Heating furnace comprehensive optimizing controlling system designing and controlling method for hot rolling process

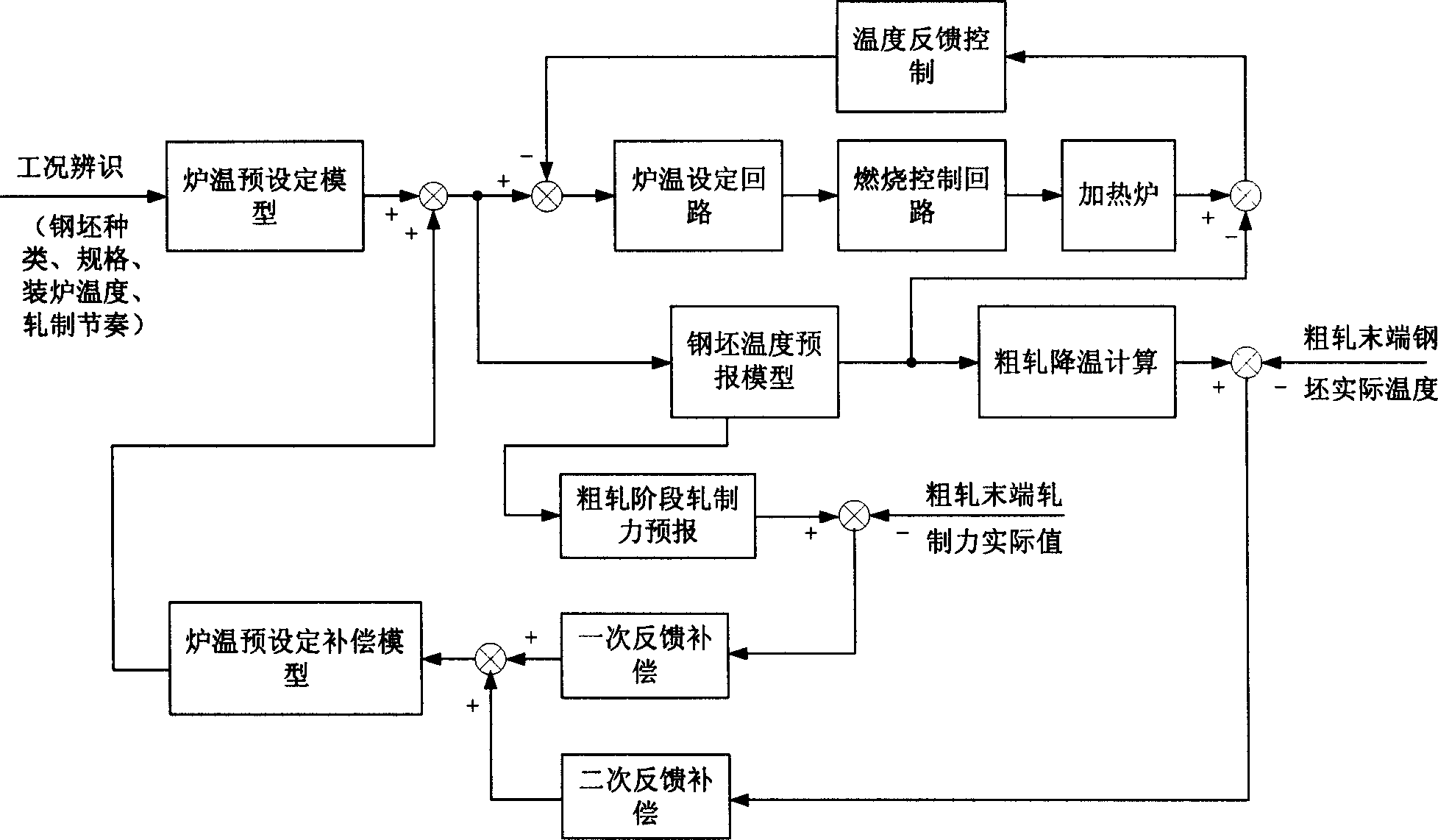

A technology for system design and optimal control, applied in general control systems, control/regulation systems, temperature control, etc., can solve the problem of not taking into account the inseparability of the close connection between the heating furnace and the rolling mill, and the inability to ensure that the hot rolling process always works. energy consumption, inability to achieve optimization of heating furnaces and roughing mills, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

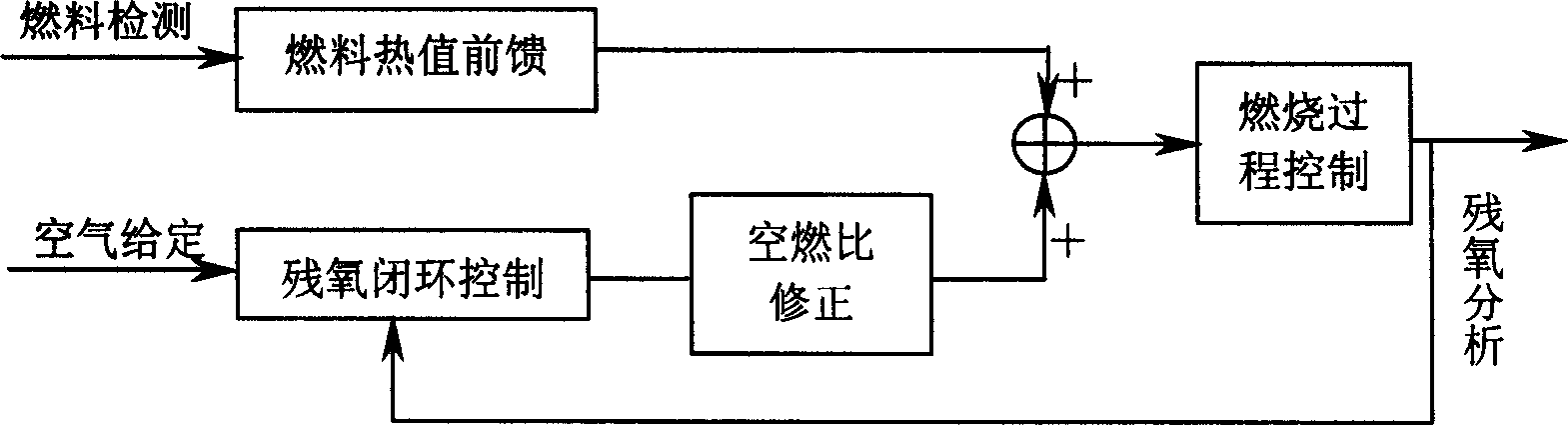

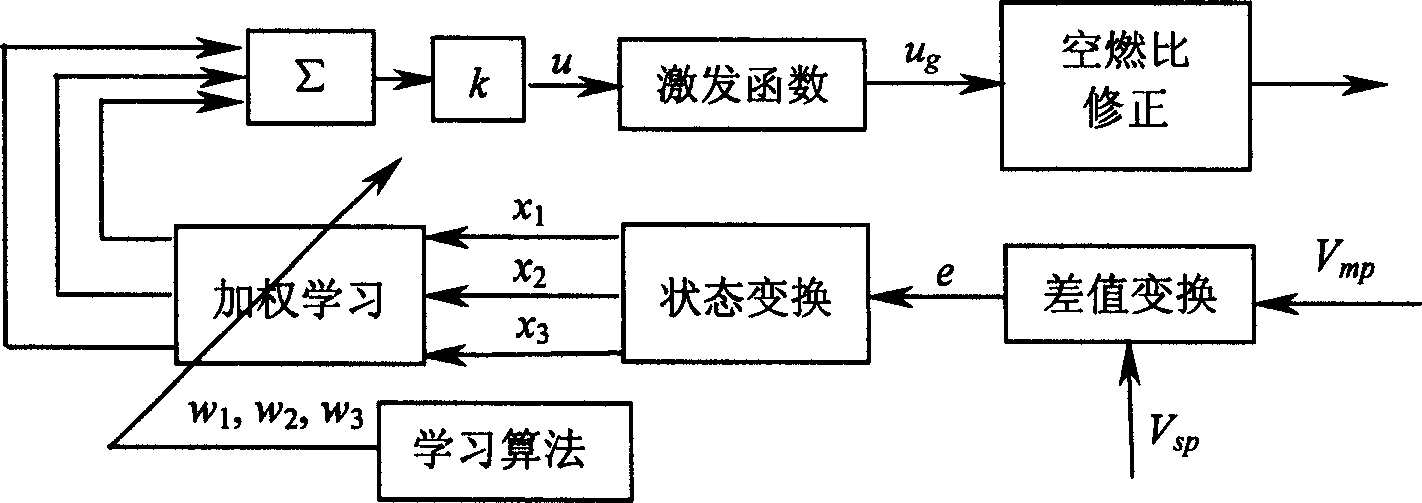

Method used

Image

Examples

Embodiment Construction

[0046] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0047] The heating furnace of a domestic medium and heavy plate factory is a six-stage walking heating furnace, and the rough rolling unit is a two-roll reversing rolling mill. The residence time of the billet in the furnace is 4 to 5 hours, rough rolling 5 times, the biting speed is 30 rpm, the stable rolling speed is 50 rpm, the throwing speed is 40 rpm, the rough rolling mill allows The rolling force is 24000KN, and water cooling is used between passes. The charging temperature of the steel billet is 25°C, and the furnace temperature is 1200°C-1250°C. The cross-sectional temperature difference of the billet should be less than 50°C when the billet is released from the furnace. The steel pushing speed of the heating furnace is 0.0021m / s~0.0028m / s, and the specification requirements of billets and rough rolling export bil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com