Energy-saving type roller hearth continuous bright normalizing annealing furnace

An energy-saving, annealing furnace technology, applied in the direction of furnaces, furnace components, furnace types, etc., can solve the problems of large energy consumption, deterioration of working conditions for workers, high temperature, etc., to reduce secondary oxidation burning loss, improve the quality of the outer surface, The effect of lowering the temperature of the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

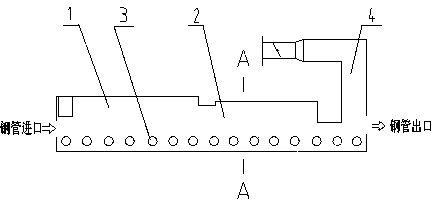

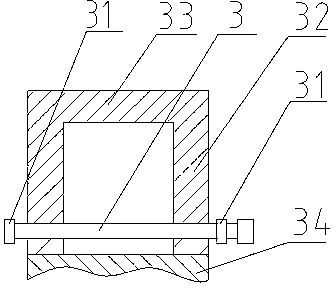

[0027] Such as image 3 , 4 Shown: an energy-saving roller bottom continuous bright positive annealing furnace, including a heating chamber 1, a heat preservation chamber 2, a furnace roller 3, a flue 4 and a waste heat recovery section 5, a heating chamber 1, a heat preservation chamber 2 and a waste heat recovery section 5 Connected in sequence, the furnace roller 3 is installed in the heating chamber 1, the heat preservation chamber 2 and the waste heat recovery section 5 through the bearing housing 31 outside the furnace wall 32, the furnace wall 32 of the waste heat recovery section 5 is above the waste heat recovery boiler 6, and below is the furnace bottom 34, flue 4 is arranged at the tail end of insulation chamber 2.

[0028] In the roller hearth continuous positive annealing furnace, the steel pipe is heated rapidly at a high temperature in the heating chamber 1 and kept warm in the heat preservation chamber 2, and then released from the furnace after being utilized...

Embodiment 2

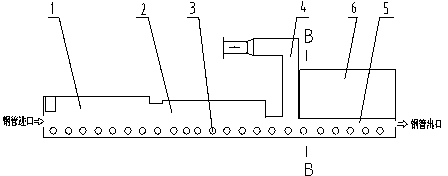

[0030] Such as Figure 5 Shown: an energy-saving roller bottom continuous bright positive annealing furnace, including a heating chamber 1, a heat preservation chamber 2, a furnace roller 3, a flue 4 and a waste heat recovery section 5, a heating chamber 1, a heat preservation chamber 2 and a waste heat recovery section 5 Connected in sequence, the furnace roller 3 is installed in the heating chamber 1, the heat preservation chamber 2 and the waste heat recovery section 5 through the bearing housing 31 outside the furnace wall 32, the furnace wall 32 of the waste heat recovery section 5 is above the waste heat recovery boiler 6, and below is the furnace bottom 34. There is a flue 4 at the end of the waste heat recovery boiler 6, and there is a smoke pipe inside the waste heat recovery boiler 6.

[0031] In the roller hearth continuous positive annealing furnace, the steel pipe is heated rapidly at a high temperature in the heating chamber 1 and kept warm in the heat preservati...

Embodiment 3

[0033] Such as Figure 6 Shown: an energy-saving roller bottom continuous bright positive annealing furnace, including a heating chamber 1, a heat preservation chamber 2, a furnace roller 3, a flue 4 and a waste heat recovery section 5, a heating chamber 1, a heat preservation chamber 2 and a waste heat recovery section 5 Connected in sequence, the furnace roller 3 is installed in the heating chamber 1, the heat preservation chamber 2 and the waste heat recovery section 5 through the bearing housing 31 outside the furnace wall 32, the furnace wall 32 of the waste heat recovery section 5 is above the waste heat recovery boiler 6, and below is the furnace bottom 34. There is a flue 4 at the inlet end of the heating chamber 1.

[0034] In the roller hearth continuous positive annealing furnace, the steel pipe is heated rapidly at a high temperature in the heating chamber 1 and kept warm in the heat preservation chamber 2, and then released from the furnace after being utilized by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com