Hot air circulation heat storage type radiant tube heating sealing roller way kiln

A regenerative radiant tube and hot air circulation technology, applied in lighting and heating equipment, furnaces, charge materials, etc., can solve the problems of high energy consumption and production cost, high residual moisture content of blanks, unstable temperature control, etc. To achieve the effect of good product quality, easy temperature control and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

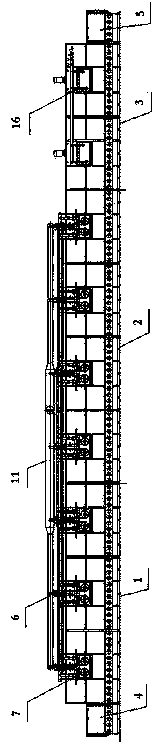

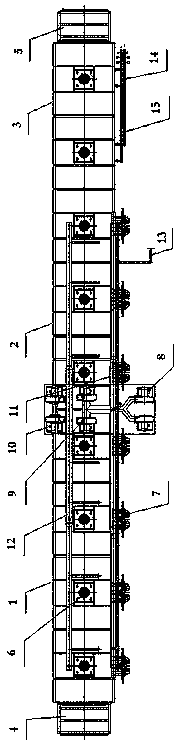

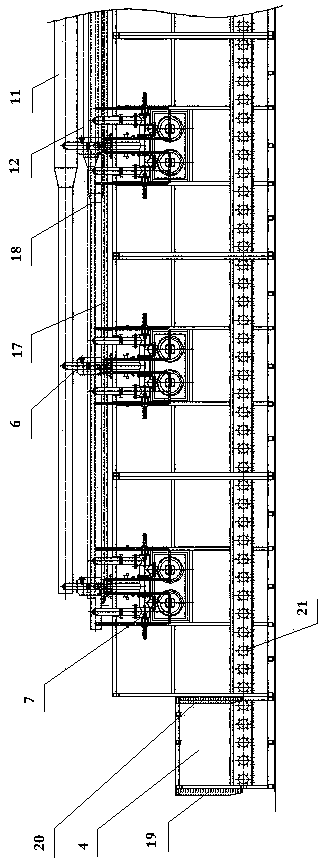

[0018] As shown in the figure, the heat treatment equipment used to produce unburned magnesia-calcium-carbon bricks is composed of a steel structure frame and a heat preservation furnace body made of refractory materials, a roller transmission device, a heating device, a cooling device, and an inlet and outlet sealing device. The furnace body is divided into three parts: a preheating section 1, a constant temperature section 2 and a cooling section 3. The roller rod transmission device is composed of a roller rod 21 arranged at the bottom of the furnace body, a speed regulating motor, a chain and a sprocket 27, and the two ends of the roller rod 21 are fixedly installed on the furnace walls on both sides of the furnace body bottom through sealed bearing seats On, the sprocket wheel 27 that one end is provided with is interconnected by chain, is driven by speed-regulating motor. Each section of the furnace is provided with a circulating air device consisting of a circulation fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com