Hot-rolled coil for wheel and preparation method thereof

A technology of hot-rolled steel coils and wheels, which is applied in the field of hot-rolled steel coils, and can solve problems affecting customer yield, high welding cracking rate, sulfide inclusions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

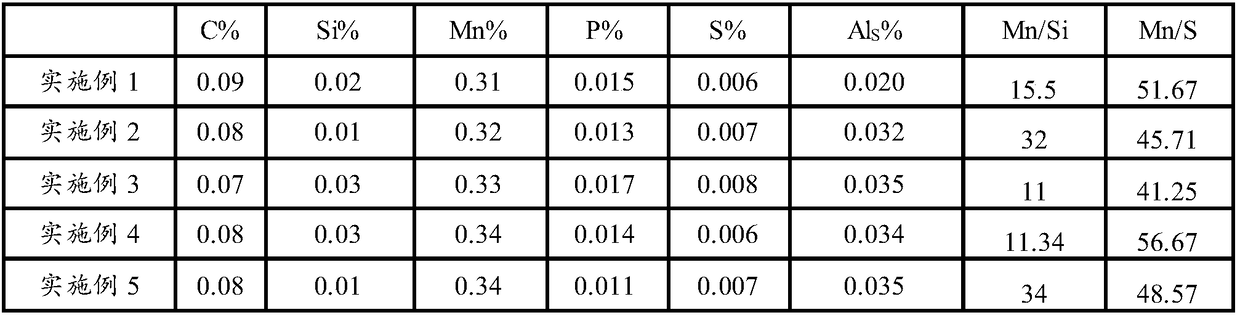

Embodiment 1

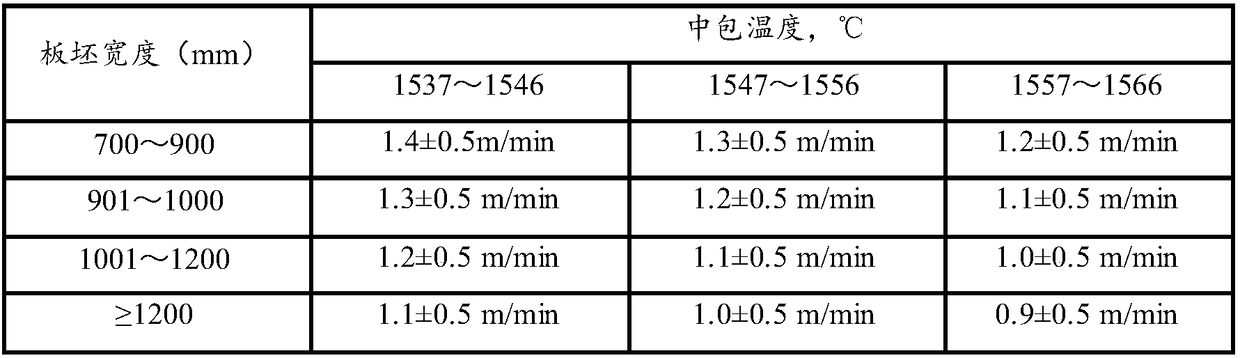

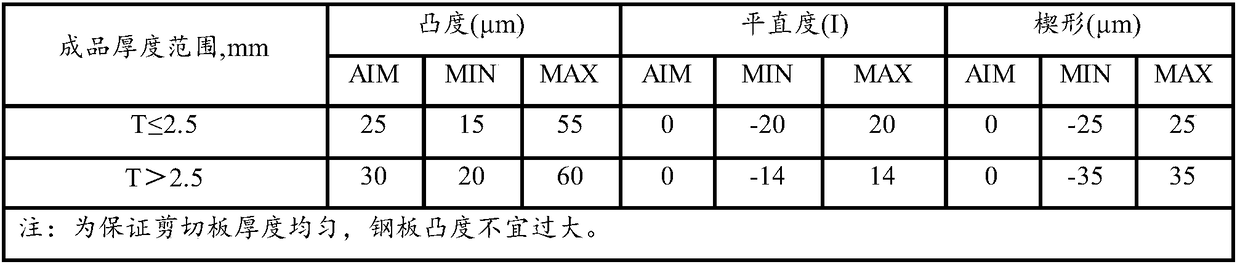

[0057] Desulfurization of molten iron, converter smelting, continuous casting and hot rolling to obtain hot rolled steel coils for wheels.

[0058] The mass content of S in the molten iron is ≤0.03%, the mass content of P is ≤0.12%, the temperature of the molten iron is 1310°C, and the mass content of S in the molten iron entering the converter smelting after desulfurization is ≤0.005%.

[0059] During the converter smelting process, adding recarburizer, medium-carbon ferromanganese, high-carbon ferromanganese, silicomanganese and ferrosilicon to the molten iron according to the required components of the molten iron to fine-tune the alloy. The tapping time of the converter smelting is 5 minutes; in order to reduce the tapping temperature and process temperature drop, the converter adopts red bag tapping; the slag is blocked during the tapping process; the thickness of the slag layer in the slag blocking process is 65mm. The converter smelting adopts the whole-process argon-bl...

Embodiment 2

[0070] Desulfurization of molten iron, converter smelting, continuous casting and hot rolling to obtain hot rolled steel coils for wheels.

[0071] The mass content of S in the molten iron is ≤0.03%, the mass content of P is ≤0.12%, the temperature of the molten iron is 1308°C, and the mass content of S in the molten iron entering the converter smelting after desulfurization is ≤0.005%.

[0072] During the converter smelting process, adding recarburizer, medium-carbon ferromanganese, high-carbon ferromanganese, silicomanganese and ferrosilicon to the molten iron according to the required components of the molten iron to fine-tune the alloy. The tapping time of the converter smelting is 4.5 minutes; in order to reduce the tapping temperature and process temperature drop, the converter adopts red bag tapping; the slag is blocked during the tapping process; the thickness of the slag layer during the slag blocking process is 56mm. The converter smelting adopts the whole-process ar...

Embodiment 3

[0083] Desulfurization of molten iron, converter smelting, continuous casting and hot rolling to obtain hot rolled steel coils for wheels.

[0084] The mass content of S in the molten iron is ≤0.03%, the mass content of P is ≤0.12%, the temperature of the molten iron is 1314°C, and the mass content of S in the molten iron entering the converter smelting after desulfurization is ≤0.005%.

[0085] During the converter smelting process, adding recarburizer, medium-carbon ferromanganese, high-carbon ferromanganese, silicomanganese and ferrosilicon to the molten iron according to the required components of the molten iron to fine-tune the alloy. The tapping time of the converter smelting is 5.5 minutes; in order to reduce the tapping temperature and process temperature drop, the converter adopts red bag tapping; the slag is blocked during the tapping process; the thickness of the slag layer in the slag blocking process is 62mm. The converter smelting adopts the whole-process argon-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com