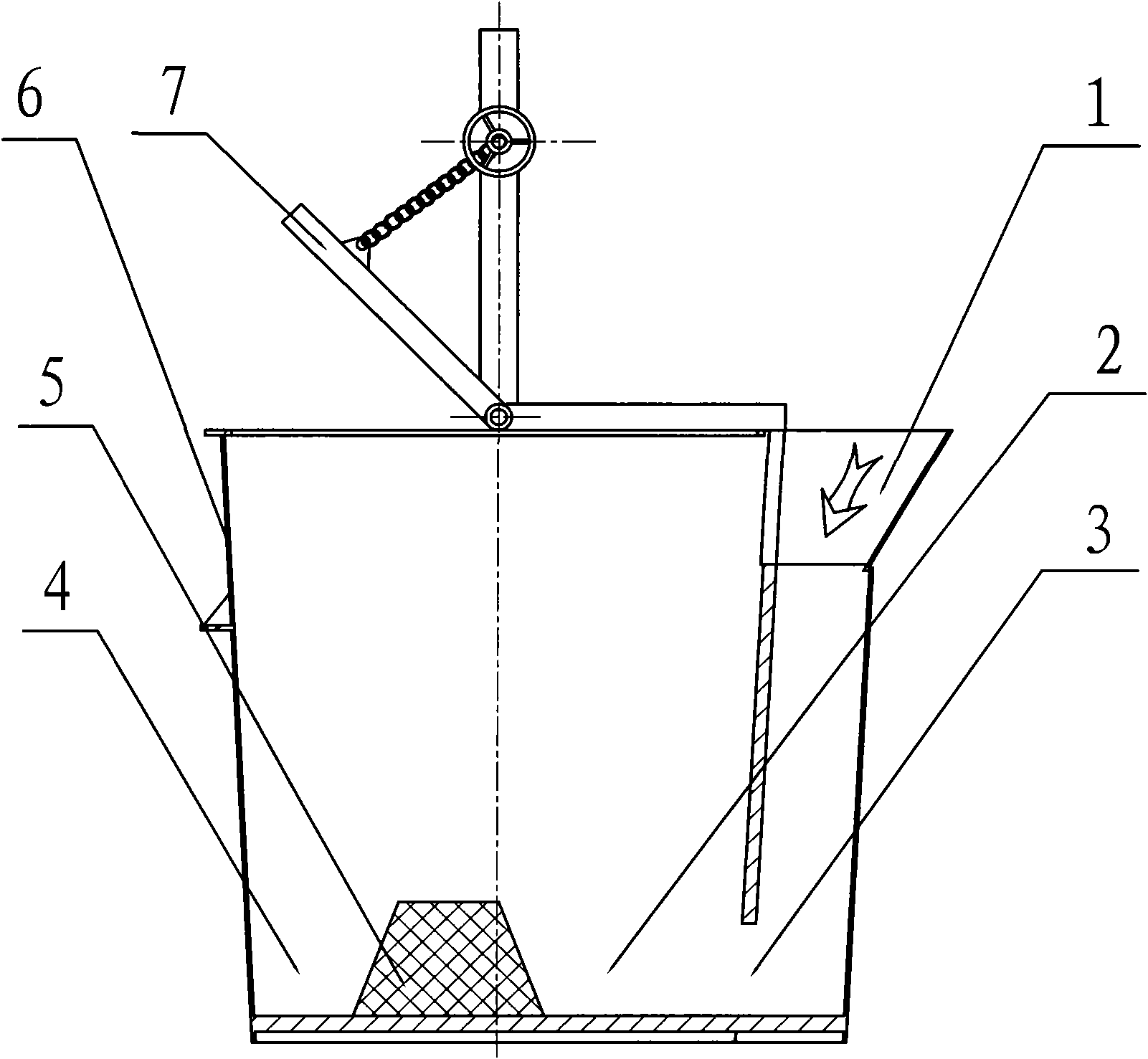

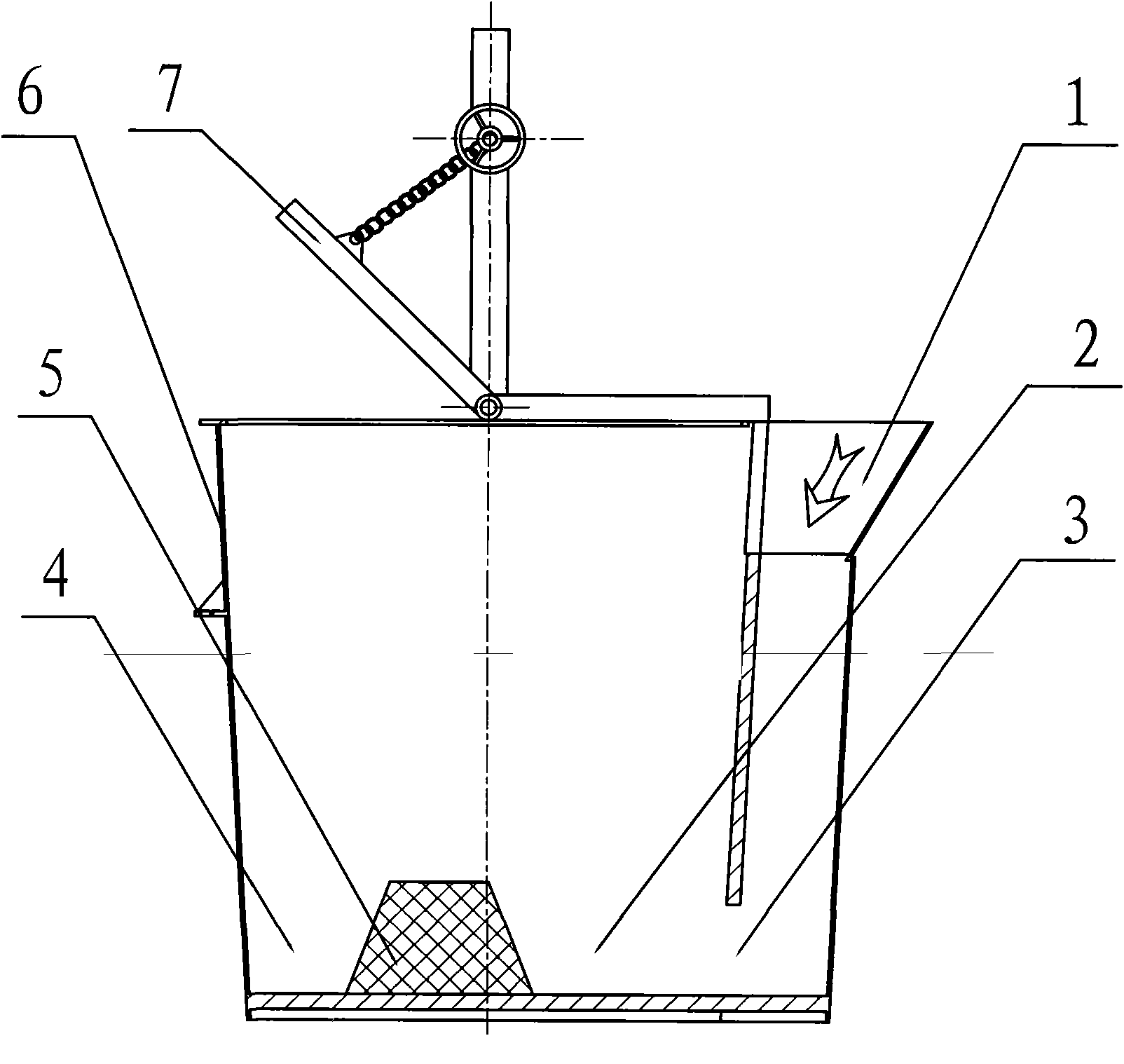

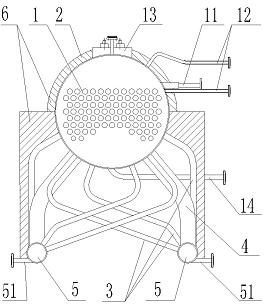

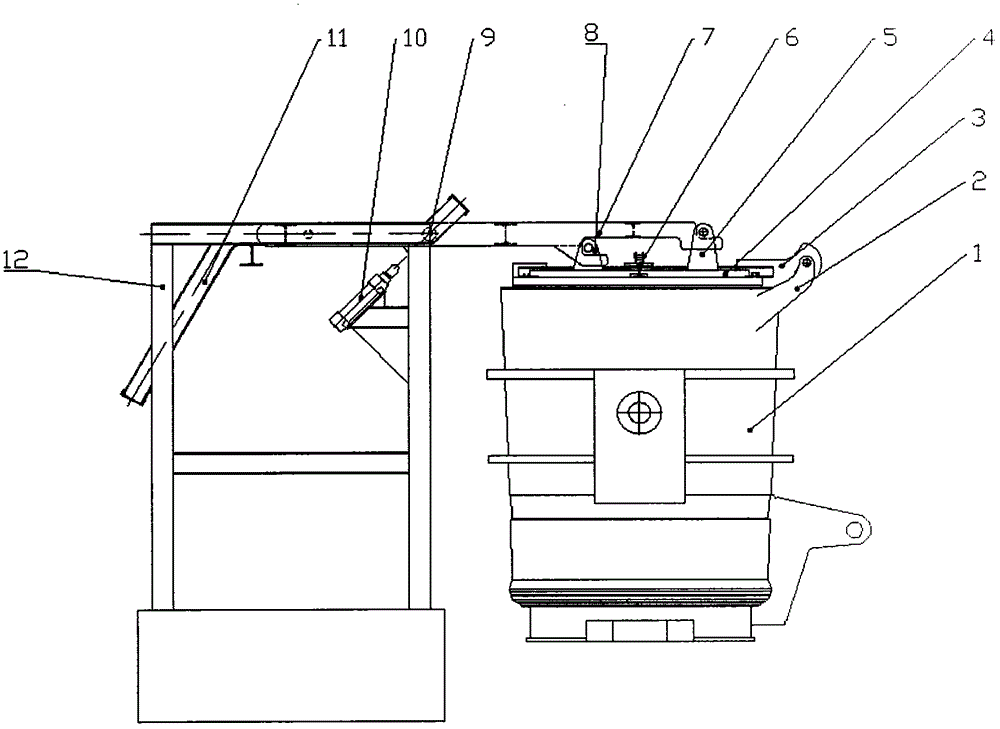

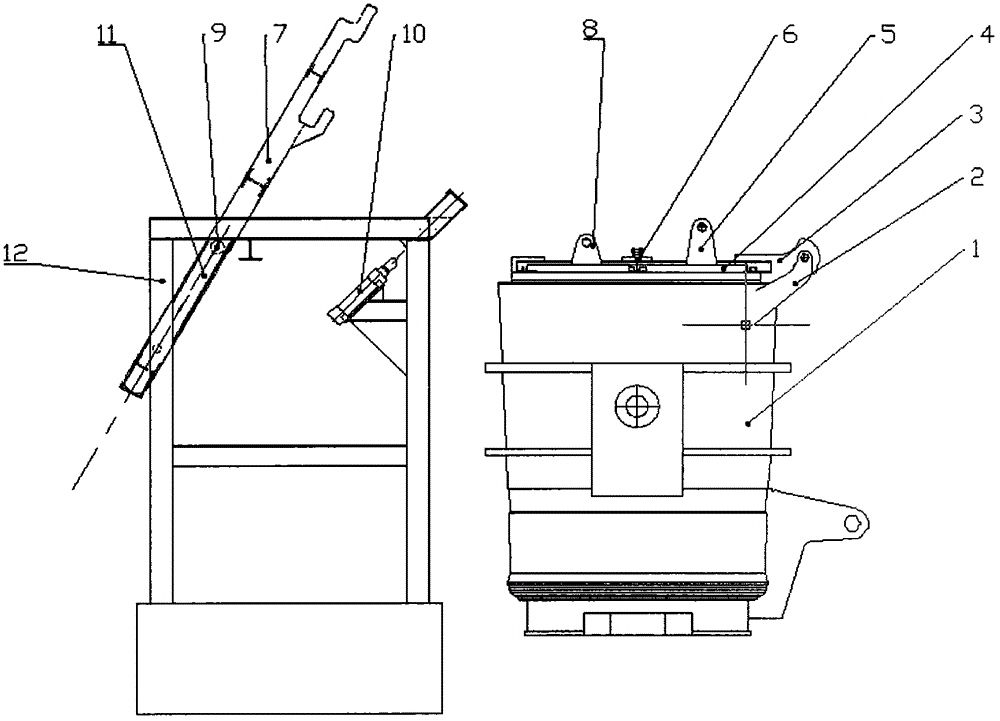

Teapot nodulizing packet

InactiveCN101817076AReduce the amount addedReduce pollutionMelt-holding vesselsWorking environmentAir pollution

The invention discloses a teapot nodulizing packet which has simple structure, convenient use and high utilization rate of nodularizer and can also be used as a pouring packet. The teapot nodulizing packet comprises a packet body (6), and the inner bottom of the packet body (6) is provided with a dike (5) which divides the bottom of the packet body (6) into a feed chamber (2) and a nodulizing chamber (4). The teapot nodulizing packet is characterized in that the upper part of the packet body (6) is provided with a single sealing side cover (7), one side of the packet body (6) is provided with a pot nozzle (1), and the lower part of the packet body (7) is provided with a molten iron inlet and outlet port (3) communicated with the pot nozzle (1). The feed chamber (2) is communicated with the pot nozzle (1) through the molten iron inlet and outlet port (3). The invention has simple and reasonable structure, and nodulizing and pouring are carried out in one packet. During a nodulizing reaction, the absorption rate of magnesium can reach more than 85 percent, the addition quantity of the nodularizer is reduced, the labor intensity is lightened, the working environment is improved, and the air pollution is reduced; meanwhile, the tapping temperature of molten iron is also reduced, so that production cost is lowered.

Owner:桃江新兴管件有限责任公司

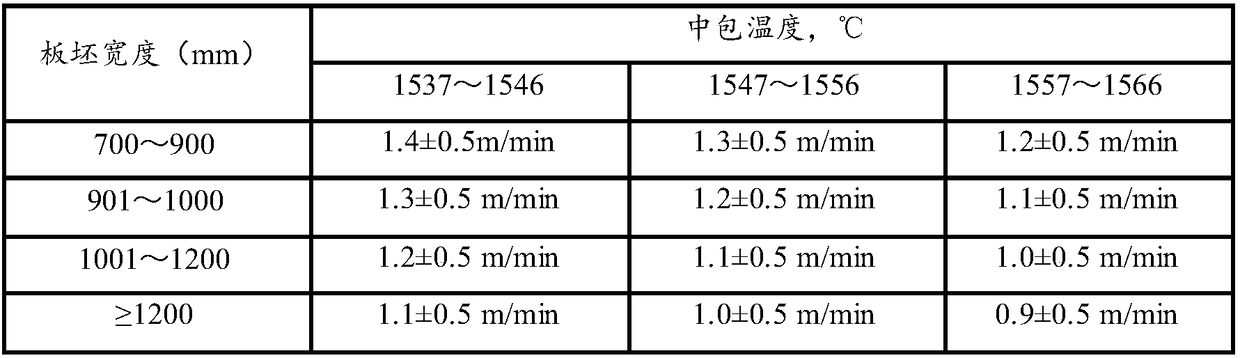

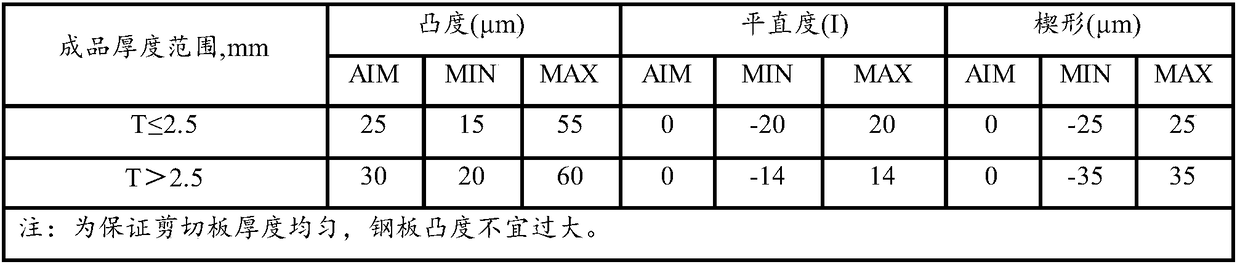

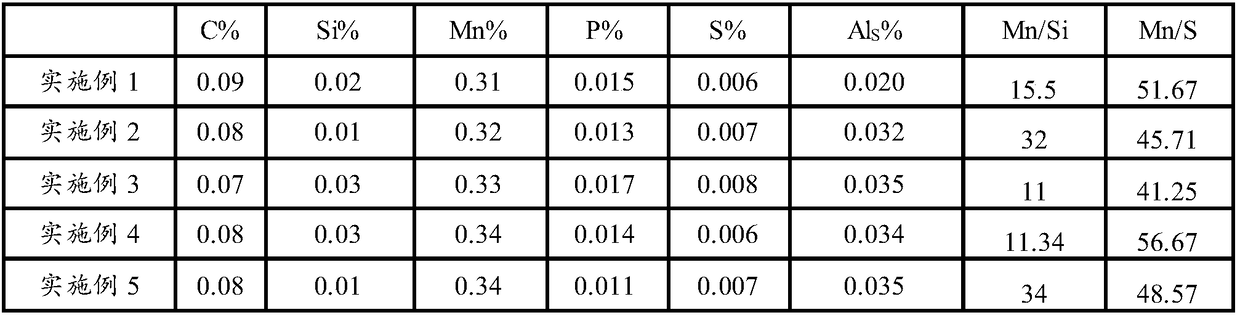

Hot-rolled coil for wheel and preparation method thereof

The invention provides a hot-rolled coil for a wheel. The hot-rolled coil is prepared from the following components in percentage by weight: 0.04 to 0.11 percent of C, 0 to 0.05 percent of Si, 0 to 0.5 percent of Mn, 0 to 0.025 percent of P, 0 to 0.015 percent of S, 0.02 to 0.04 percent of Al and the balance of Fe, wherein the ratio of the Mn to the Si is larger than or equal to 8; the ratio of the Mn to the S is larger than or equal to 15. The components of the hot-rolled coil for the wheel are controlled specially, and particularly the ratio of the Mn to the Si and the ratio of the Mn to theS are controlled, so that rolled steel prepared from the special components can be smelted directly through a rotary kiln to obtain a wheel with performance meeting the standard; the tapping temperature is low, LF external refining is avoided, the preparation process is simple, and the cost is low; moreover, sulfide inclusion in the provided hot-rolled coil is low, the problem of cracking occurring in a subsequent wheel preparing process is solved effectively, and the hot-rolled coil has high yield in the preparation of the wheel.

Owner:吉林建龙钢铁有限责任公司

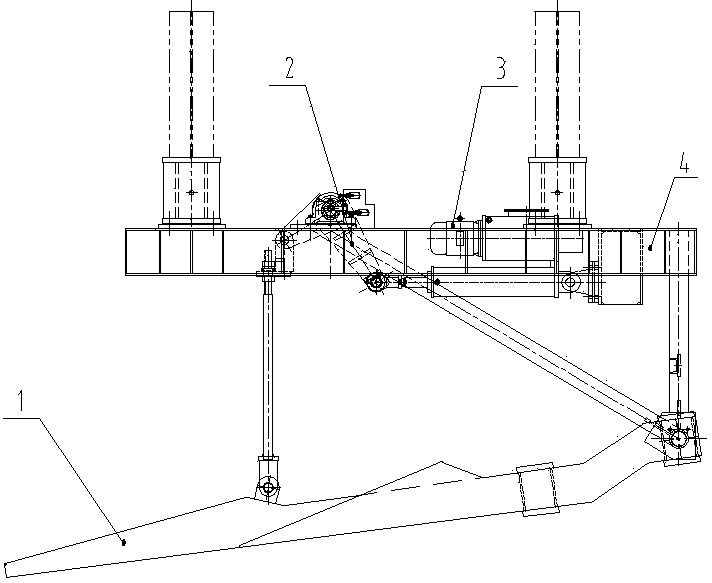

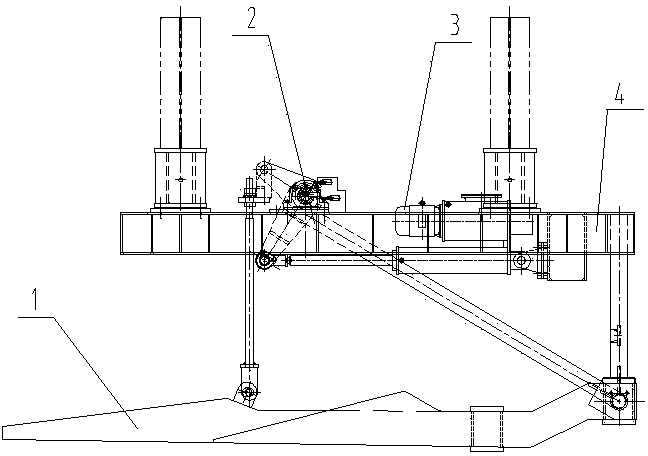

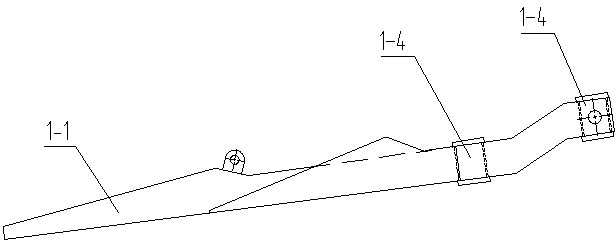

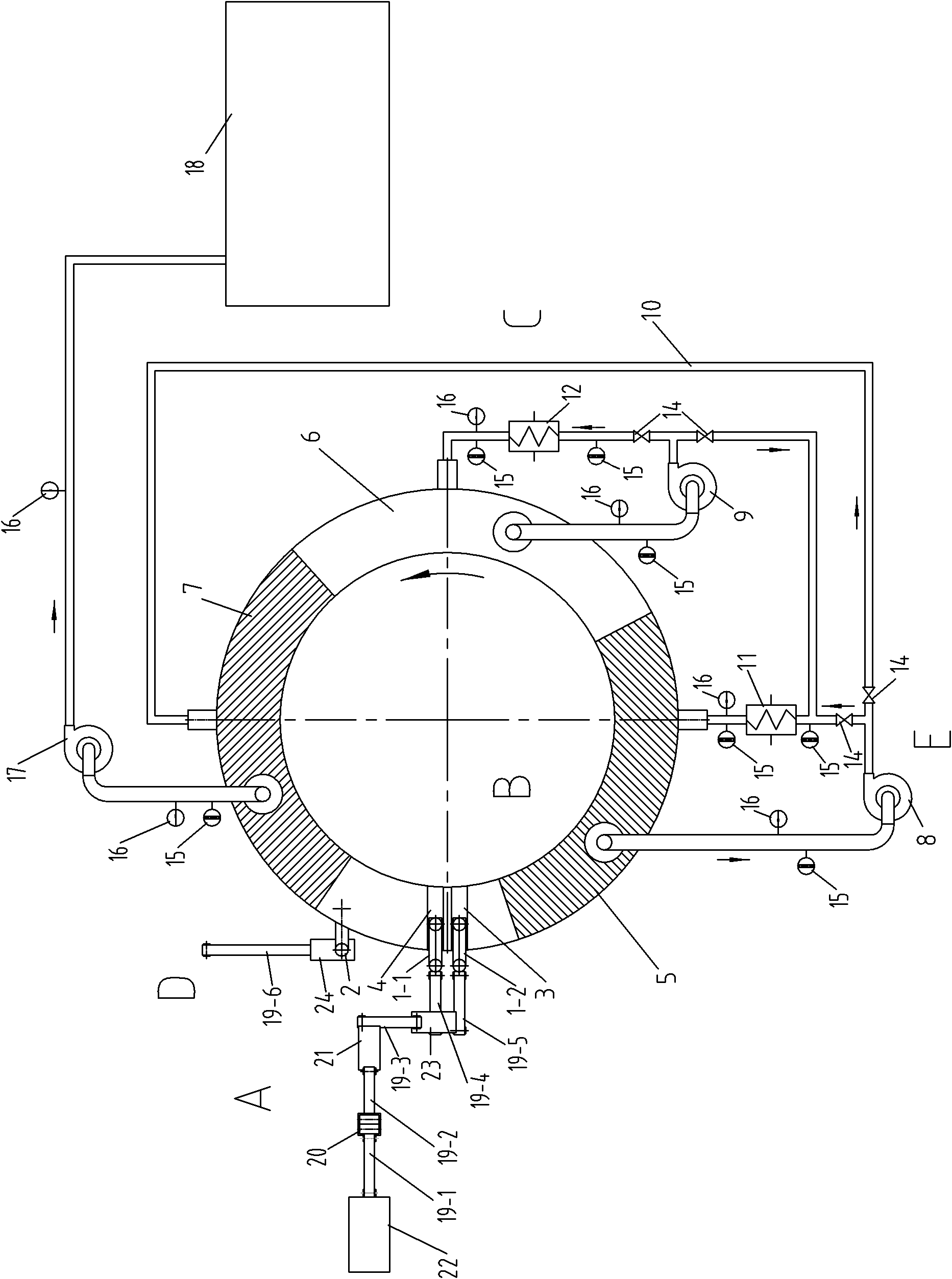

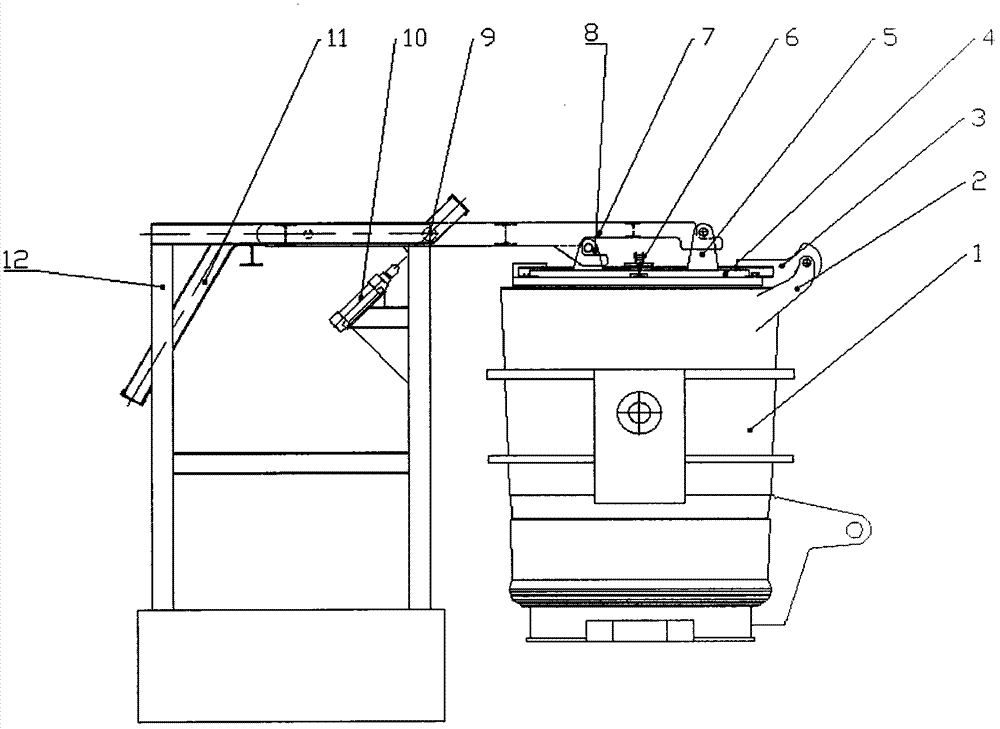

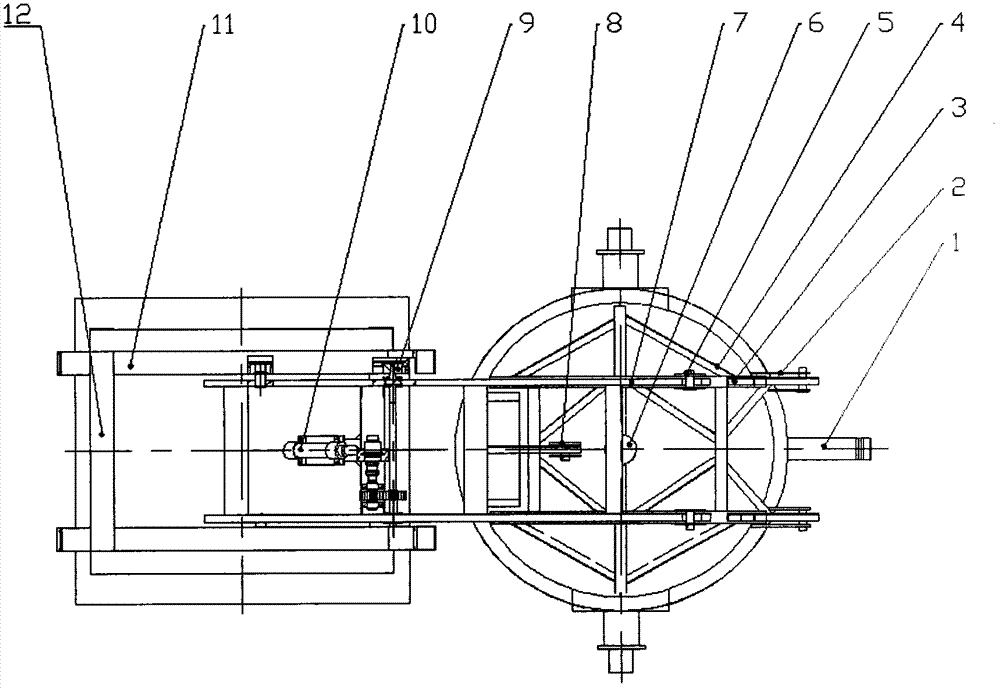

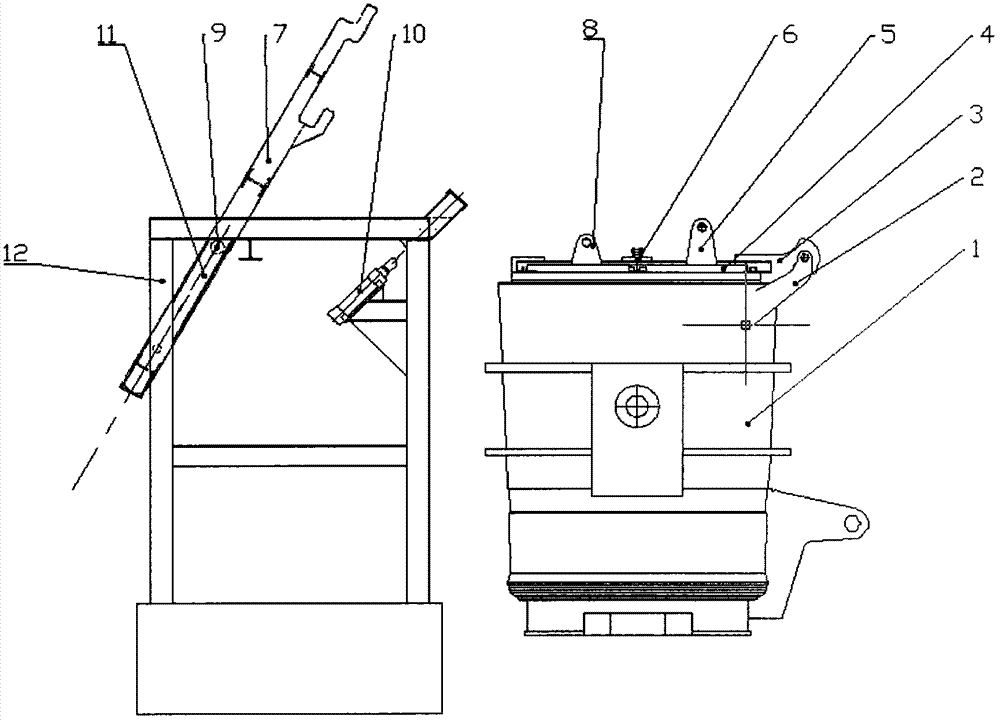

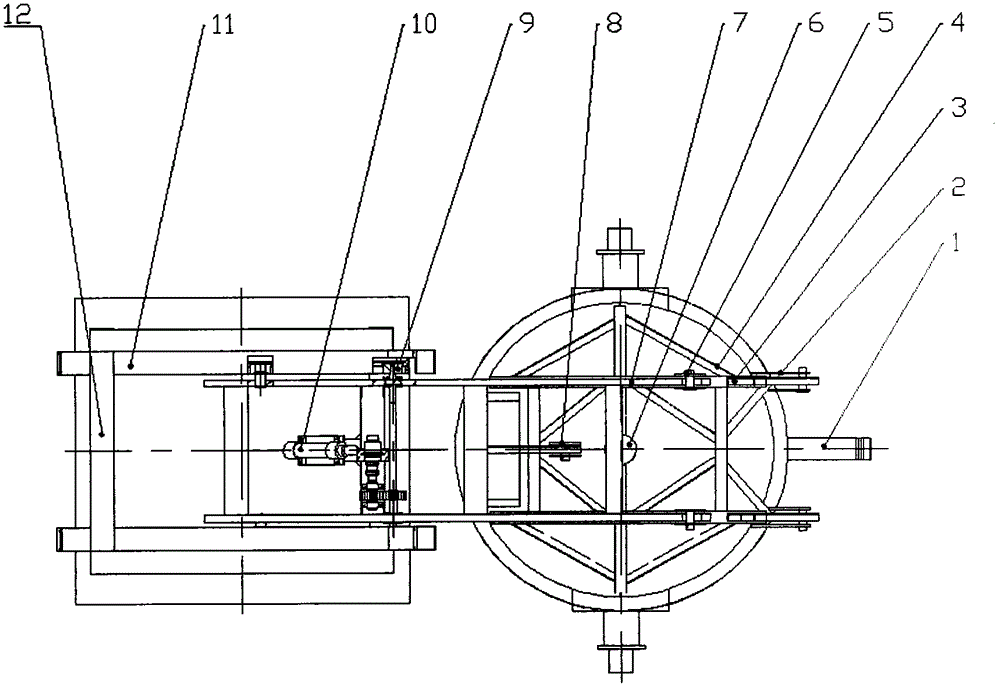

Electro-hydraulic drive M-shaped steel ladle capping and decapping device

The invention discloses an electro-hydraulic drive M-shaped steel ladle capping and decapping device, which relates to the structure of a whole-course full-automatic capping and decapping device of a high-temperature melt container in metal smelting. The electro-hydraulic drive M-type steel ladle capping and decapping device comprises a fixed frame, wherein the fixed frame is fixedly connected with an electro-hydraulic push rod and a connecting rod mechanism; the fixed frame is hinged to an M-shaped prong assembly; the electro-hydraulic push rod is connected with the connecting rod mechanism; the connecting rod mechanism is hinged to the M-shaped prong assembly. According to the electro-hydraulic drive M-type steel ladle capping and decapping device disclosed by the invention, the electro-hydraulic push rod is stretched to drive the connecting rod mechanism to control the swinging of the M-shaped prong assembly, an included angle between the M-shaped prong assembly and the horizontal plane is regulated, and capping and decapping are realized by the movement of a buggy ladle. High-cost heat energy is avoided and prevented from outwards losing to the outside from a steel ladle lining used for containing molten steel and liquid steel, the steel mill production cost is lowered, the operation condition is improved, and the production rate is improved.

Owner:JIANGSU DISA MACHINERY

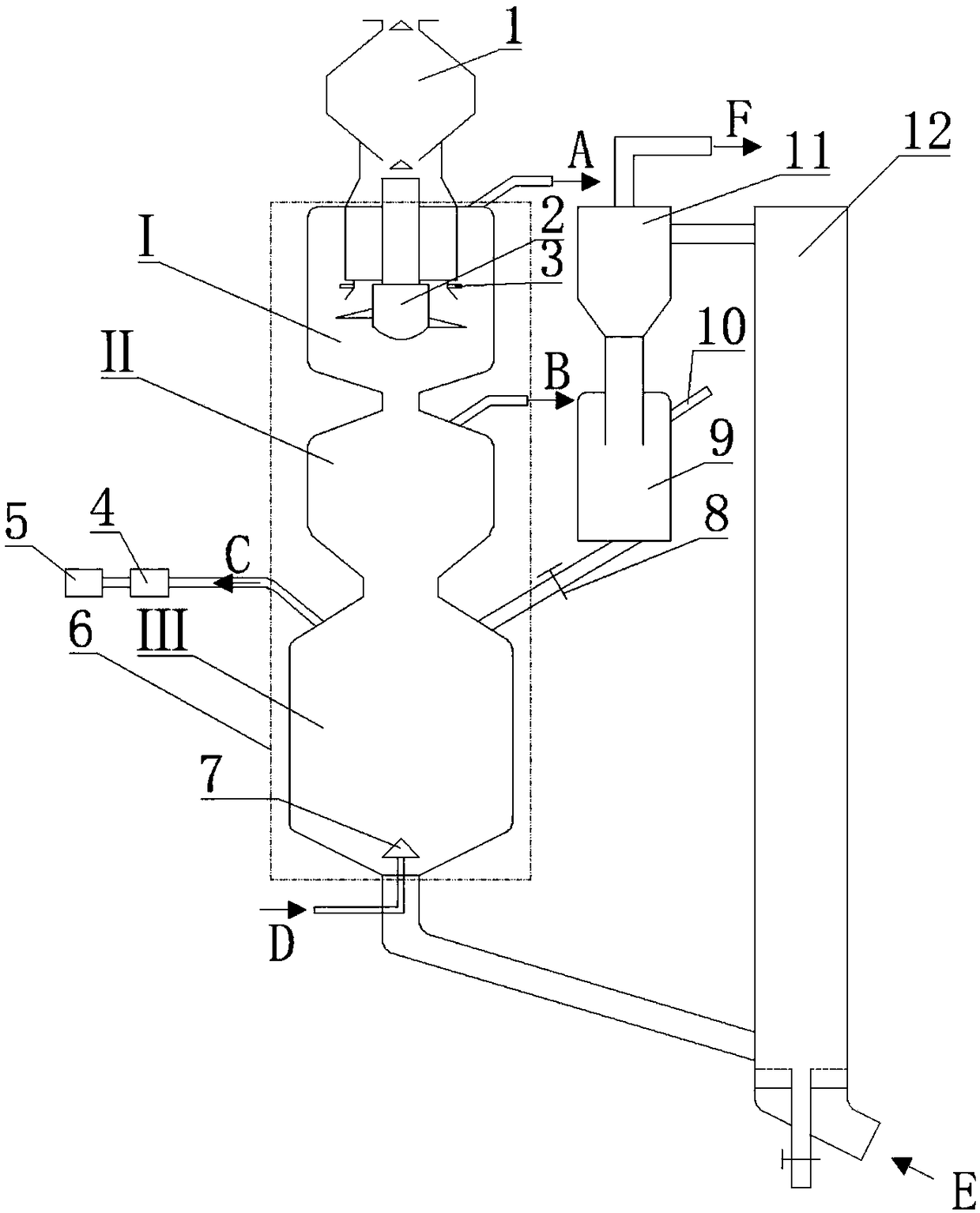

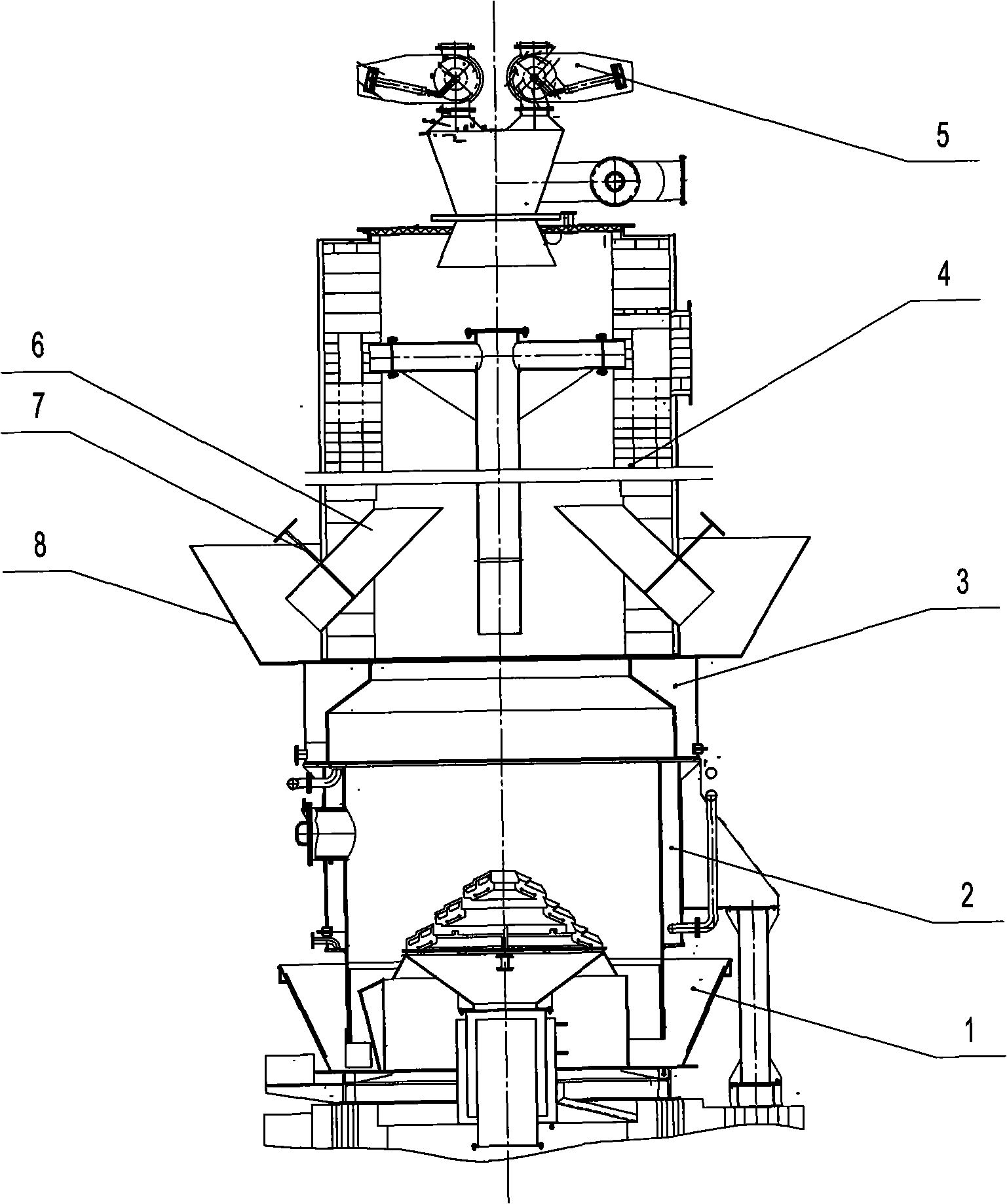

Oil shale dry distillation system

InactiveCN101818072AIncrease profitReduce resistanceDirect heating destructive distillationSpecial form destructive distillationThermal energyControl system

The invention relates to an oil shale dry distillation system. A distribution system of the oil shale dry distillation system is communicated with a reaction furnace through a related conveying output pipeline; the reaction furnace is communicated with a dry distillation gas circulating system through a control system and the related conveying output pipeline; and the dry distillation gas circulating system is communicated with a cooling system through the related conveying output pipeline. The oil shale dry distillation system can finish crushing, screening, furnace charging, heating, collection of shale dry distillation gas, cooling and collection of shale carbocoal and the like; the distribution system of the oil shale dry distillation system positions large grain size oil shale on thelower part of a batch layer and small grain size oil shale on the upper part of the batch layer, solves the problems that small grain size particles are easy to leak out of a furnace grate and carbocoal particles are easy to be blocked in a gap of the furnace grate and cannot fall off, improves the utilization ratio of the oil shale, reduces the resistance of the batch layer, prevents powder in the batch layer from being carried off, and effectively reduce the dust content; besides, the oil shale dry distillation system reduces the carbocoal tapping temperature and improves the utilization efficiency of heat energy so that the carbocoal is convenient to process. The oil shale dry distillation system has the advantages of reasonable design, compact layout, reliable performance, low-carbon environmental protection and low running cost, and is easy for industrialized extraction of shale oil.

Owner:曹志德 +2

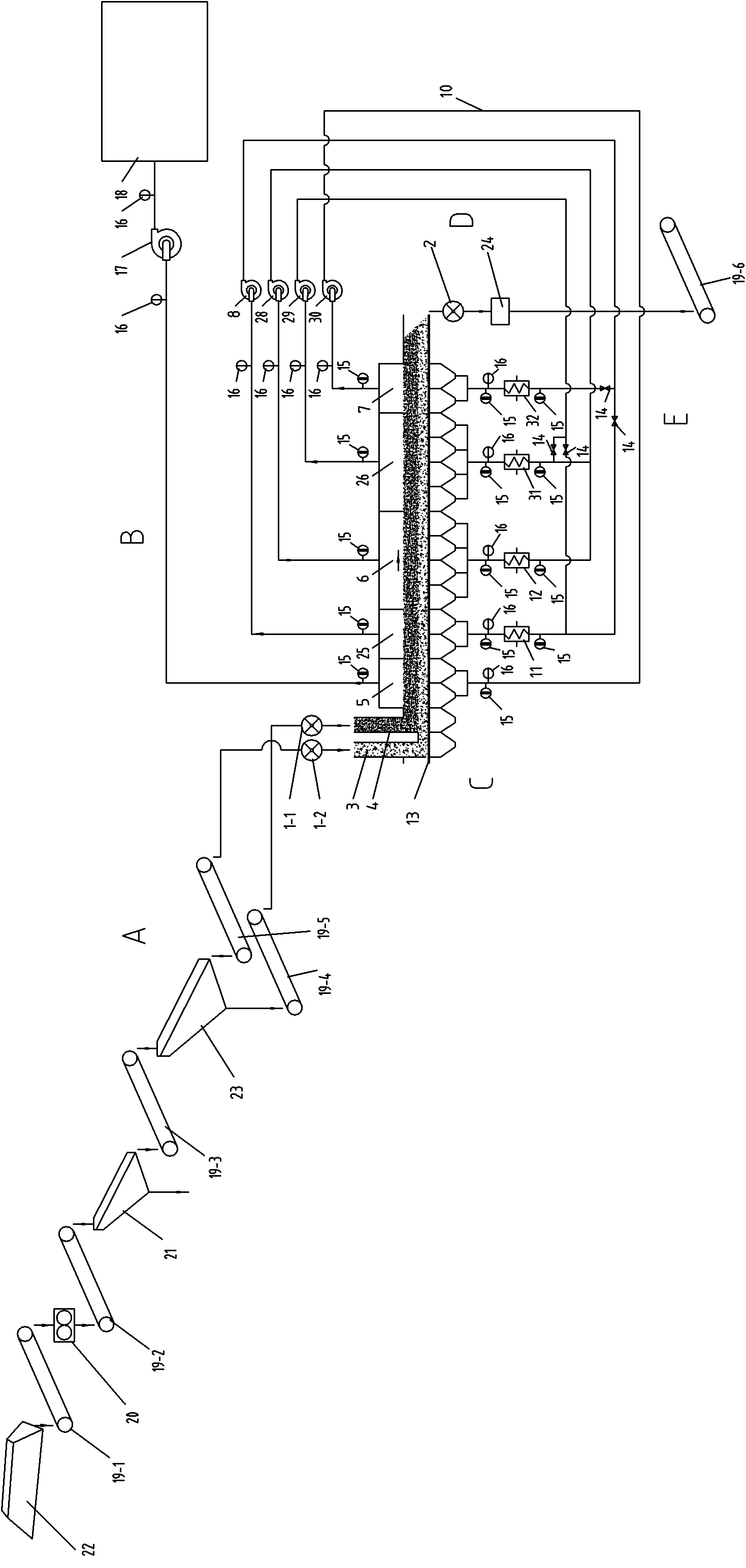

Carbon-based fuel chemical chain combustion gasification coupling device and method

PendingCN108504389ALower conversion rateExtended stayGasification processes detailsSpecial form destructive distillationGas solidCombustion

The present invention provides a carbon-based fuel chemical chain combustion gasification coupling device comprising a moving bed fuel reactor, a fast bed air reactor, a cyclone separator and an oxygen carrier storer; the moving bed fuel reactor includes a drying pyrolysis section I, a gasification section II and a combustion section III; a feeding device is arranged on one end of the drying pyrolysis section I, and the other end of the drying pyrolysis section I is connected to one end of the gasification section II, the other end of the gasification section II is in communication with one end of the combustion section III, and the combustion section III is sequentially connected to the fast bed air reactor, the cyclone separator and the oxygen carrier storer through a pipeline to form aclosed loop; tan active oxygen carrier is placed in the oxygen carrier storer; and a gasification agent distribution device is disposed at the bottom of the combustion section III. The carbon-based fuel chemical chain combustion gasification coupling device can prolong the time of gas-solid and solid-solid contact in the reactor, thereby improving the conversion rate of a carbon-based fuel, and can realize the preparation of crude gas, clean gas and the effective separation of CO2.

Owner:JIANGSU UNIV

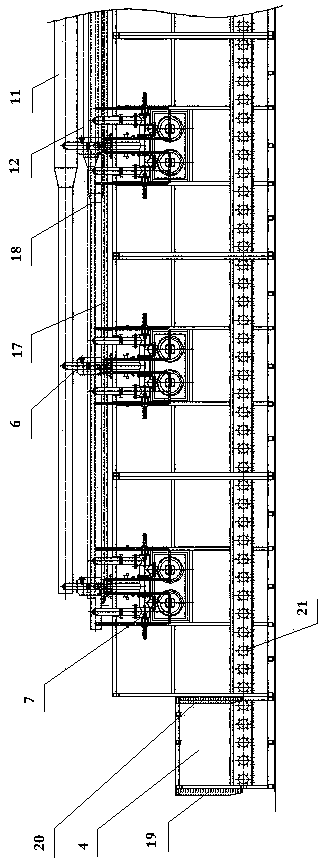

Hot air circulation heat storage type radiant tube heating sealing roller way kiln

PendingCN108870958ADischarge in timeGuaranteed tightnessCharge composition/stateCharge treatment typeTemperature controlControl system

The invention discloses a hot air circulation heat storage type radiant tube heating sealing roller way kiln. The problems that in the prior art, temperature control is unstable, the heat efficiency is low, and the product percent of pass is low are solved. The kiln is characterized in that a kiln body comprises a preheating section (1), a constant-temperature section (2) and a cooling section (3); a roller transmission device, a circulation air device, a heating device and a cooling device are arranged in the kiln body, and a feeding kiln door (20) and a discharging kiln door (22) are formedin the two ends of the kiln body; a feeding chamber (4) and a discharging chamber (5) are additionally arranged at the two ends of the kiln body, a feeding chamber door (19) is formed in the feeding chamber (4), and a discharging chamber door (23) is formed in the discharging chamber (5); moisture eliminating systems are arranged on the preheating section and the constant-temperature section on the top of the kiln. The whole equipment is good in sealing performance and reasonable in structure and has the advantages that heating is uniform, the temperature is easy to control, and the quality ofproducts is high, the whole kiln is provided with a full-automatic feeding and discharging mechanism and a full-automatic detection and control system, the labor intensity of workers is reduced, theworking efficiency is improved, the firing percent of pass of the products reaches 99%, and energy is saved by 38%.

Owner:HUANGGANG HUAYAO ZHONGZHOU KILN

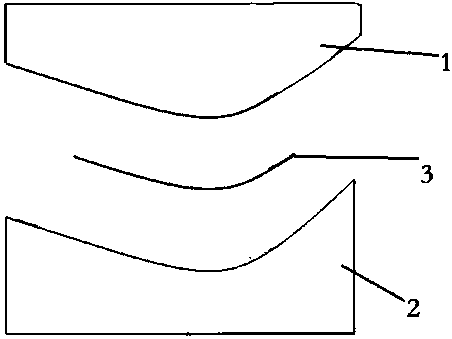

Vacuum thermal creep type forming method of titanium alloy skin and titanium alloy skin

The invention discloses a vacuum thermal creep type forming method of titanium alloy skin. The vacuum thermal creep type forming method comprises the following steps: 1) a to-be-formed titanium alloymask is positioned between an upper mold and a lower mold which are matched; 2) the skin and the mold are heated in a vacuum environment, the forming temperature is 700 DEG-900 DEG C, and after the temperature is maintained for a preset time, the skin is cooled with a furnace and then discharged into the furnace; and 3) the mold is disassembled, and forming of the titanium alloy skin is completed.Due to the fact that the integral vacuum heating is adopted, the creep deformation of the titanium alloy skin is realized by the gravity of the mold, the furnace discharge temperature is low, the skin is cooled to be below 150 DEG C along with the furnace, the rebound amount of the skin is small after forming, the residual stress is small, and the size precision is high.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

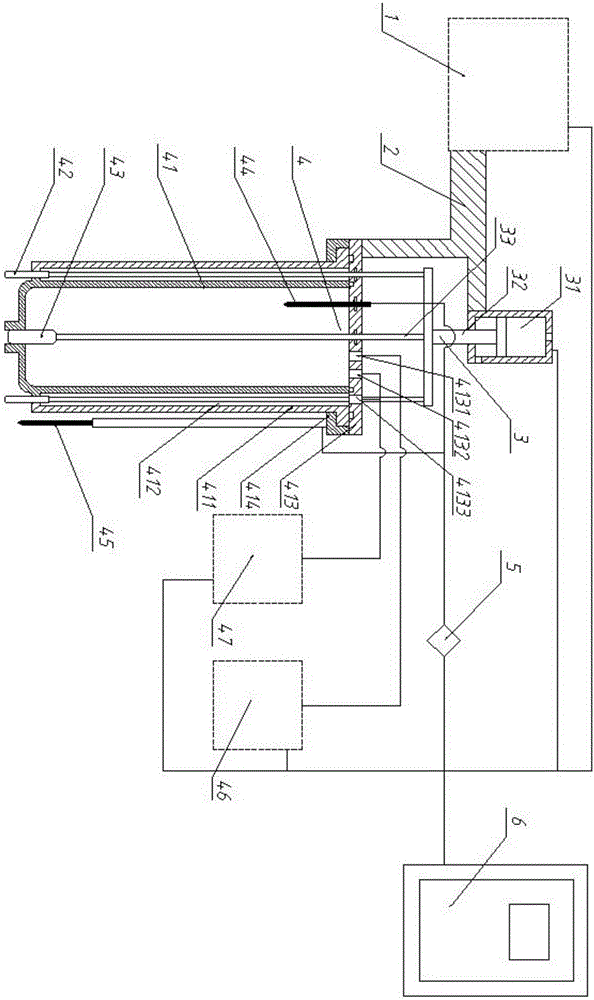

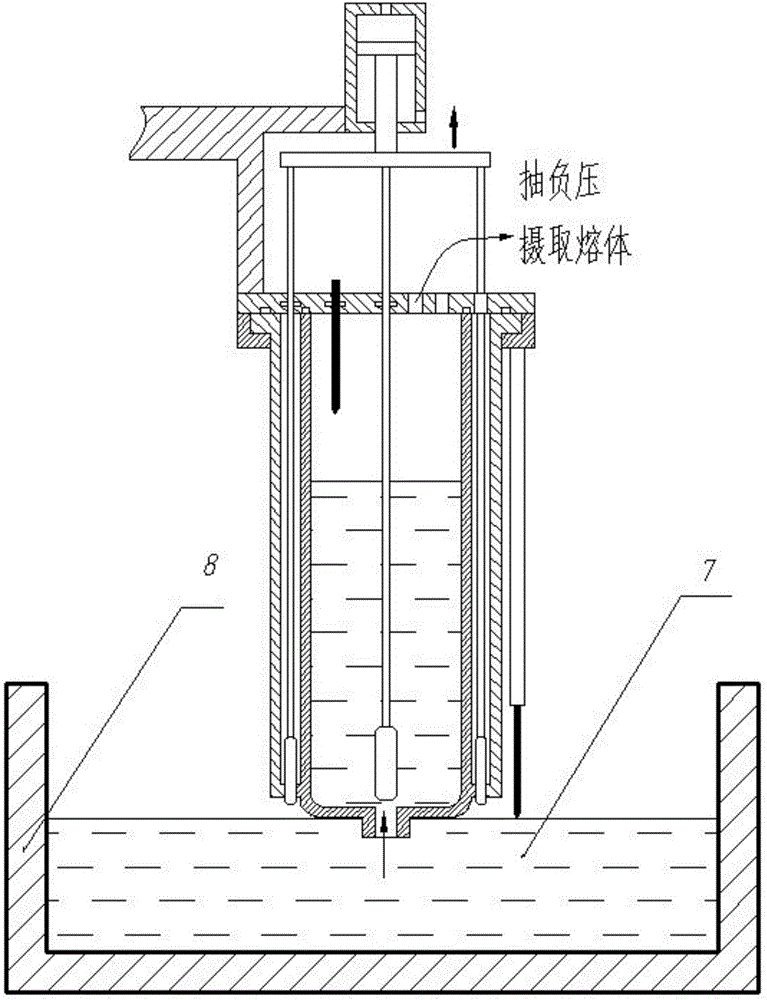

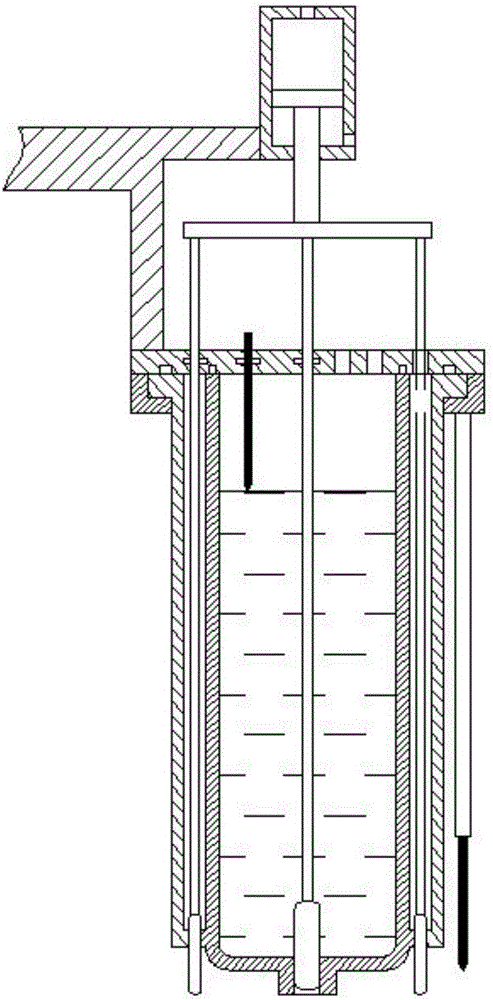

Equipment and method capable of achieving vacuum quantitative casting of molten metal

ActiveCN106670441AReduce oxidationReduce hydrogen absorptionMolten metal supplying equipmentsControl systemHydrogen absorption

The invention discloses equipment capable of achieving vacuum quantitative casting of molten metal. The equipment comprises a mechanical device, a vacuum quantitative casting device, an opening and closing device and a control system; the vacuum quantitative casting comprises a seal container with internal space, a gas filling mechanism, a vacuum mechanism and an exhaust opening; the exhaust opening comprises a liquid draining opening allowing molten metal to be drained, a pipeline allowing gas to pass through is further arranged in the internal space, and passes through the liquid draining opening, the pipeline is provided with a gas exhaust opening allowing gas not in contact with the molten metal to be exhausted, the opening and closing device achieves independent control over the liquid draining opening and the gas exhaust oponeing, that is, the opening and closing device can independently control opening and closing of the liquid draining opening and the gas exhaust opening, it is ensured that during casing of the molten metal, the oxidation and hydrogen absorption of the molten metal can be reduced, gas holes and oxide inclusion of a casting are reduced, and the casting quality is improved.

Owner:北京航大新材科技有限公司

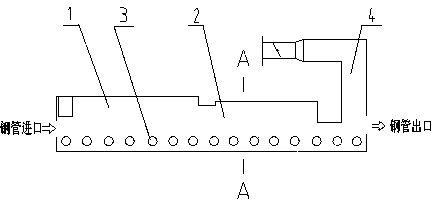

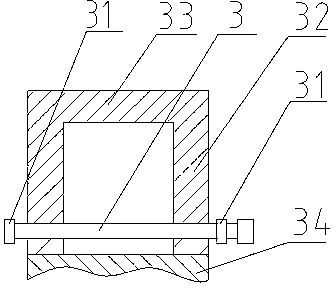

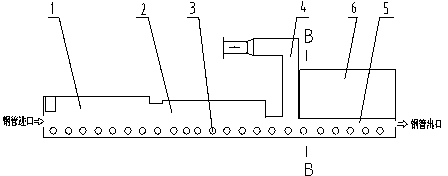

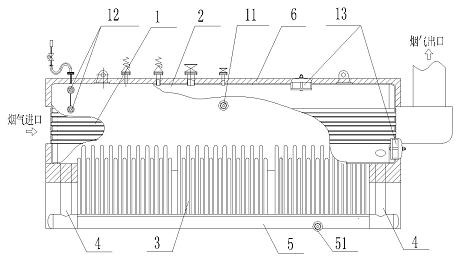

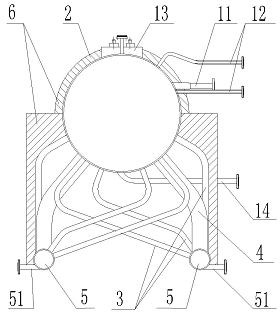

Energy-saving type roller hearth continuous bright normalizing annealing furnace

ActiveCN102676788BImprove heat recoveryImprove exterior surface qualityFurnace typesIncreasing energy efficiencyWaste heat recovery unitProcess engineering

An energy-saving type roller hearth continuous bright normalizing annealing furnace comprises a heating chamber (1), a heat preservation chamber (2), a furnace roller (3), a flue (4) and a waste heat recovery section (5). A waste heat recovery boiler (6) is arranged on the furnace wall of the waste heat recovery section (5), the flue (4) is arranged at the tail end of the waste heat recovery boiler (6), and a smoke tube is installed in the waste heat recovery boiler (6); a steel tube which is subjected to waste heat utilization by means of the waste heat recovery boiler (6) on waste heat recovery section (5) is discharged from the boiler, and cooled in the air, and the tapping temperature of the steel tube can be controlled around 250 DEG C; and simultaneously, high temperature smoke in the heating chamber (1) and the heat preservation chamber (2) is subjected to waste heat utilization by means of the smoke tube in the waste heat recovery boiler (6) and discharged from the flue (4) at the tail end of the waste heat recovery boiler (6). According to the energy-saving type roller hearth continuous bright normalizing annealing furnace, the waste heat recovery boiler can simultaneously exchange high temperature smoke heat energy and radiant heat energy of the steel tube to produce steam which is used for steel tube production and ordinary life; and besides, the tapping temperature of the steel tube is reduced so that secondary oxidation burning loss is reduced and qualities of outer surfaces of products are improved.

Owner:丁永健

Heating furnace energy-saving control method based on strip steel mechanical property forecasting model

ActiveCN102560081BProcess temperature optimization controlRealize energy saving and consumption reductionFurnace typesHeat treatment process controlFurnace temperatureMechanical property

A heating furnace energy-saving control method based on a strip steel mechanical property forecasting model belongs to the field of process control and comprises the following steps: controlling the furnace temperature of a heating furnace on the basis of a process control computer, and establishing an industrial forecasting model for mechanical properties of a hot-rolled strip steel; before an ingot blank enters the heating furnace, forecasting the mechanical properties of the rolled strip steel according to chemical components and preset technical parameters; if the forecasted values of the mechanical properties are greater than the target values of the mechanical properties, optimizing the strip steel discharging technical temperature; and on the premise of ensuring the mechanical properties of the strip steel and not going against other necessary constraints, reducing the fuel gas consumption of the heating furnace by reducing the discharging temperature, so that the strip steel discharging technical temperature is optimized and controlled, and the fuel gas consumption of the heating furnace or the energy consumption of a unit product is reduced. The control method has a wide steel variety adapting range and can be widely applied to the field of temperature control of heating furnaces in slab blank hot rolling production lines.

Owner:BAOSHAN IRON & STEEL CO LTD

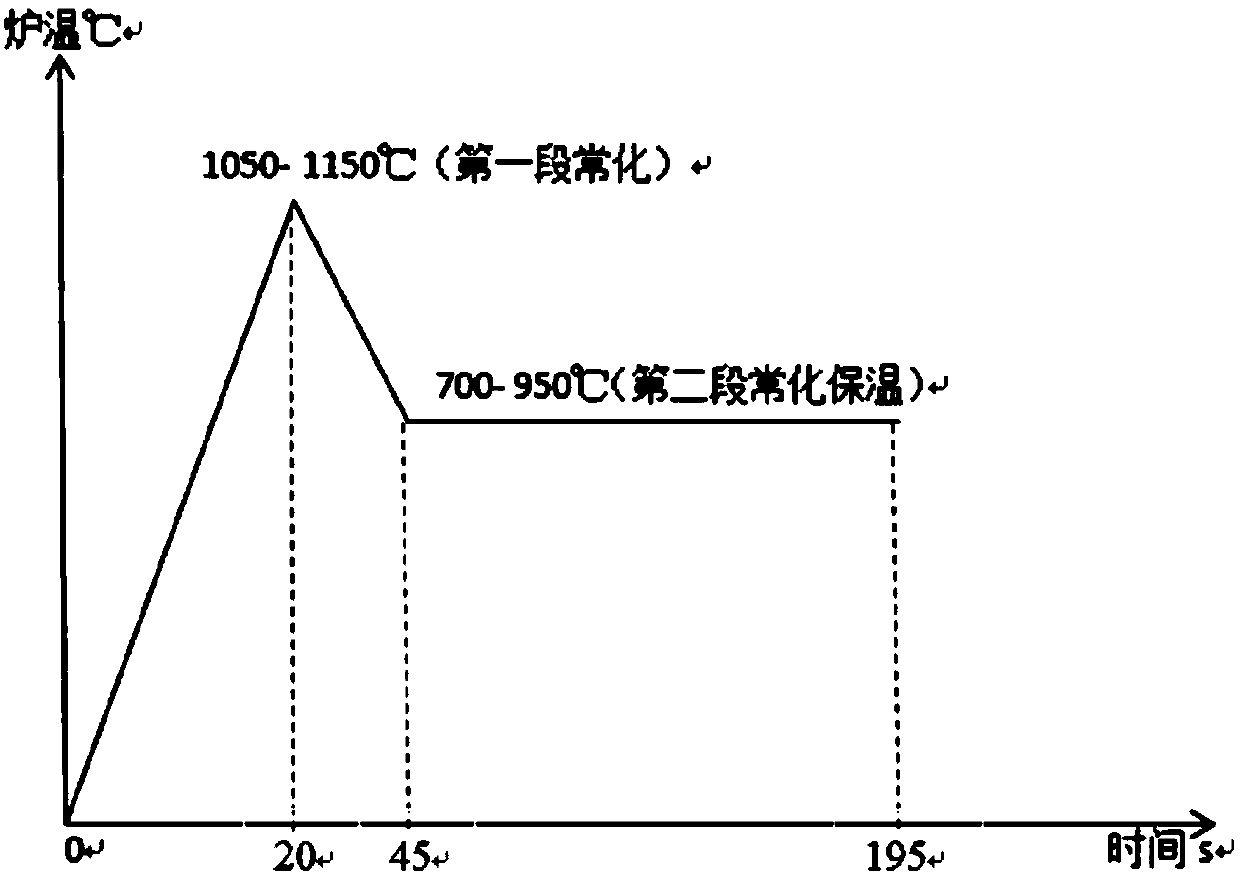

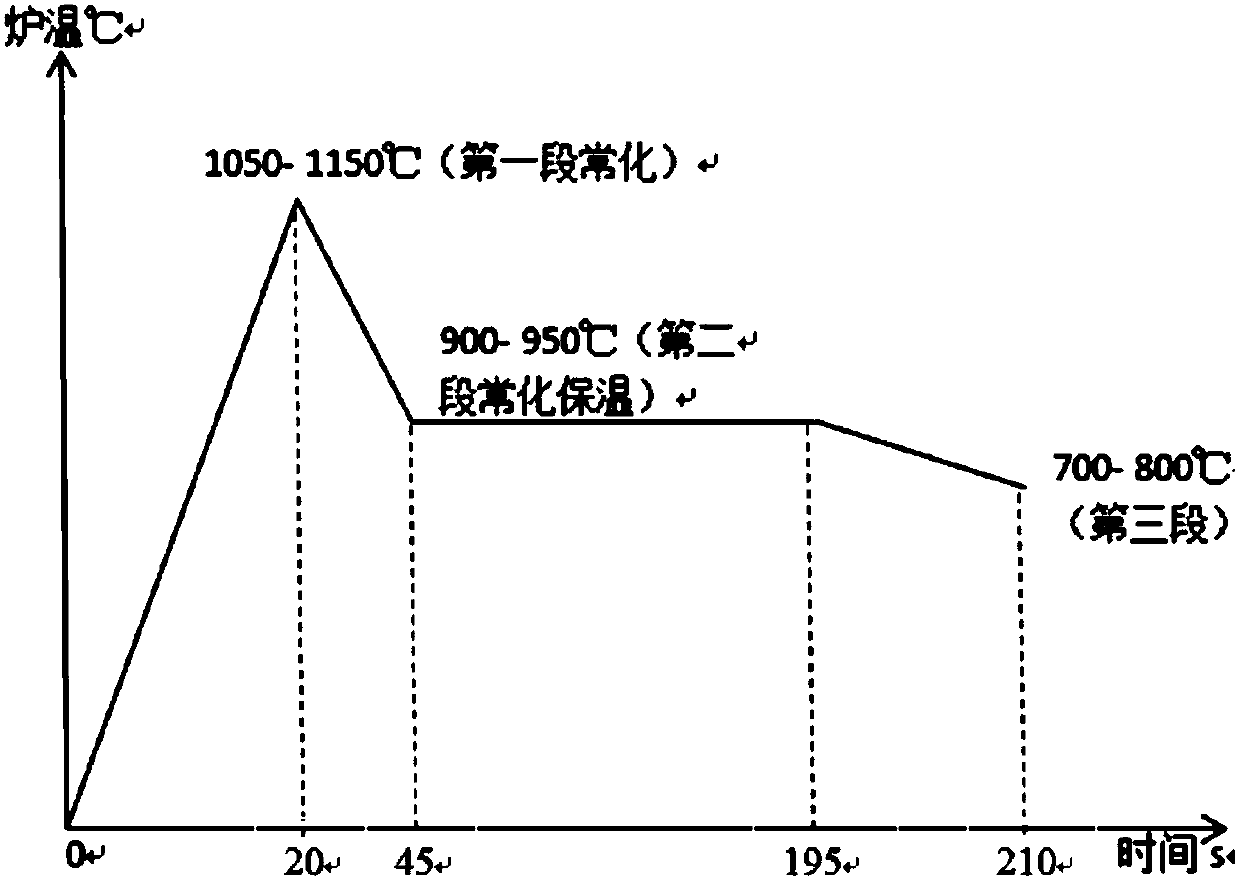

Novel production method for normalizing and cooling high-magnetic-induction oriented silicon steel and product

InactiveCN110551885AImprove magnetismStrong magnetismFurnace typesHeat treatment furnacesQuenchingWater spray

The invention aims to provide a novel production method for normalizing and cooling high-magnetic-induction oriented silicon steel. The method is used for improving the magnetic performance of the high-magnetic-induction oriented silicon steel and simultaneously improving the plate shape and the rolling property of an oriented silicon steel normalizing plate. The production method of the normalized cooling comprises the following steps of decreasing the temperature from normalizing temperature of 1050-1150 DEG C to 900-950 DEG C at the cooling speed of 5-8 DEG C / s after maintaining the normalizing temperature for not greater than 20 s; maintaining the temperature for 100-150 s for the second time; controlling the cooling speed at 10-15 DEG C / s until the temperature reaches 700-800 DEG C; discharging; and carrying out water spraying quenching.

Owner:武汉尚瑞科技有限公司

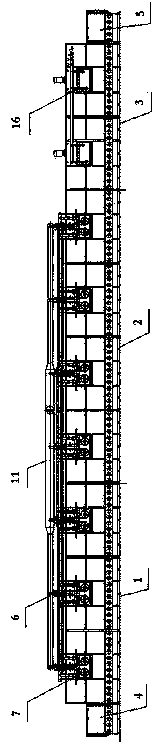

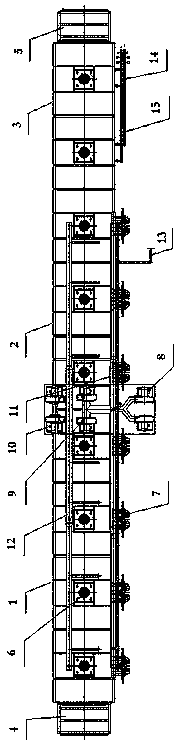

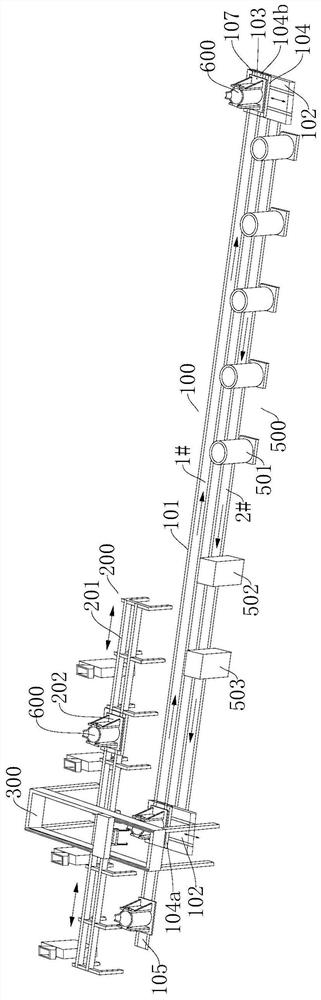

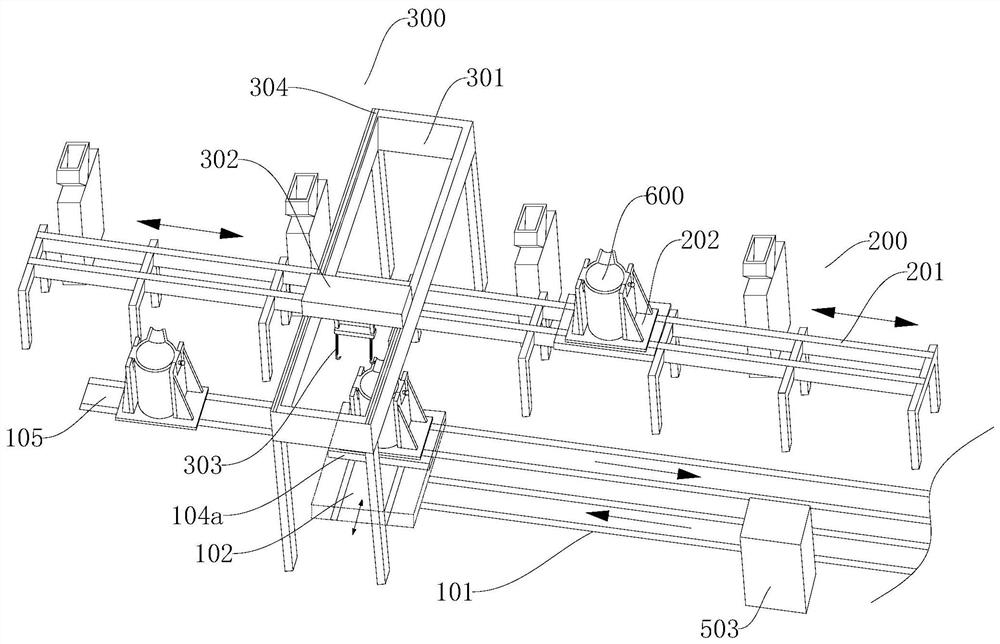

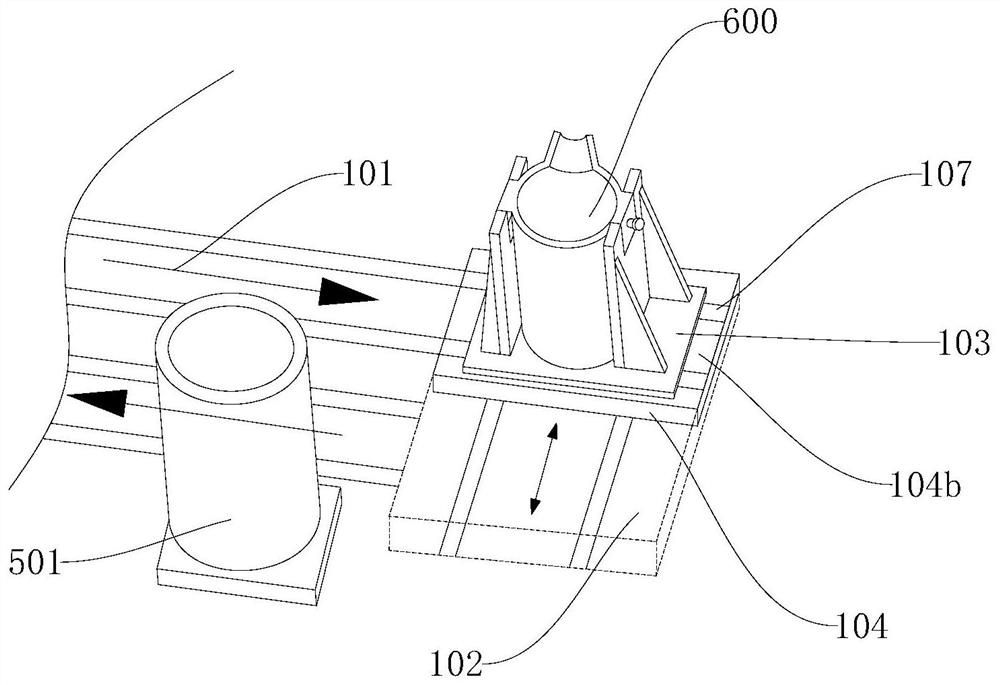

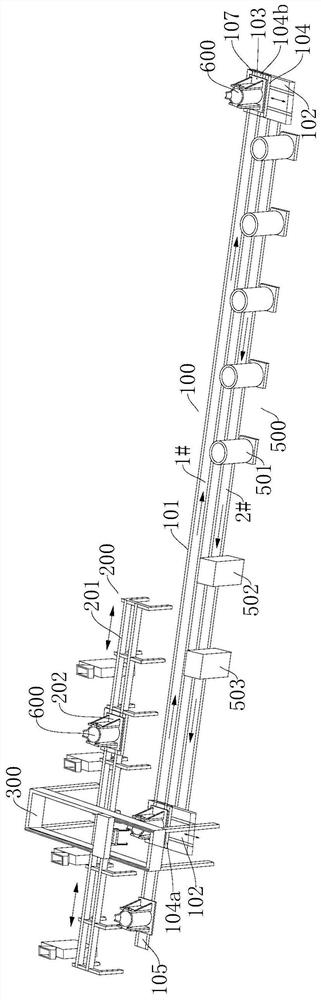

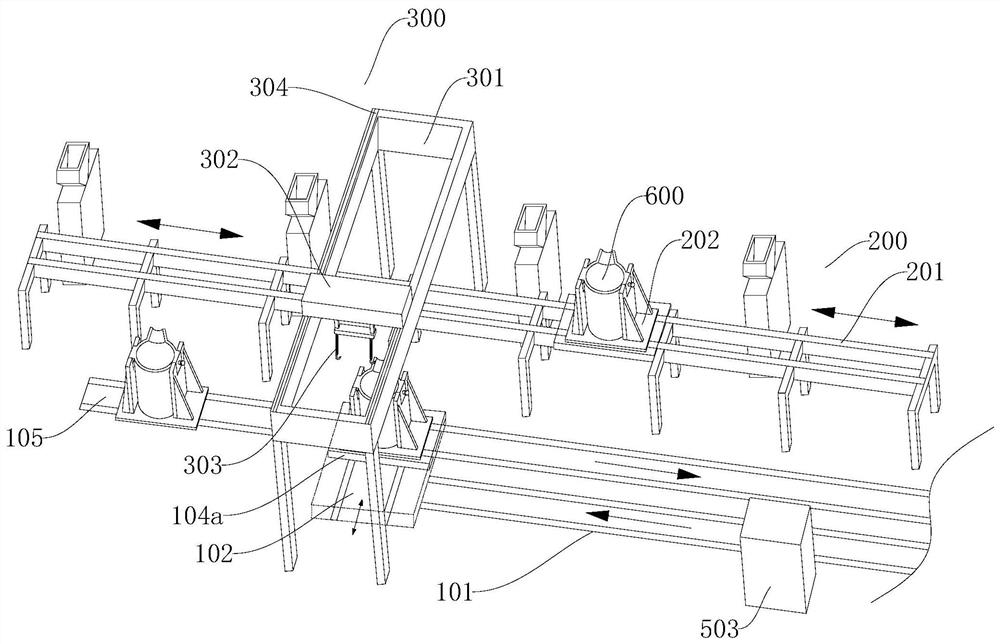

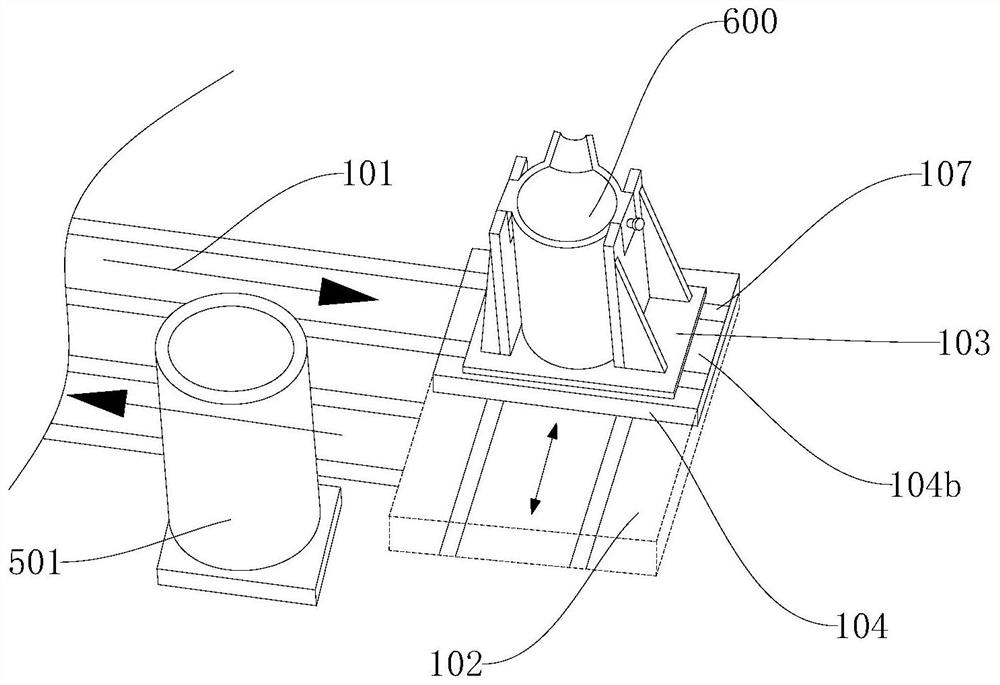

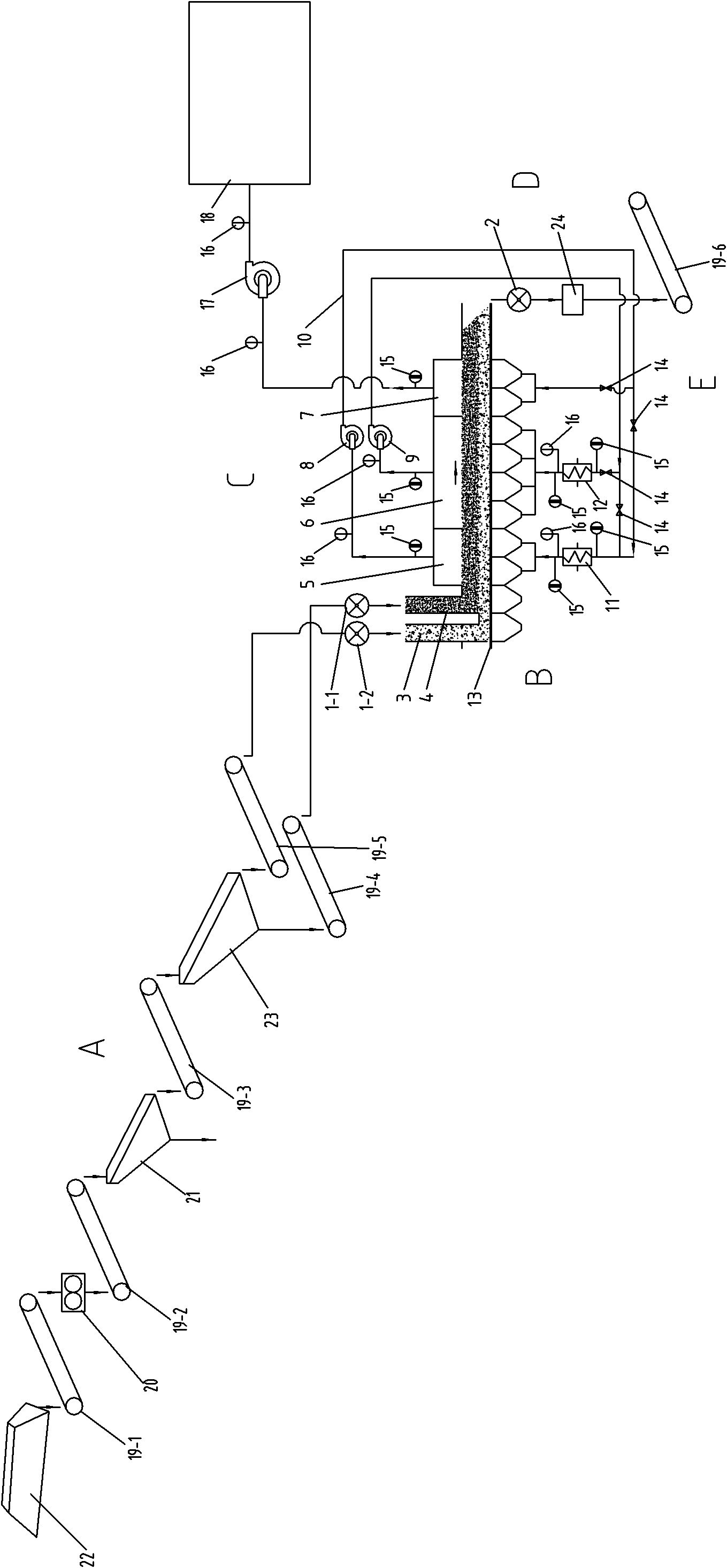

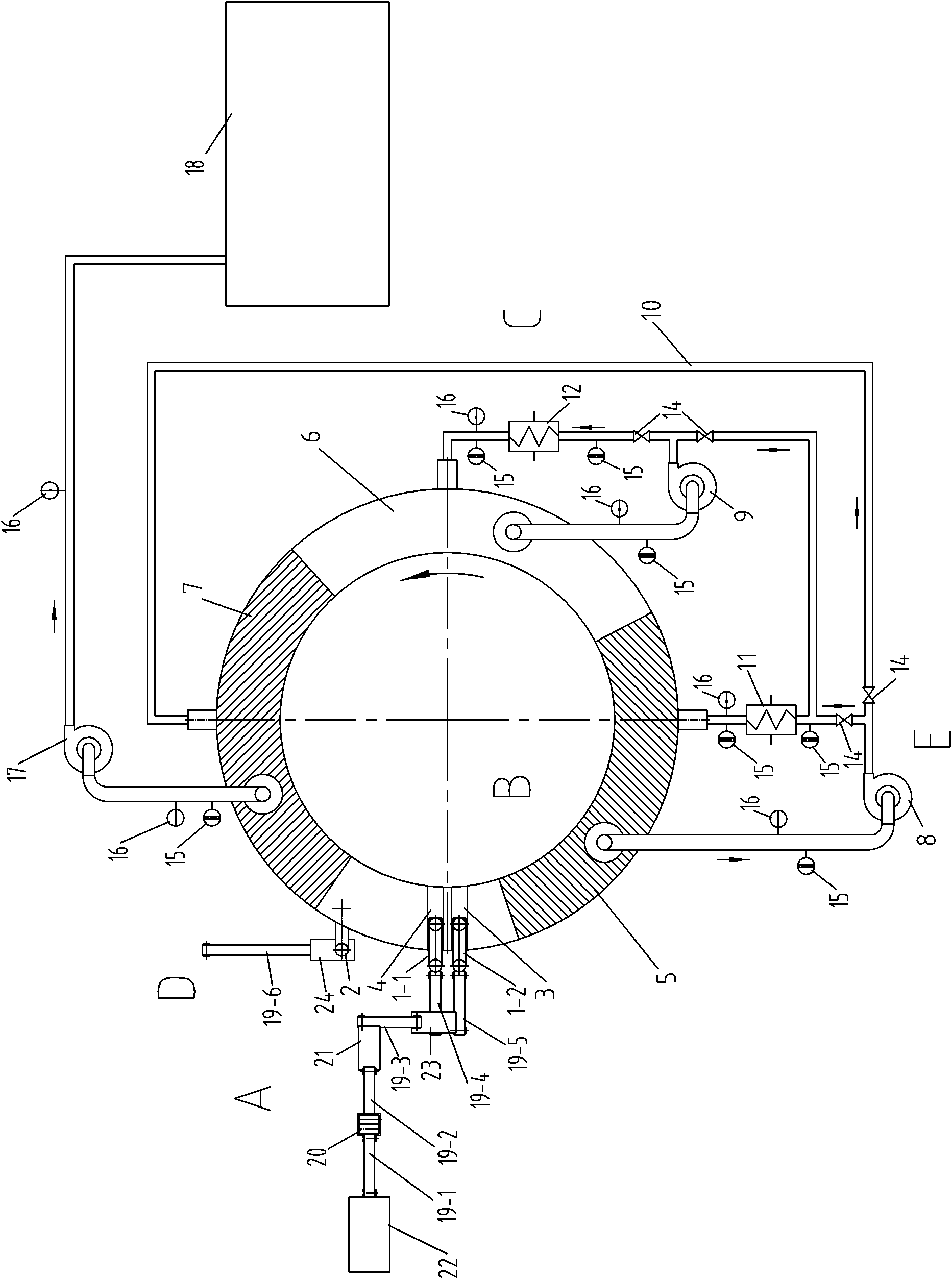

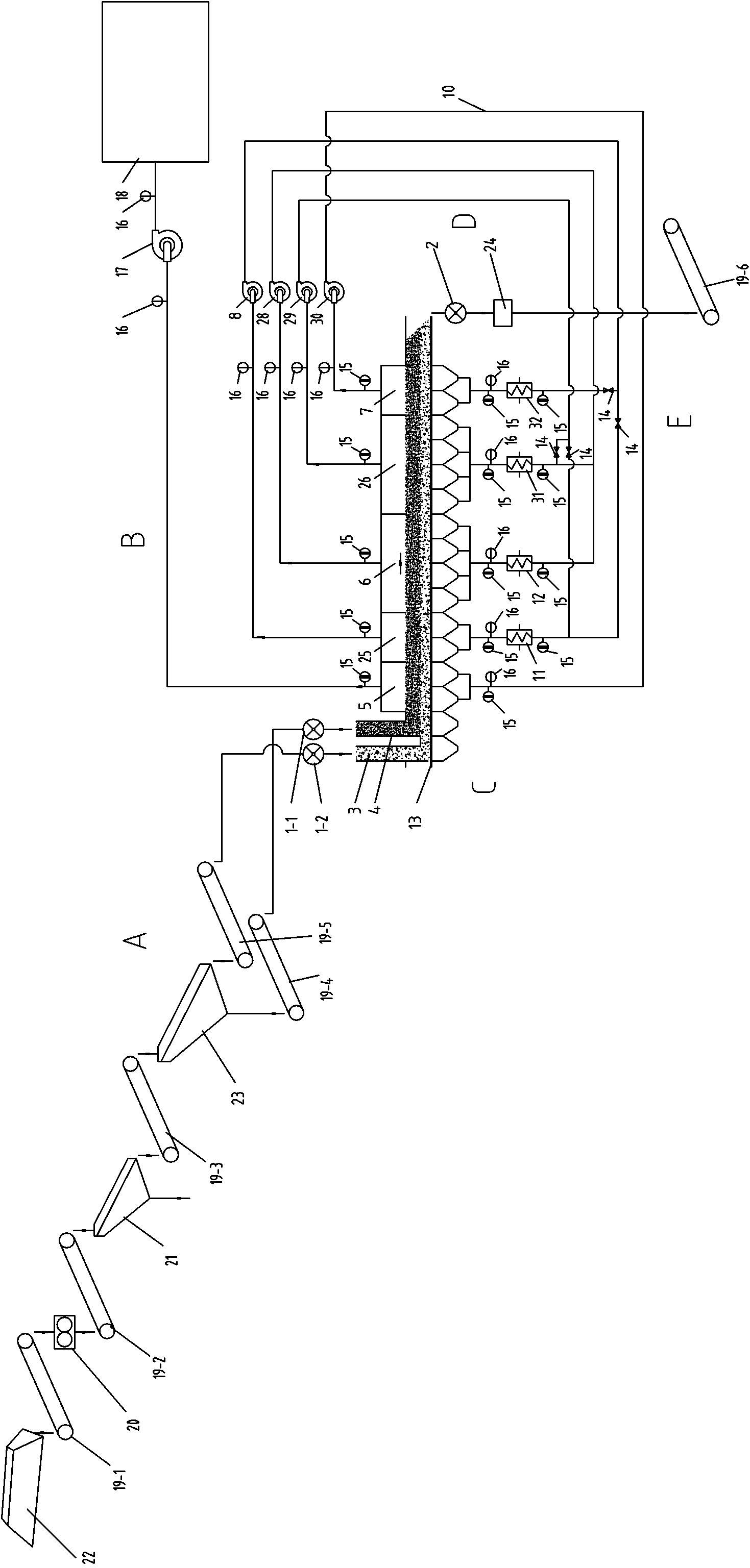

Molten iron transportation line

ActiveCN112846164BOrderly transportationLower the furnace temperatureMelt-holding vesselsProcess efficiency improvementProcess engineeringIndustrial engineering

The invention provides a molten iron transportation line, which belongs to the technical field of molten iron transportation, including an iron supply system, an iron connection system, a dumping system and a lifting device, and a lifting device is also provided between the iron connection system and the dumping system The iron connection system includes a sub-running track, a mother running track, a sub-car and a mother car, and a plurality of them are arranged along a path perpendicular to the axis of the sub-running track; end; the sub-car is used to support the ladle; the mother car is used to accept the sub-car from the sub-running track; the dumping system includes a dumping track and a dumping car, the The dumping track is arranged on one side of the sub-running track; the dumping car is used to run on the dumping track. The molten iron transportation assembly line provided by the invention reduces the frequent movement of high-altitude transportation, increases safety, reduces personnel costs, lowers the temperature of molten iron from the furnace, and reduces energy consumption.

Owner:XINXING DUCTILE IRON PIPES CO LTD

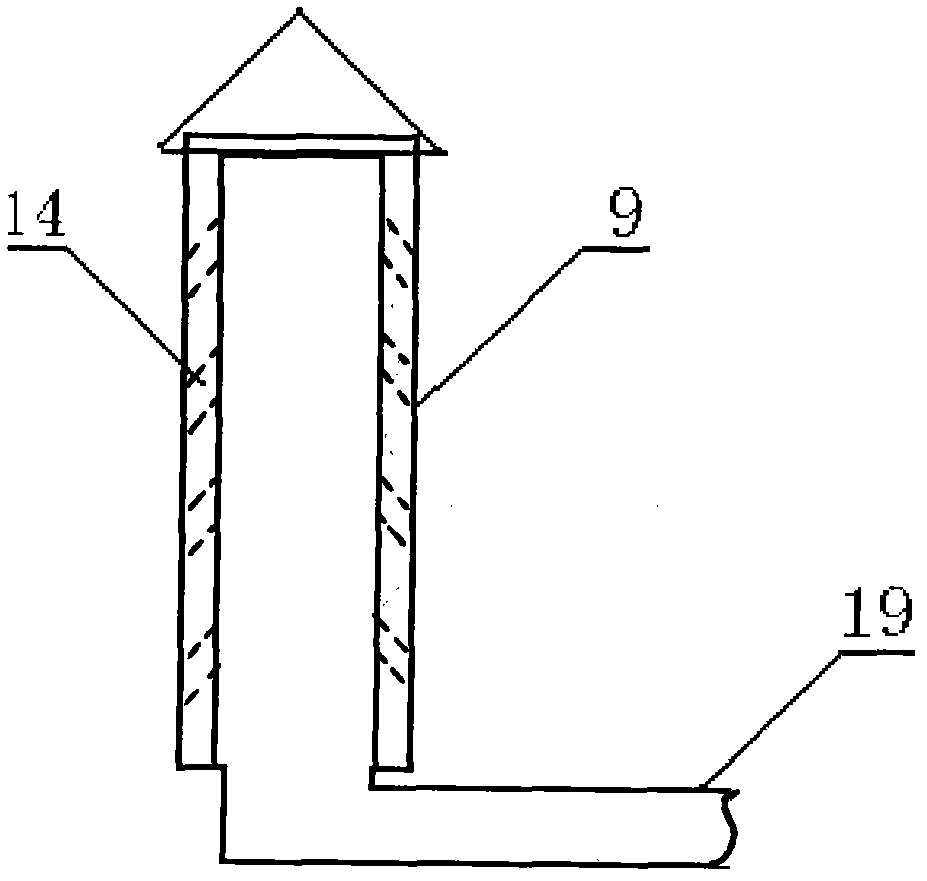

Coal gas producer capable of producing semi coke

InactiveCN101407733ALower the furnace temperatureSpeed up heat exchangeCombined combustion mitigationCombustible gas productionProcess engineeringHearth

The invention relates to a gas producer which can produce semi-cokes at the same time, comprising a supporting bracket, an ash pan, a lower gas producer body, a middle water tank, an upper gas producer body and a coal feeding mechanism. The gas producer is characterized in that: a water sealing groove is added outside a joint between the middle water tank and the upper gas producer body; an oblique discharge tube is arranged between the hearth of the upper gas producer body and the water sealing groove. While producing the gas, the gas producer produces the semi-cokes by utilizing the high-temperature gas, thus reducing the energy consumption.

Owner:淄博昊科机械有限公司

Production method for reducing temperature drop of hot-rolled intermediate blank

InactiveCN110586663AReduce temperature dropLower the furnace temperatureTemperature control deviceStrip millTemperature difference

The invention relates to a production method for reducing the temperature drop of a hot-rolled intermediate blank. Whether an R2 rolling mill finishes rolling or not is not checked before a first passand a second pass of steel feeding of an R1 rolling mill, the R1 rolling mill rolls in advance, and the time gap of the R1 rolling mill is 1-3 seconds; the pressure of roller body cooling water in arough rolling area is controlled to be 0.8-1.0 MPa in summer and 0.6-0.8 MPa in winter; in the rough rolling process, the temperature difference between the middle and the edge of the plate blank is controlled to be 20-30 DEG C; water spray on the inlet side and the outlet side of the rolling mill is changed to air spray, and the temperature difference of the cross section is controlled to be within 20 DEG C; and the abrasive width of a resin strip of a water cutting plate of the rolling mill does not exceed 20 mm. The production method has advantages that the plate blank discharging temperature is reduced, the energy consumption is saved, the cost is reduced, and the rolling stability of a machine frame and the next process is improved.

Owner:ANGANG STEEL CO LTD

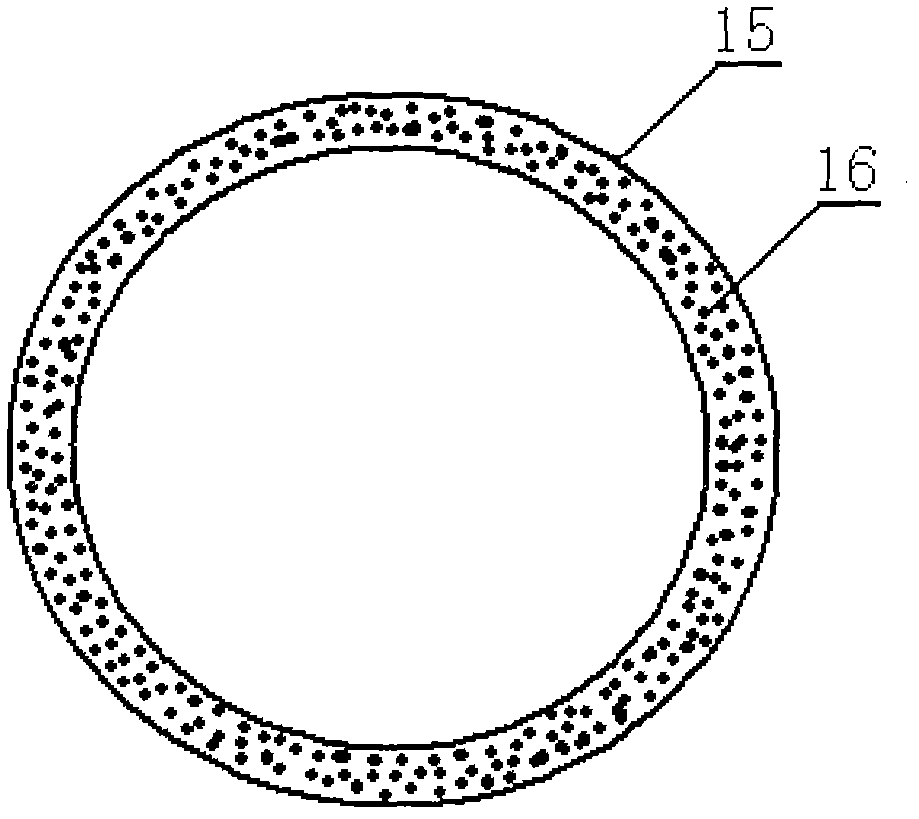

Energy-saving roller-hearth continuous kiln waste heat boiler

InactiveCN102679301AImprove heat recoveryImprove exterior surface qualityIncreasing energy efficiencySteam generation using hot heat carriersThermal energyHearth

The invention discloses an energy-saving roller-hearth continuous kiln waste heat boiler, which comprises a smoke pipe 1, a drum 2, heat exchange tubes 3, down pipes 4 and header pipes 5, wherein the smoke pipe 1 is positioned in the drum 2; the heat exchange tubes 3 have an L shape so as to be close to a steel pipe as much as possible; the lower parts of the heat exchange tubes 3 are respectively connected with the left and right header pipes 5, and the upper parts of the heat exchange tubes 3 are connected with the drum 2; the lower parts of the down pipes 4 are respectively connected with the left and right header pipes 5, and the upper parts of the down pipes 4 are connected with the drum 2; and thermal insulating layers 6 are arranged on the outer sides of the drum 2 and the heat exchange tubes 3 and at the peripheries of the down pipes 4 and the header pipes 5. Two kinds of heat energy, namely high-temperature smoke heat energy and radiating heat energy of the steel pipe, can be simultaneously exchanged into steam to serve as steam for production of the steel pipes and domestic steam; and moreover, the tapping temperature of the steel pipe is reduced, the secondary oxidation loss is reduced, and the outer surface quality of a product is improved.

Owner:HENGYANG DINGDIANER IND FURNACE ENERGY CONSERVATION

Drying oven

InactiveCN106196923AReduce the temperatureReduce energy consumptionDrying gas arrangementsDrying machines with local agitationEngineeringCopper

The invention discloses a drying oven used for conducting drying and degreasing on an air conditioner component which comprises fins and copper pipes. The drying oven is provided with a drying chamber used for accommodating the air conditioner component, and further provided with an air blowing device which is movably arranged in the drying chamber. The air blowing device is used for blowing out compressed air with the temperature higher than the drying indoor temperature to orifices of the copper pipes. By means of the drying oven, the problem that a drying oven in the prior art is large in energy consumption is effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC

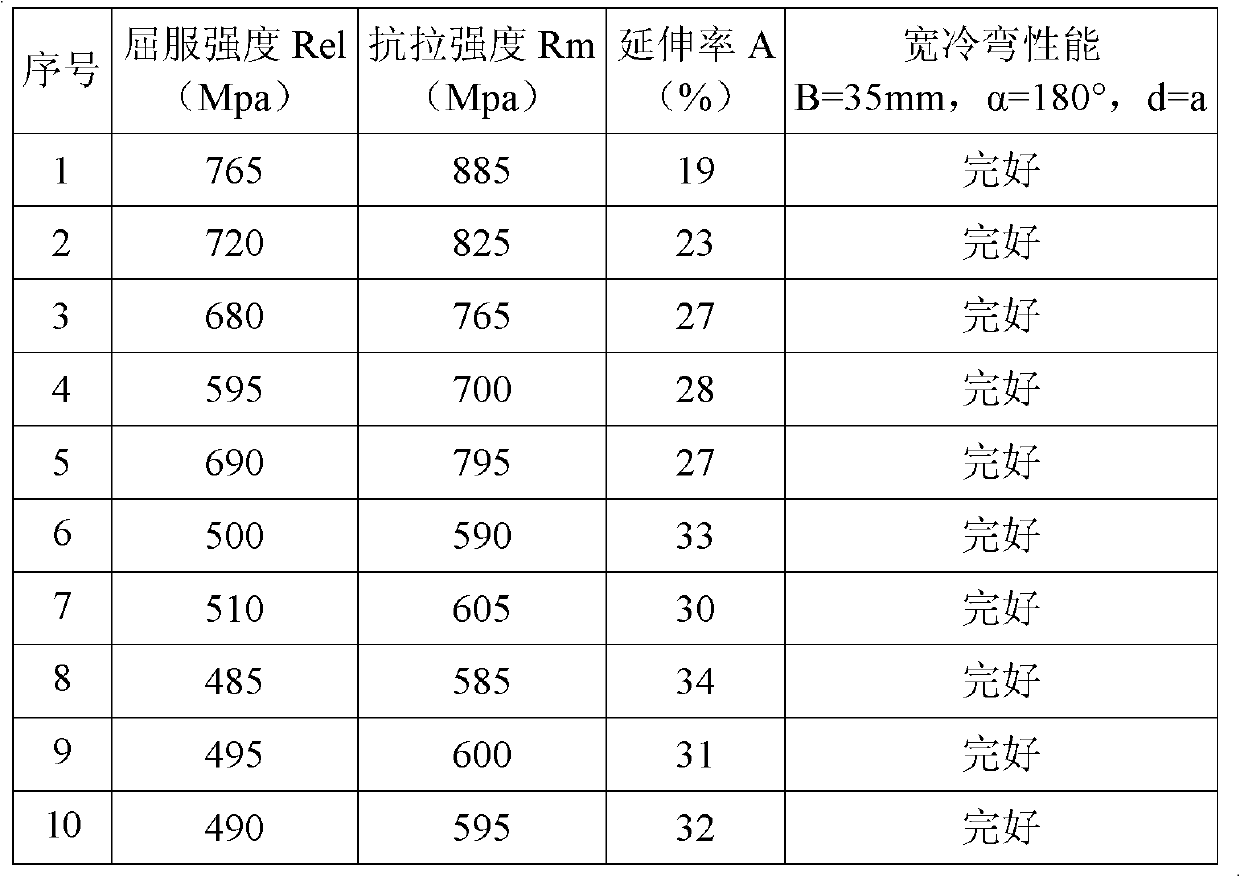

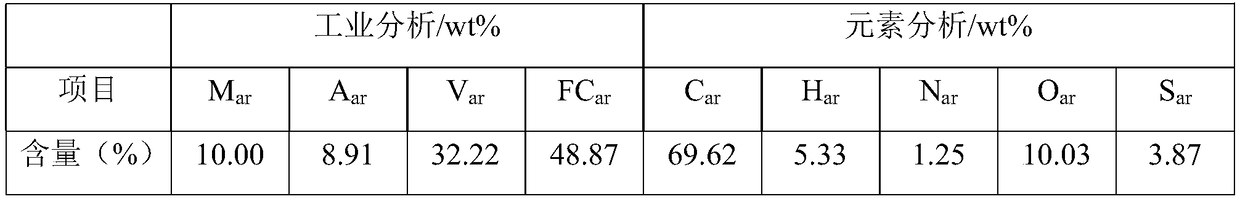

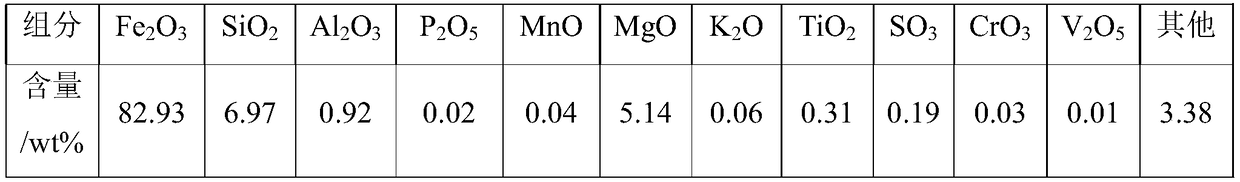

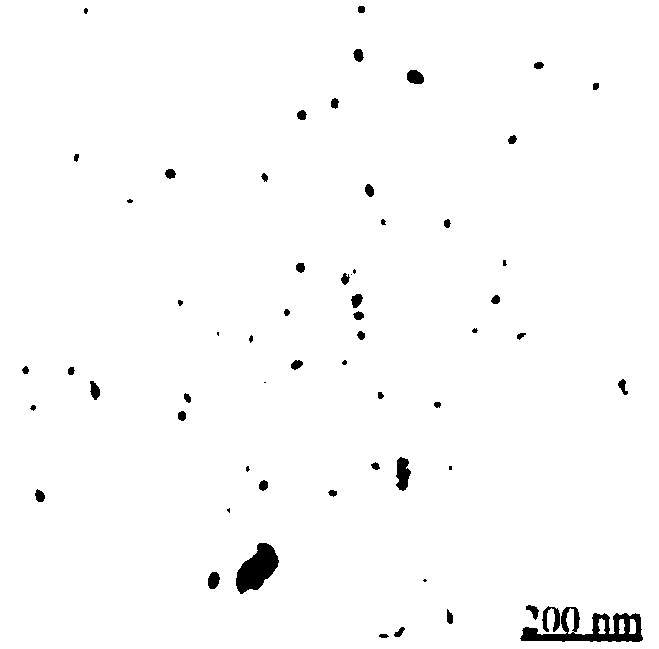

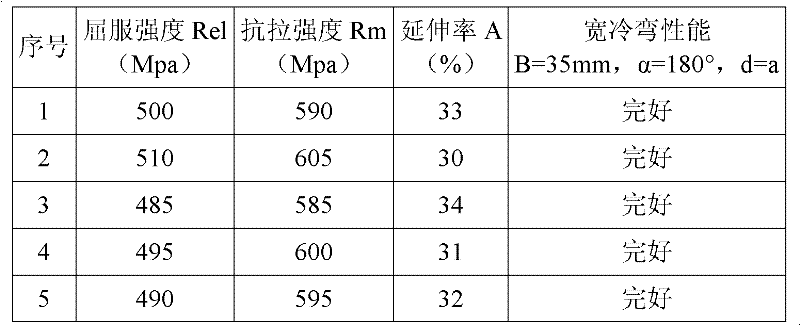

Composite micro-alloying hot rolled steel plate containing V and Nb and preparation method thereof

InactiveCN101899614BLower the furnace temperatureReduce the number of spawnsChemical compositionMetallurgy

The invention belongs to the technical field of hot continuous rolled plate strips, in particular relates to a composite micro-alloying hot rolled steel plate containing V and Nb and a preparation method thereof, which can achieve the purpose of controlling the surface quality thereof. The composite micro-alloying hot rolled steel plate containing V and Nb, which is provided by the invention, notonly can reduce the generation of red scales but also can not increase the production cost. The composite micro-alloying hot rolled steel plate comprises the following chemical components in percentage by weight: C which is greater than or equal to 0.06% and is less than or equal to 0.08%, Si which is greater than 0.20% and is less than or equal to 0.30%, Mn which is greater than or equal to 0.70% and is less than or equal to 0.90%, V which is greater than 0.04% and is less than or equal to 0.05%, Nb which is greater than or equal to 0.02% and is less than or equal to 0.03%, P which is less than or equal to 0.025%, S which is less than or equal to 0.015%, and the balance iron and inevitable impurities. The preparation method provided by the invention has no need of reconstructing the existing equipment, has simple and controllable technological conditions, realizes the purpose of reducing the generation of scales by controlling the tapping temperature, the precision rolling temperature, the finishing temperature, the coiling temperature and the cooling mode of a plate blank, and has the advantages of low energy consumption and low cost.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Molten iron transportation assembly line

ActiveCN112846164AOrderly transportationReduce furnace temperature and reduce energy consumptionMelt-holding vesselsProcess efficiency improvementProcess engineeringAssembly line

The invention provides a molten iron transportation assembly line, and belongs to the technical field of molten iron transportation. The molten iron transportation assembly line comprises an iron supply system, an iron receiving system, a material dumping system and a lifting device; the lifting device is further arranged between the iron receiving system and the material dumping system; the iron receiving system comprises a sub running track, a main running track, a plurality of sub trolleys and a plurality of main trolleys, wherein the sub trolleys and the main trolleys are arranged along a path perpendicular to the axis of the sub running track; the main running track is arranged at the end part of the sub running track; the sub trolleys are used for supporting ladles; the main trolleys are used for receiving the sub trolleys from the sub running track; the material dumping system comprises a material dumping track and a material dumping trolley, and the material dumping track is arranged on one side of the sub running track; and the dumping trolley is used for running on the dumping track. According to the molten iron transportation assembly line, frequent movement of high-altitude transportation is reduced; the safety is improved; the personnel cost is reduced; the tapping temperature of molten iron is reduced; and the energy consumption is reduced.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Double layer roller bottom type continuous spheroidizing annealing furnace

ActiveCN100463980CGood for healthEasy and reliable annealing transferFurnace typesHeat treatment furnacesCooling chamberHearth

the invention discloses a double-layer roll-bottom continuous-balling annealing furnace, which contains furnace, wherein the hearth consists of upper hearth and lower hearth, whose inlet and outlet are set on one end of furnace; the residual heat exchanging chamber is set near the furnace; the sealing rapid-cooling chamber is set in the furnace far away from inlet and outlet, which interconnects upper and lower furnaces; the upper driving roll is set on the upper furnace; the lower driving roll is set in the lower furnace; the elevator and pushing rod are set in the sealing rapid-cooling chamber; the upper heater and heat coupler are set in the upper furnace and lower heater is set in the lower furnace.

Owner:杭州骏马轴承有限公司

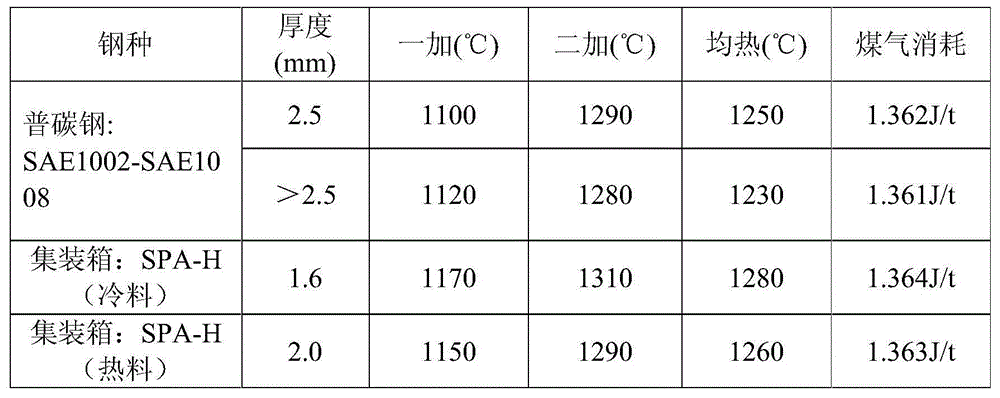

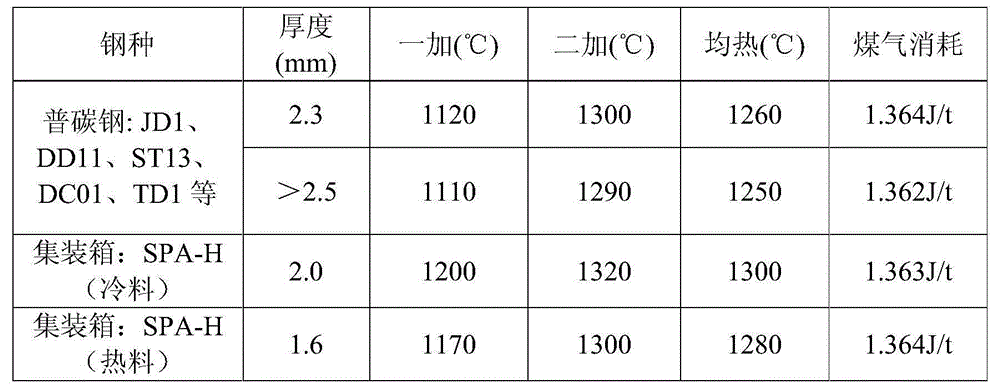

Method for reducing heating gas consumption

ActiveCN105436212ALower the furnace temperatureReduce gas consumptionTemperature control deviceHeating furnaceGas consumption

The invention discloses a method for reducing heating gas consumption. By adjusting a first heating section, a second heating section and the soaking temperature, the tapping temperature of cold rolled steel is reduced, and accordingly the heating gas consumption is reduced; in addition, plate blanks at the similar temperature are put into a heating furnace at the same time, so that the plate blanks are heated uniformly; iron scale produced by uneven temperature is decreased, and the quality of plate blank sintered steel is improved. Compared with the prior art, the method for reducing the heating gas consumption has the beneficial effects that by means of the effective measures, the tapping temperature of the cold rolled steel is reduced, and accordingly the gas consumption of the heating furnace is reduced; according to different temperatures, the cold rolled steel is added into the heating furnace in batches, the temperature difference is decreased, and the producing amount of the iron scale is reduced; in addition, due to the fact that the plate blanks are heated in the furnace sufficiently, the process cost investment in the follow-up rolling process can also be decreased, the rolling efficiency is improved, and the ultimate purposes of reducing cost and improving benefits are reached; the gas unit consumption target is reduced from the previous 1.392 GJ / t to 1.364 GJ / t, and the gas consumption is reduced effectively.

Owner:ANGANG STEEL CO LTD

Rail bracket type steel ladle adding cover device

InactiveCN104607625BImprove the environmentAchieve heat preservationMelt-holding vesselsEngineeringStructural engineering

The invention provides a track bracket type steel ladle cover adding and removing device. The track bracket type cover adding and removing device is arranged and used for covering a steel ladle, provided with hinge bases, with a special steel ladle cover, a steel ladle car stops in front of a bracket device after conveying the steel ladle to a finery inlet, the bracket device advances along tracks till making contact with three hanging rings on the ladle cover, and at the moment, the bracket device drives the ladle cover to rise together when pushed by rising power, steel ladle cover hinges are disengaged from the steel ladle hinge bases and the steel ladle cover is left on the bracket device. Molten steel runs in the reverse direction and stops below the bracket device after refining is completed, the bracket device drives the steel ladle cover to begin to fall together, and after the steel ladle cover hinges touch the steel ladle hinge bases, the bracket device stops falling and starts to retreat along the tracks to the waiting position. By means of the track bracket type steel ladle cover adding and removing device, the cover pick-up and adding actions are achieved through the free movement of the special steel ladle cover and the bracket device along the tracks, and the structure is simple and reliable.

Owner:BEIJING ANBOO TECH DEV

Dry distillation system for oil shales

InactiveCN101812307BIncrease profitReduce resistanceDirect heating destructive distillationSpecial form destructive distillationControl systemOil shale gas

The invention relates to a dry distillation system for oil shales. In the dry distillation system, a material distributing system is communicated with a reaction furnace by related charging and discharging pipelines, the reaction furnace is communicated with a dry distillation gas circulation system by related charging and discharging pipelines, and the dry distillation gas circulation system is communicated with a cooling system by related charging and discharging pipelines; and a grading screen of the material distributing system is communicated with a belt conveyor and a sealing feeder to input the big-gain diameter oil shales to and spread the big-gain diameter oil shales on a fire grate of the reaction furnace and to input the small-gain diameter oil shales to and spread the small-gain diameter oil shales on the big-gain diameter oil shale layer. The dry distillation system has the advantages of realizing crushing, screening, furnace charging and heating of the oil shales, collection of the oil shale dry distillation gas, cooling and collection of shale semicoke and the like, solving the problem that the small-grain size grains are easily leaked out of the fire grate and the problem that the semicoke grains are easily clipped in the seams of the fire grate and do not fall off, improving the utilization ratio of the oil shales, reducing the resistance of the material layers, avoiding the loss of the powder in the material layers, effectively lowering the dust content, lowering the tapping temperature of the semicoke, improving the utilization efficiency of the heat energy, along with reliable performance, low-carbon environmental protection and easy industrialized extraction of the oil shales.

Owner:曹志德 +2

Track bracket type steel ladle cover adding and removing device

InactiveCN104607625ARealize automatic cover removalImprove the environmentMelt-holding vesselsStructural engineeringMolten steel

The invention provides a track bracket type steel ladle cover adding and removing device. The track bracket type cover adding and removing device is arranged and used for covering a steel ladle, provided with hinge bases, with a special steel ladle cover, a steel ladle car stops in front of a bracket device after conveying the steel ladle to a finery inlet, the bracket device advances along tracks till making contact with three hanging rings on the ladle cover, and at the moment, the bracket device drives the ladle cover to rise together when pushed by rising power, steel ladle cover hinges are disengaged from the steel ladle hinge bases and the steel ladle cover is left on the bracket device. Molten steel runs in the reverse direction and stops below the bracket device after refining is completed, the bracket device drives the steel ladle cover to begin to fall together, and after the steel ladle cover hinges touch the steel ladle hinge bases, the bracket device stops falling and starts to retreat along the tracks to the waiting position. By means of the track bracket type steel ladle cover adding and removing device, the cover pick-up and adding actions are achieved through the free movement of the special steel ladle cover and the bracket device along the tracks, and the structure is simple and reliable.

Owner:BEIJING ANBOO TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com