Conveying device for water pump accessory production and machining

A technology of transportation devices and accessories, which is applied in the direction of transportation and packaging, conveyor control devices, conveyors, etc., can solve problems such as processing difficulties, and achieve an effect that is conducive to connection processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

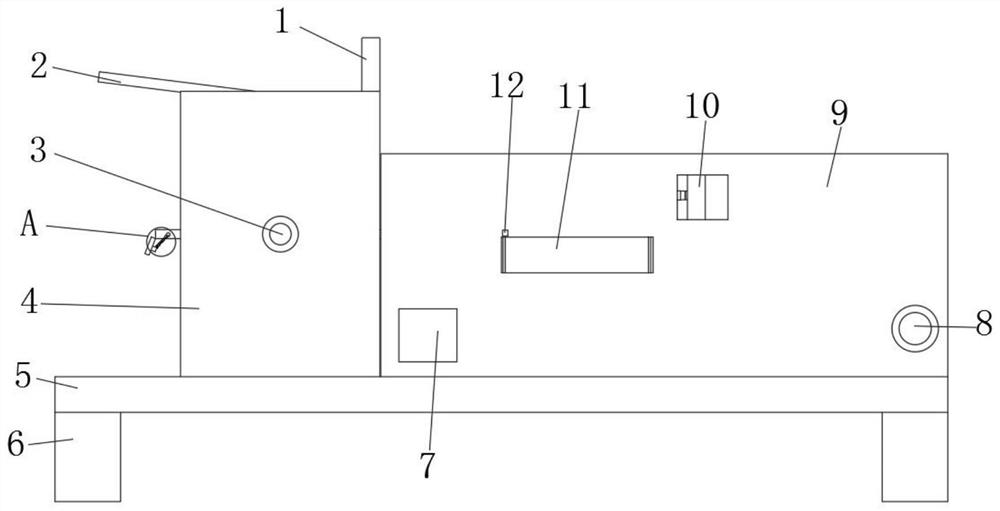

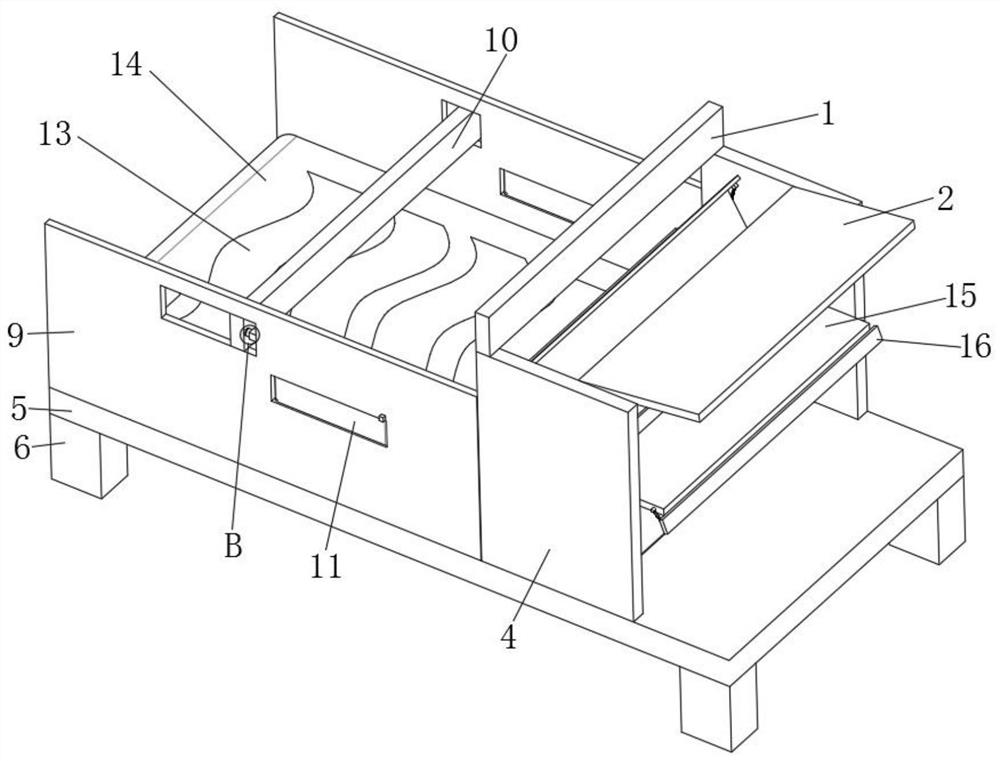

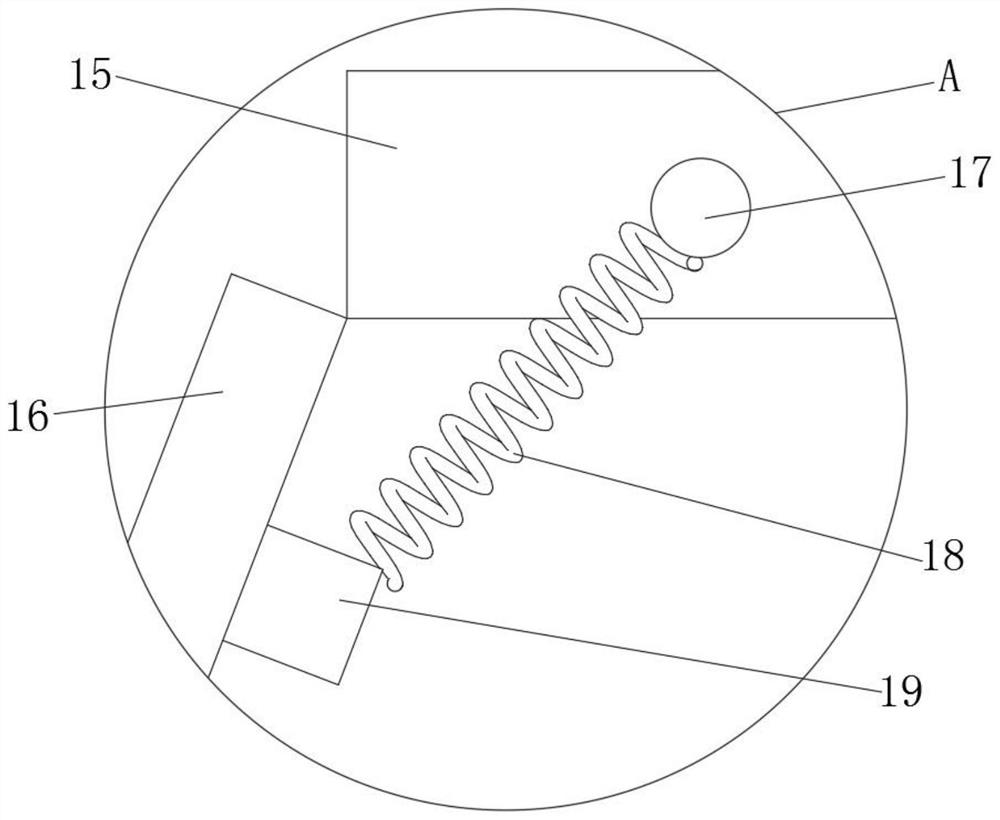

[0031] refer to Figure 1-5 , a transportation device for the production and processing of water pump accessories, including a workbench 5, a second support plate 9 is fixed on the top outer wall of the workbench 5 by screws, and a transmission mechanism is provided on the opposite inner wall of the second support plate 9, and the second support plate on the right side is One side of the outer wall of the two support plates 9 has a first rectangular hole, the upper and lower inner walls of the first rectangular hole are rotatably connected with the first baffle 10, and the rear side outer wall of the first baffle 10 is fixed with a metal Block 20, a side outer wall of the second support plate 9 on the left side has a second rectangular hole, and one end of the first baffle plate 10 is located inside the second rectangular hole, and one side inner wall of the second rectangular hole is fixed with a screw close to Switch 22, and proximity switch 22 is fixed with rubber pad 21 by...

Embodiment 2

[0042] refer to Figure 6 , a transportation device for the production and processing of water pump accessories. Compared with Embodiment 1, this embodiment also includes support legs 6 fixed by screws at the four corners of the bottom outer wall of the workbench 5, and the bottom outer wall of the support leg 6 is provided with anti-skid pads 25.

[0043] Working principle: the anti-skid pad 25 is provided to increase the friction force at the bottom of the device, enhance the stability of the device, and make the device safer in use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com