A Dynamic Equivalent Modeling Method of Ball Bearing Based on Adams

An equivalent modeling and ball bearing technology, applied in the field of effective modeling, can solve problems such as multi-body contact, complex mechanical properties, and parts influence, and achieve the goal of simplifying the modeling steps, reducing the addition of constraints, and reducing the simulation calculation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific accompanying drawings.

[0020] Concrete steps of the present invention are as follows:

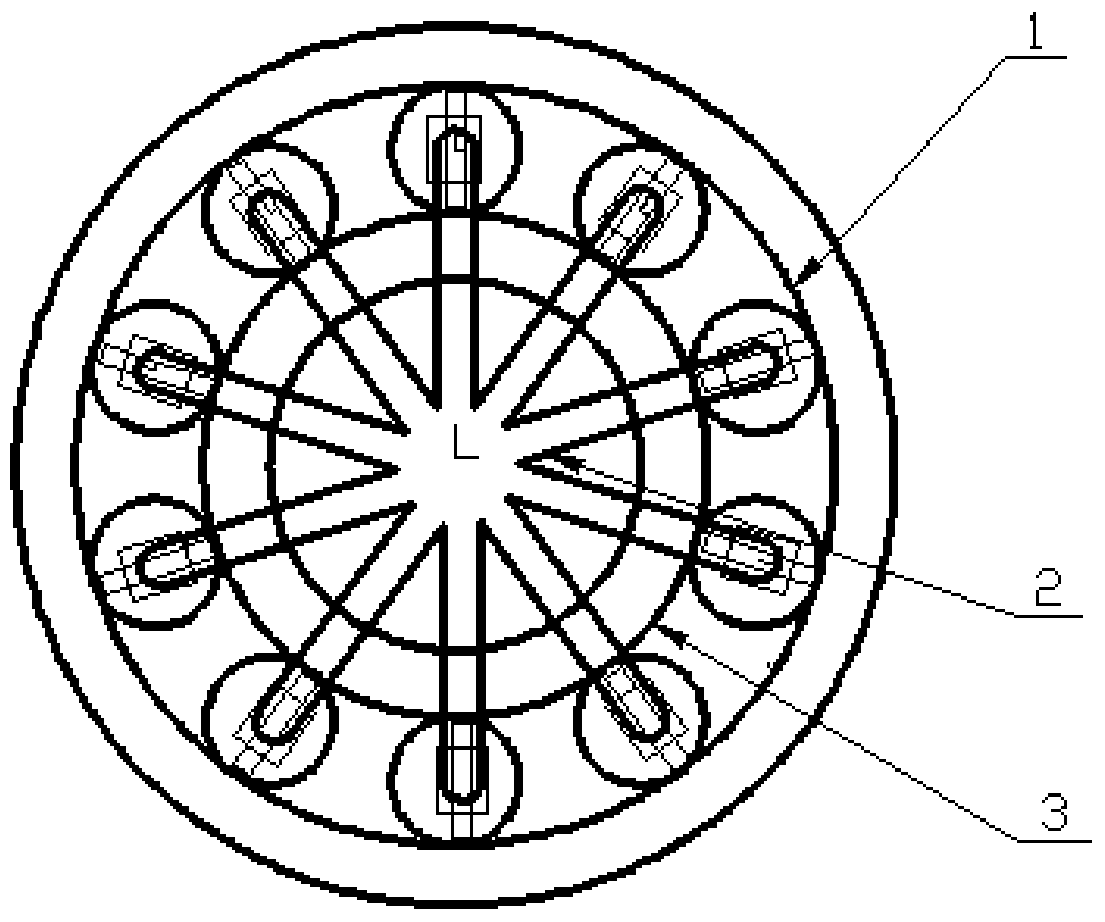

[0021] Step 1: Create a three-dimensional stereogram of the ball bearing on the three-dimensional software. The ball bearing includes a bearing inner ring 1, a bearing outer ring 3 and balls 4, and import the three-dimensional model of the ball bearing into ADAMS.

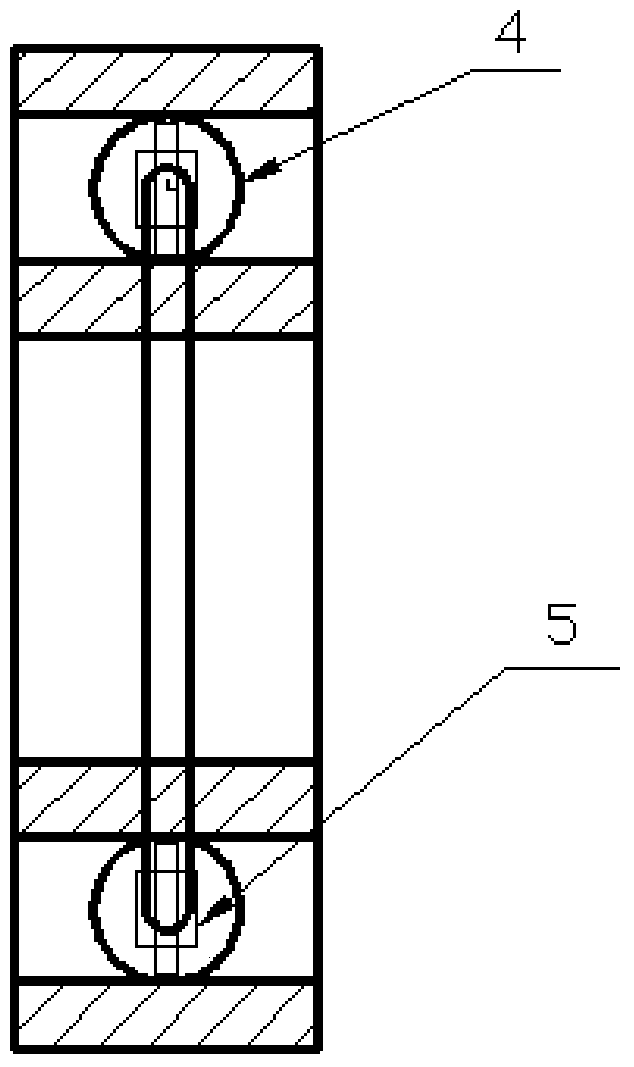

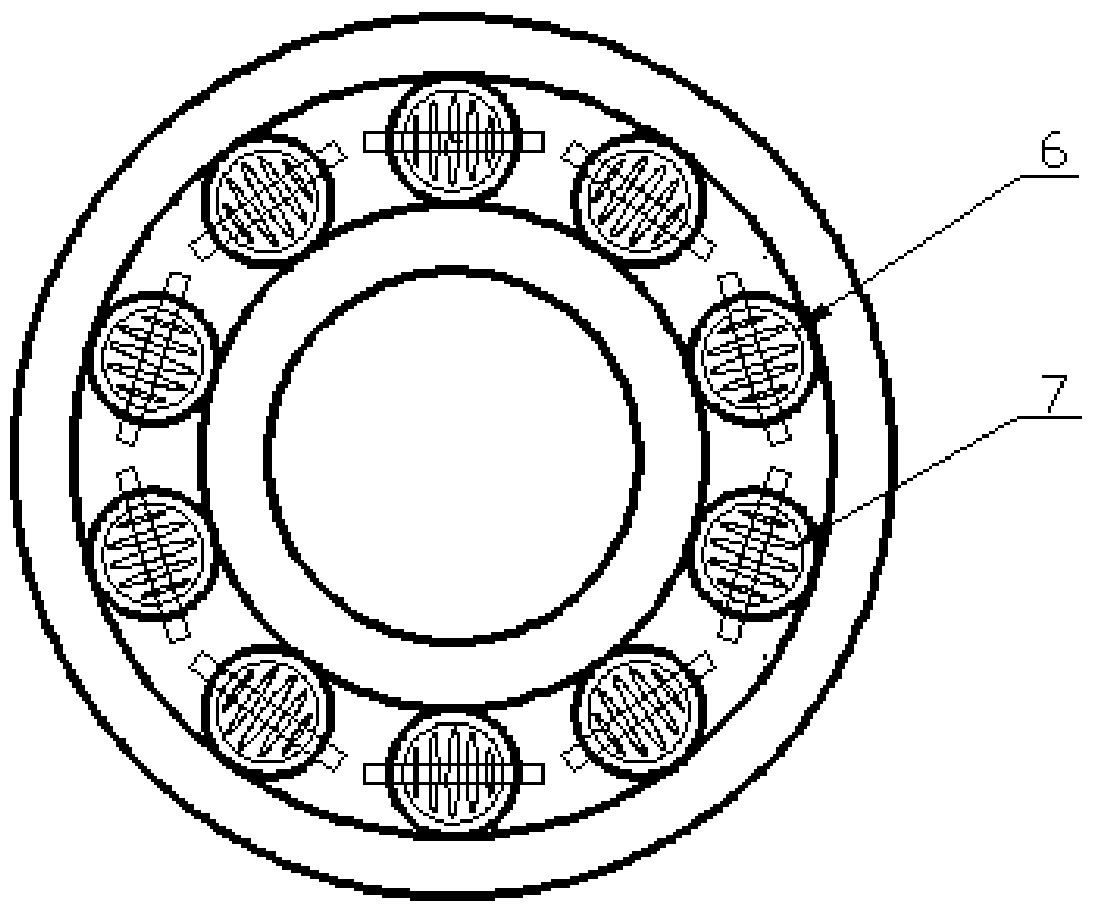

[0022] Step 2: Create connecting rods corresponding to the number of ball bearings in ADAMS. The connecting rods are set along the radial direction of the ball bearings, and the connecting rods pass through the centroids of the corresponding balls; add slip between the centroids of each ball and the corresponding connecting rods Deputy 5, and then combine all the connecting rods into a connecting rod member 2 through Boolean operations (such as Figure 5 shown) to replace the cage of the original model, and modify the quality attribute p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com