Batch process 2D constraint fault-tolerance control method through infinite time domain optimization

A fault-tolerant control and time-domain technology, applied in the advanced control field of automation technology, can solve the problems of uncertain initial value and inability to improve control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

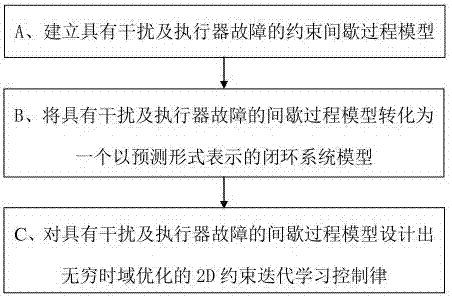

Method used

Image

Examples

Embodiment

[0116] The injection molding process is a complex industrial manufacturing process. The quality of injection molded products depends on material parameters, machine parameters, process parameters, and the interaction of these parameters. The quality of injection molded products includes many aspects, such as appearance quality, dimensional accuracy and mechanical (optical, electrical) performance and so on. Different users have different concerns about quality. These quality indicators are jointly determined by the materials, molds and process parameters used in the processing process. At the same time, various interference factors exist in different links in the injection molding process.

[0117] The injection molding process is essentially a multi-stage intermittent product production process. In each main stage, there are one or more key parameters that play a decisive role in the quality of the final product. The injection speed in the injection phase, the holding pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com