Composite micro-alloying hot rolled steel plate containing V and Nb and preparation method thereof

A hot-rolled steel plate and micro-alloying technology, which is applied in the field of hot-rolled strips, can solve the problems of increased production costs of hot-rolled steel plates, and achieve the effects of reducing metal oxidation and burning loss, reducing the amount of production, and increasing the amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

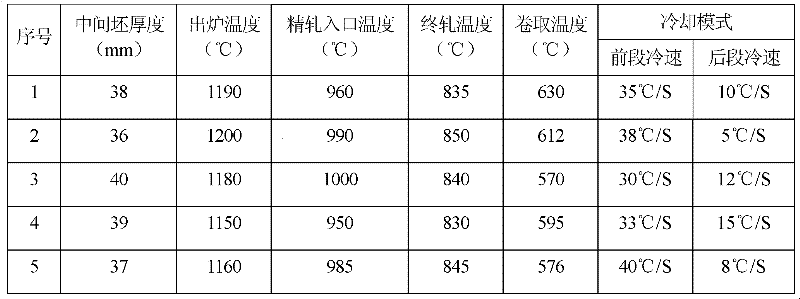

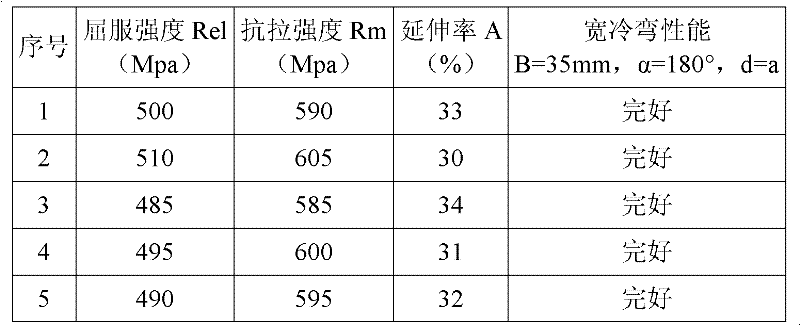

[0027] The chemical composition weight percentage of the hot-rolled steel sheet of the present invention is: 0.06%≤C≤0.08%, 0.20<Si≤0.30%, 0.70≤Mn≤0.90%, 0.04<V≤0.05%, 0.02≤Nb≤0.03%, P≤ 0.025%, S≤0.015%, and the balance is iron and unavoidable impurities. The preparation method comprises the following steps: casting slab → heating → descaling with high-pressure water → rough rolling → hot coil box coiling → finishing rolling → cooling → coiling.

[0028] The improvement points of the process part are:

[0029] 1. Heating: Control the furnace temperature to 1150°C-1200°C.

[0030] 2. Finish rolling: the starting rolling temperature is controlled at 950-1000°C, and the finishing rolling temperature is controlled at 830°C-850°C.

[0031] 3. Cooling: the cooling method of fast cooling in the front section + sparse cooling in the back section. Specifically, the front stage: cooling to 730-750°C at a cooling rate of 30-40°C / s; the latter stage: cooling to 580-620°C at a cooling r...

Embodiment

[0033] The chemical composition weight percentage of the hot-rolled steel sheet of the present invention is C: 0.06%≤C≤0.08%, 0.20<Si≤0.30%, 0.70≤Mn≤0.90%, 0.04<V≤0.05%, 0.02≤Nb≤0.03%, P ≤0.025%, S≤0.015%, the balance is iron and unavoidable impurities. Melt steel was smelted according to Table 1.

[0034] The chemical composition (weight percent %) of hot-rolled steel plate of the present invention of table 1

[0035] serial number

C

Si

mn

P

S

V

Nb

1

0.07

0.25

0.80

0.019

0.009

0.045

0.025

2

0.08

0.28

0.90

0.012

0.012

0.050

0.030

3

0.06

0.30

0.70

0.016

0.007

0.041

0.022

4

0.07

0.21

0.85

0.017

0.015

0.048

0.020

5

0.06

0.24

0.75

0.012

0.008

0.046

0.026

[0036] The above-menti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com