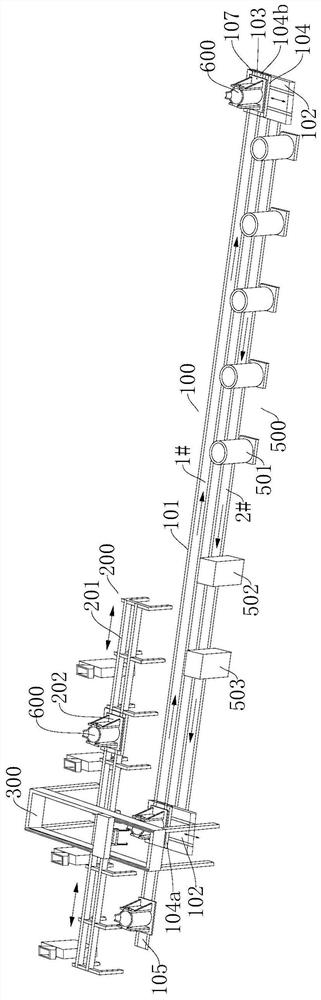

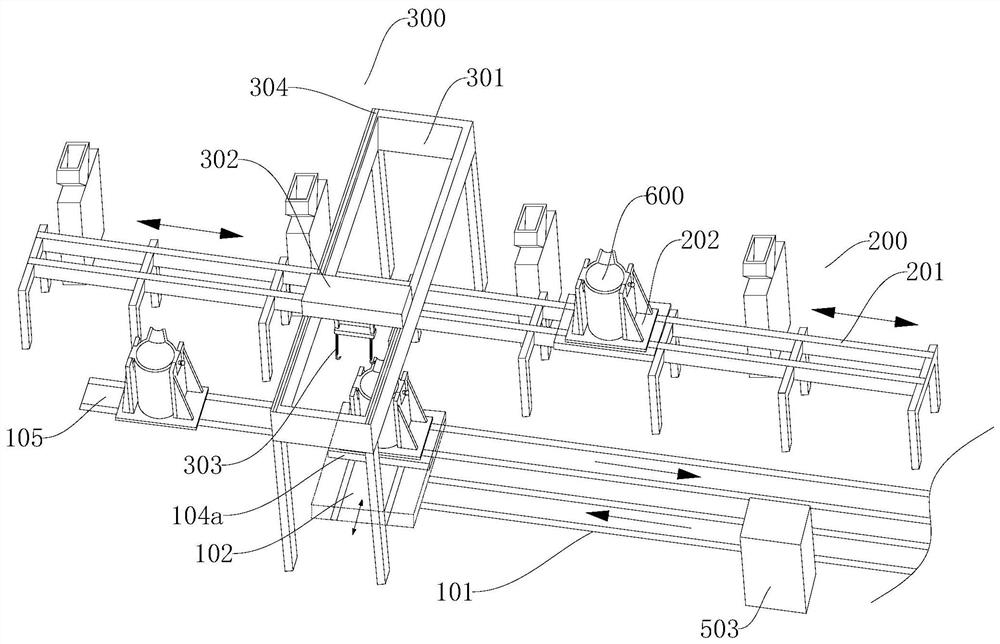

Molten iron transportation line

An assembly line and molten iron technology, applied in the direction of manufacturing tools, casting molten material containers, and improving process efficiency, etc., can solve problems such as high cost and potential safety hazards, reduce energy consumption, increase safety, and reduce heat loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

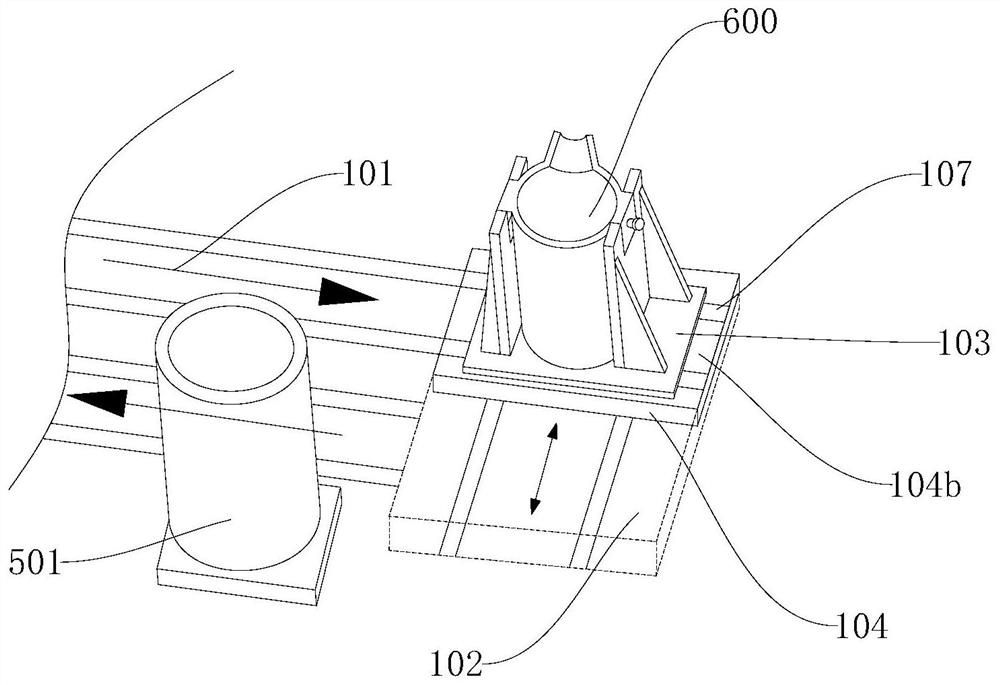

[0068] Further, the driving mechanism 109 can be a hydraulic cylinder, a rack and pinion structure, etc., the driving mechanism 109 and the control system

[0070] Specifically, the first support bracket 110 includes two baffle plates arranged at intervals in the direction of the parallel sub-running track 101,

[0074] Further, the flip frame 207 is provided on the arc guide groove 209, and the second support bracket 204 is provided with the guide groove 209

[0077] Wherein, the lowering and lifting of the hook 303 by the lifting trolley 302 can be realized by a motor and a chain.

[0078] In the above-described embodiments, all structures related to the control of power mechanisms (such as hydraulic cylinders, motors, etc.) can be

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com