Novel production method for normalizing and cooling high-magnetic-induction oriented silicon steel and product

A high magnetic induction orientation and production method technology, applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problems of unfavorable AlN precipitation, unfavorable cold rolling, high temperature control, etc., achieve excellent magnetic properties, improve yield, Precipitation improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

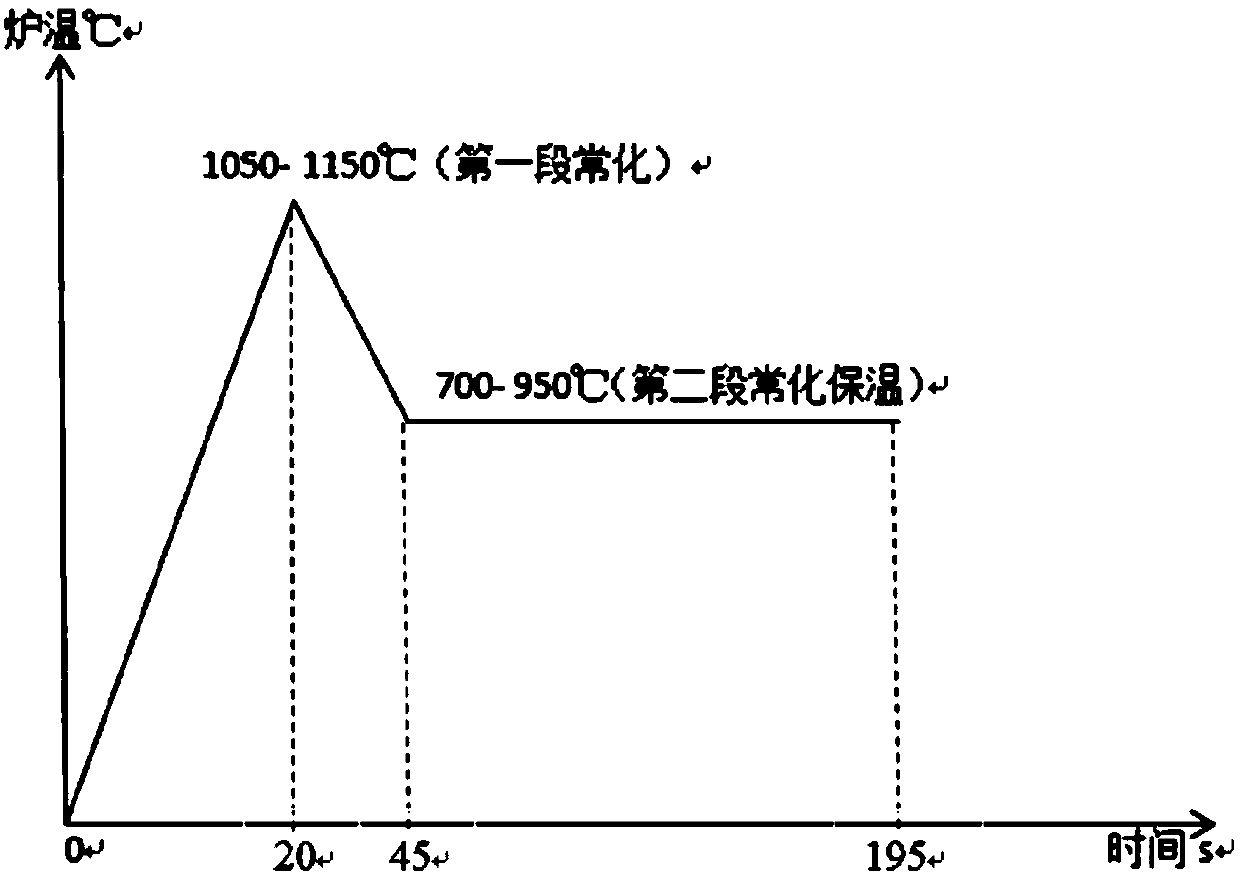

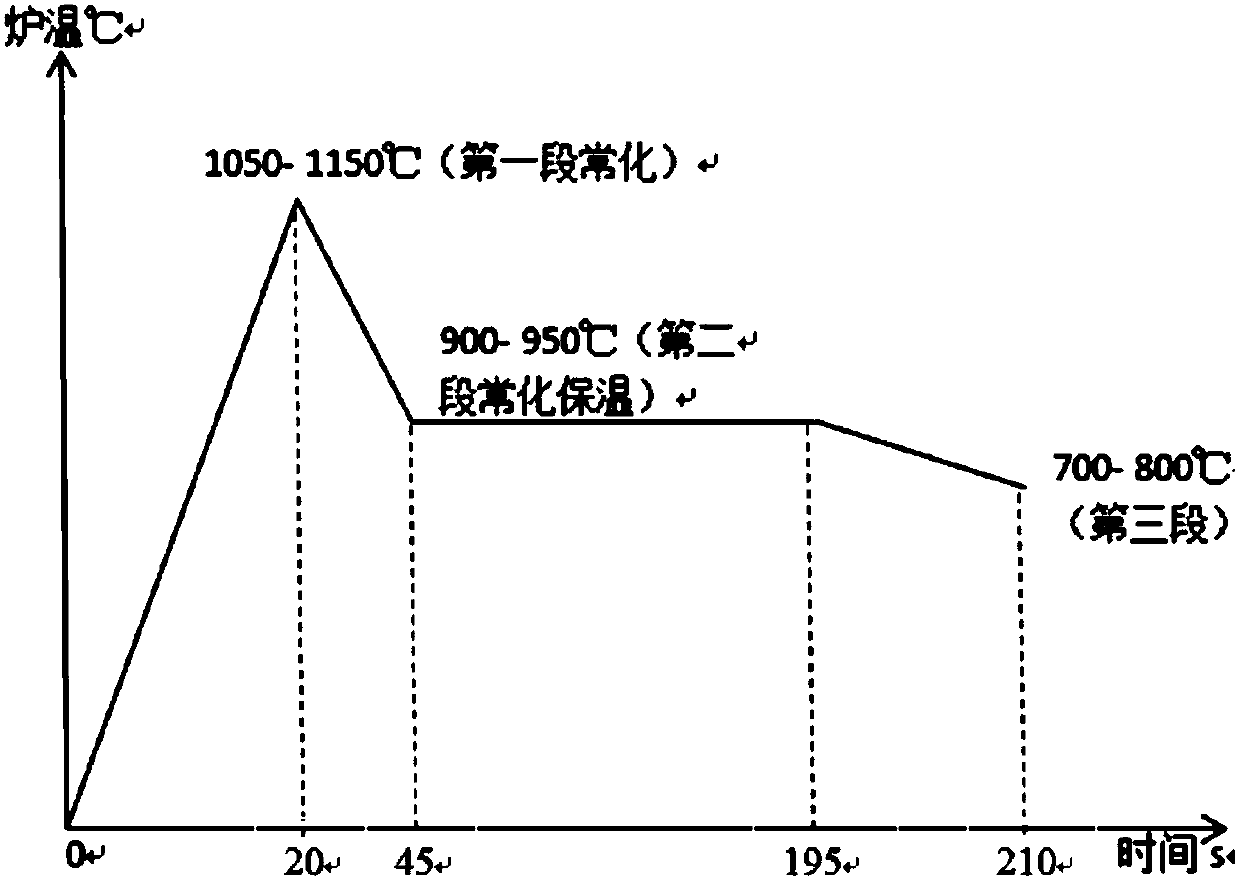

[0016] figure 2 It is the temperature curve of the normalized cooling technology of the present invention. Such as figure 2 As shown, the first stage of normalization is carried out in the temperature range of 1050-1150 ° C for the high magnetic induction grain-oriented silicon steel plate to be normalized, and the holding time is ≤ 20s; 950°C, the cooling time is about 25s, and the second heat preservation is carried out, the time is 100-150s; then the cooling rate is controlled at 10-15°C / s to 700-800°C; then the water spray is rapidly cooled to room temperature.

[0017] Among them, air-cooling control is performed after the second heat preservation at 900-950°C, and the cooling rate is 10-15°C / s to 700-800°C. In the second stage of the normalized cooling process of the present invention, the temperature is maintained at 900-950°C for 100-150s, and then the cooling rate is controlled at 10-15°C / s to 700-800°C. This is different from the process in the prior art which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com