Method for reducing heating gas consumption

A technology of coal gas and heating section, applied in the direction of temperature control, etc., can solve the problems of insufficient combustion of coal gas, waste of energy, increased cost pressure, etc., so as to reduce the generation of raw iron oxide scale in the furnace, reduce the investment of process cost, and reduce the temperature of the furnace. Effect

Active Publication Date: 2016-03-30

ANGANG STEEL CO LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the continued downturn in the steel market, the cost pressure has further increased, and it is imminent to solve this problem

At present, the step-by-step heating used in steel mills is limited by the original steel-sintering process system, and the unit gas consumption is relatively high. In addition, the difference in temperature of incoming slabs leads to uneven distribution of heat during the steel-sintering process, resulting in large losses and large problems. In addition, due to insufficient combustion of gas, there are more oxide scales, and there are differences in the quality of slab fired steel

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

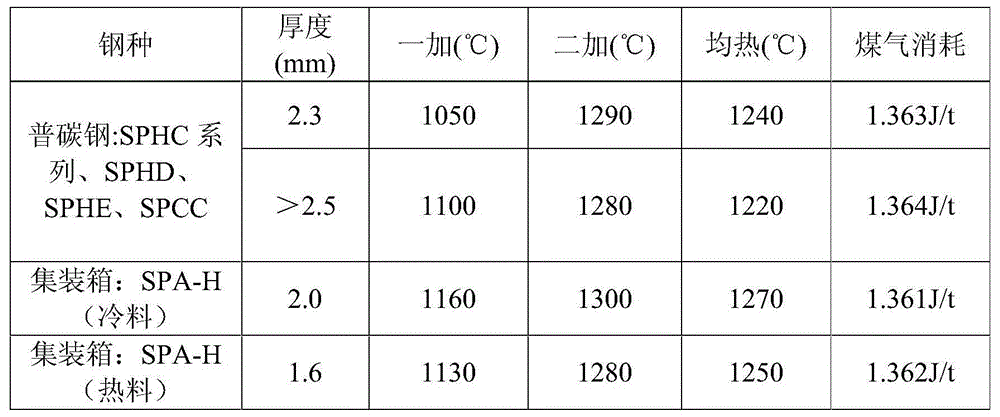

Embodiment 1

[0025]

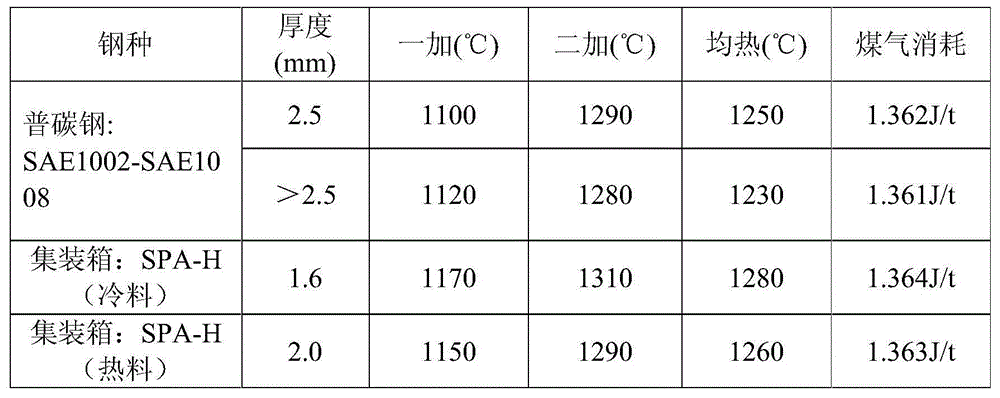

Embodiment 2

[0027]

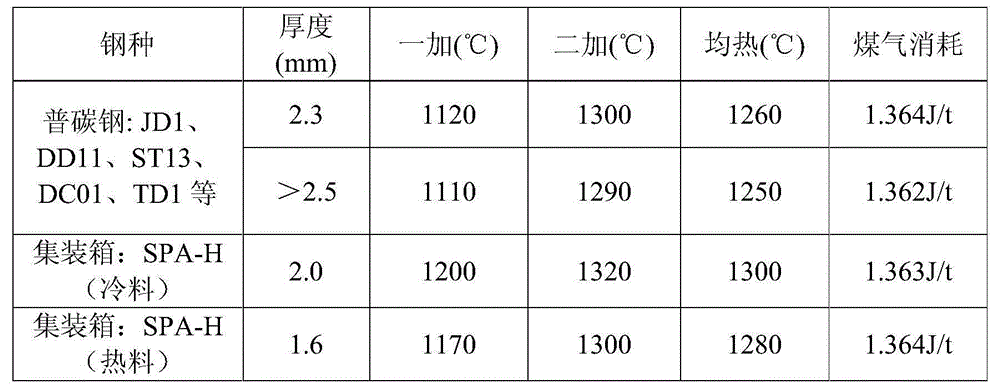

Embodiment 3

[0029]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a method for reducing heating gas consumption. By adjusting a first heating section, a second heating section and the soaking temperature, the tapping temperature of cold rolled steel is reduced, and accordingly the heating gas consumption is reduced; in addition, plate blanks at the similar temperature are put into a heating furnace at the same time, so that the plate blanks are heated uniformly; iron scale produced by uneven temperature is decreased, and the quality of plate blank sintered steel is improved. Compared with the prior art, the method for reducing the heating gas consumption has the beneficial effects that by means of the effective measures, the tapping temperature of the cold rolled steel is reduced, and accordingly the gas consumption of the heating furnace is reduced; according to different temperatures, the cold rolled steel is added into the heating furnace in batches, the temperature difference is decreased, and the producing amount of the iron scale is reduced; in addition, due to the fact that the plate blanks are heated in the furnace sufficiently, the process cost investment in the follow-up rolling process can also be decreased, the rolling efficiency is improved, and the ultimate purposes of reducing cost and improving benefits are reached; the gas unit consumption target is reduced from the previous 1.392 GJ / t to 1.364 GJ / t, and the gas consumption is reduced effectively.

Description

technical field [0001] The invention relates to the technical field of energy-saving iron and steel metallurgy, is applicable to the field of hot-rolled strip heating technology, and particularly relates to a method for reducing heating gas consumption. Background technique [0002] As an important cost factor, gas consumption has always occupied a relatively high proportion of production costs. Due to the increasing cost pressure, the impact of gas consumption is becoming more and more obvious. Due to the continuous downturn in the steel market, the cost pressure has further increased, and it is imminent to solve this problem. At present, the step-by-step heating used in steel mills is limited by the original steel-sintering process system, and the unit gas consumption is relatively high. In addition, the difference in temperature of incoming slabs leads to uneven distribution of heat during the steel-sintering process, resulting in large losses and large problems. In addi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B21B37/74

Inventor 孙国宝王健徐守云

Owner ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com