Energy-saving roller-hearth continuous kiln waste heat boiler

A waste heat boiler, continuous technology, applied in the direction of furnace, waste heat treatment, furnace components, etc., can solve the problems of large energy consumption, worse working conditions of workers, poor heat transfer effect, etc., to reduce secondary oxidation burning loss, improve external Effect of surface quality and improvement of heat recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

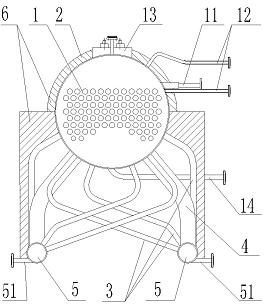

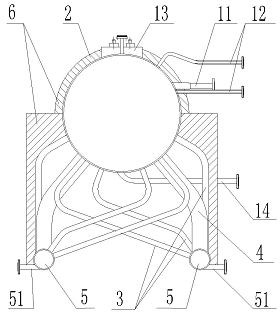

[0018] Such as figure 1 , 2 Shown: an energy-saving roller bottom continuous kiln waste heat boiler with a smoke pipe, including a smoke pipe 1, a drum 2, a heat exchange pipe 3, a downcomer 4 and a header pipe 5, and the smoke pipe 1 is located in the drum 2 Inside, there is a water inlet pipe 21, a water level gauge pipe 22 and an inspection manhole 23 on the drum 2, a sewage pipe 24 is arranged at the bottom, and the shape of the heat exchange pipe 3 is L-shaped so as to be as close as possible to the steel pipe. Afterwards, it is divided into several rows, and each row has six tubes in total. The lower parts of three heat exchange tubes 3 are connected with the left header tube 5, the lower parts of the other three heat exchange tubes 3 are connected with the right header tube 5, and the upper parts of the six heat exchange tubes 3 are connected to each other. It is connected with the drum 2; the downpipes 4 are divided into two rows in total, four in total, and the front...

Embodiment 2

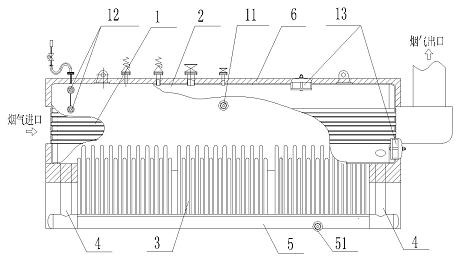

[0021] Such as image 3 , 4 Shown: an energy-saving roller bottom continuous kiln waste heat boiler without smoke tubes, including a drum 2, a heat exchange tube 3, a downcomer 4 and a header tube 5, and a water inlet pipe 21 and a water level gauge on the drum 2 Pipe 22 and maintenance manhole 23, bottom has blowdown pipe 24, and the shape of heat exchange pipe 3 is L shape, so that close to steel pipe as far as possible, heat exchange pipe 3 is divided into several rows from front to back, each row has six altogether, and wherein three The lower part of the exchange tube 3 is connected to the left header tube 5, the lower parts of the other three heat exchange tubes 3 are connected to the right header tube 5, and the upper parts of the six heat exchange tubes 3 are connected to the drum 2; There are four in total, and the front row and the rear row each have two left and right downcomers 4, the lower parts of the left and right downcomers 4 are respectively connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com