Electro-hydraulic drive M-shaped steel ladle capping and decapping device

A technology of uncovering device and section steel, which is applied in metal processing equipment, casting melt container, casting equipment, etc., can solve the problem that the ladle capping operation is far from achieving the effect of energy saving and environmental protection of steel smelters, has not been effectively controlled, and can be Operability restrictions and other issues, to achieve the effect of increasing the free pouring rate, reducing mechanical damage, and reducing the need for cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

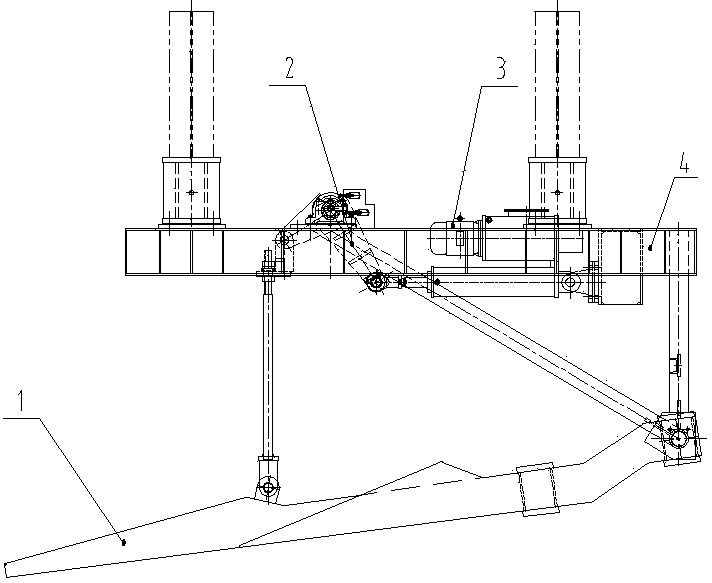

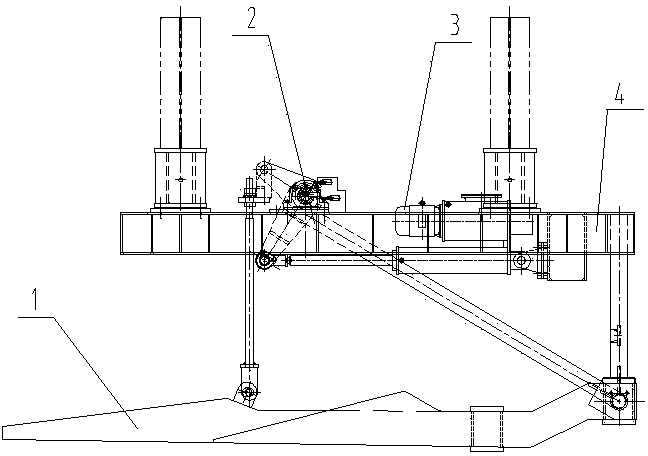

[0020] Such as figure 1 , 2 As shown, it is an electro-hydraulic M-type ladle capping and uncovering device, including a fixed frame 4, on which the electro-hydraulic push rod 3 and the linkage mechanism 2 are fixedly connected, and on the fixed frame 4, the M-type fork tine assembly is hinged. 1, the electro-hydraulic push rod 3 is connected to the link mechanism 2, and the link mechanism 2 is hingedly connected to the M-type fork assembly 1.

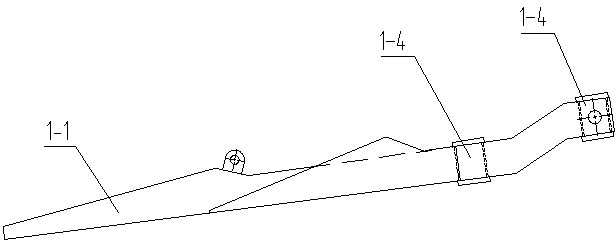

[0021] Such as image 3 , 4 As shown, the M-type fork tooth assembly 1 includes two long slope racks 1-1 and a short slope rack 1-2, and the short slope rack 1-2 is arranged between the two long slope racks 1-1 Two long slope racks 1-1 and one short slope rack 1-2 are fixed by welding two box girders 1-4, one of the two box girders 1-4 is one box girder 1- 4 and each long slope rack 1-1 and short slope rack 1-2 are respectively fixed by channel steel 1-3 welding.

[0022] Such as Figure 5 , 6 As shown, when the ladle 6 with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com