Double layer roller bottom type continuous spheroidizing annealing furnace

A spheroidizing annealing furnace and roller hearth technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of unused waste heat of annealed parts, large heat loss, and high energy consumption of annealing, so as to achieve good health and heatstroke prevention The effect of cooling measures to simplify and optimize the furnace structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

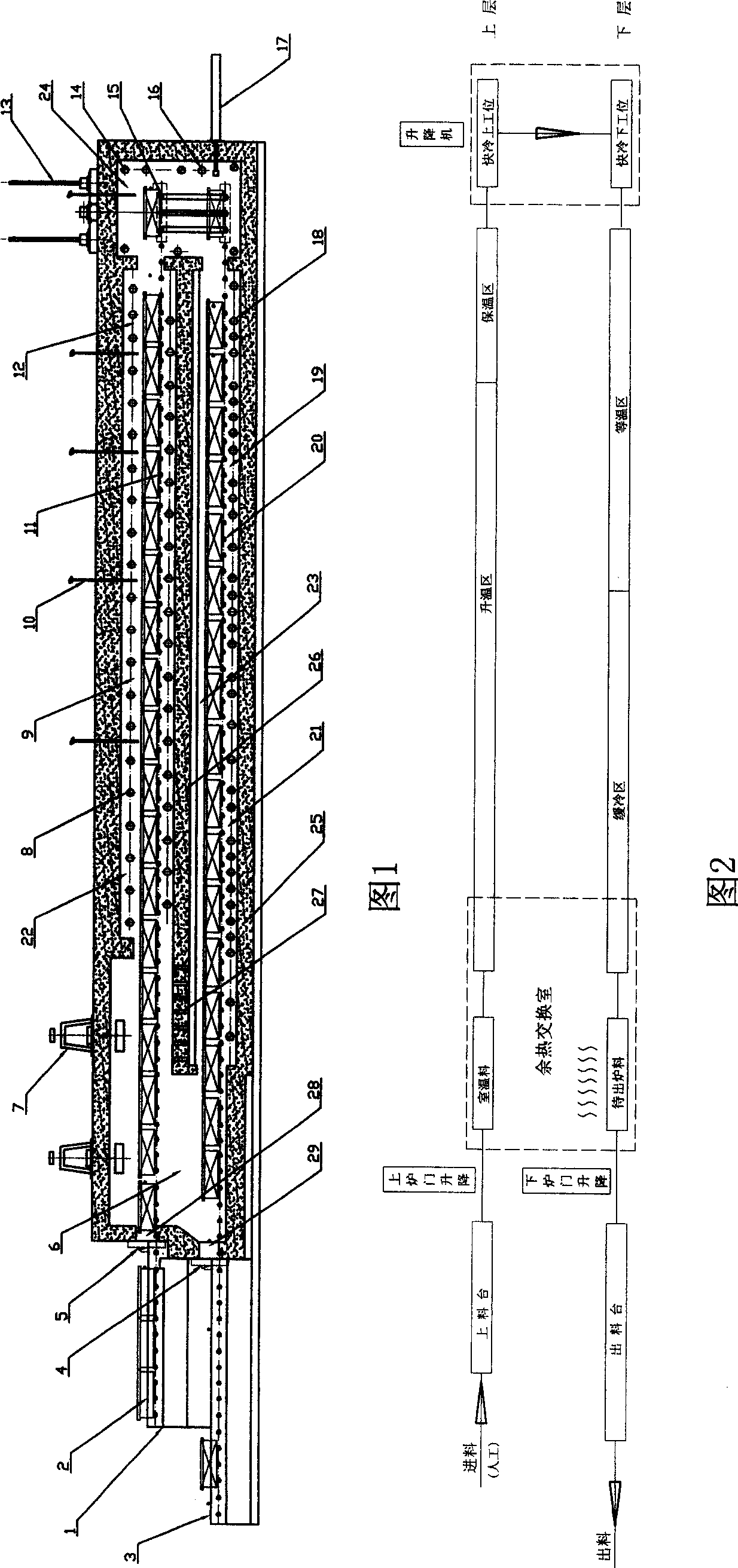

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0017] As shown in Figure 1, this double-deck roller hearth type continuous spheroidizing annealing furnace mainly comprises furnace body 25, and the hearth in furnace body 25 comprises upper layer furnace hearth 22 and lower layer furnace hearth 23, and upper layer furnace hearth 22 and lower layer furnace hearth 23 are formed by furnace hearth Partitions 26 are separated. The feeding furnace port 28 and the discharging furnace port 29 are arranged at the same end of the furnace body 25, the feeding furnace port 28 is arranged on the upper layer and communicates with the upper furnace hearth 22, and the discharging furnace port 29 is arranged on the lower layer and is connected with the lower layer furnace hearth 23 Through, the upper furnace door 5 is provided at the charging furnace mouth 28 of the furnace body 25, and the lower furnace door 4 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com