System and method for monitoring optimum hoisting height of shore bridge container

A monitoring system and container technology, applied in the direction of safety devices, transportation and packaging, load hanging components, etc., can solve the problems of not very sensitive observation of the height of the spreader, shorten the life of the wire rope, increase the hoisting time, etc., to achieve low cost and reduce Effects of mechanical wear and life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

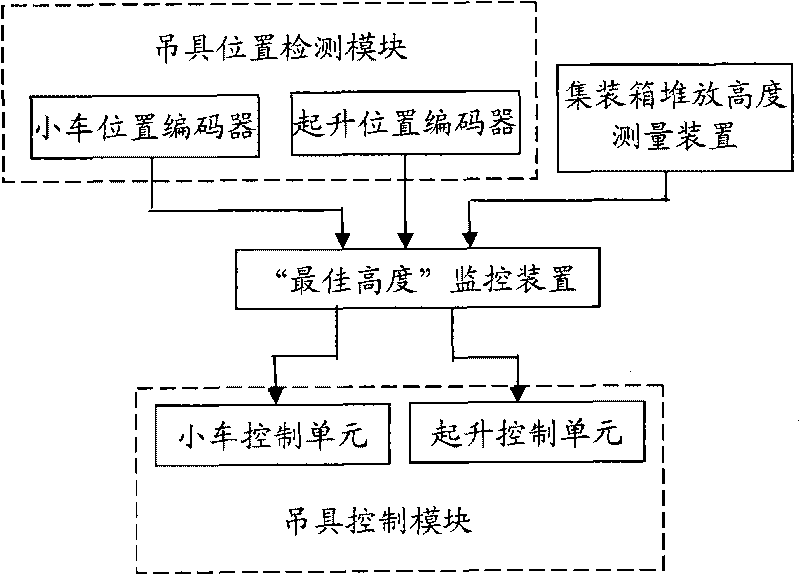

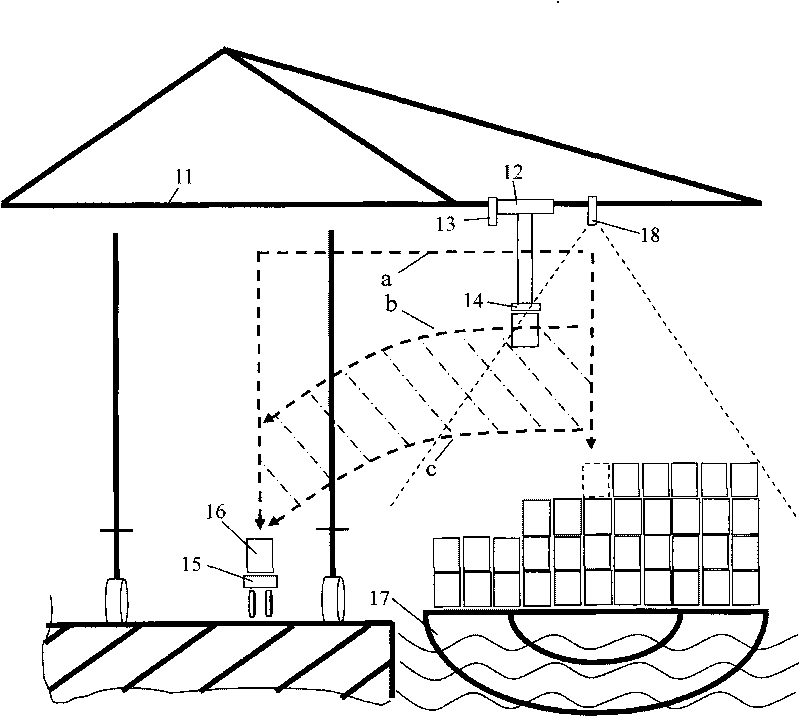

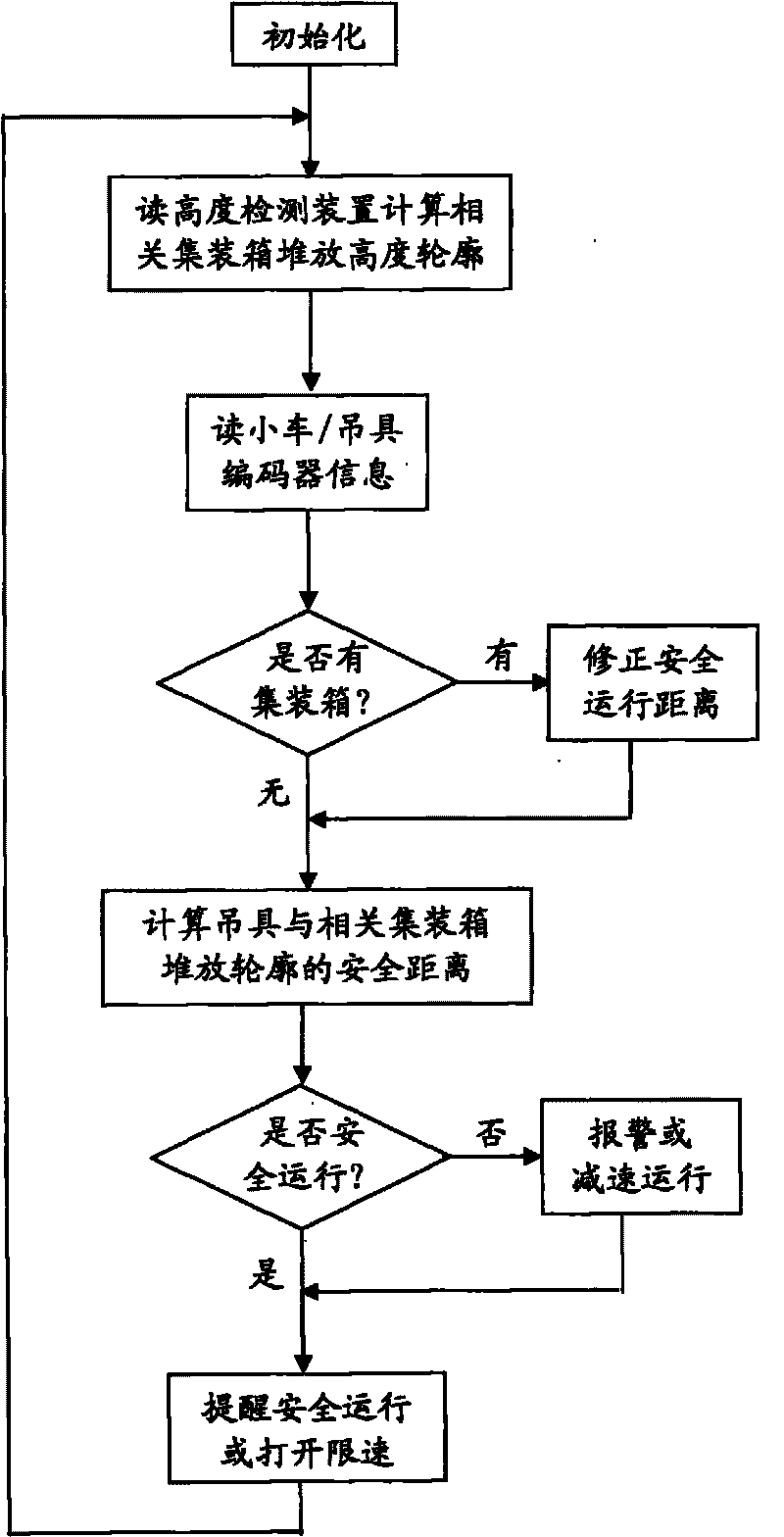

[0037] See figure 1 As shown, the "best height" monitoring system for quay crane container hoisting of the present invention includes a spreader position detection module, a container stacking height measuring device, a "best height" monitoring device, a spreader control module and / or a warning reminder device. The spreader position detection module and the container stacking height measuring device are respectively electrically connected to the spreader control module and / or the warning reminder device through the "optimum height" monitoring device. The spreader position detection module detects the operating height of the spreader, the container stacking height measuring device is responsible for measuring the height profile of the container stacking under the spreader, and the "best height" monitoring device is responsible for checking the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com