Coal gas producer capable of producing semi coke

A technology of gasifier and blue carbon, which is applied in the manufacture of combustible gas, petroleum industry, joint combustion mitigation, etc., can solve the problems of high gas temperature and lower efficiency of gasifier, so as to improve thermal efficiency, prolong heat exchange process, increase The effect of the amount of coal into the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings of the embodiments.

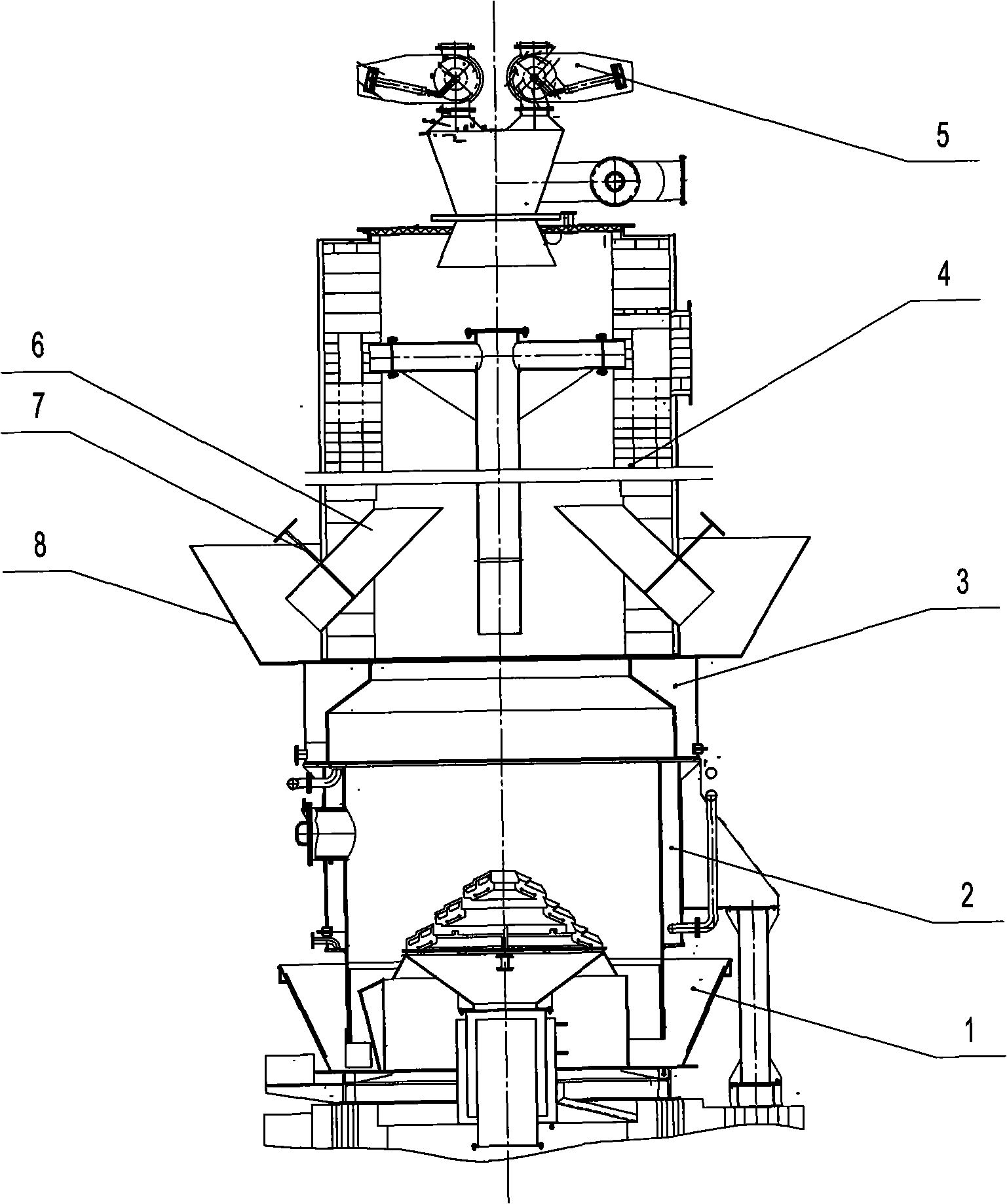

[0014] As shown in the figure, the coal gasifier that can also produce blue carbon according to the present invention includes a support frame, an ash basin 1, a lower furnace body 2, a middle water tank 3, an upper furnace body 4 and a coal feeding mechanism 5, and the upper furnace body The height of 4 is designed to be 6.5-8 meters, such as: 6.6 meters, 7 meters, 7.5 meters, 8 meters, etc., and an annular water seal groove 8 is added outside the joint between the middle water tank 3 and the upper body of furnace 4, and the upper body of furnace 4 An inclined discharge pipe 6 is provided between the hearth and the water seal tank 8, and the discharge pipe 6 is provided with a control valve 7, and the discharge pipe 6 can be distributed with 2-20 on the annular water seal tank 8, such as 4, 6, 8, 10, 12, 16, etc.

[0015] During the normal producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com