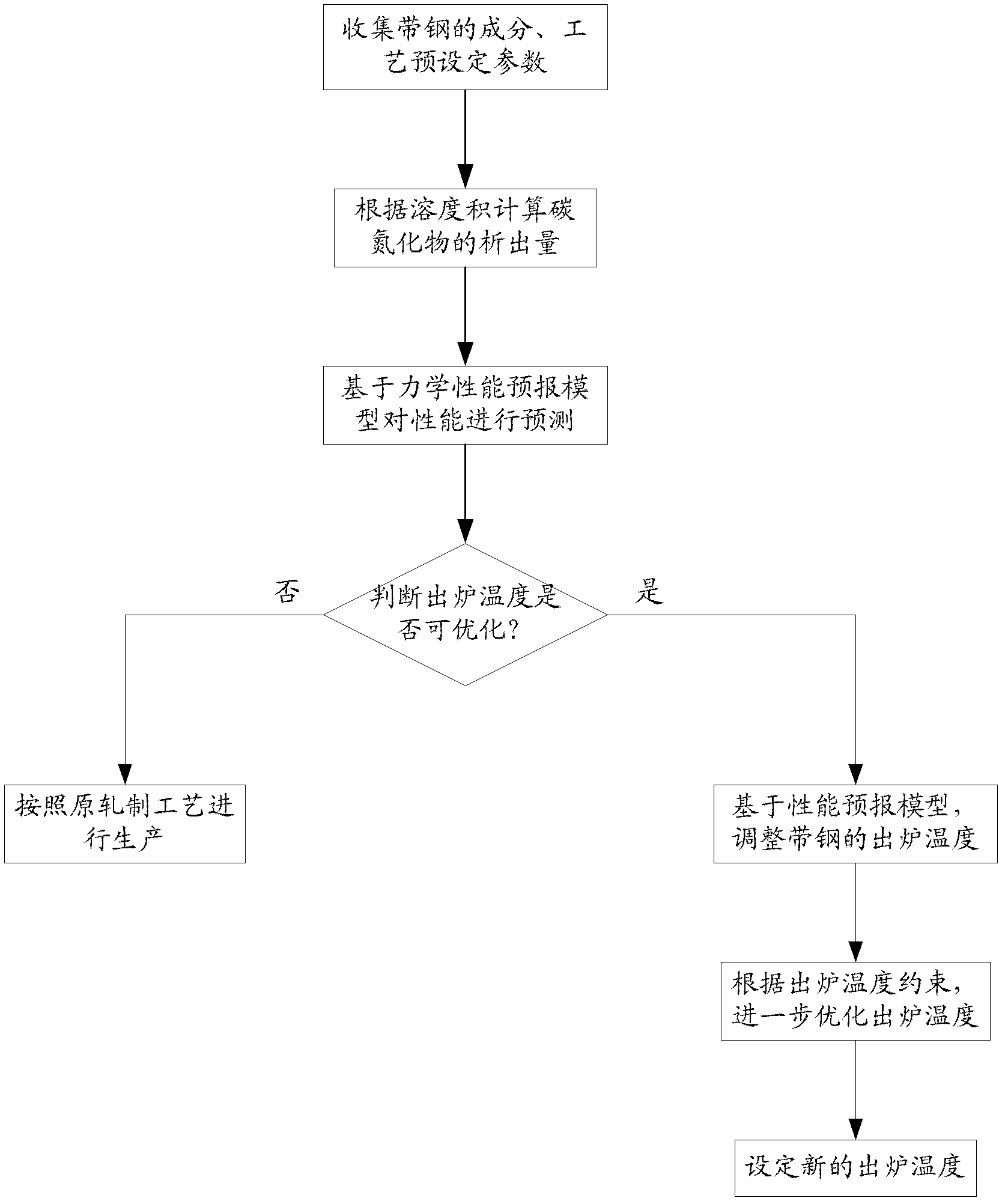

Heating furnace energy-saving control method based on strip steel mechanical property forecasting model

A forecasting model and energy-saving control technology, applied in heat treatment process control, heat treatment furnaces, furnaces, etc., can solve problems such as large gas consumption, and achieve the effect of reducing the furnace temperature, covering a wide range of steel types, and reducing energy consumption per unit product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

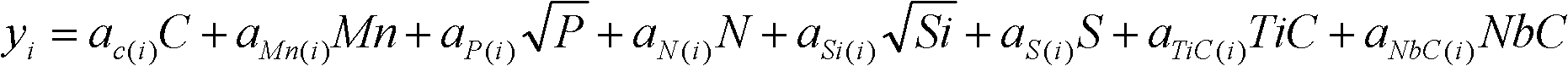

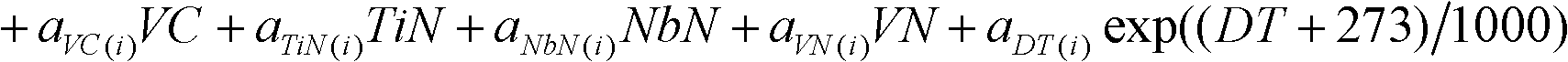

Method used

Image

Examples

Embodiment

[0164] In order to illustrate the specific application of the technical invention, the specific implementation steps of the present invention will be introduced below by taking the hot rolling production line of a certain steel plant as an example.

[0165] According to the form of the mechanical performance prediction model given above, based on the actual production data, the model coefficients are determined by the method of statistical regression, and the composition range of the strip steel is as follows:

[0166] serial number

ingredient name

Content upper limit (%)

1.

the carbon

0.22

2.

2

3.

0.053

4.

0.01

5.

0.42

6.

0.03

7.

0.12

8.

0.002

9.

0.002

[0167] Table 2 Range of chemical compositions in the data used for m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com