Rail bracket type steel ladle adding cover device

A technology of bracket device and ladle cover, applied in metal processing equipment, casting melt container, casting equipment, etc., can solve the problems of increasing the number of online ladle, increasing the cost of steelmaking, lowering the temperature of the molten steel, etc., so as to reduce the temperature of the molten steel. Loss, improve the quality of steel products, reduce the effect of the furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

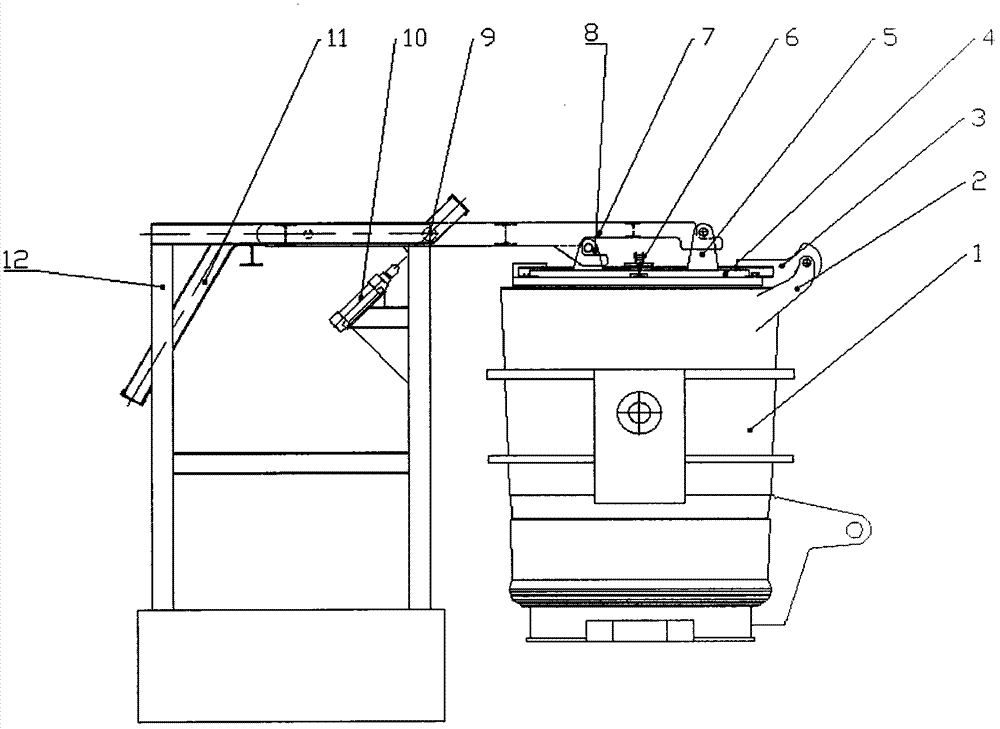

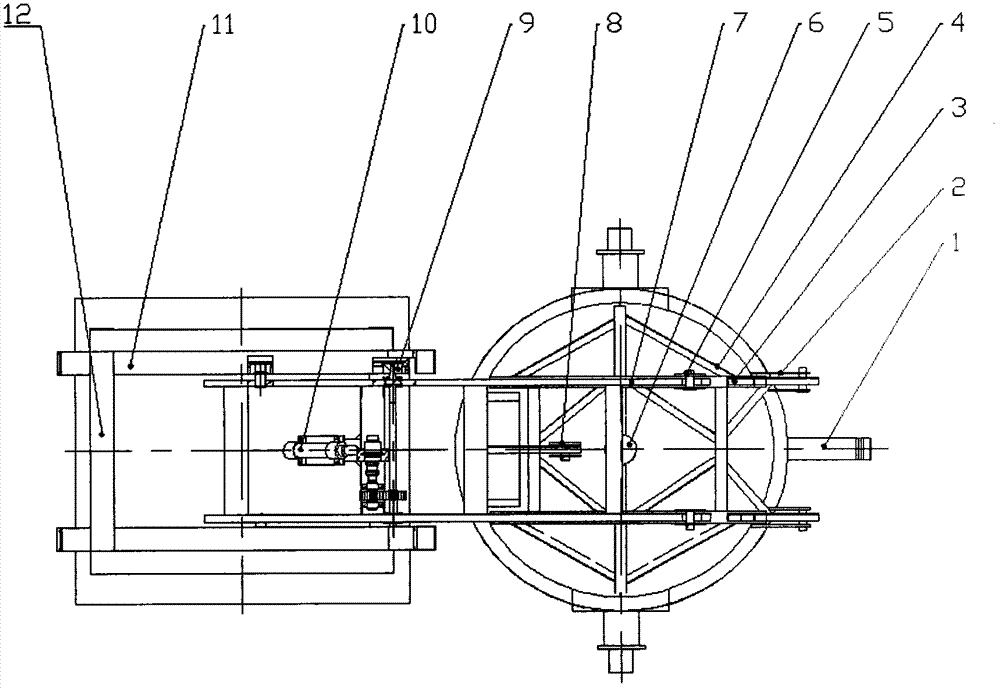

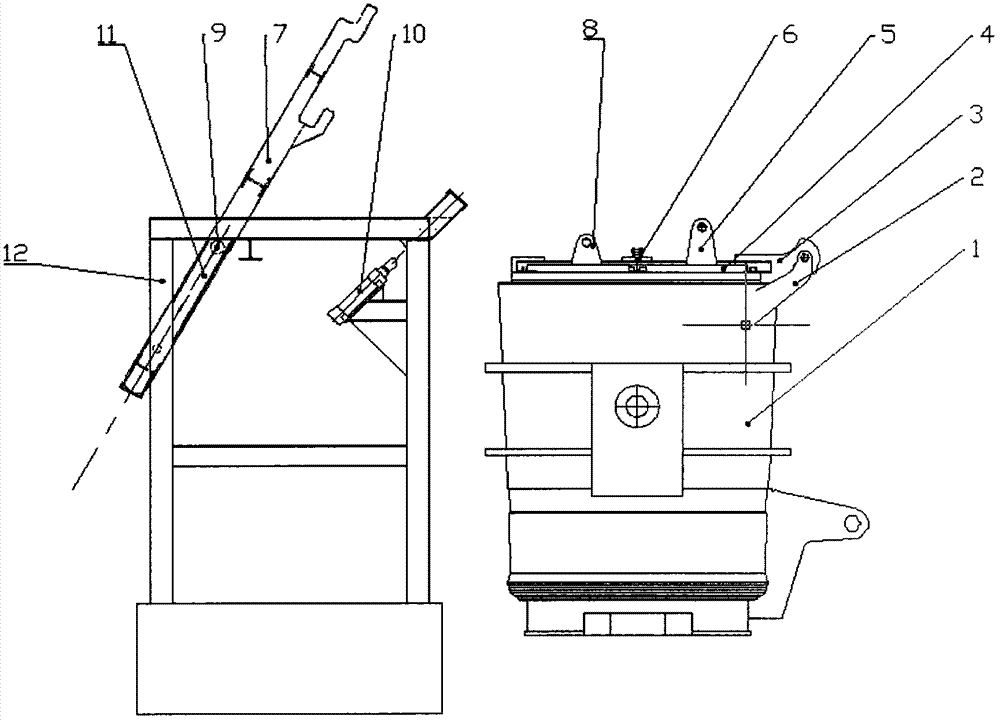

[0018] The bracket-12 is fixed on the foundation, the track-11 and the bracket-12 are fixedly connected into one body, the bracket device-7 is provided with rollers, and the rollers roll on the track-11 through the driving motor-9, so that the bracket device-7 can Moving along the track-11, one end of the thrust hydraulic cylinder-10 is fixed, and the other end is connected with the bracket device-7, and the bracket device is raised along the track-11 through the thrust hydraulic cylinder-10.

[0019] Two lifting rings-5 and one lifting ring 2-8 are set on the ladle cover-4, and the hot repair hole-6 realizes the hot repair purpose of ladle-1 with the ladle cover-4, and the ladle cover-4 is provided with two hinges-3 It can cooperate with the ladle-1 hinge seat-2 to realize the function of pouring molten steel and steel slag with the ladle cover on the ladle, and prevent the ladle cover-4 from falling off from the ladle-1.

[0020] function realization

[0021] Cap removal: W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com