Multivariable predictive control method with firing system based on pulse response die

An impulse response model and predictive control technology, applied in adaptive control, general control system, control/regulation system, etc., to achieve the effect of improving equipment operation rate, simplifying modeling steps, and reducing prediction errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The purpose and effects of the present invention will become more apparent by referring to the accompanying drawings in detail of the present invention.

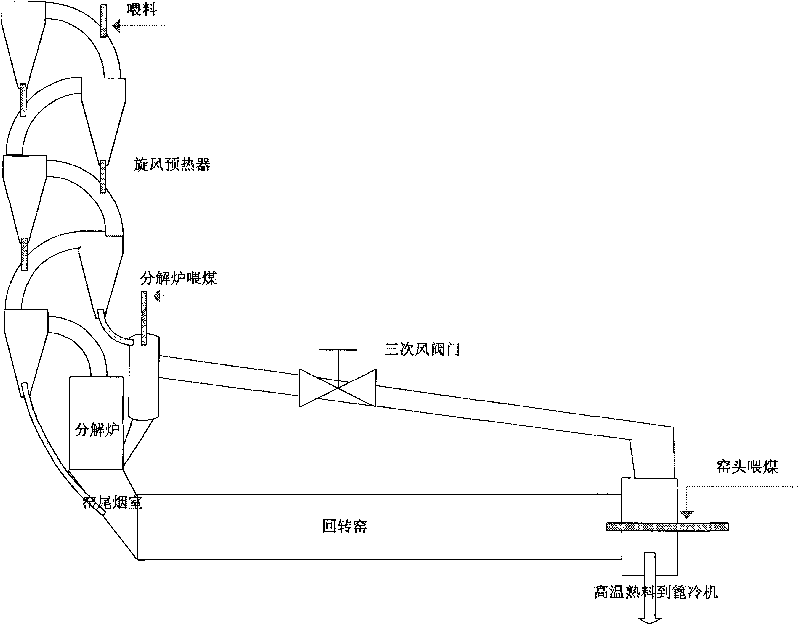

[0029] The predictive control method of the present invention is mainly applied to figure 1 The cement production firing system shown, the specific implementation method is as follows:

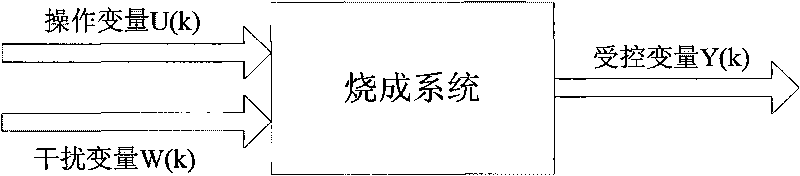

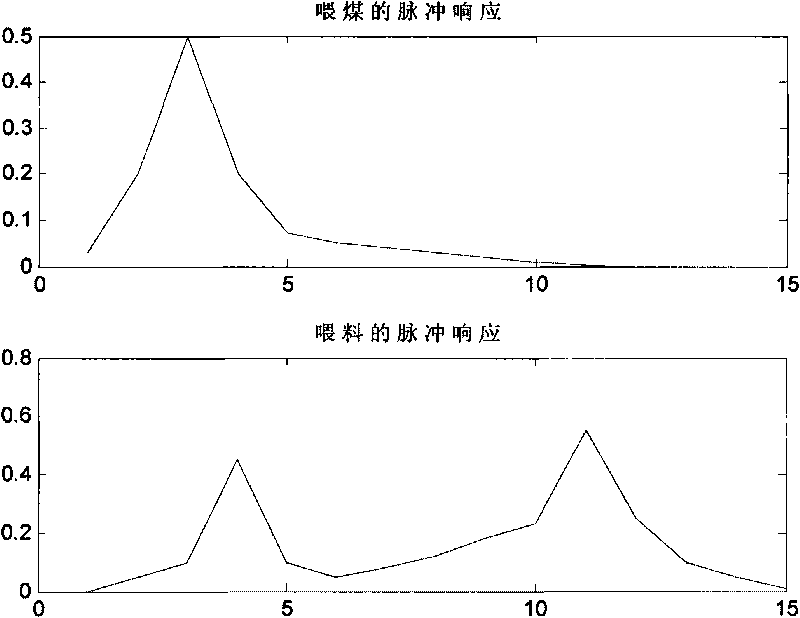

[0030] 1. Multivariate prediction model based on impulse response

[0031] The predictive control algorithm of the present invention adopts the impulse response non-parametric model of the characteristics of the controlled system as the internal predictive model. figure 2 The input-output relationship diagram of the variables is given, in which the coal feeding amount of the calciner, the coal feeding amount of the kiln head and the opening of the tertiary air valve are taken as the operating variables, the raw meal feeding amount is used as the disturbance variable, and the O2 content at the outlet of the top cyclone , the CO con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com