Patents

Literature

47 results about "Decapping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Decapping (decapsulation) or delidding of an integrated circuit is the process of removing the protective cover of a microchip so that the contained die is revealed for visual inspection of the micro circuitry imprinted on the die. This process is typically done in order to debug a manufacturing problem with the chip, or possibly to copy information from the device. Modern integrated circuits can be encapsulated in plastic, ceramic, or epoxy.

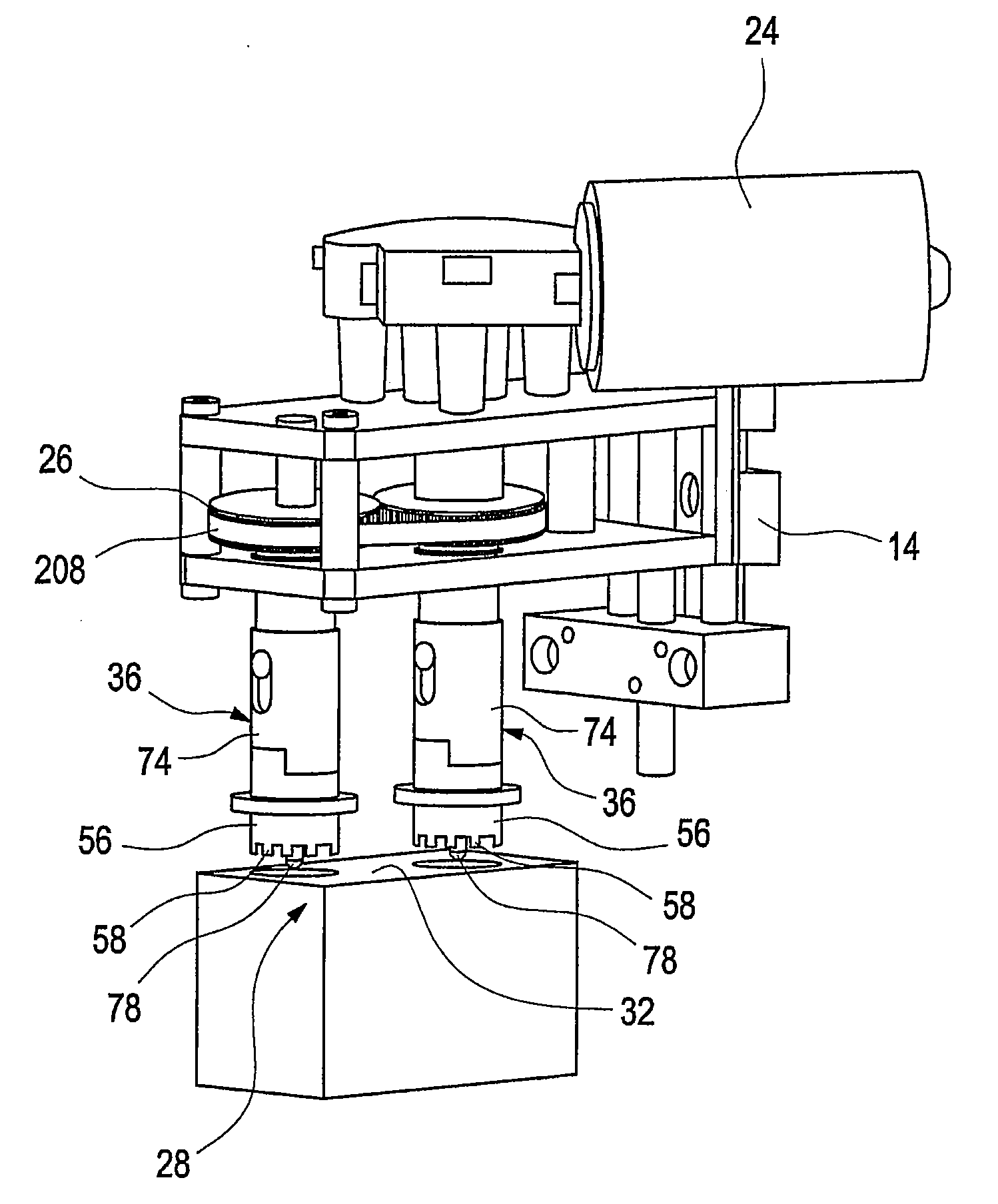

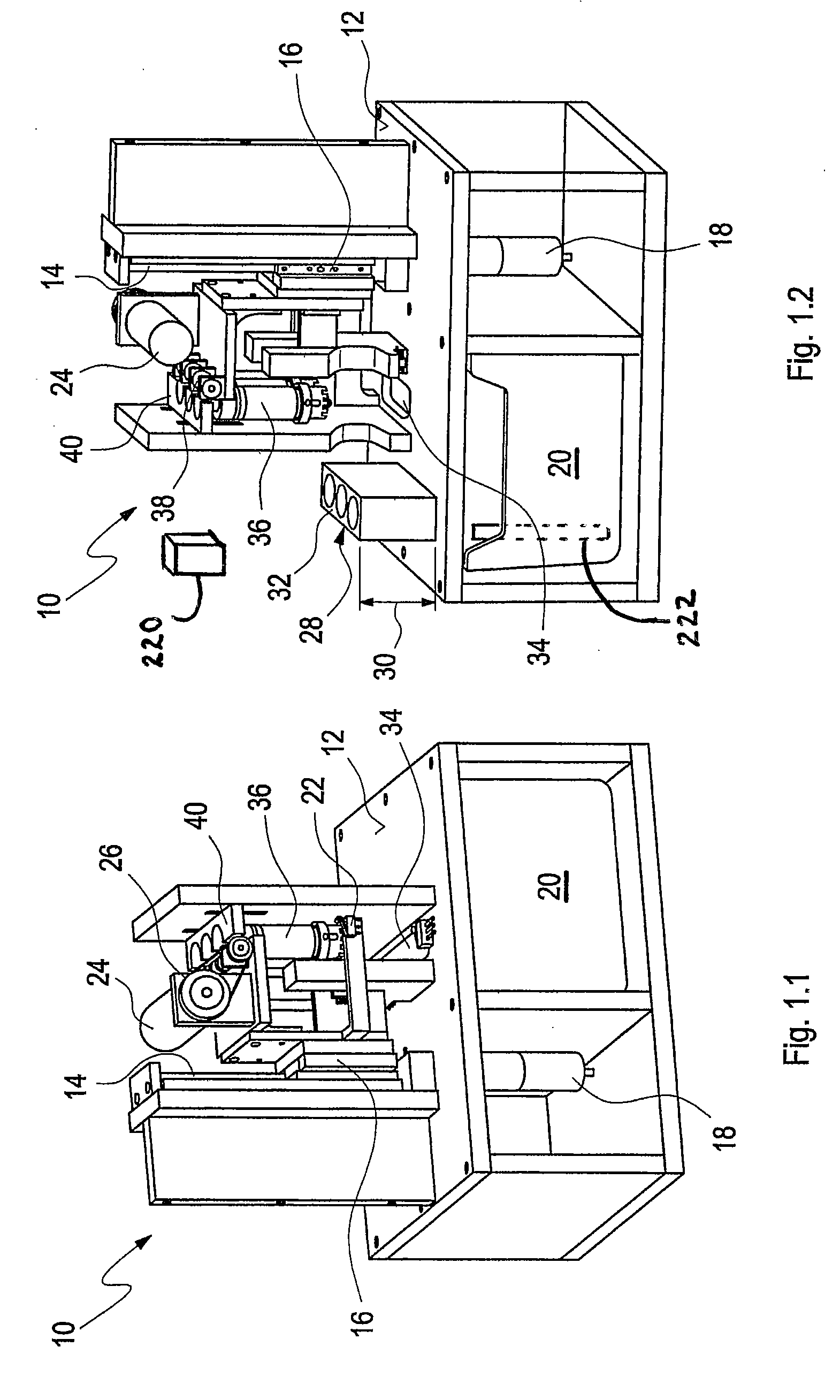

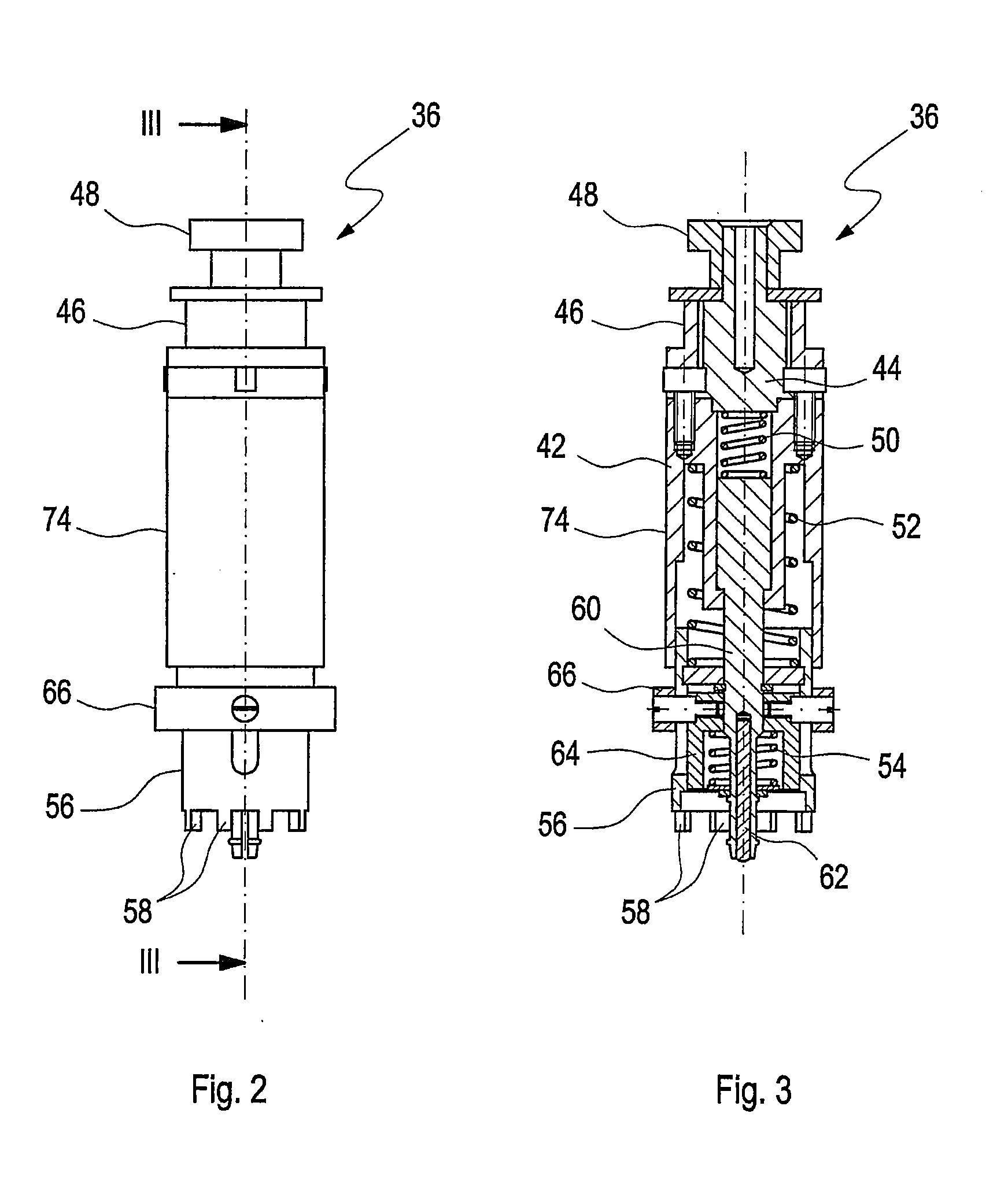

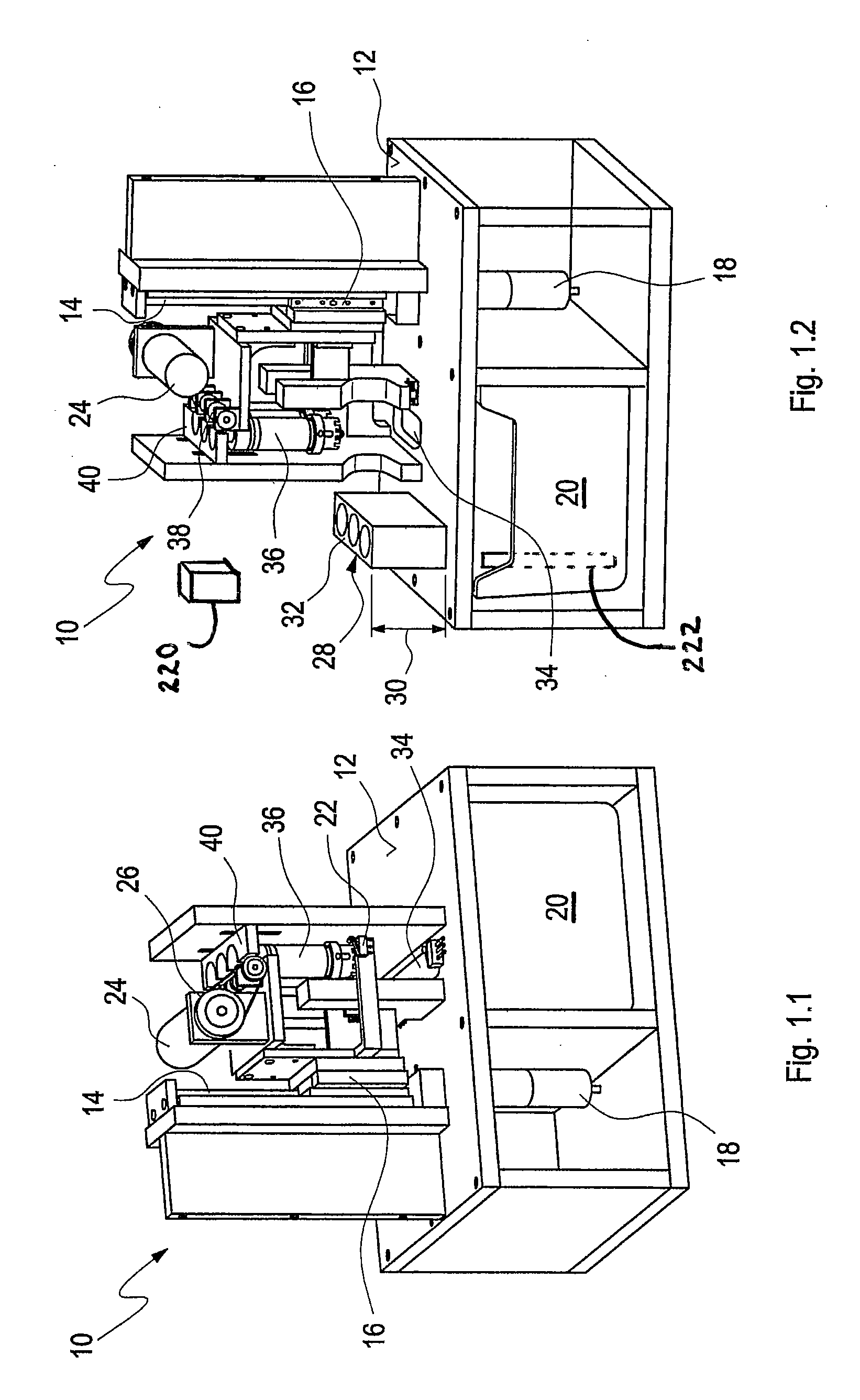

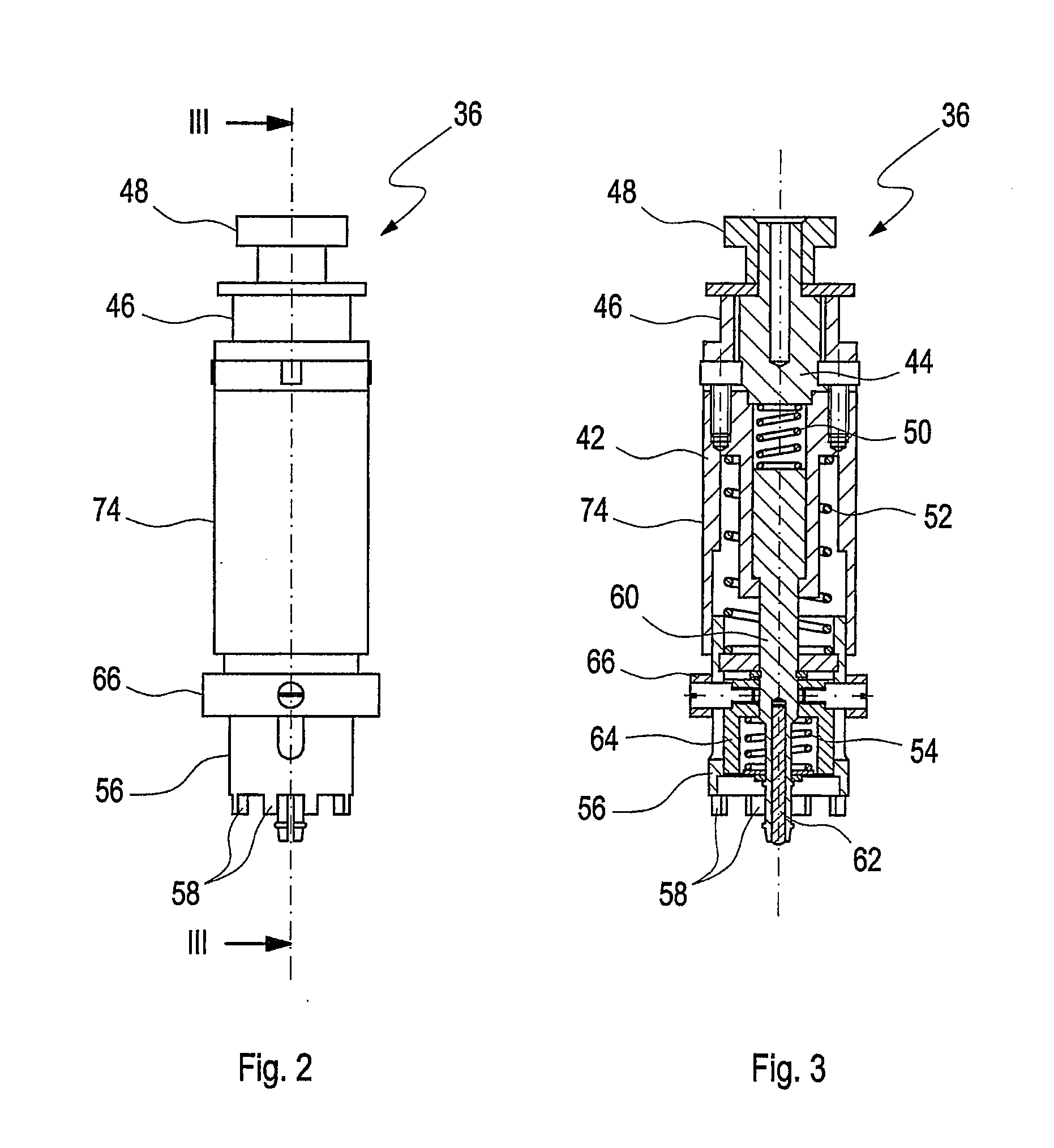

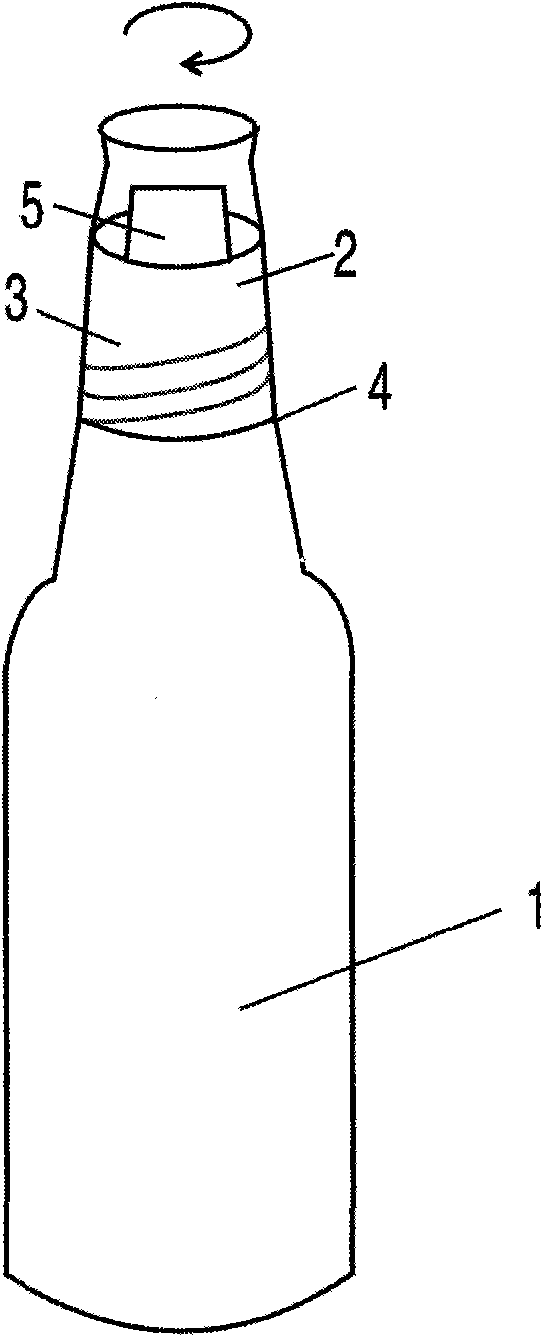

Decapping system

Decapping system for opening or closing reagent containers or cartridge systems closed by a lid the which is removed and secured by a rotational movement and method thereof are disclosed. The decapping system has a centering unit that the at its lower end provides a snap-in element which engages the lid, and a plurality of simultaneously driven and vertically movable screwing heads which compensates for variable heights and / or sizes of cartridge systems to be processed.

Owner:ROCHE DIAGNOSTICS OPERATIONS INC

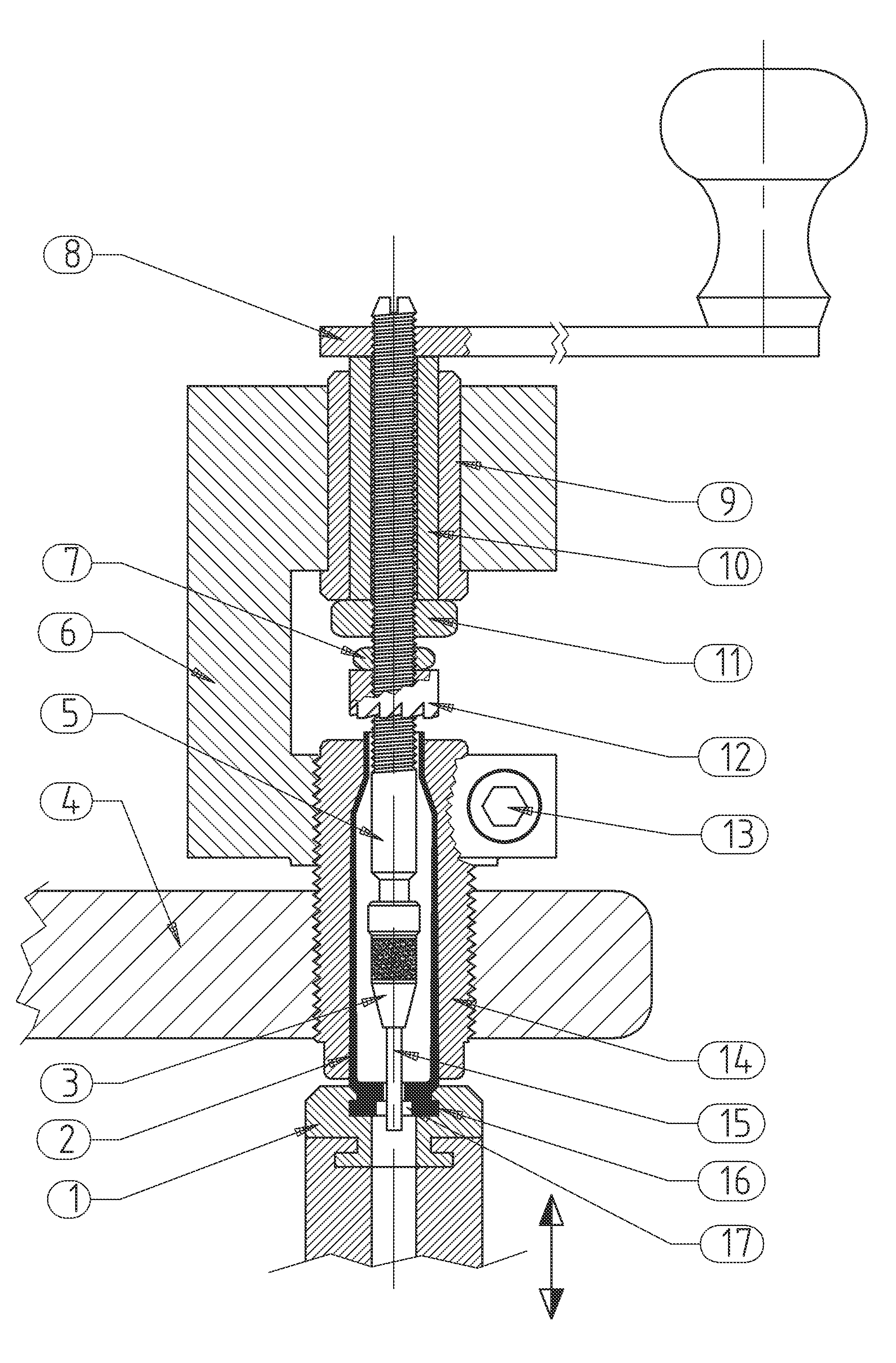

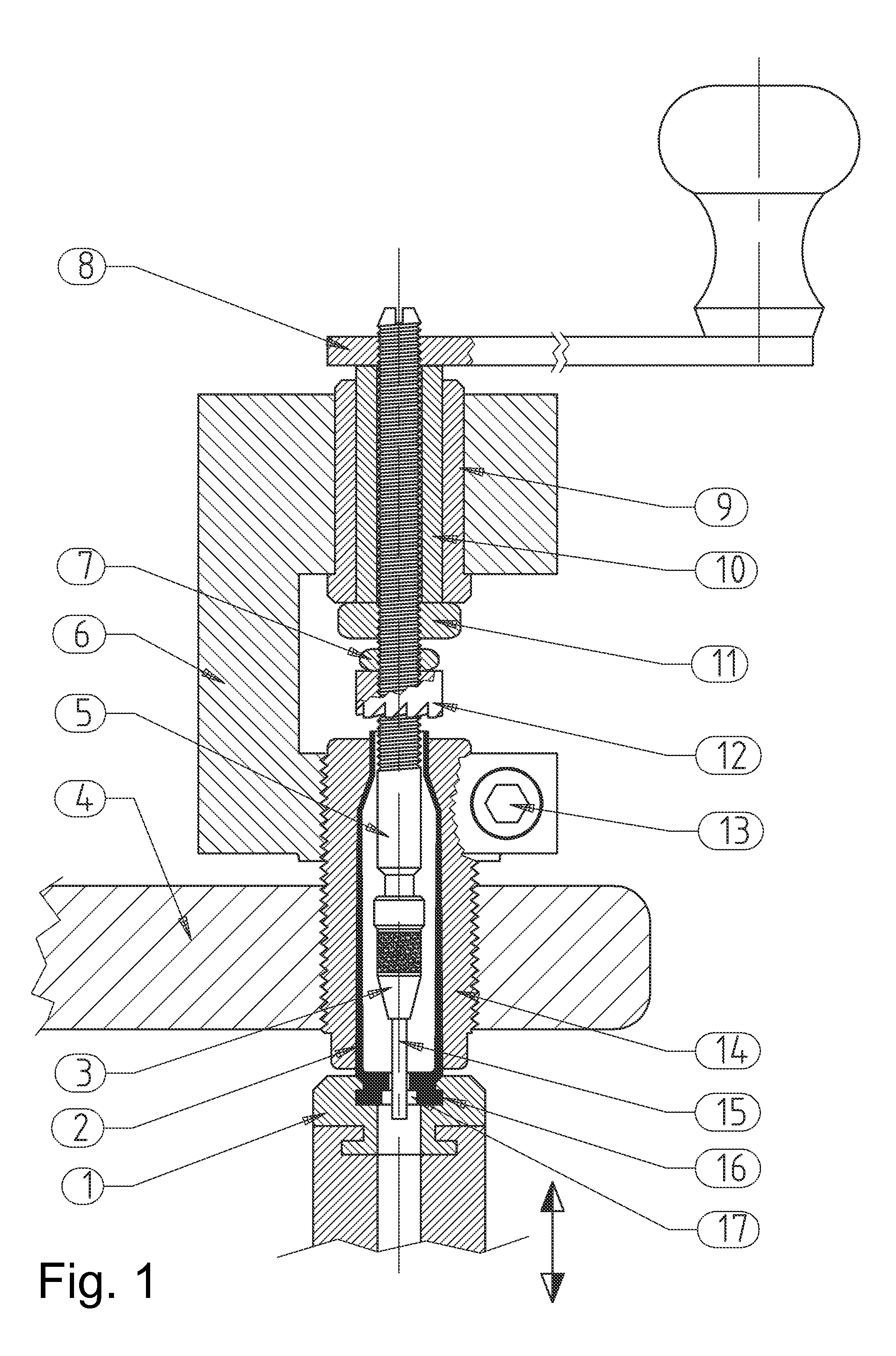

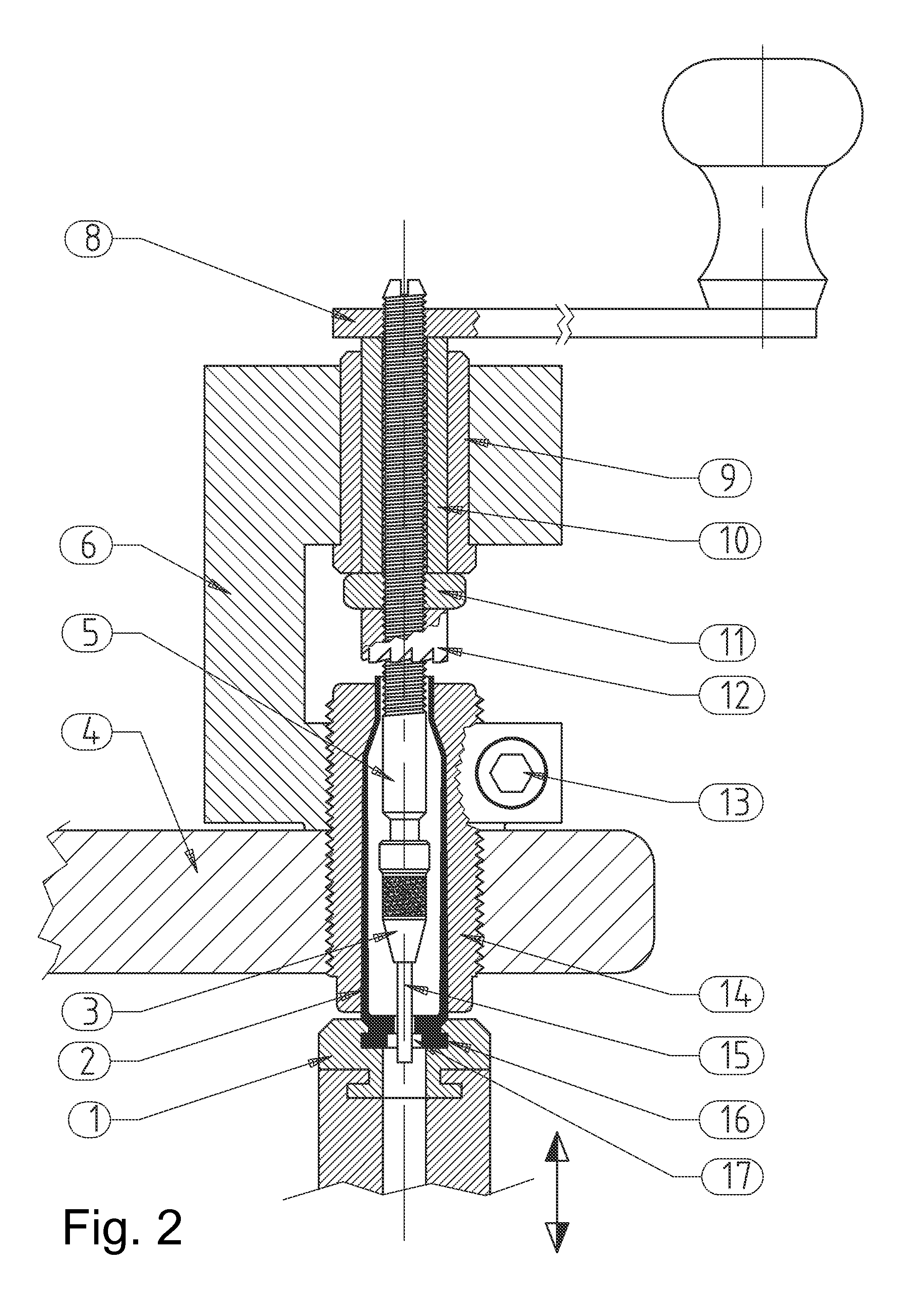

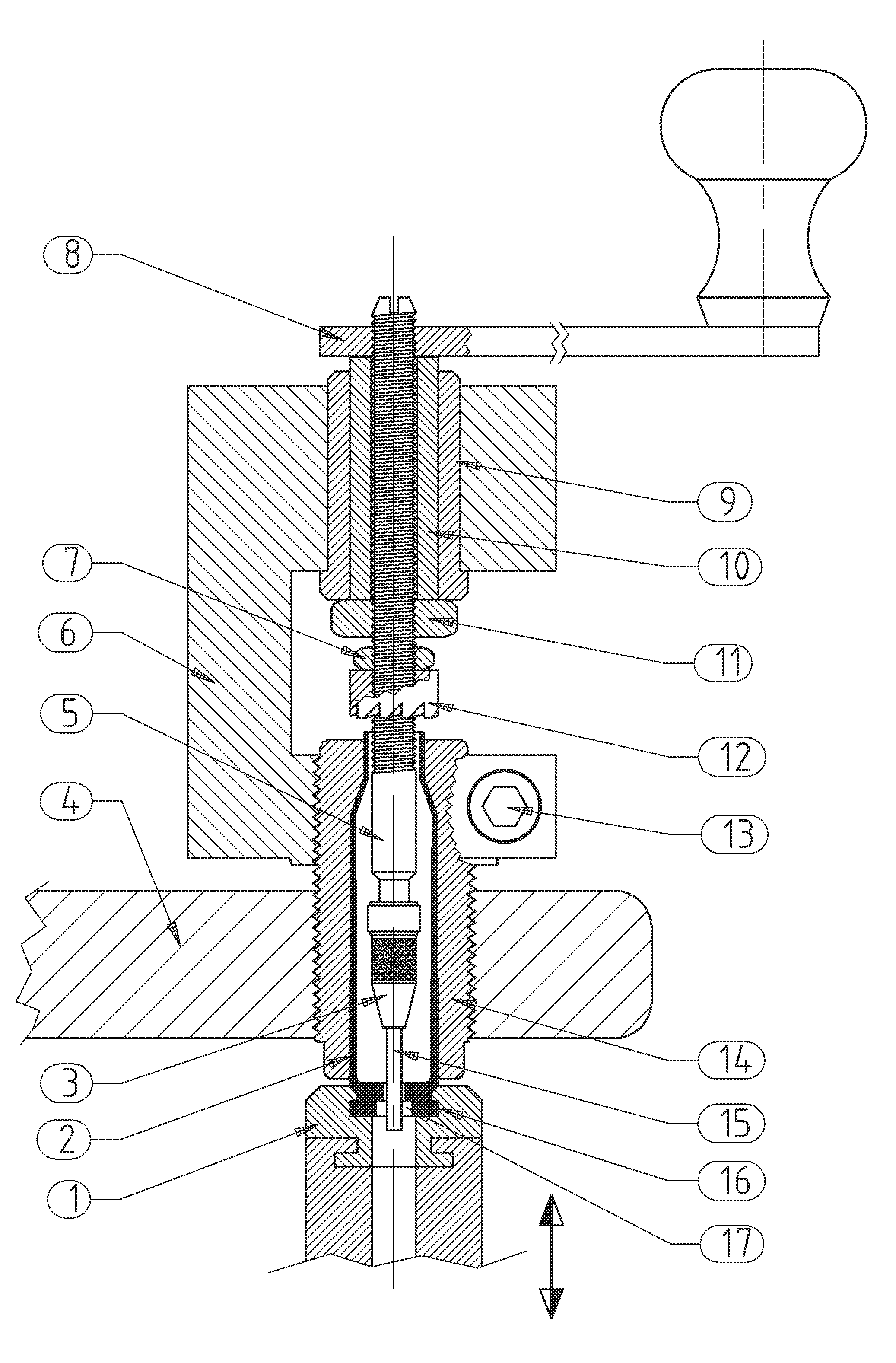

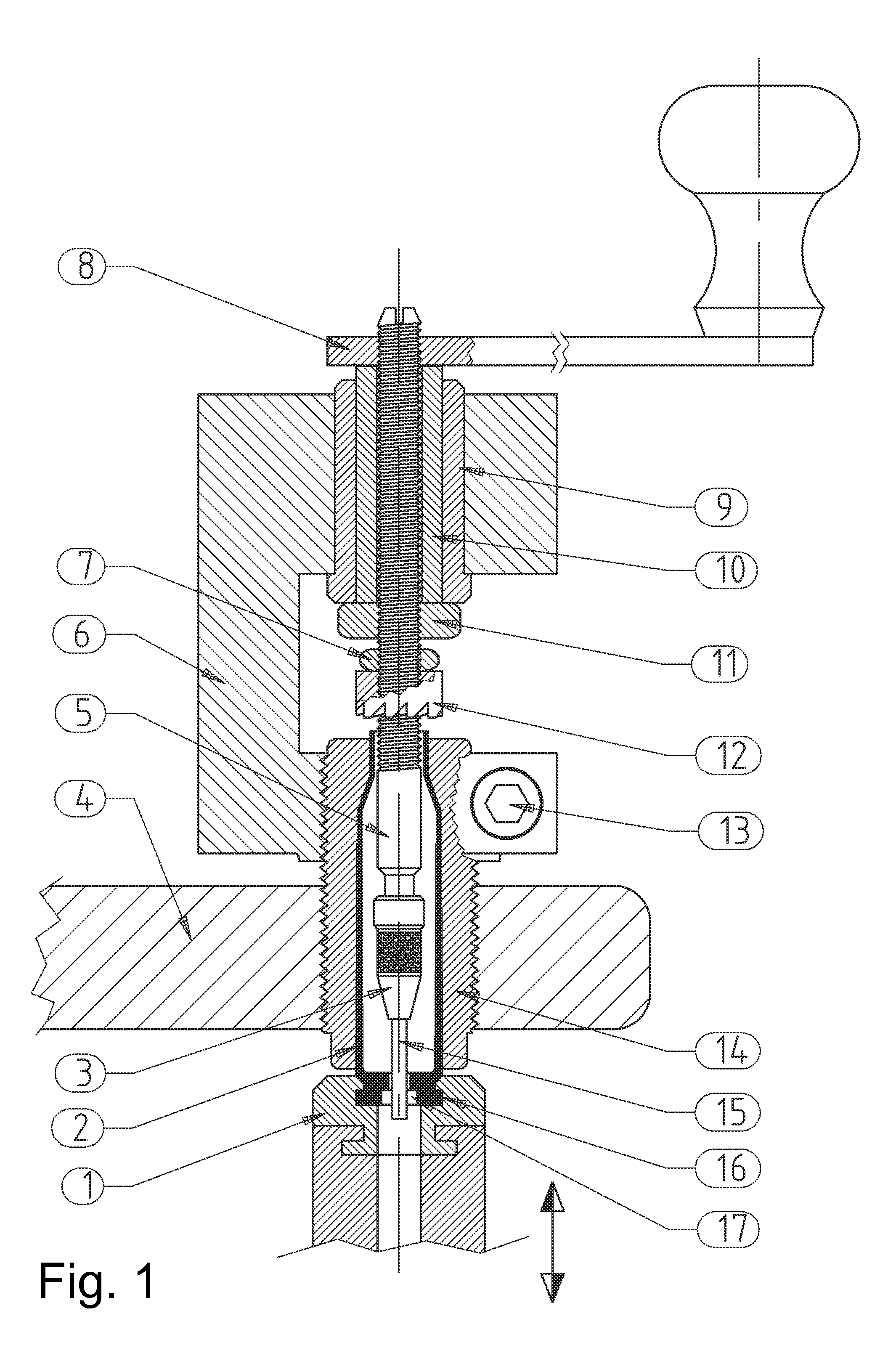

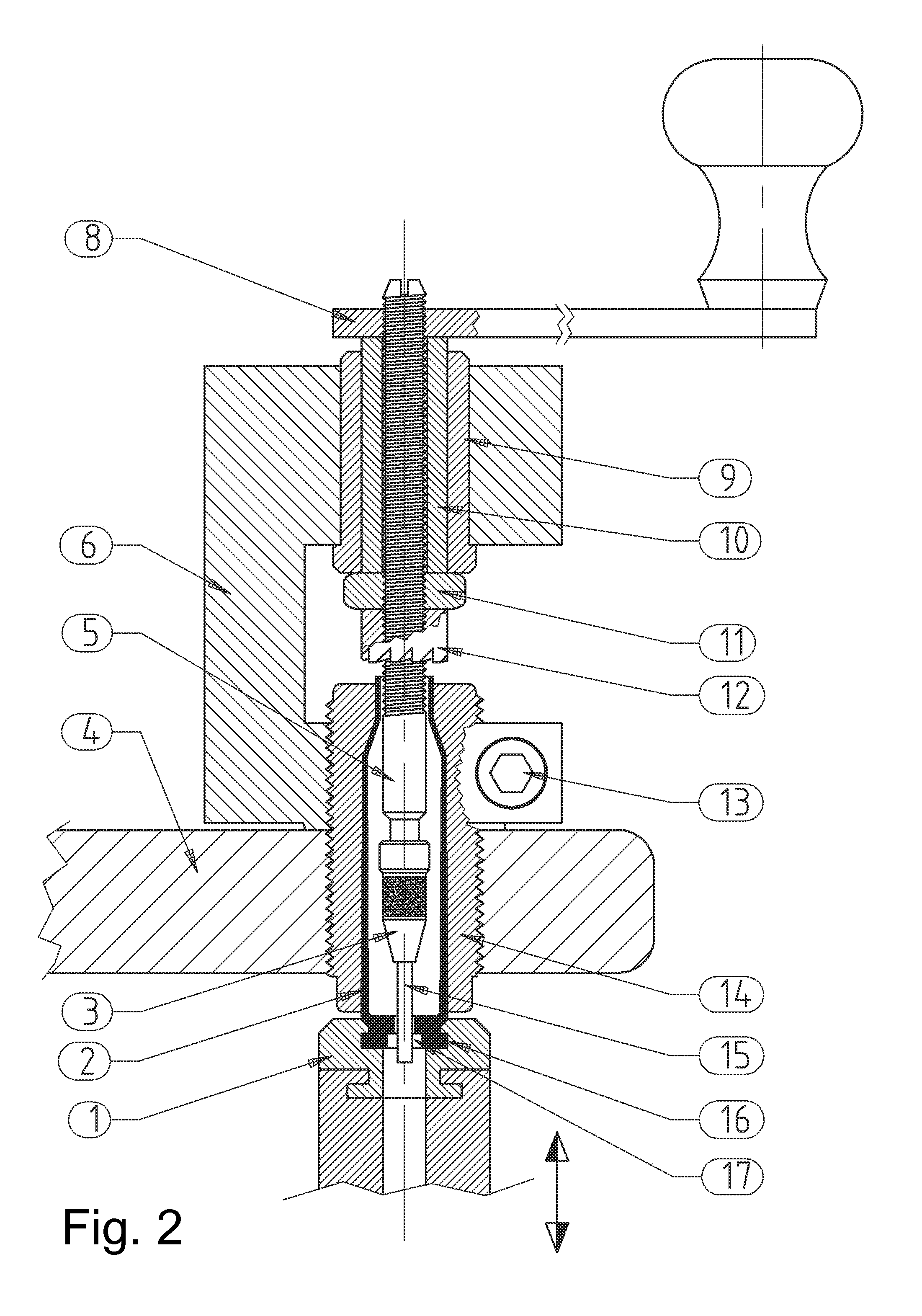

Trimming and sizing device to produce or prepare empty cartridge cases and a method to produce or prepare empty cartridge cases

A trimming, sizing and decapping device that has a simple, very compact construction and that allows the user to economically and quickly produce, restore or prepare cartridge cases to the utmost precision. The device consistently produces very smooth processing surfaces and has good tolerances with respect to various cartridge case wall sizes and materials. Furthermore, a method is detailed for producing or preparing empty cartridge cases using the trimming, sizing and decapping device that allows efficient preparation of the cartridge cases for subsequent loading or reloading in as few process steps as possible.

Owner:KESKA WOJTEK

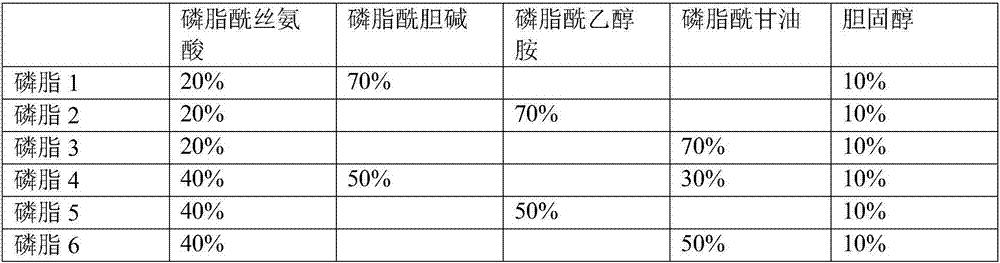

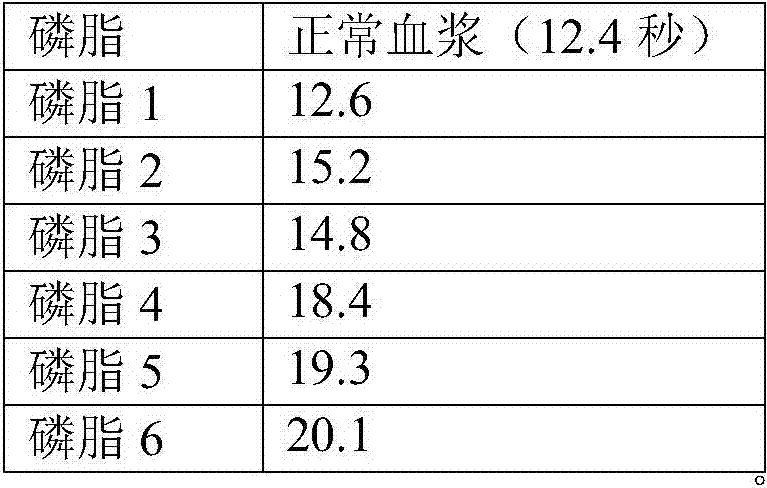

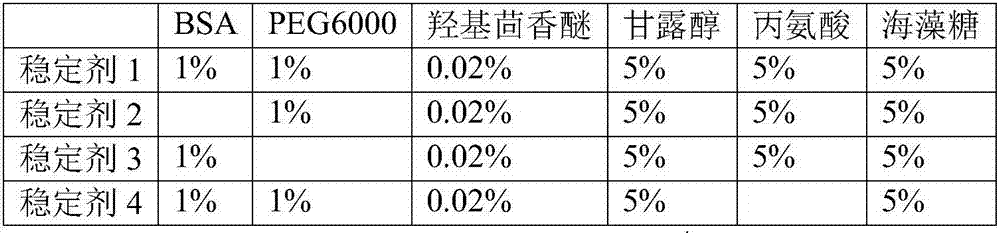

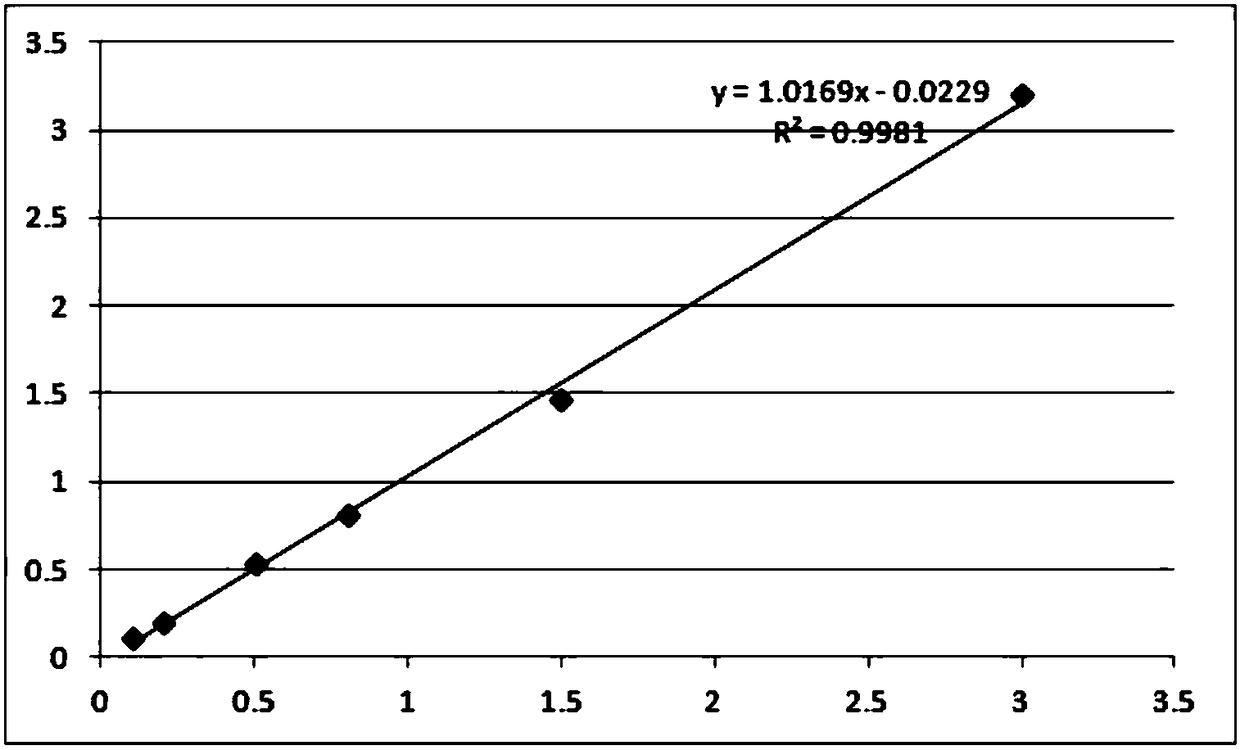

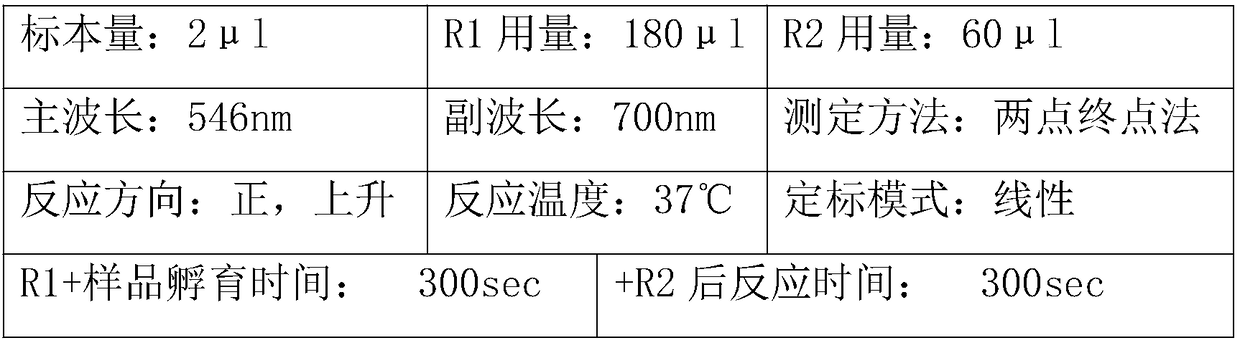

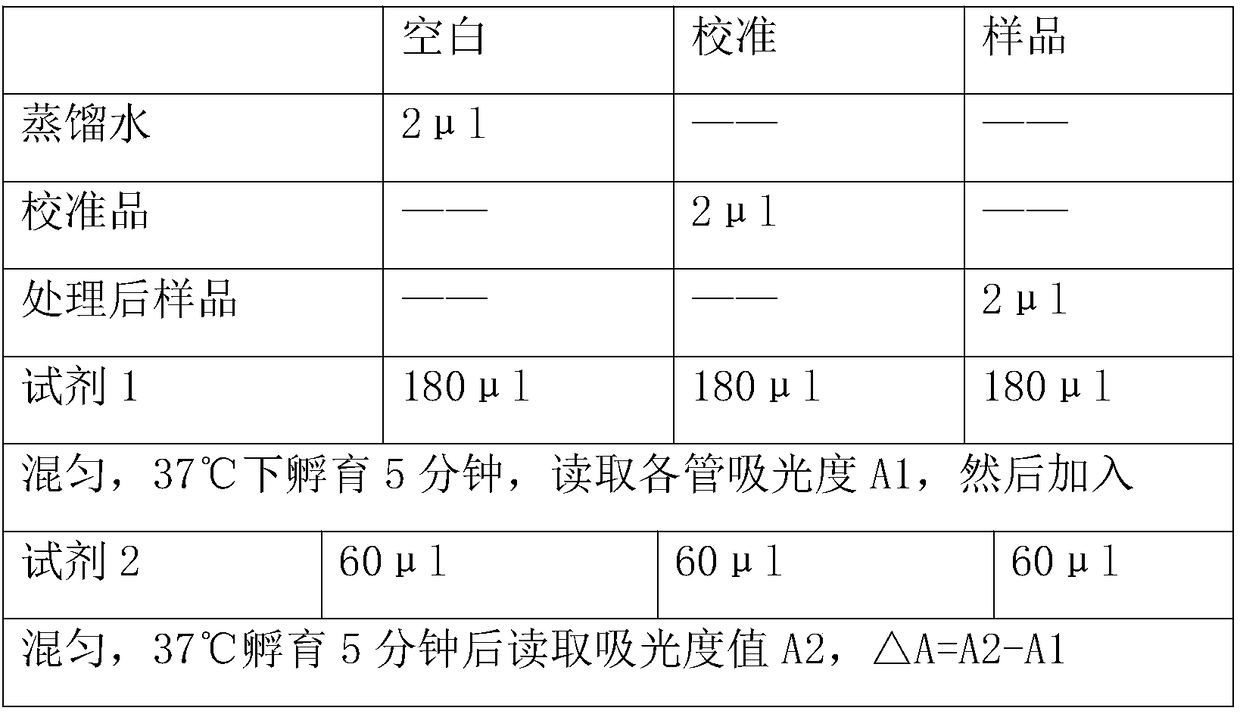

Liquid ready-to-use prothrombin time detection reagent

InactiveCN107356768AOvercome the difference between bottlesOvercome the defect of large batch differenceBiological testingTissue factorCholesterol

The invention discloses a liquid ready-to-use prothrombin time detection reagent, which includes a buffer, a synthetic phospholipid, a recombinant rabbit tissue factor, a surfactant and a stabilizer. The synthetic phospholipid is composed of phosphatidylserine, phosphatidylcholine and Cholesterol composition. The present invention uses rabbit recombinant factors and synthetic phospholipids to prepare prothrombin time detection reagents by selecting synthetic phospholipid components and optimizing stabilizers. It does not need to be reconstituted during use and can be used immediately after opening the bottle. The reagent overcomes the problem of difficult-to-control batch-to-batch variation of existing prothrombin time detection reagents and has high sensitivity, good stability, small batch-to-batch variation, easy quality control, and easy production.

Owner:NINGBO ACCUTECH BIOSCI LTD

System for processing closed sample tube

The present invention refers to a system (900) for processing sample tubes (12) comprising biological samples, the system (900) comprising two or more work cells (901-909) for processing samples, wherein in correspondence to at least two of the work cells (901-909), the system comprises one of the following units: a pipetting unit (921-928) for withdrawing a volume of sample from a sample tube to be processed by the work cell and / or dispensing a volume of liquid into the sample tube, an analytical unit (931, 937) for determining at least one sample parameter of a sample contained in a sample tube. The system (900) further comprises a decapping / recapping device (911-918) for each of the at least two work cells (901-908) for removing a closure (11) from a sample tube (12) and for reclosing the sample tube (12) before it is transported to another work cell (901-909).

Owner:F HOFFMANN LA ROCHE & CO AG

SdLDL-C (small and dense LDL cholesterol) detection kit

ActiveCN108424952AImprove stabilityImprove accuracyMicrobiological testing/measurementBiological material analysisDecappingBuffer solution

Owner:天津中成佳益生物科技有限公司

Trimming and sizing device to refurbish empty cartridge cases and a method to refurbish empty cartridge cases

A trimming, sizing and decapping device that has a simple, very compact construction and that allows the user to economically and quickly produce, restore or prepare cartridge cases to the utmost precision. The device consistently produces very smooth processing surfaces and has good tolerances with respect to various cartridge case wall sizes and materials. Furthermore, a method is detailed for producing or preparing empty cartridge cases using the trimming, sizing and decapping device that allows efficient preparation of the cartridge cases for subsequent loading or reloading in as few process steps as possible.

Owner:KESKA WOJTEK

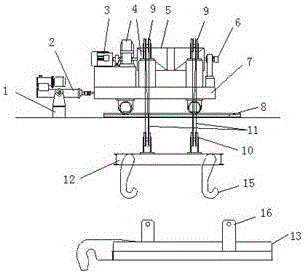

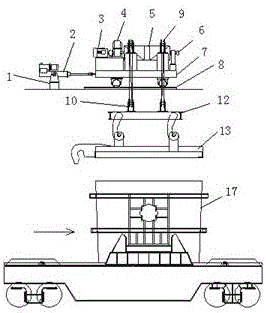

Device and method capable of conducting whole-process capping and decapping on steel ladle

The invention discloses a device and method capable of conducting whole-process capping and decapping on a steel ladle and belongs to steel ladle capping and decapping equipment and method. The device and method capable of conducting whole-process capping and decapping on the steel ladle are used for conducting capping and decapping operation on the steel ladle. According to the technical scheme, a body of an electric-hydraulic push rod is connected with a support; the front portion of the electric-hydraulic push rod is connected with a moving trolley; a rail is mounted on a platform on the upper portion of a workshop; the moving trolley is located on the rail; a winding device is mounted on the moving trolley; the lower portion of the winding device is connected with a cap hoisting; and the cap hoisting is detachably connected with a cap. By means of the moving trolley, the rail and the electric-hydraulic push rod of the device, the cover hoisting can be moved to the hoisting position of the cap; by means of the winding device, the cap hoisting tool is ascended and descended; and the tasks of mounting and removing the cap are completed. The steel ladle capping and decapping device is compact in structure, small in occupied space, steady and reliably in operation and particularly applicable to rebuilding and upgrading of a steel mill; and after rebuilding, the original technological arrangement structure is not affected. The steel ladle capping and decapping method is convenient and fast to use, operation time is saved, and potential safety hazards are eliminated.

Owner:宣化钢铁集团有限责任公司

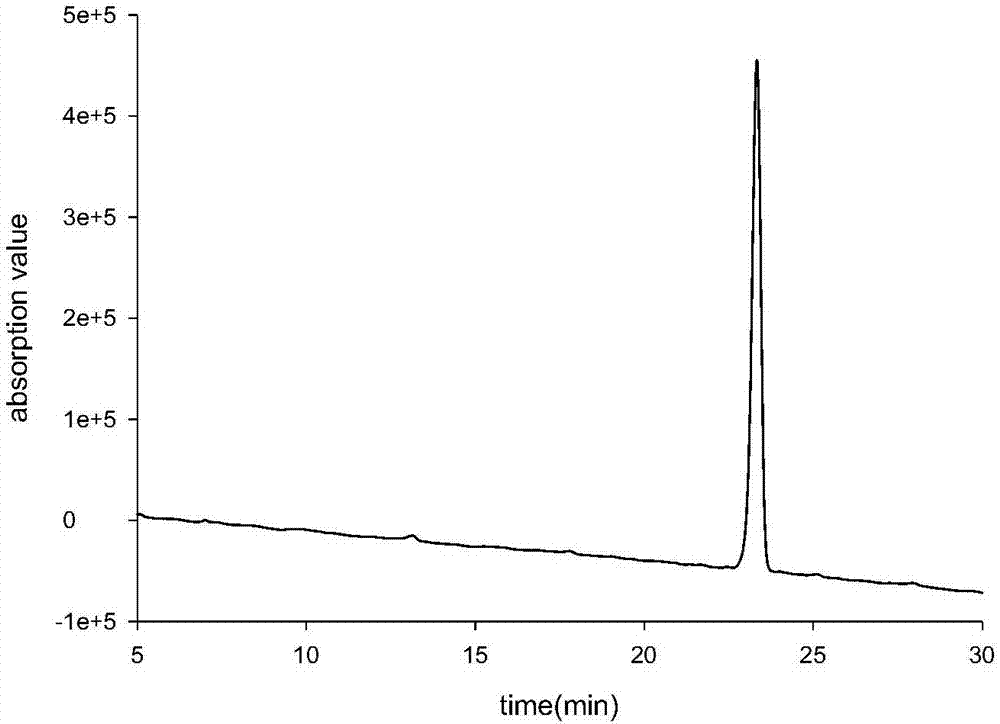

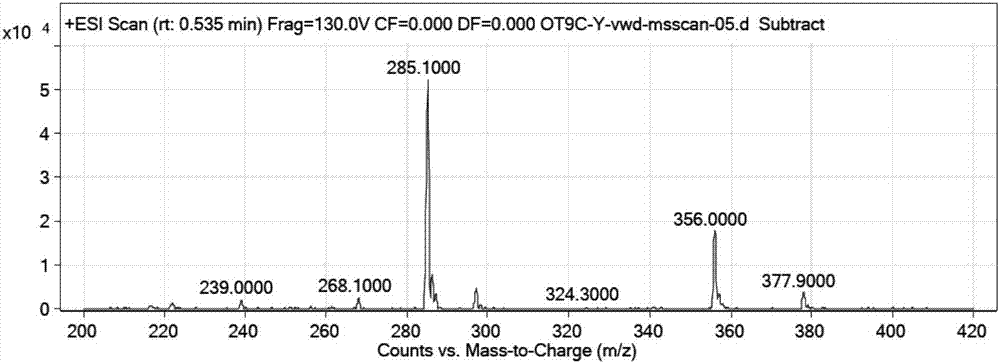

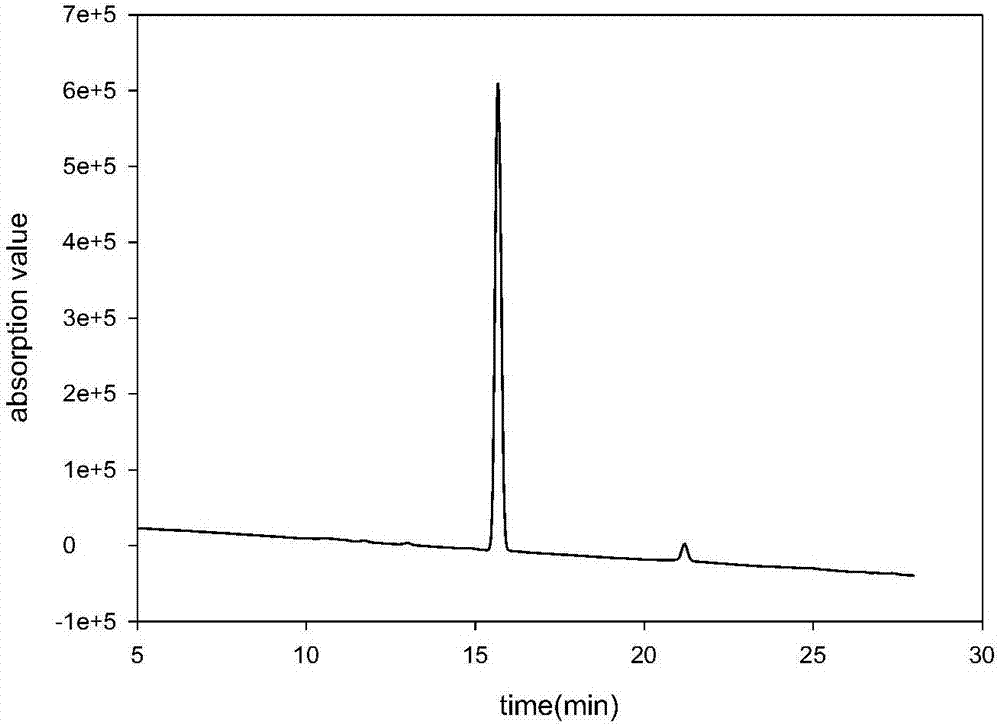

Polypeptide liquid-phase synthesizing method of oxytocin

ActiveCN106967155ALower synthesis costHigh purityOxytocins/vasopressinsPeptide preparation methodsReversed-Phase Liquid ChromatographyEthyl acetate

The invention discloses a liquid-phase synthesizing method of oxytocin for the first time. The method which is mild in reaction conditions is characterized in that three oxytocin fragments which include Boc-Cys(Acm)-Tyr(tBu)-OH, H-Ile-Gln(Trt)-Asn(Trt)-Cys(Acm)-Pro-OMe and H-Leu-Gly-NH2 are synthesized for the first time, the fragments are assembled to synthesize an all-protected oxytocin amino acid sequence, iodine is used to remove Acm while cyclization is performed to form a disulfide bond to obtain protected cyclic oxytocin, trifluoroacetic acid is used to remove residual protecting groups to obtain crude oxytocin, ethyl acetate is used to perform recrystallization, and reversed-phase chromatography purification is performed to obtain high-purity (crude product purity reaches 95%) and high-titer oxytocin (588IU / mg). The liquid-phase synthesizing method has the advantages that a Boc polypeptide synthesizing method and an Fmoc polypeptide synthesizing method are used in a combined manner, all reactions are performed under mild conditions, and the ammonia-sodium-method decapping reaction reported in all domestic and abroad oxytocin liquid-phase synthesizing literature, the synthesizing cost of the oxytocin is lowered greatly, and a method is provided for the industrial production of the oxytocin.

Owner:LANZHOU KAIBO PHARMA

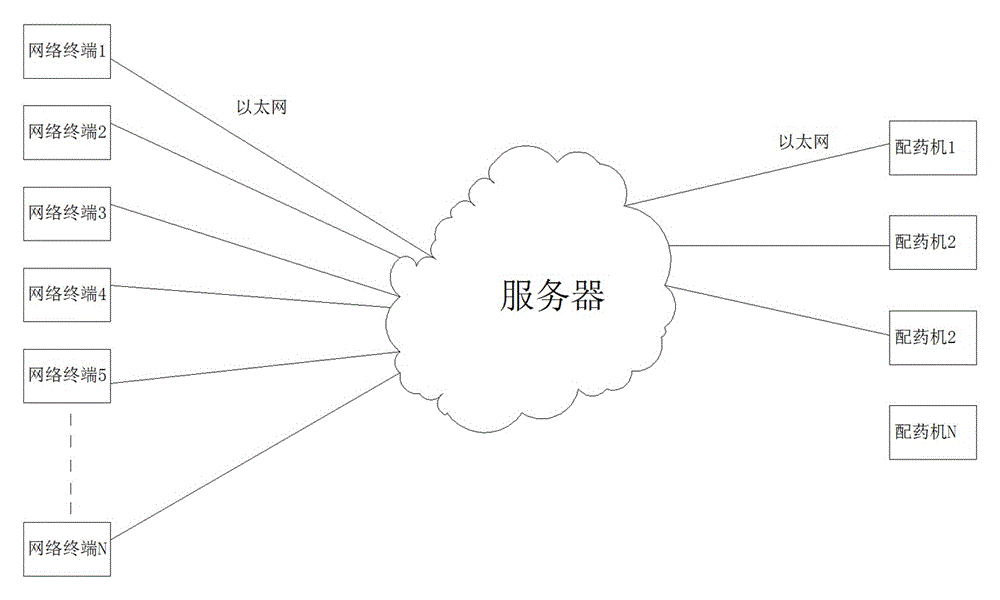

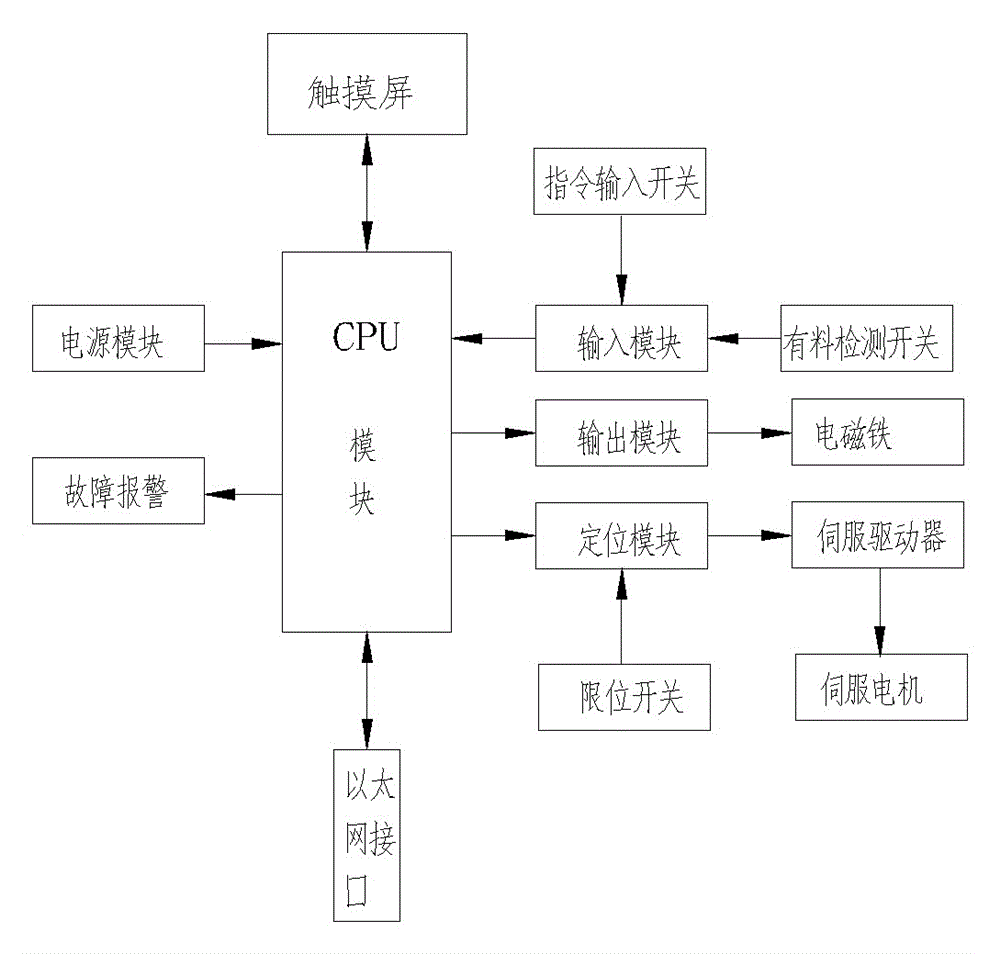

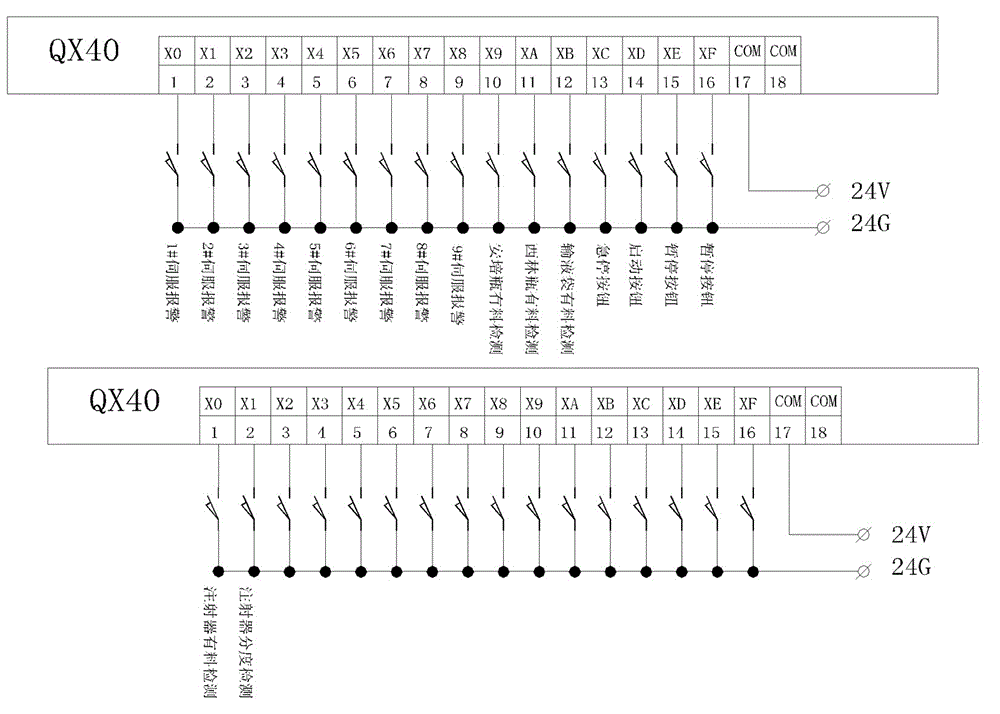

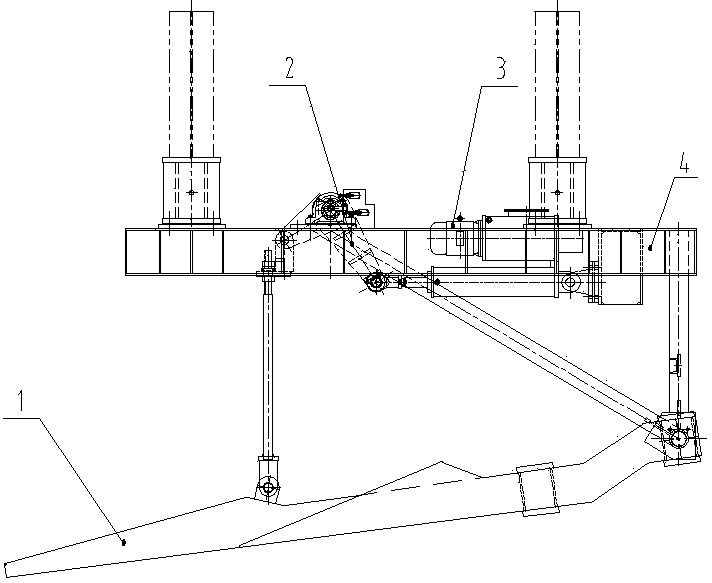

Clinic automatic dispensing system

The invention relates to a clinic automatic dispensing system, and the system comprises a server, a plurality of network terminals, and a plurality of automatic dispensing machines. The network terminals are used for transmitting transfusion prescription data inputted by a doctor to the server through an Ethernet. The server is used for storing the transfusion prescription data, and enables the transfusion prescription data to be transmitted to the automatic dispensing machines through an Ethernet. The automatic dispensing machines respectively comprise a controller, a touch screen, a printer, a material detection switch, a limiting switch, an instruction input switch, an electric dividing plate, an injector extraction electromagnet, a clamping electromagnet, a decapping electromagnet, a conveying drive motor, a medicine extraction drive motor, an angle adjustment drive motor, a liquid-mixing drive motor, and an ampoule bottle decapping drive motor. The system is high in intelligent degree, reduces the work intensity of dispensing workers, improves work efficiency, and greatly improves the safety and reliability.

Owner:THE SECOND AFFILIATED HOSPITAL ARMY MEDICAL UNIV

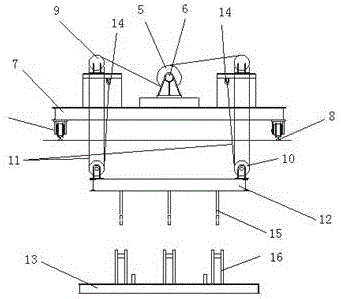

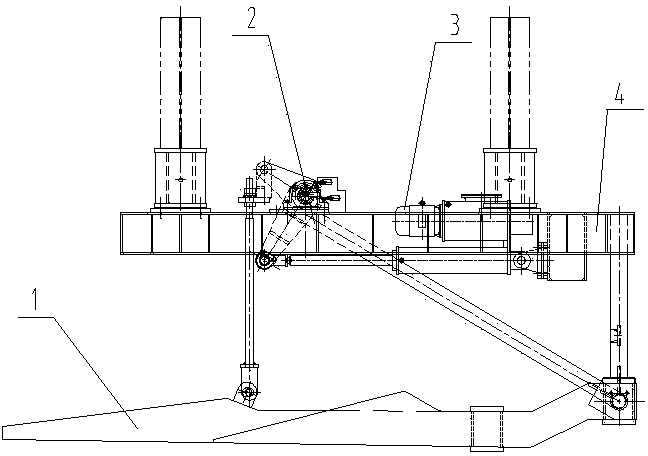

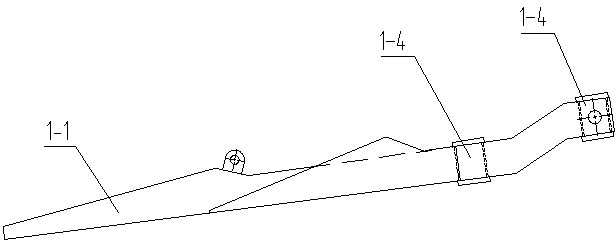

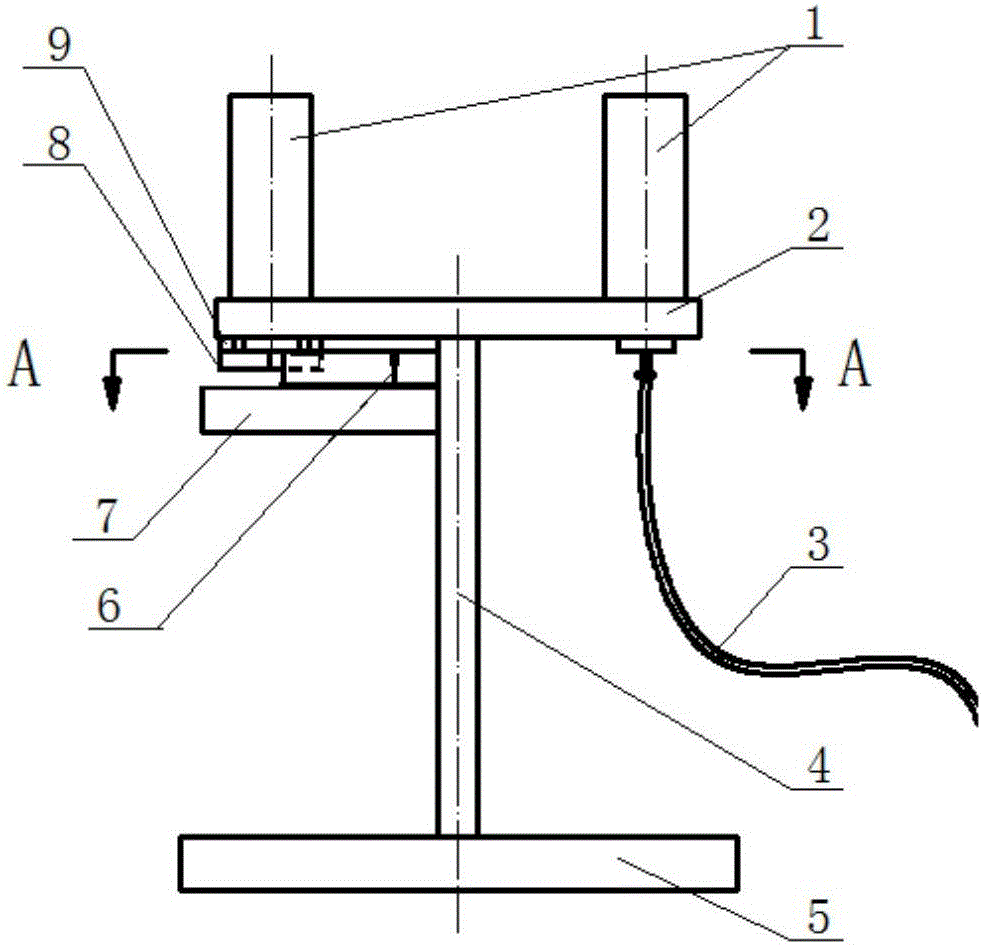

Electro-hydraulic drive M-shaped steel ladle capping and decapping device

The invention discloses an electro-hydraulic drive M-shaped steel ladle capping and decapping device, which relates to the structure of a whole-course full-automatic capping and decapping device of a high-temperature melt container in metal smelting. The electro-hydraulic drive M-type steel ladle capping and decapping device comprises a fixed frame, wherein the fixed frame is fixedly connected with an electro-hydraulic push rod and a connecting rod mechanism; the fixed frame is hinged to an M-shaped prong assembly; the electro-hydraulic push rod is connected with the connecting rod mechanism; the connecting rod mechanism is hinged to the M-shaped prong assembly. According to the electro-hydraulic drive M-type steel ladle capping and decapping device disclosed by the invention, the electro-hydraulic push rod is stretched to drive the connecting rod mechanism to control the swinging of the M-shaped prong assembly, an included angle between the M-shaped prong assembly and the horizontal plane is regulated, and capping and decapping are realized by the movement of a buggy ladle. High-cost heat energy is avoided and prevented from outwards losing to the outside from a steel ladle lining used for containing molten steel and liquid steel, the steel mill production cost is lowered, the operation condition is improved, and the production rate is improved.

Owner:JIANGSU DISA MACHINERY

Automatic red wine decapping device

The invention discloses an automatic red wine decapping device, comprising an L-shaped support, a motor, an auger bit, a sliding rail, a horizontal plate and a control module, wherein the sliding rail is mounted on the vertical part of the L-shaped support; the horizontal plate is mounted on the sliding rail, and is capable of vertically moving along the sliding rail; the motor is mounted on the horizontal plate and is connected with the auger bit; the control module comprises a control unit and a motor driving module which are connected; the control unit controls the motor to rotate and vertically move through the drive of the motor. The automatic red wine decapping device has the advantages of simpleness in operation and convenience in use, and is applicable to the decapping operation for all people, and the error easily existing in the manual bottle stopper opening process can be also avoided.

Owner:NANTONG YAOHUA MECHANICAL & ELECTRICAL

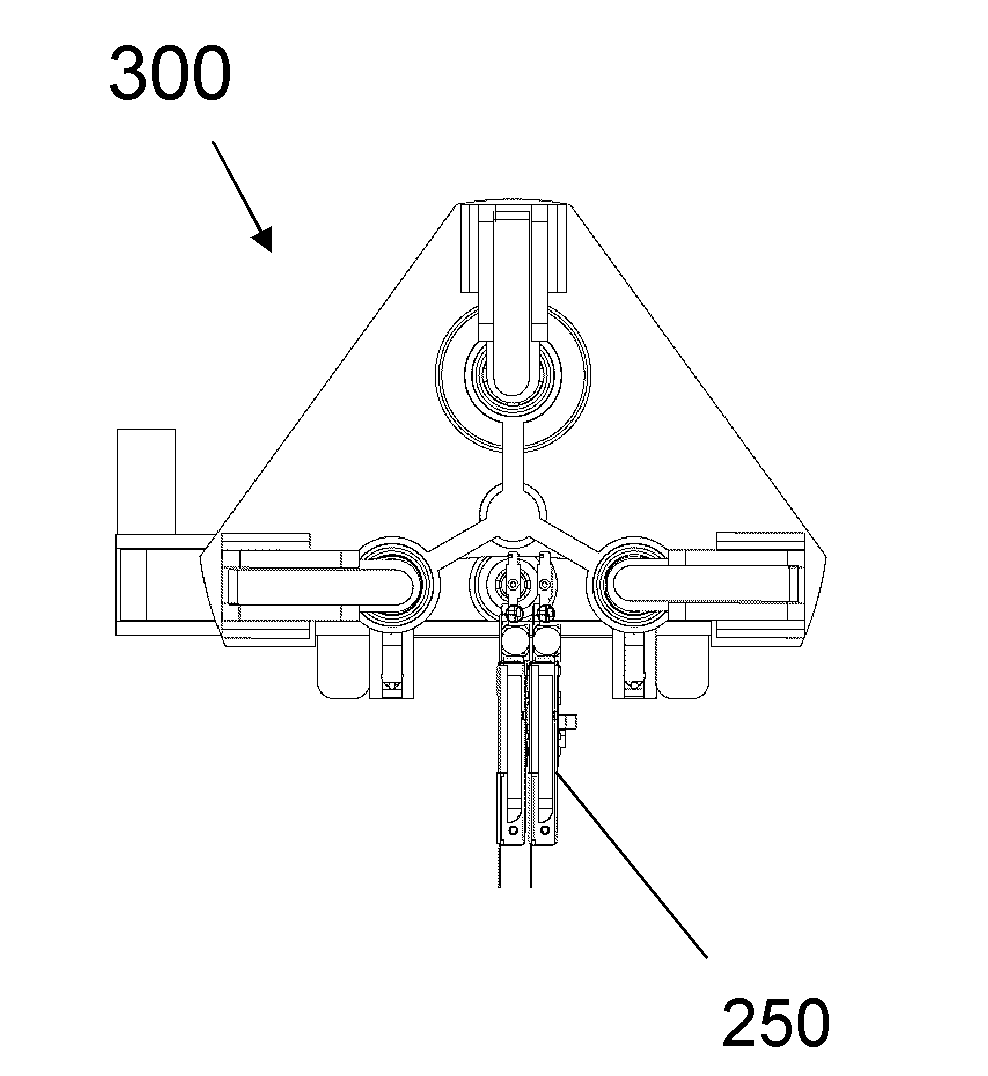

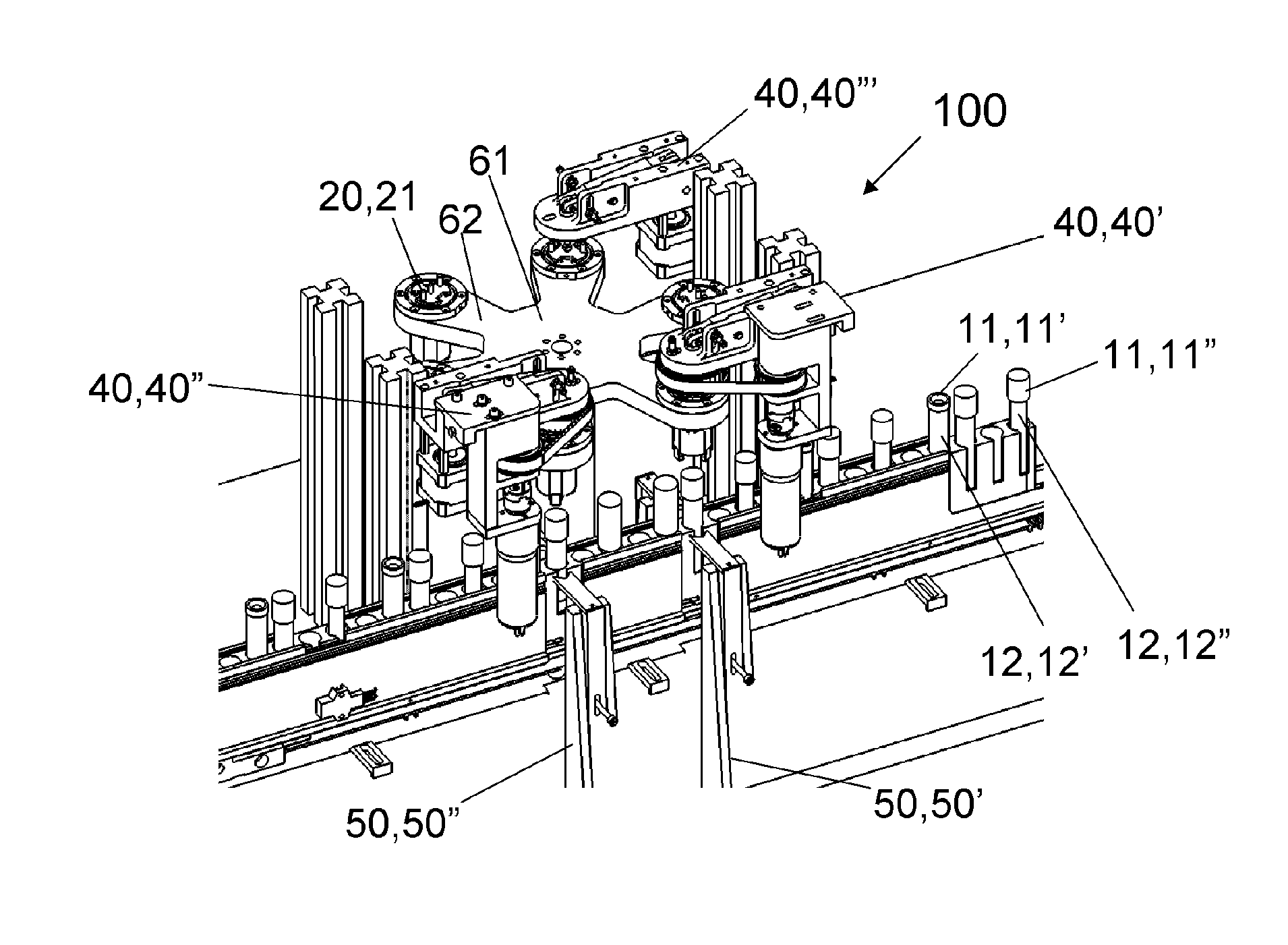

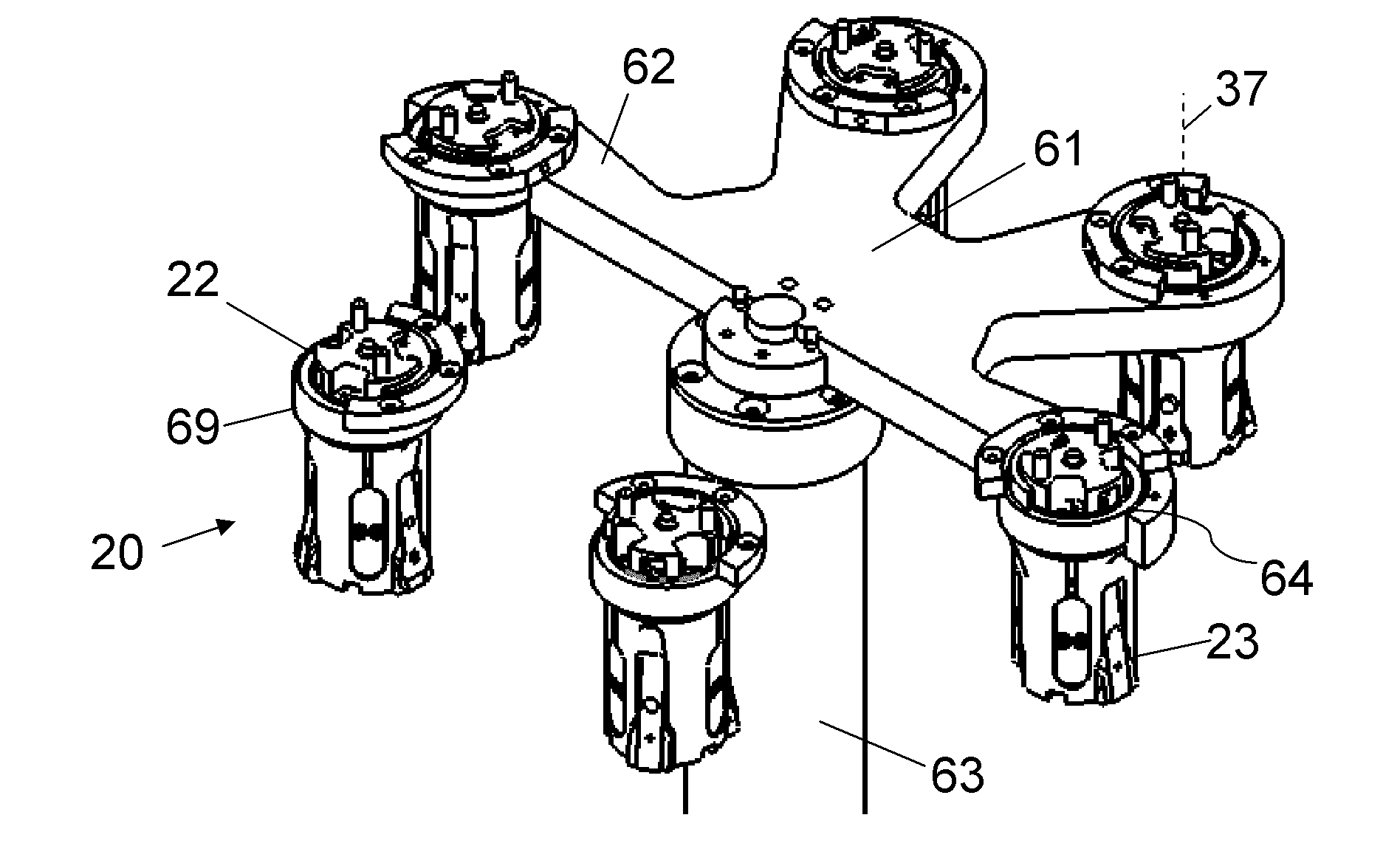

Decapping system

Decapping system for opening or closing reagent containers or cartridge systems closed by a lid the which is removed and secured by a rotational movement and method thereof are disclosed. The decapping system has a centering unit that the at its lower end provides a snap-in element which engages the lid, and a plurality of simultaneously driven and vertically movable screwing heads which compensates for variable heights and / or sizes of cartridge systems to be processed.

Owner:ROCHE DIAGNOSTICS OPERATIONS INC

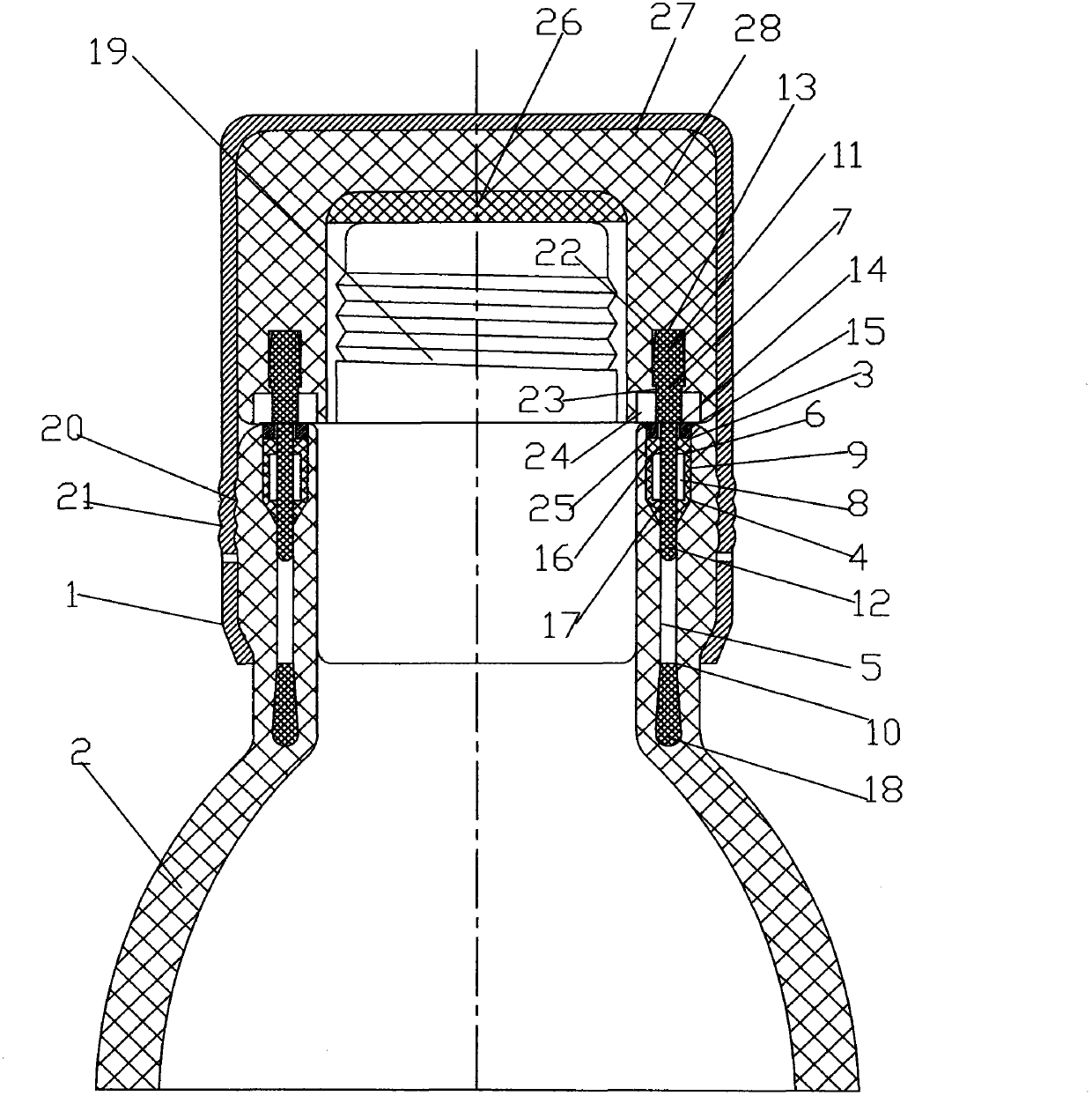

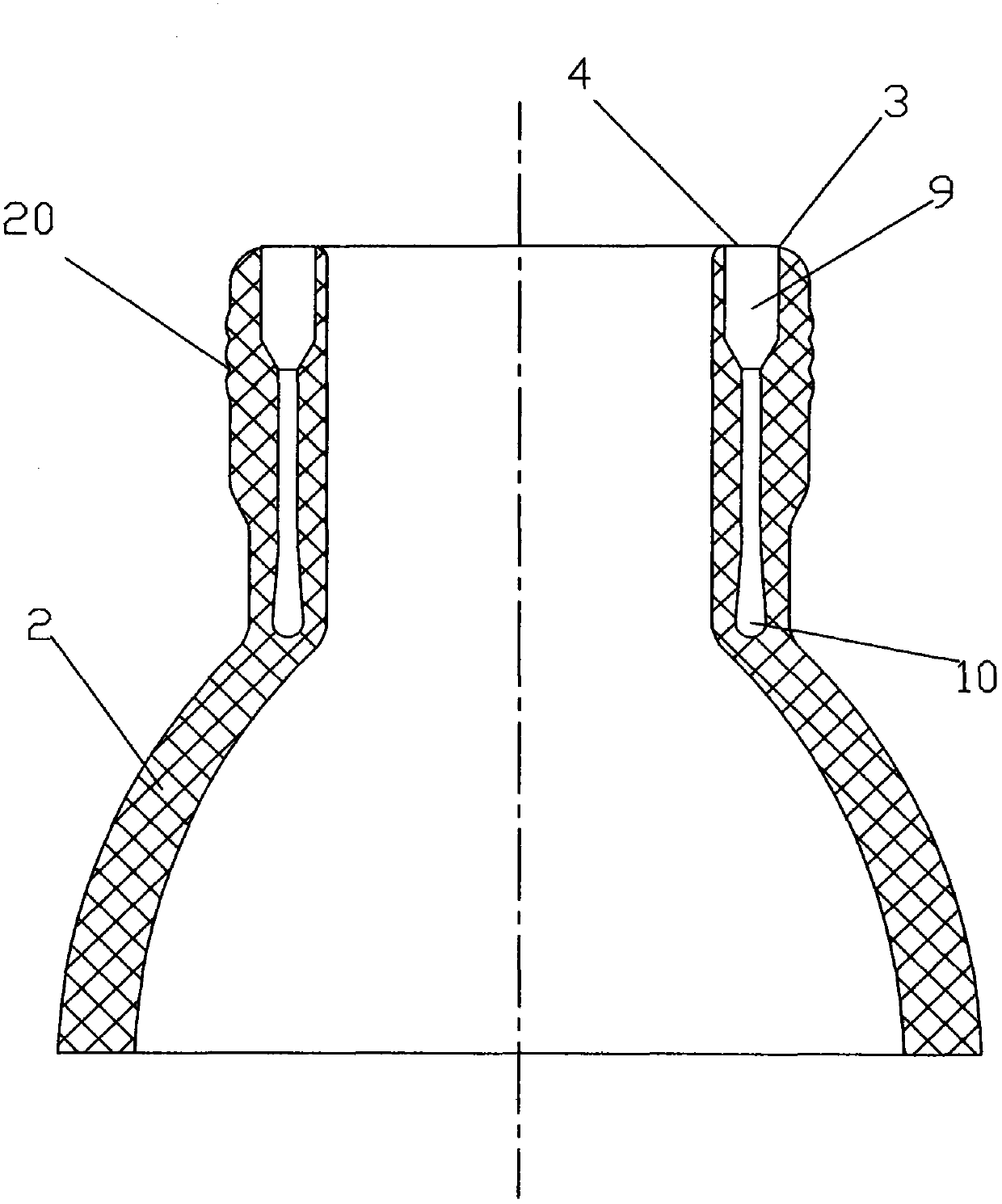

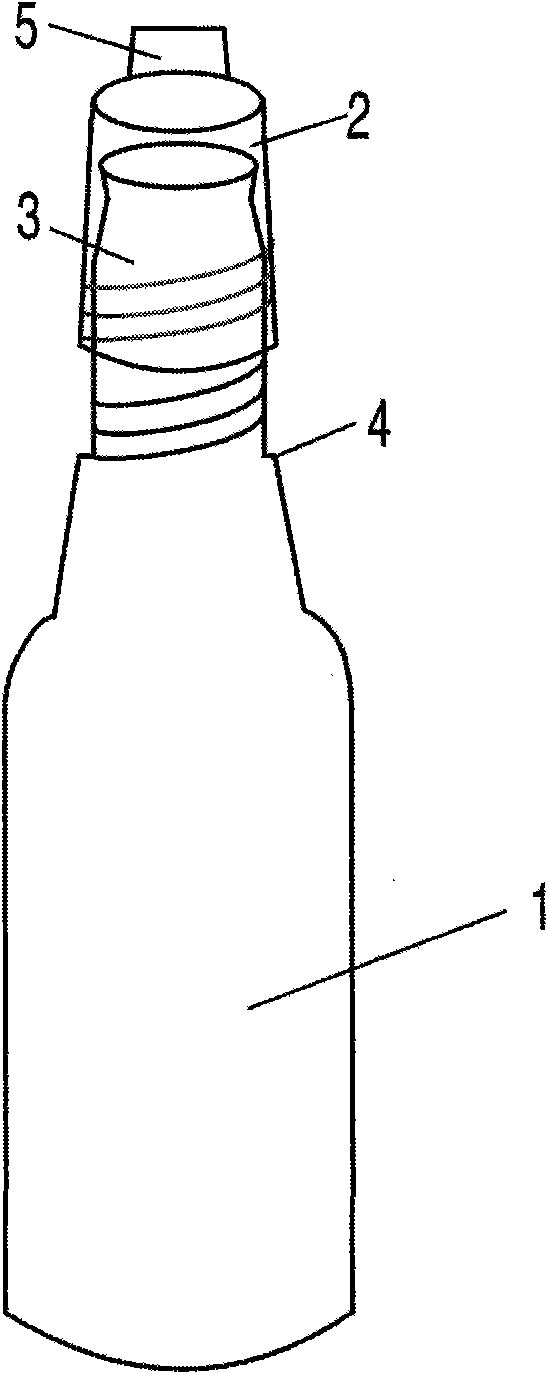

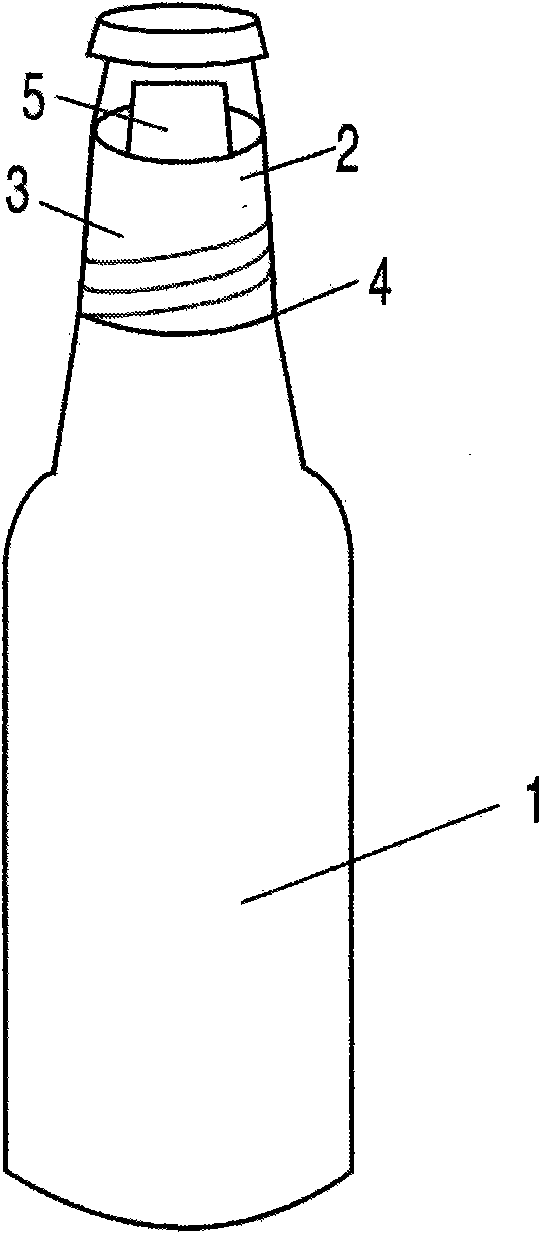

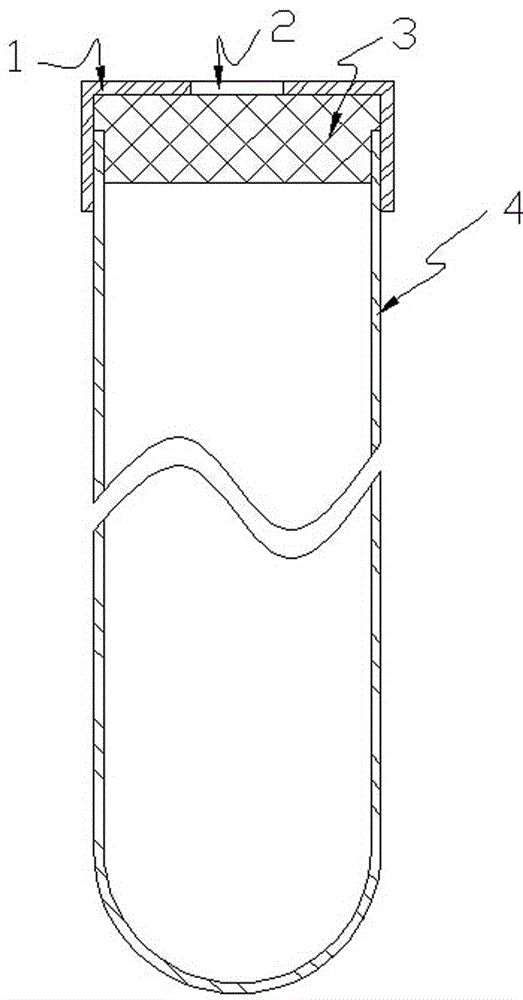

Anti-counterfeiting bottle with decapping mark

An anti-counterfeiting decapping-marked bottle comprises a bottle cap and a bottle body, wherein an anti-counterfeiting hole is arranged in the wall of a bottleneck of the bottle body, and is provided with an anti-counterfeiting agent, an anti-counterfeiting device is arranged in the anti-counterfeiting hole, the anti-counterfeiting device is formed by an anti-counterfeiting container and an anti-counterfeiting cork, the anti-counterfeiting cork is in seal connection with the anti-counterfeiting container, an anti-counterfeiting liquid with a specific color is contained in the anti-counterfeiting container, and the anti-counterfeiting cork is fixedly connected with the bottle cap and in seal connection with the anti-counterfeiting hole. After the anti-counterfeiting bottle is opened, the anti-counterfeiting liquid and the anti-counterfeiting agent are reacted to solidify, a solidified anti-counterfeiting mark which is difficult to eliminate and has a specific color is left in the anti-counterfeiting hole of the bottleneck, so consumers can identify the old bottle, and counterfeiters can be prevented from repeatedly using the old bottles of famous brands.

Owner:林智勇

Automatic sampling device and automatic sampling method for gas adsorption pipe

ActiveCN109799117AAvoid duplication of workSave human effortComponent separationWithdrawing sample devicesProcess engineeringDecapping

The invention provides an automatic sampling device and an automatic sampling method for a gas adsorption pipe. The automatic sampling device comprises a gas adsorption pipe feeding and discharging mechanism, a gas adsorption pipe decapping mechanism, a gas adsorption pipe sealing mechanism, a rotary clamping mechanism and a sampling control mechanism, the gas adsorption pipe feeding and discharging pipe is provided with multiple hole positions for clamping of the gas adsorption pipe, the gas adsorption pipe decapping mechanism is used for pulling down and clamping caps at two ends of the gasadsorption pipe taken down from the gas adsorption pipe feeding and discharging mechanism, and the rotary clamping mechanism is used for controlling circulation of the gas adsorption pipe among the mechanisms. Compared with existing sampling modes, the automatic sampling device and the automatic sampling method have the advantages that an operator only needs to mount and clamp the gas adsorption pipe onto a turnplate of the feeding and discharging mechanism, set sampling parameters and taking away the gas adsorption pipe after sampling is completed, so that the operator is avoided repeatedly working for a long time on a large scale. Therefore, an automatic sampling system saves both time and cost.

Owner:北京鸿远通达科技有限公司

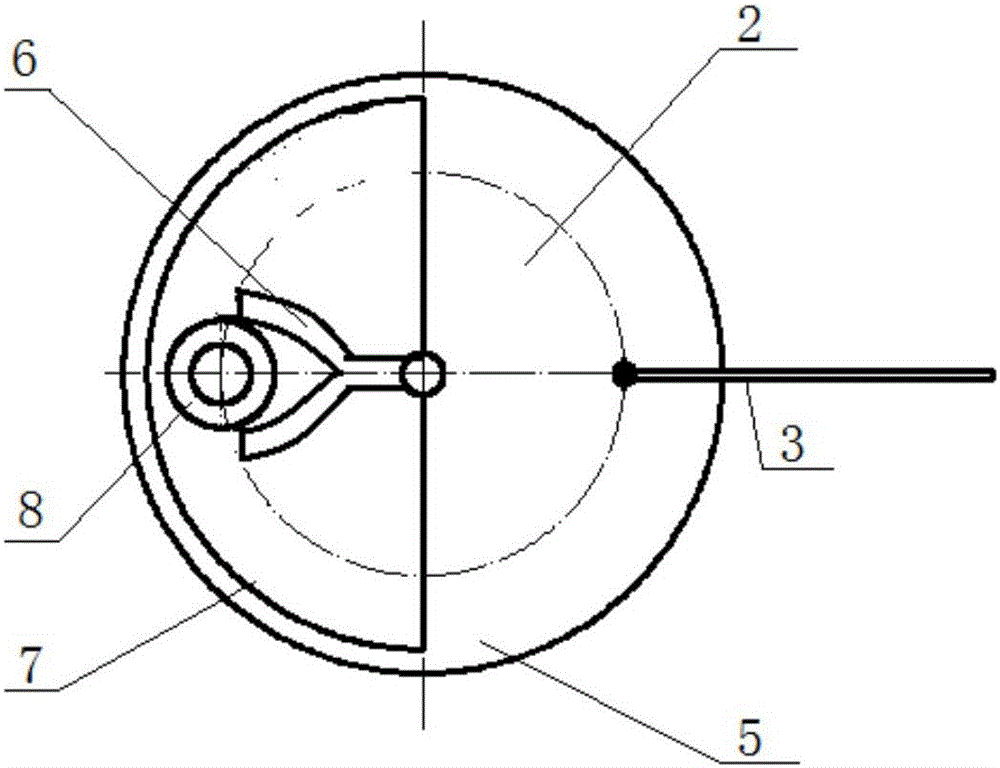

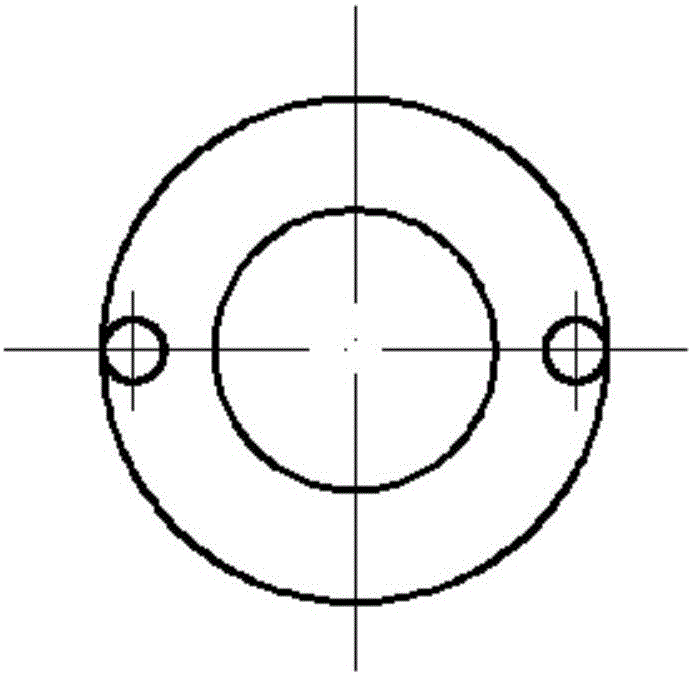

Magnetic disinfection maintaining mechanism for infusion bottle

The invention discloses a magnetic disinfection maintaining mechanism for an infusion bottle. The magnetic disinfection maintaining mechanism comprises a chassis (5), a spindle (4), an infusion bottle mounting disc (2), a magnetic attraction cap (8), a horseshoe-shaped decapping mechanism (6) and a horseshoe-shaped decapping mechanism mounting disc (7). The infusion bottle mounting disc (2) is mounted at the position, higher than the horseshoe-shaped decapping mechanism mounting disc (7), of the spindle (4) and can rotate around the spindle (4); the horseshoe-shaped decapping mechanism (6) is mounted on the horseshoe-shaped decapping mechanism mounting disc (7); disinfecting cotton is mounted in the magnetic attraction cap (8), a plurality of magnets (83) are embedded into a top round ring (82) of the magnetic attraction cap (8), and a plurality of iron block protrusions (9) are fixed to the infusion bottle mounting disc (2). When the magnetic disinfection maintaining mechanism is used for infusion, the magnetic attraction cap is attracted to the infusion bottle mounting disc; when the bottle needs to be replaced, the magnetic attraction cap can be stripped by the horseshoe-shaped decapping mechanism, and operation of a nurse is convenient by means of the whole mechanism; meanwhile, a better disinfection effect is achieved.

Owner:HANGZHOU GUOCHEN MED LINK ROBOT TECH CO LD

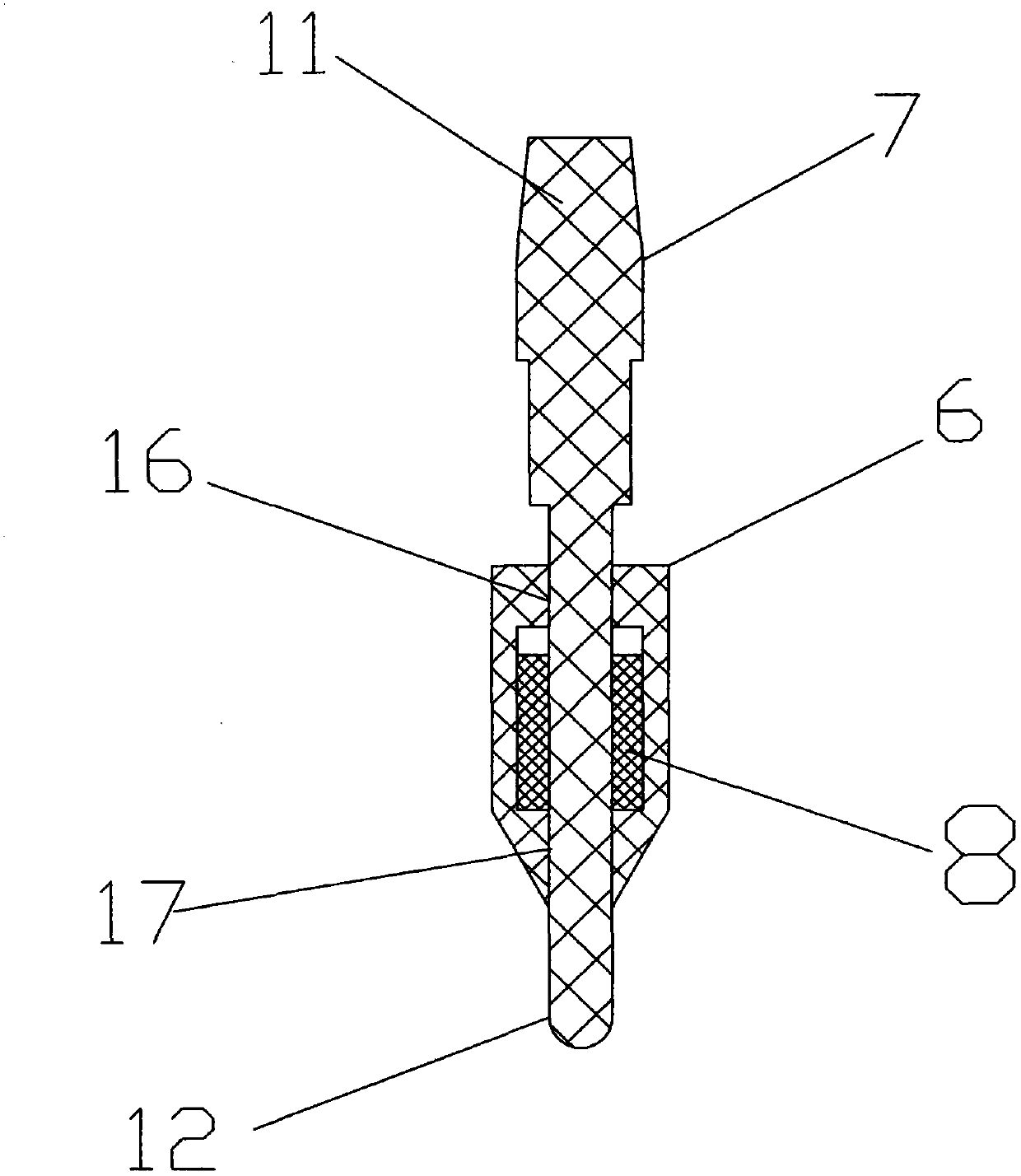

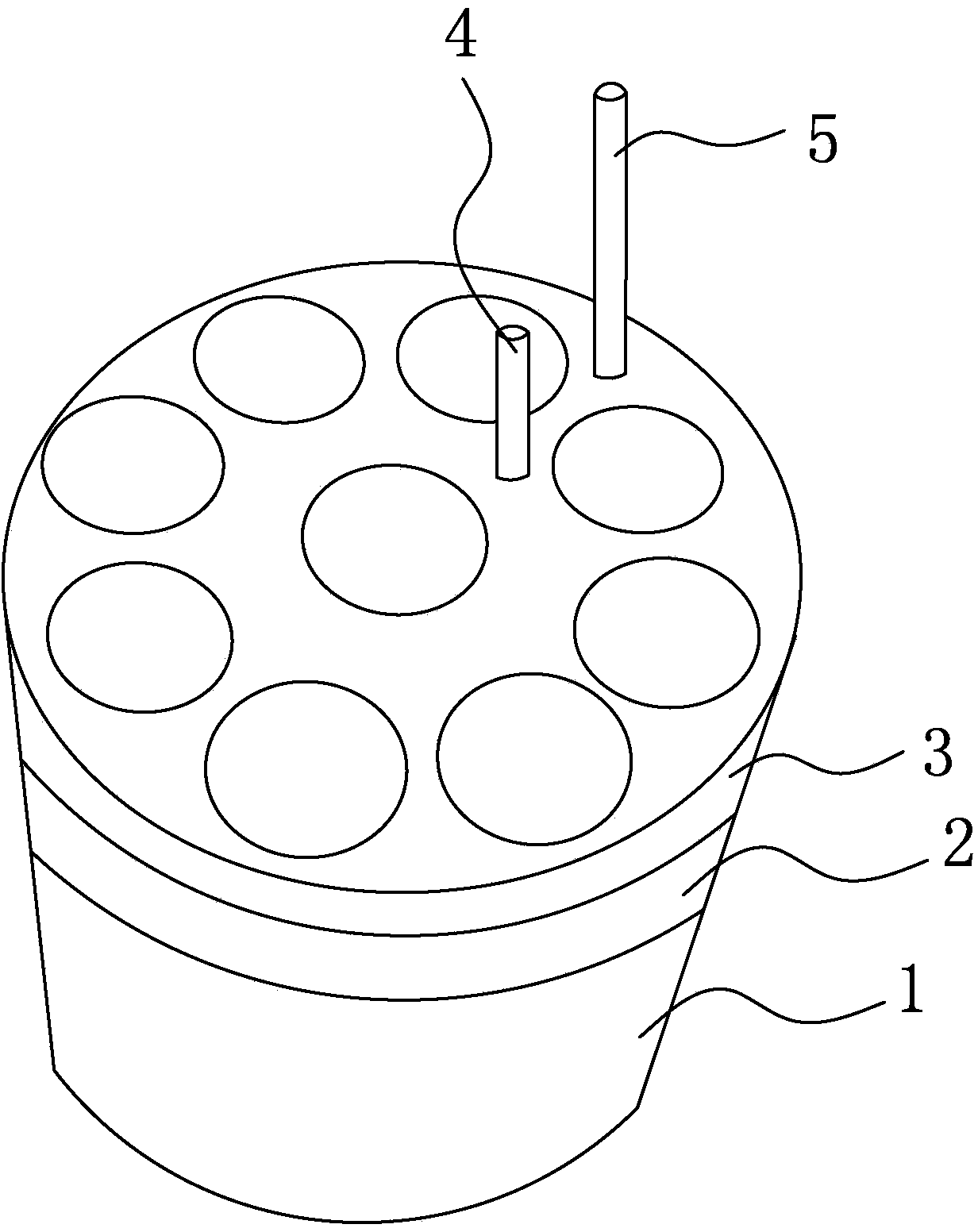

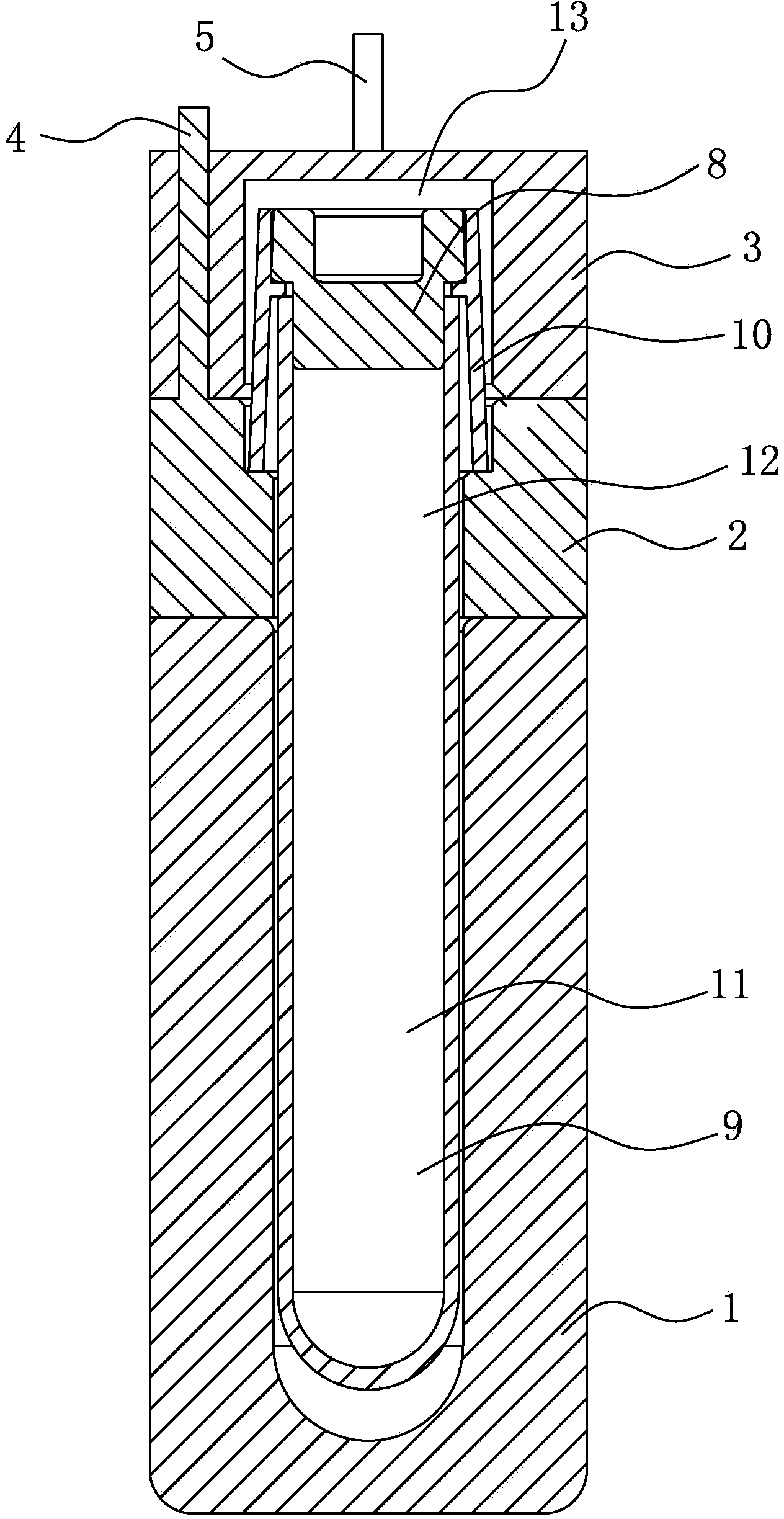

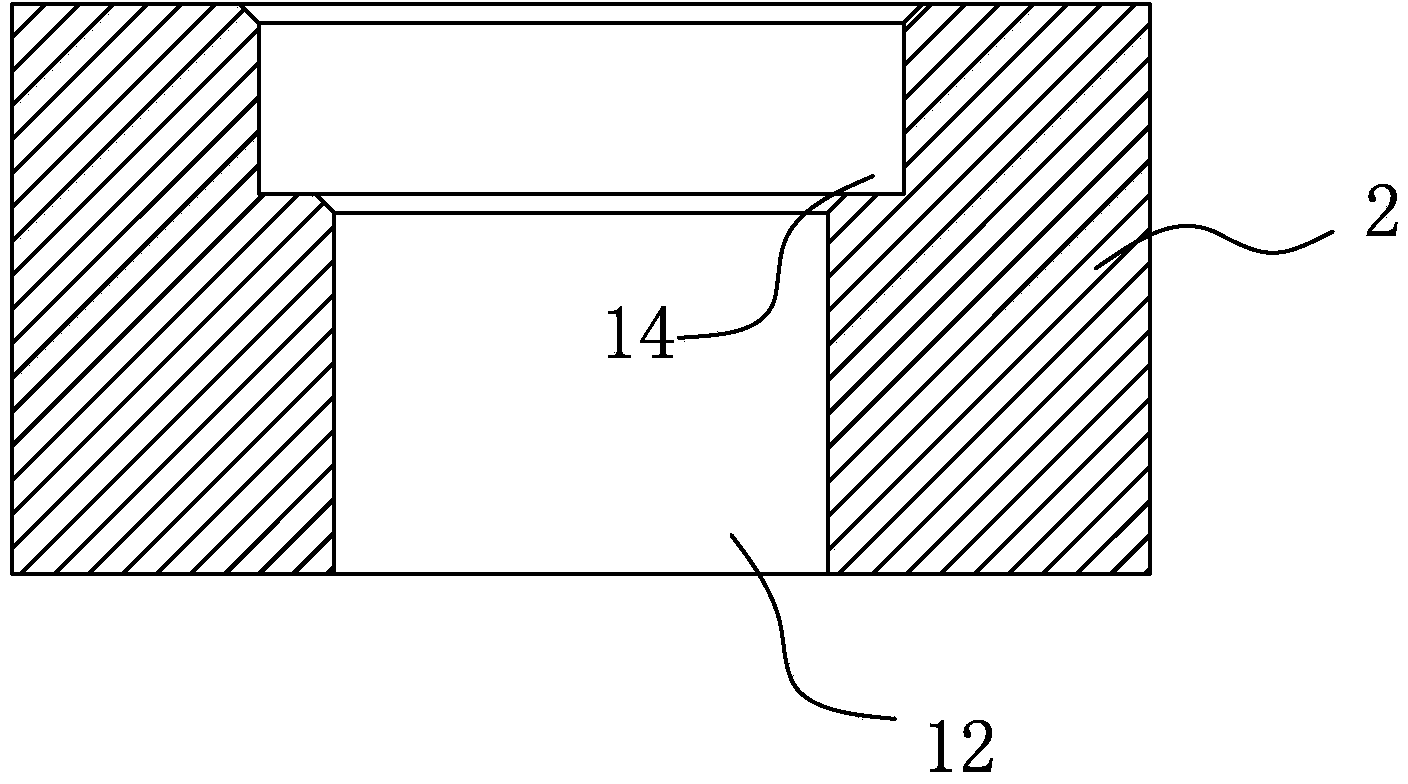

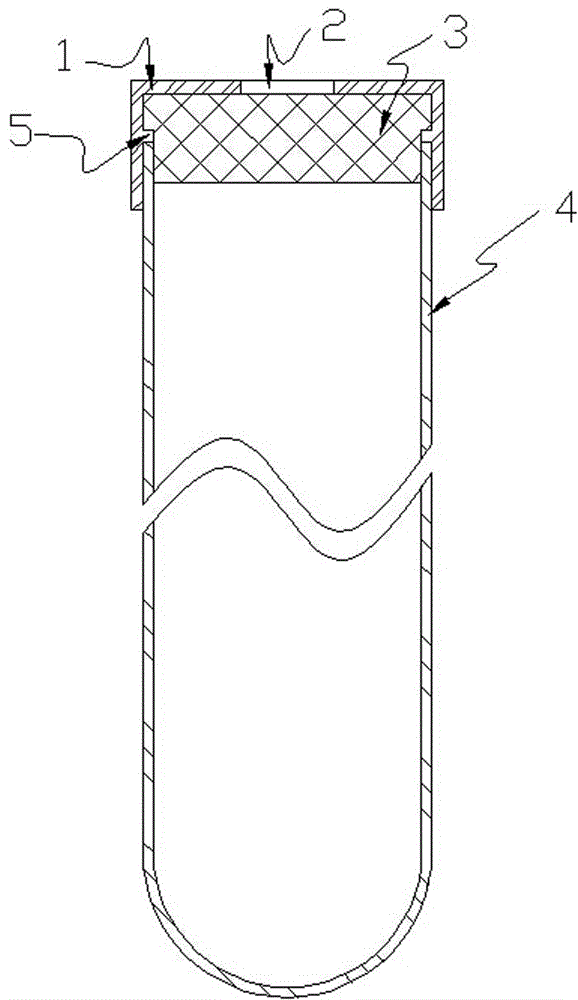

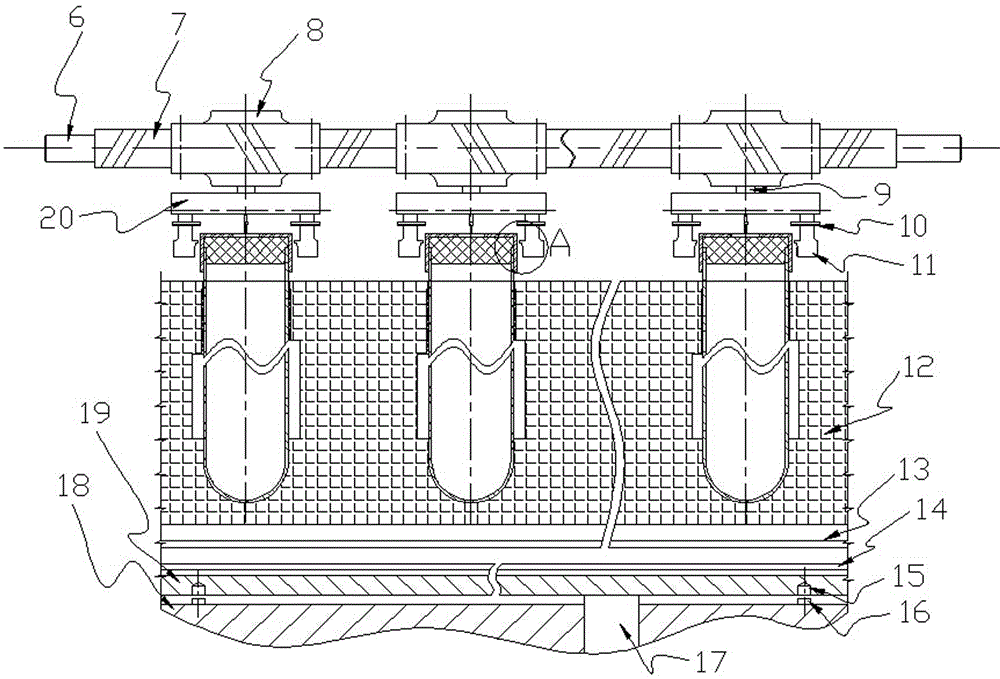

Centrifugal machine adapter

ActiveCN103657887APrevent splashTo achieve the purpose of automatic uncappingCentrifugesBlood Collection TubeDecapping

Disclosed is a centrifugal machine adapter. The centrifugal machine adapter is characterized in that a first adapter main body section, a second adapter main body section, a third adapter main body section, a first locating pin, a second locating pin, a first mark and a second mark are included; blind holes are formed in the first adapter main body section, and the depth of the blind holes is smaller than the length of a tube body; through holes which are composed of upper sections and lower sections in the hole axis direction are formed in the second adapter main body section, steps are arranged at the joints of the upper sections and the lower sections, and the sum of the depth of the lower sections and the depth of the blind holes is larger than the length from the lower end of a protective cap to the bottom end of the tube body in the assembling state of a blood collection tube; concave holes are formed in the third adapter main body section, openings of the concave holes face the tops of the upper sections of the through holes 12, and the internal diameter of the concave holes is larger than the external diameter of the protective cap. By means of the centrifugal machine adapter, automatic decapping of the blood collection tube can be achieved in the centrifuging process, it is also guaranteed that the protective cap can not be splashed, the protective cap of the blood collection tube and the tube body can be in one-to-one correspondence after centrifuging, and the tube body can be taken out conveniently.

Owner:SUZHOU YUYUE MEDICAL TECH

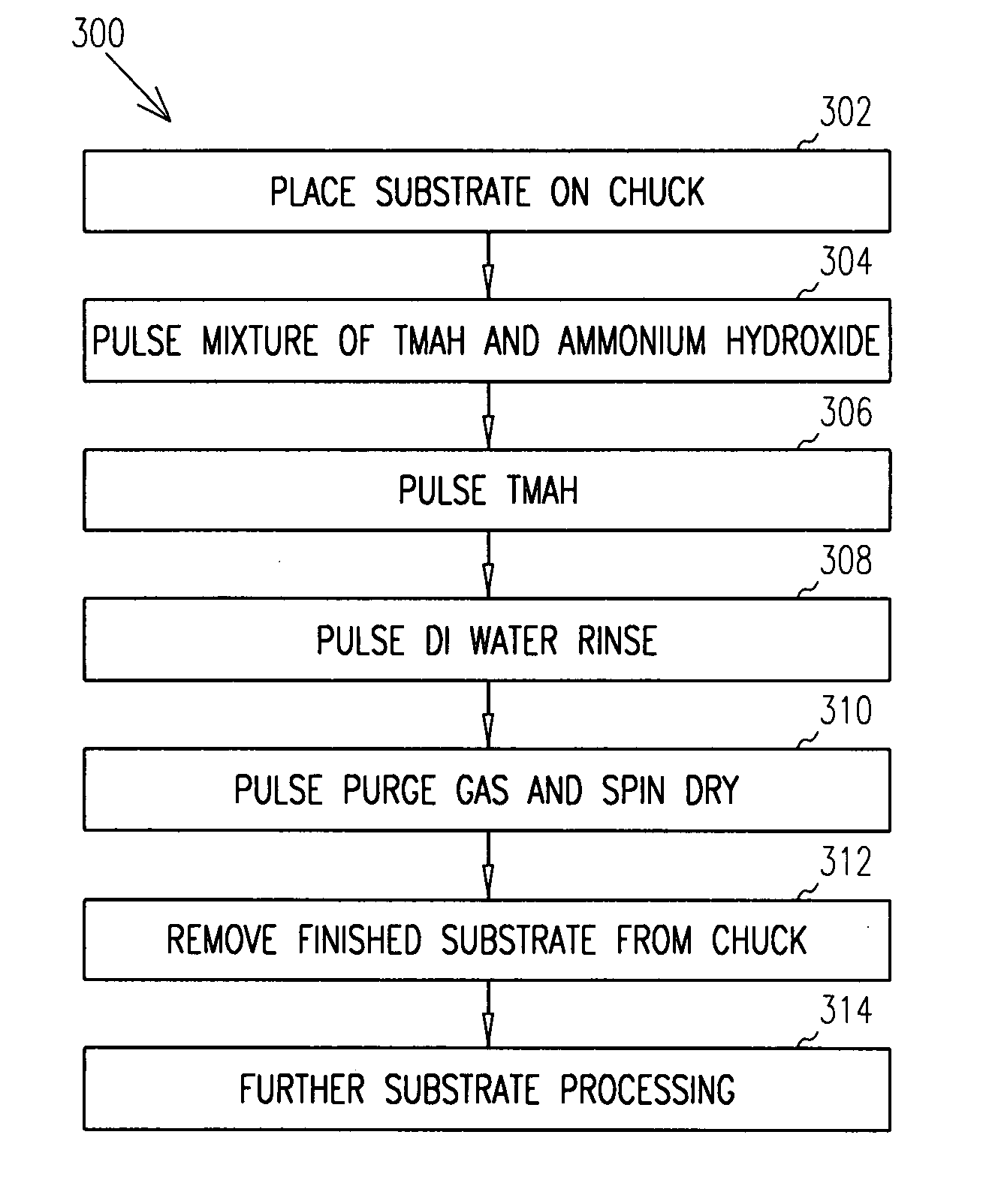

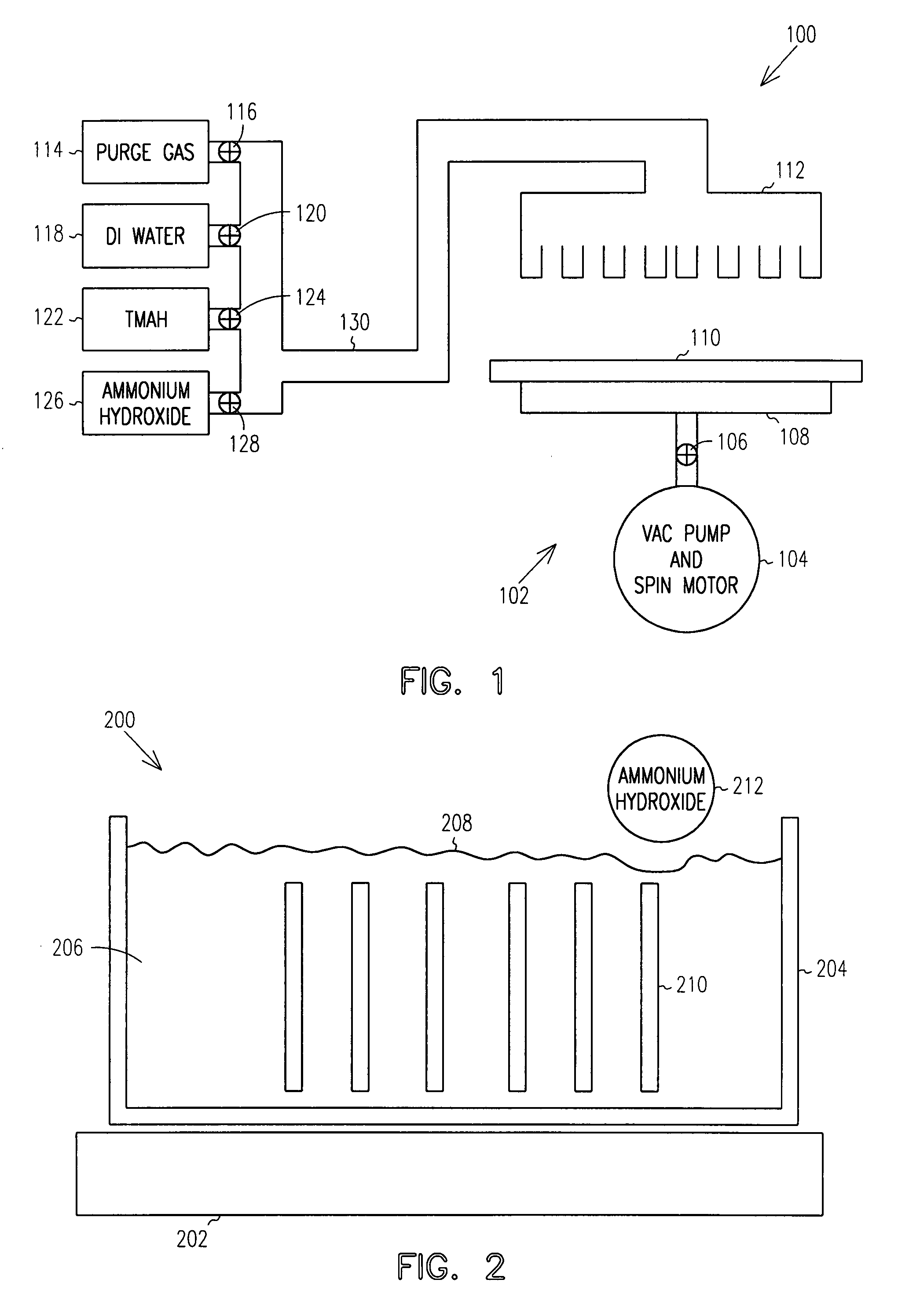

Poly etch without separate oxide decap

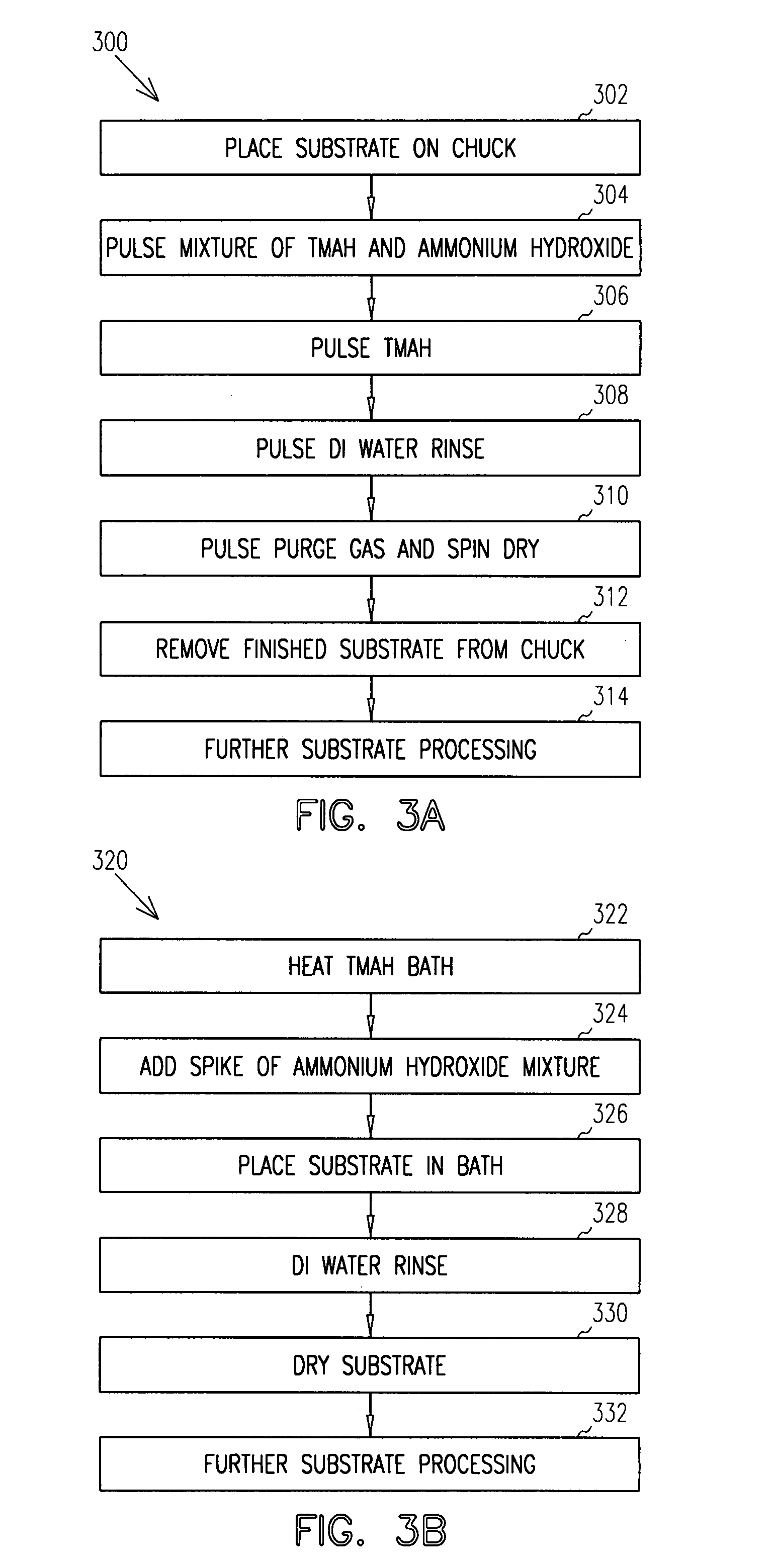

InactiveUS7927500B2Decorative surface effectsSolid-state devicesTetramethylammonium hydroxideEvery Hour

The use of an ammonium hydroxide spike to a hot tetra methyl ammonium hydroxide (TMAH) solution to form an insitu poly oxide decapping step in a polysilicon (poly) etch process, results in a single step rapid poly etch process having uniform etch initiation and a high etch selectivity, that may be used in manufacturing a variety of electronic devices such as integrated circuits (ICs) and micro electro-mechanical (MEM) devices. The etching solution is formed by adding 35% ammonium hydroxide solution to a hot 12.5% TMAH solution at about 70° C. at a rate of 1% by volume, every hour. Such an etch solution and method provides a simple, inexpensive, single step self initiating poly etch that has etch stop ratios of over 200 to 1 over underlying insulator layers and TiN layers.

Owner:MICRON TECH INC

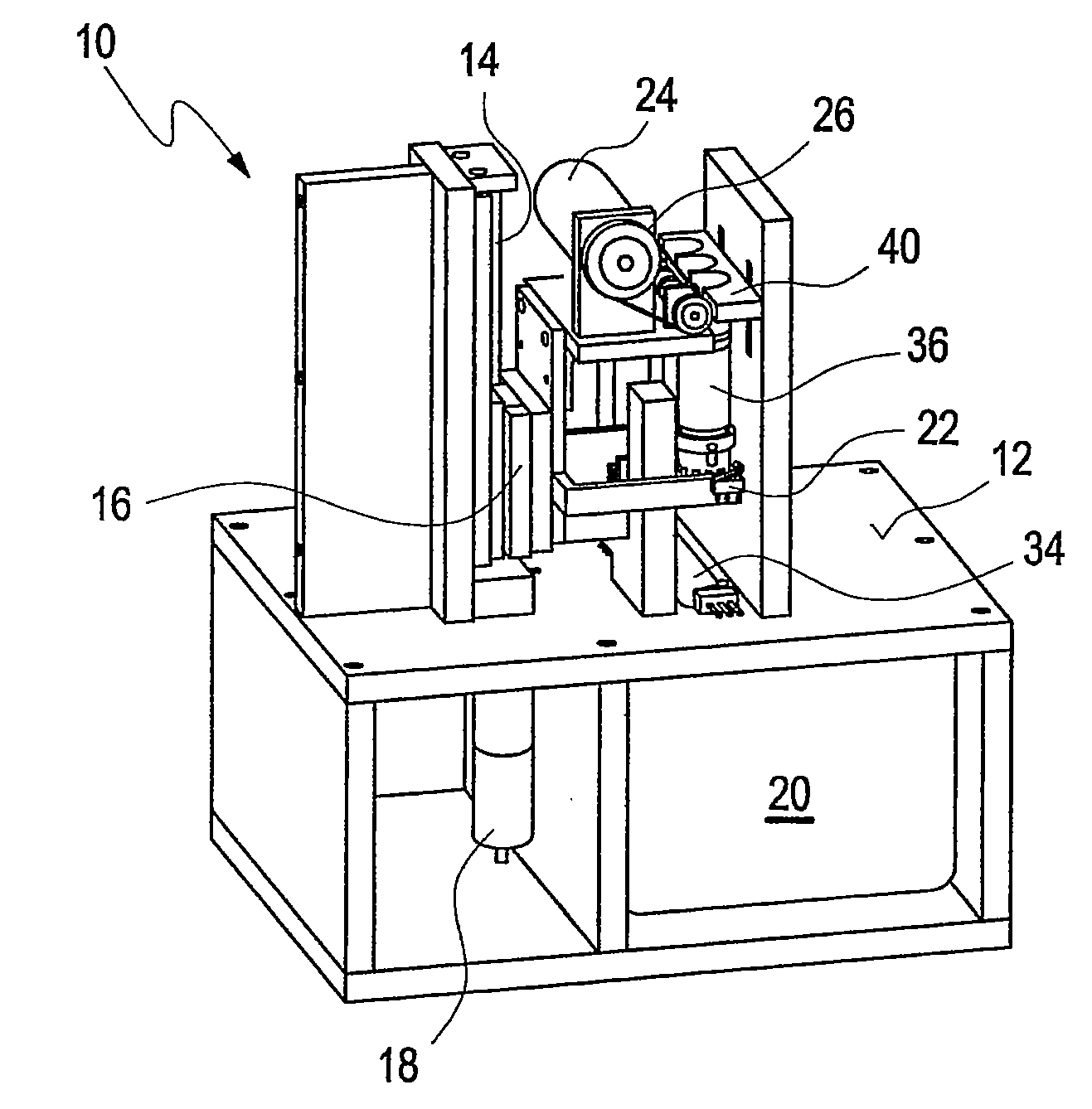

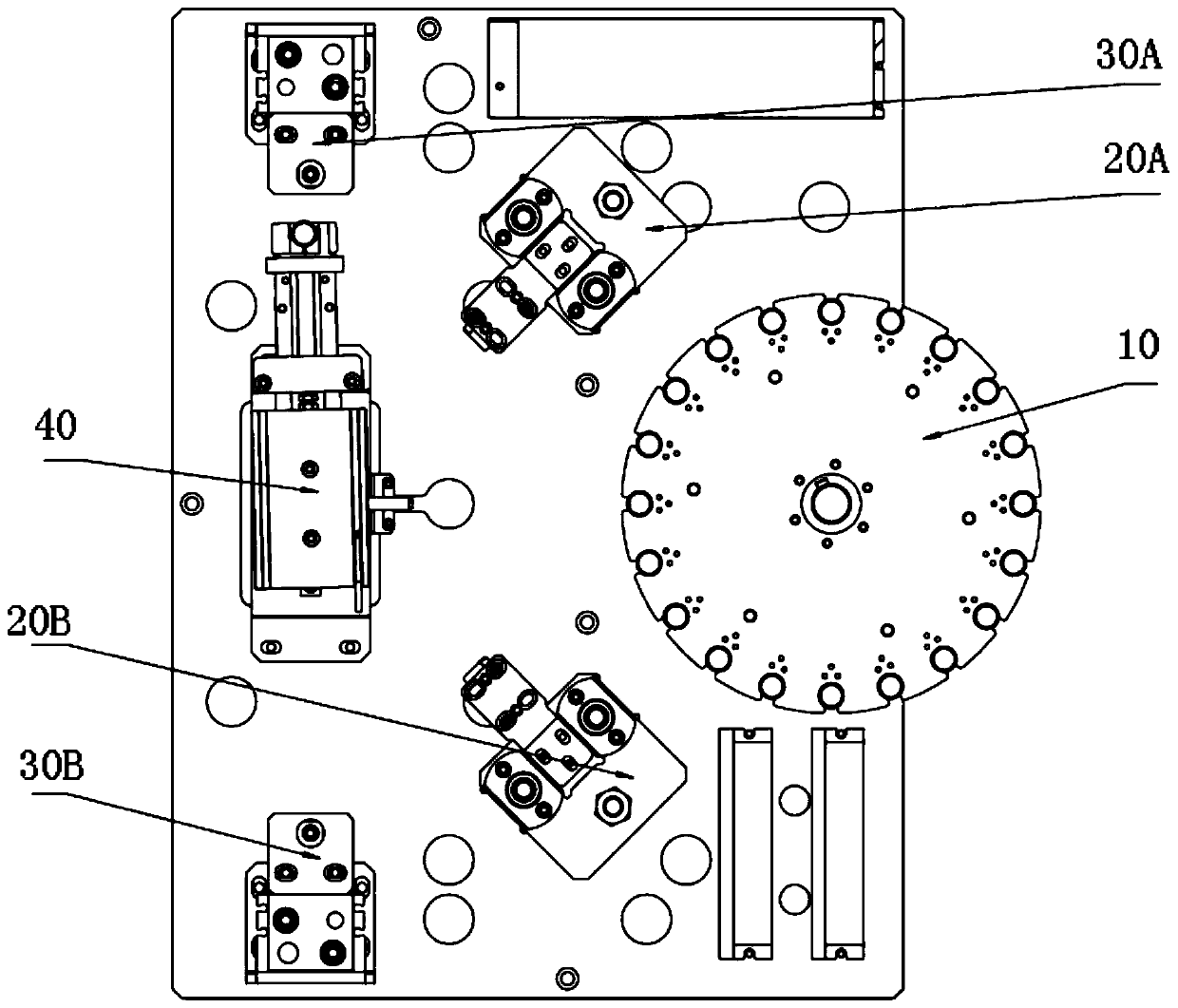

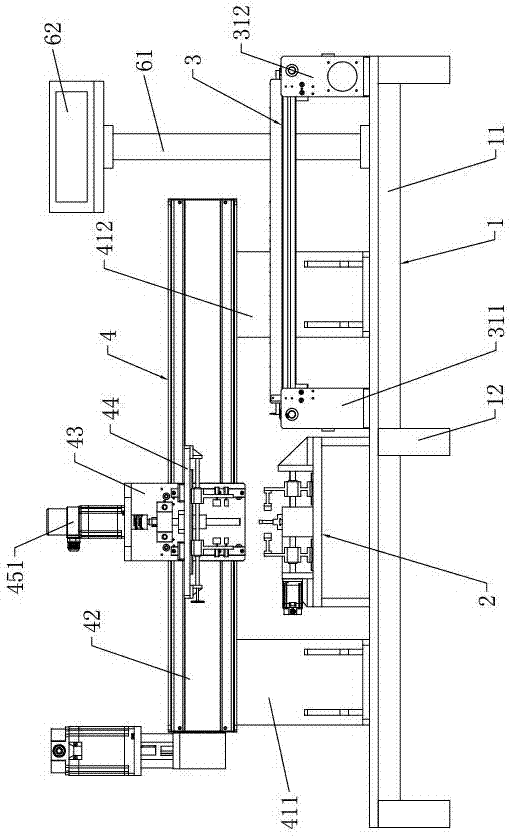

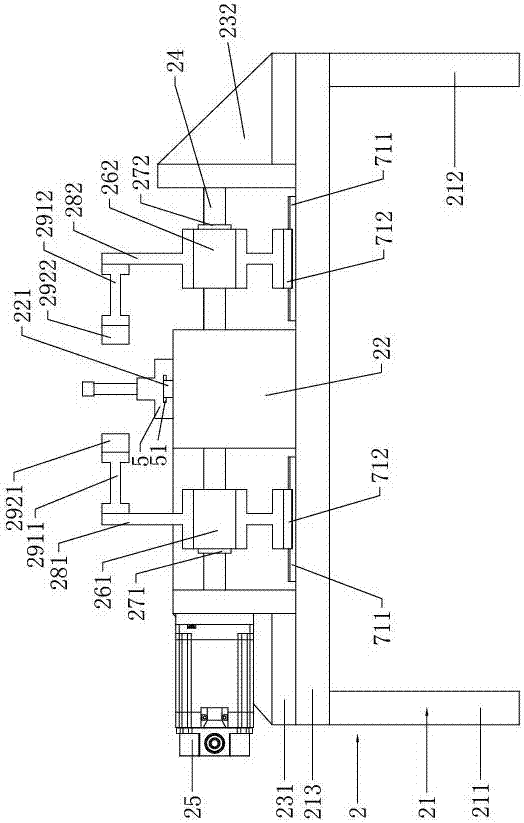

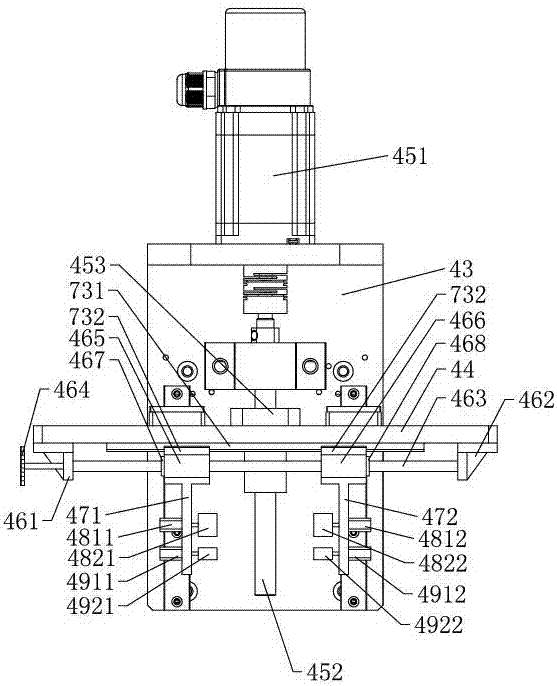

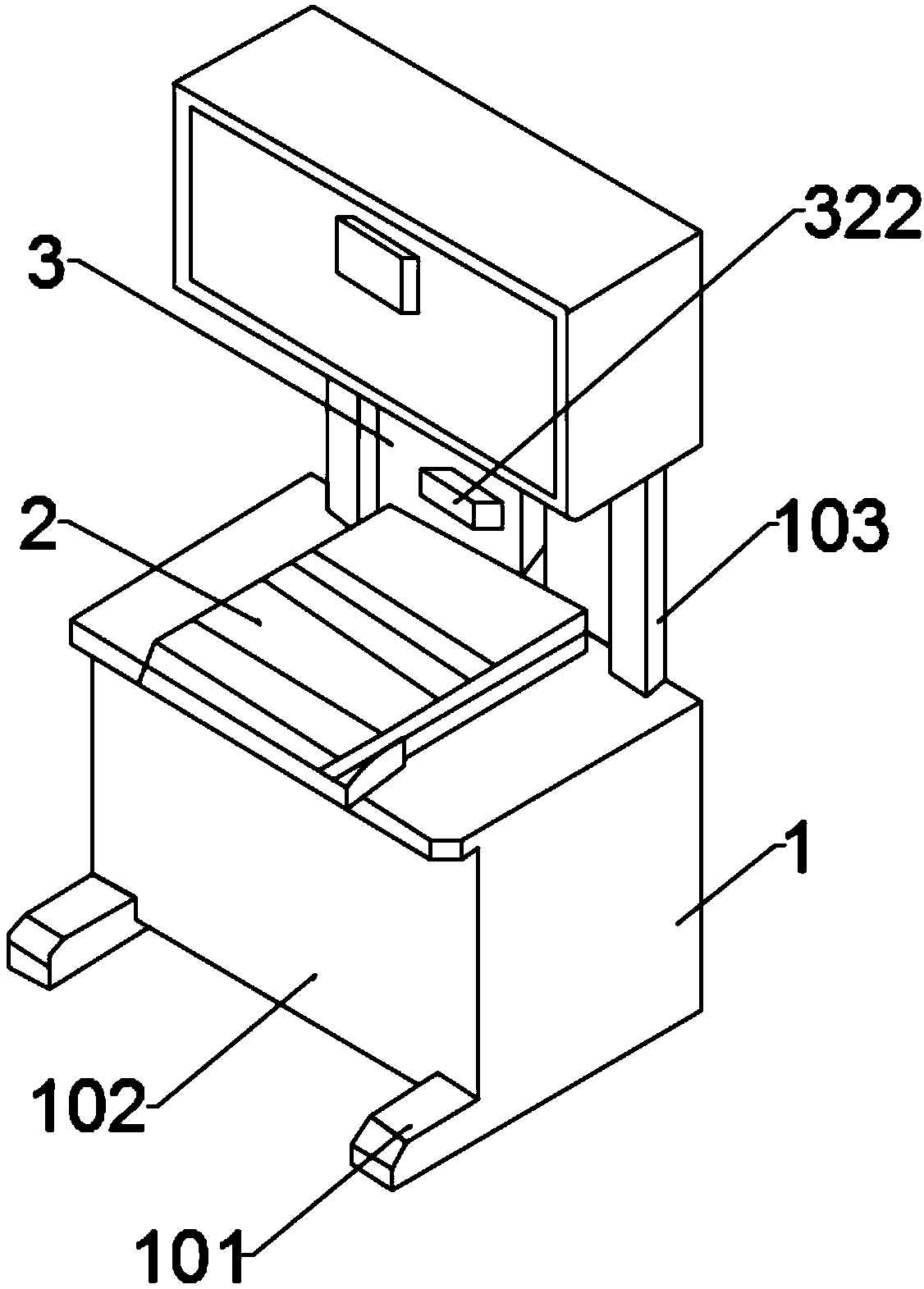

Novel automatic feeding blood-collecting tube decapping device

ActiveCN107512690AAutomatic and efficient cap openingHigh degree of automationTight-fitting lid removalThreaded caps removalBlood Collection TubeEngineering

The invention discloses a novel automatic feeding blood-collecting tube decapping device. A supporting rack of the novel automatic feeding blood-collecting tube decapping device comprises a fixed supporting plate and fixed supporting feet. A blood-collecting tube storing and clamping assembly, an automatic blood-collecting tube conveying assembly and a blood-collecting tube transferring and decapping assembly are installed on the upper surface of the fixed supporting plate, wherein the automatic blood-collecting tube conveying assembly is located on the right end side of the blood-collecting tube storing and clamping assembly, the blood-collecting tube storing and clamping assembly and the automatic blood-collecting tube conveying assembly are arranged in a spaced mode, and the blood-collecting tube transferring and decapping assembly is located on the upper end side of the blood-collecting tube storing and clamping assembly. The automatic blood-collecting tube conveying assembly is used for achieving automatic conveying operation of a blood-collecting tube; the blood-collecting tube storing and clamping assembly is used for storing a blood-collecting tube frame and clamping a tube body of the blood-collecting tube in a positioning mode; and the blood-collecting tube transferring and decapping assembly is used for transferring the blood-collecting tube frame of the automatic blood-collecting tube conveying assembly to the blood-collecting tube storing and clamping assembly and achieving the decapping action. Through the structural design, the decapping operation of the blood-collecting tube can be automatically and efficiently achieved, and the novel automatic feeding blood-collecting tube decapping device has the advantages of novel structural design, high automation degree and high working efficiency.

Owner:东莞市第三人民医院 +1

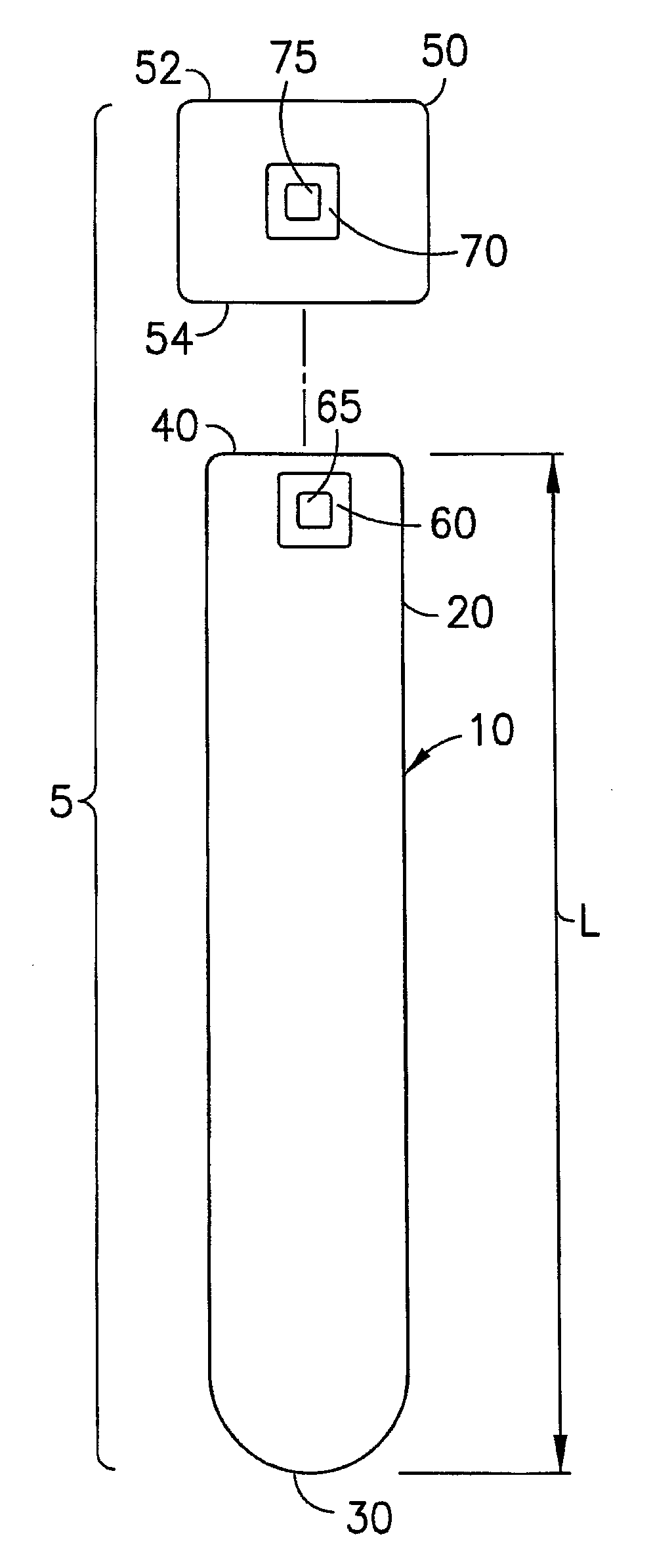

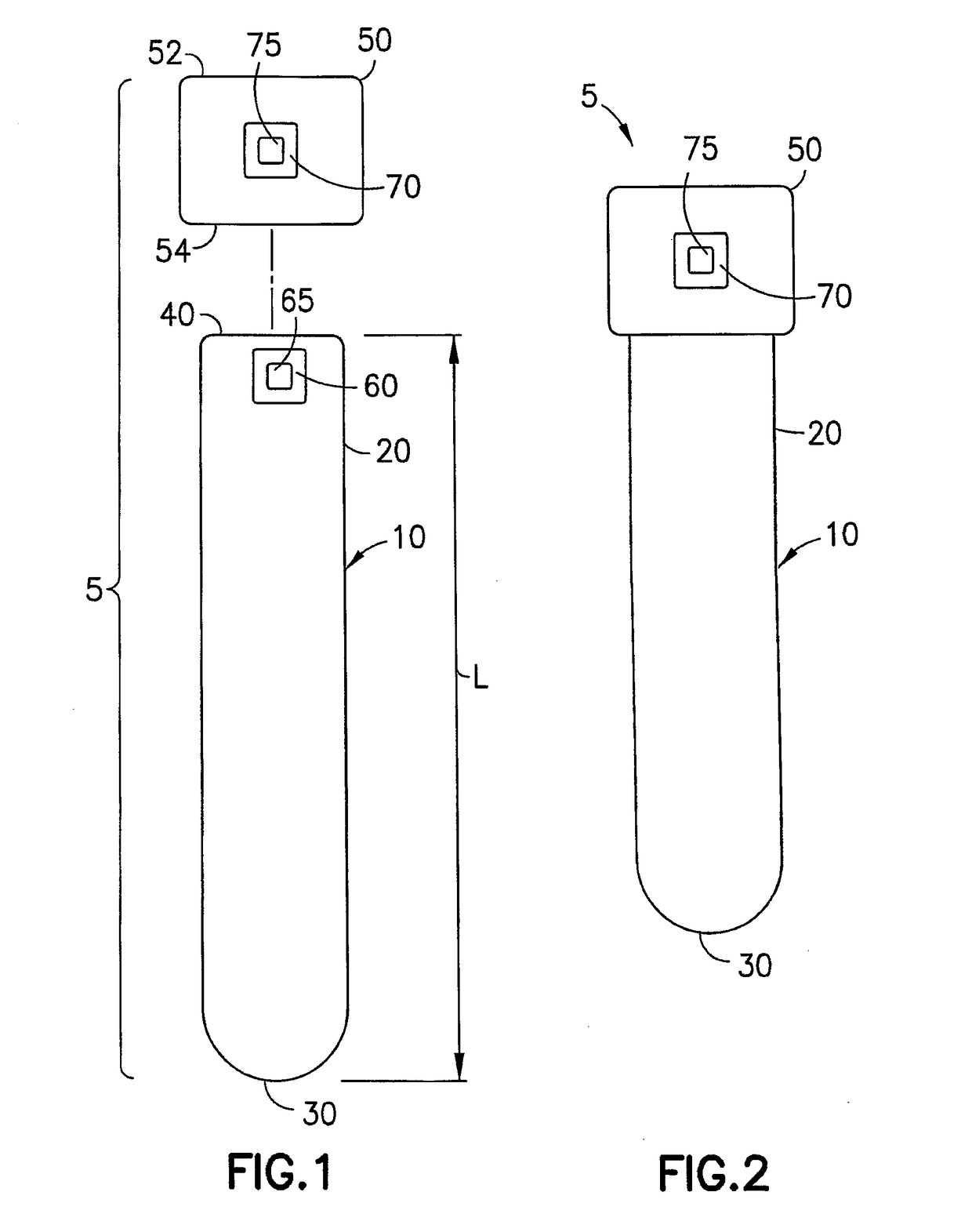

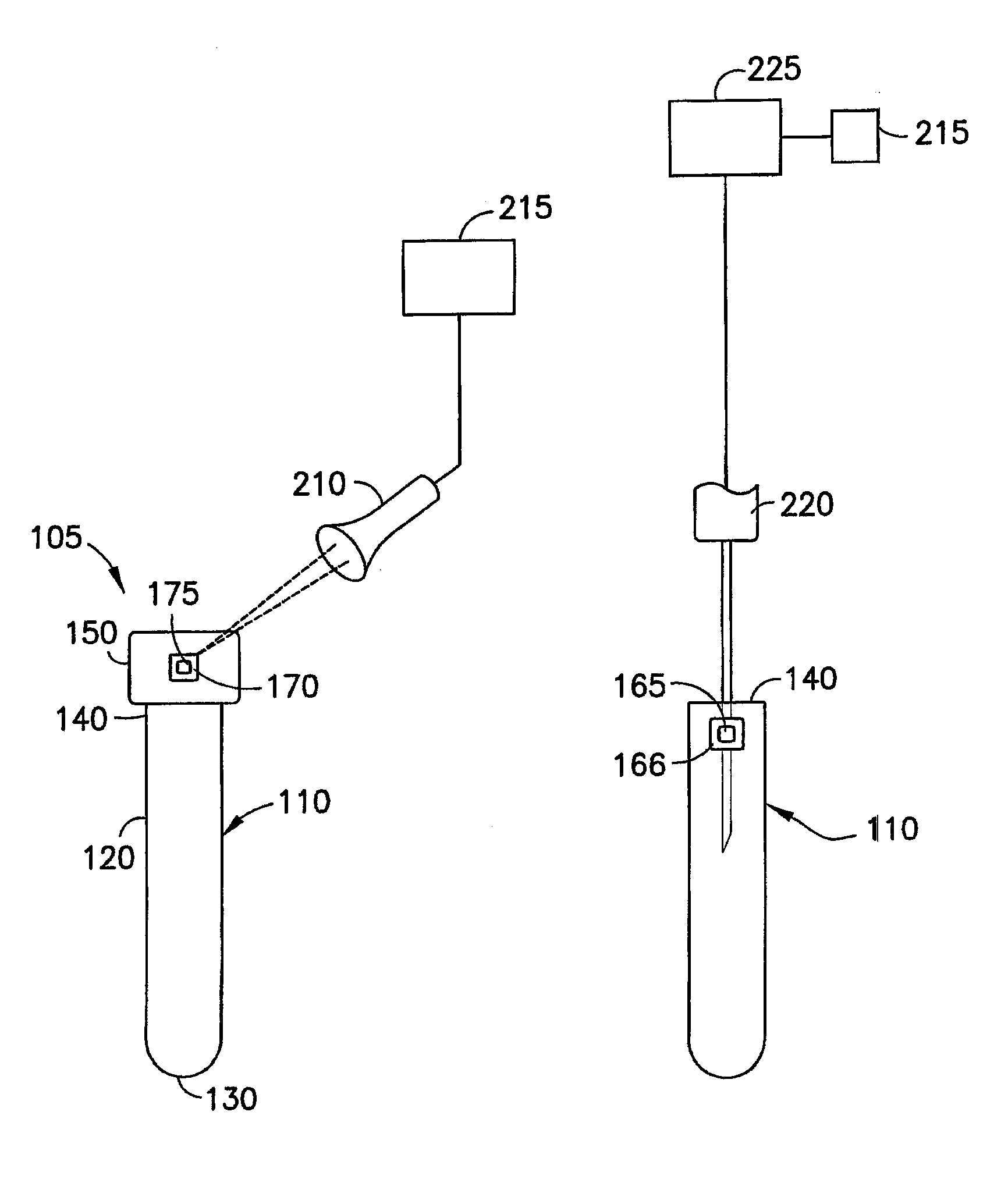

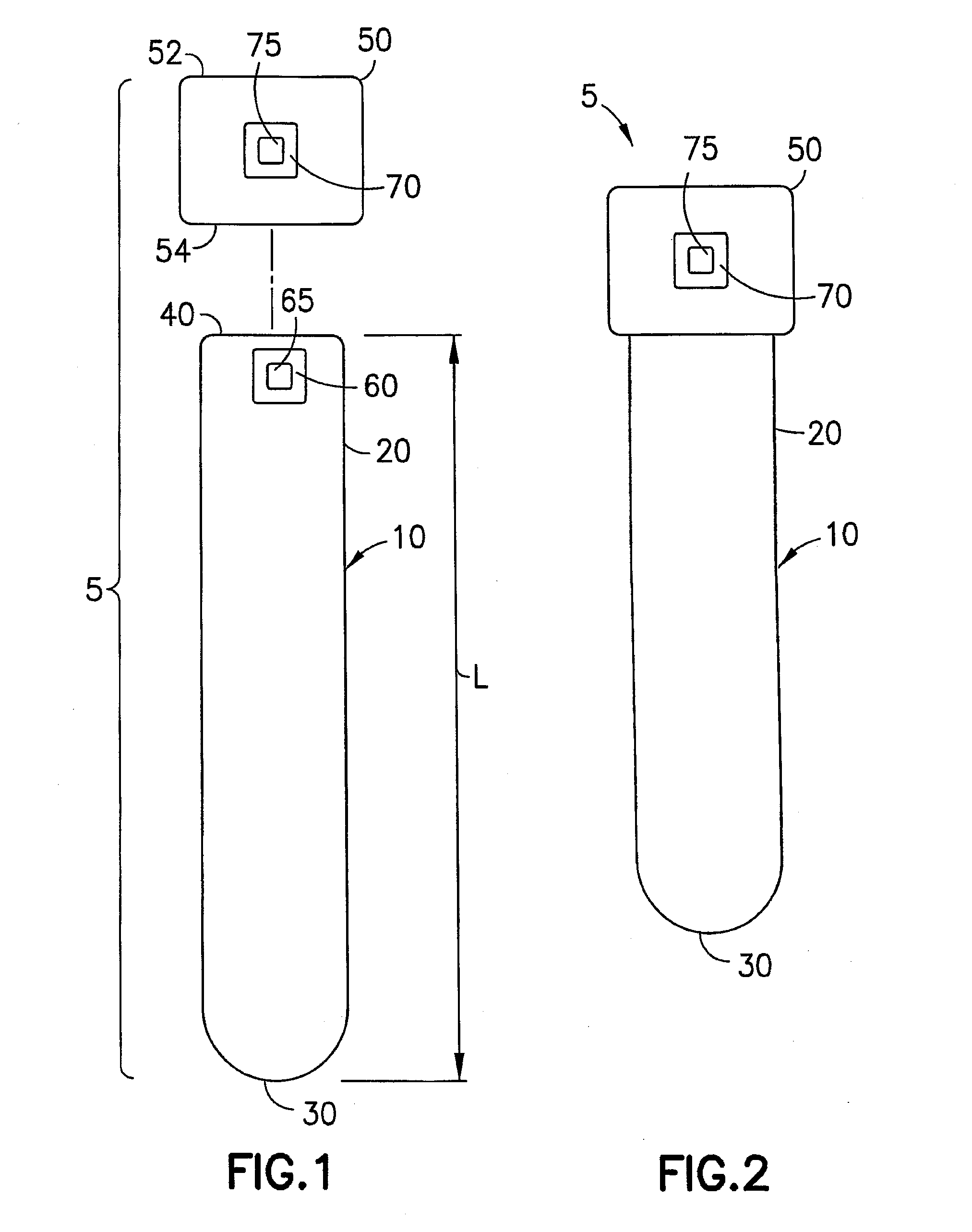

Dual barcode labeling facilitating automated decapping

A specimen collection assembly and method for detecting the same are disclosed. The specimen collection assembly includes a specimen collection container having an open top end, a closed bottom end, and a sidewall extending therebetween defining an interior adapted to receive a biological specimen. The specimen collection container also includes first indicia containing information. The assembly further includes a cap having thereon second indicia, the cap being removably engagable with the open top end of the container. The second indicia contains the same information as the first indicia.

Owner:BECTON DICKINSON & CO

Bottle with decapping function

The invention relates to a bottle with decapping function, in particular to a bottle which is convenient for opening a metal-cap occluding seal. The bottle comprises a bottle body and a sleeve. The invention is characterized in that the bottle body and the sleeve are cooperatively sheathed at the bottle neck through screw threads; and the top of the sleeve is provided with a bulge for opening the occluding metal cap. By using the bottle with the decapping function, after the bottle neck is sealed, the bottle can be easily opened by self decapping function without the need of other auxiliary tools. Thus, the invention has the advantages of convenience, high safety and wide applicability.

Owner:陈海兵

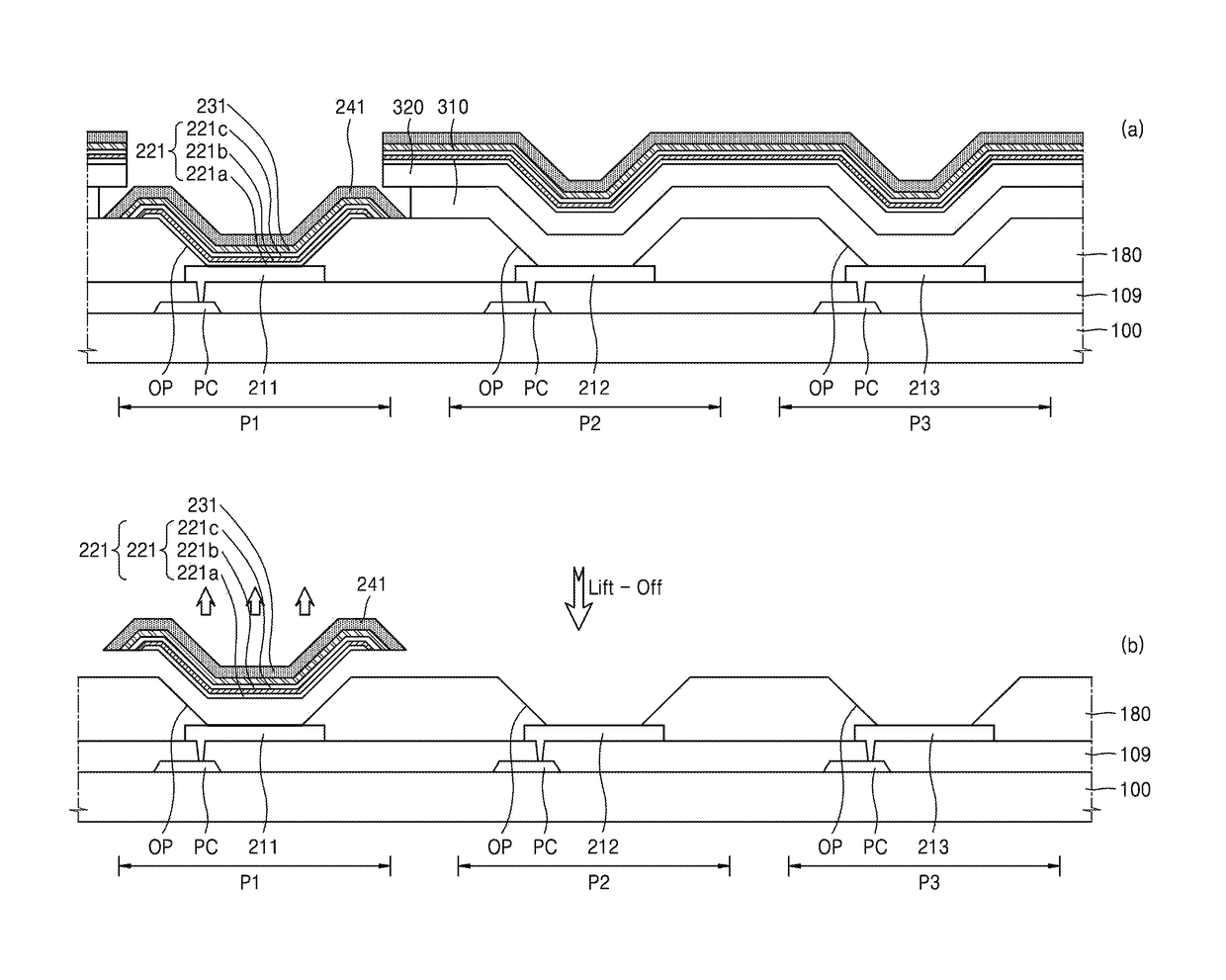

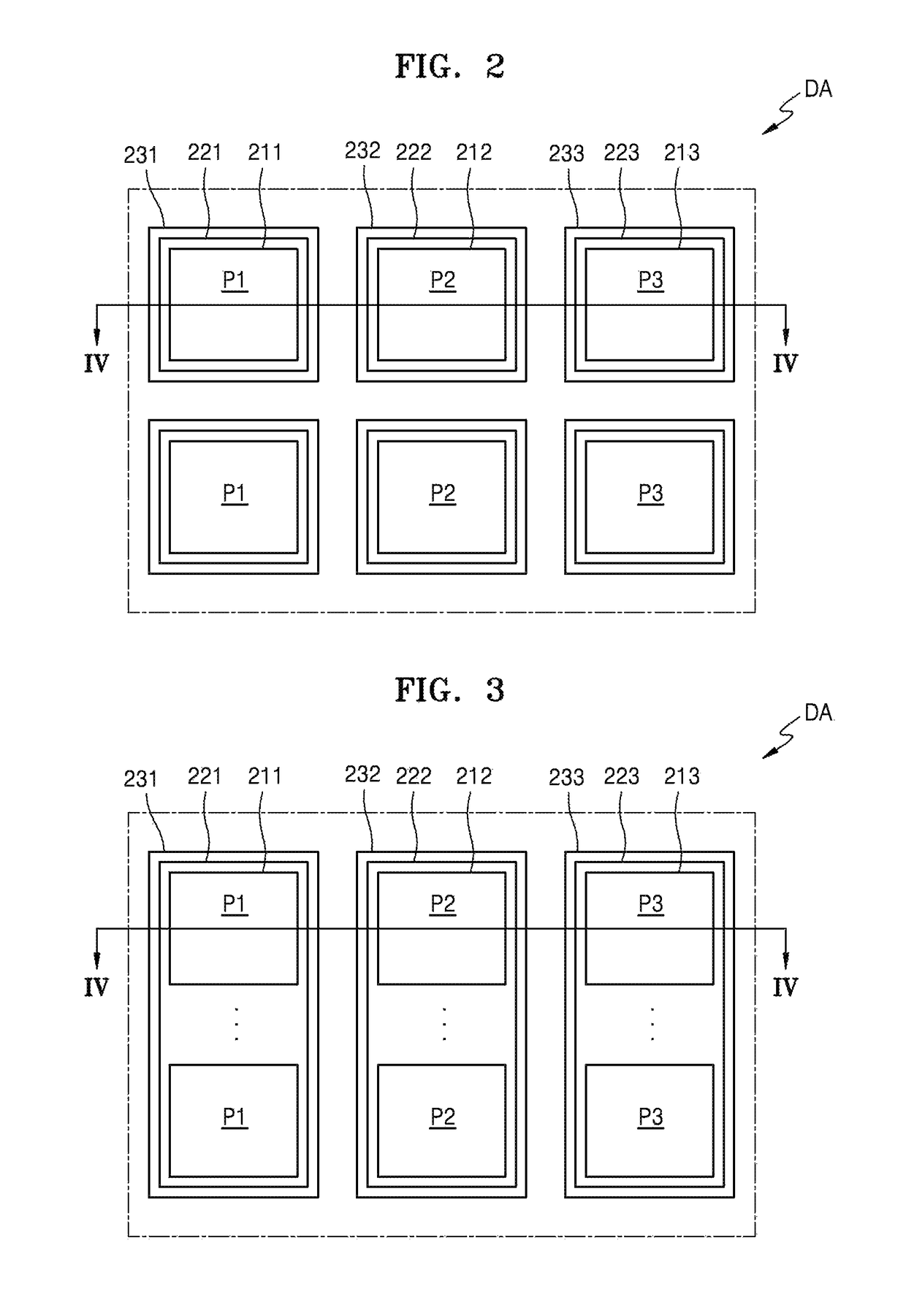

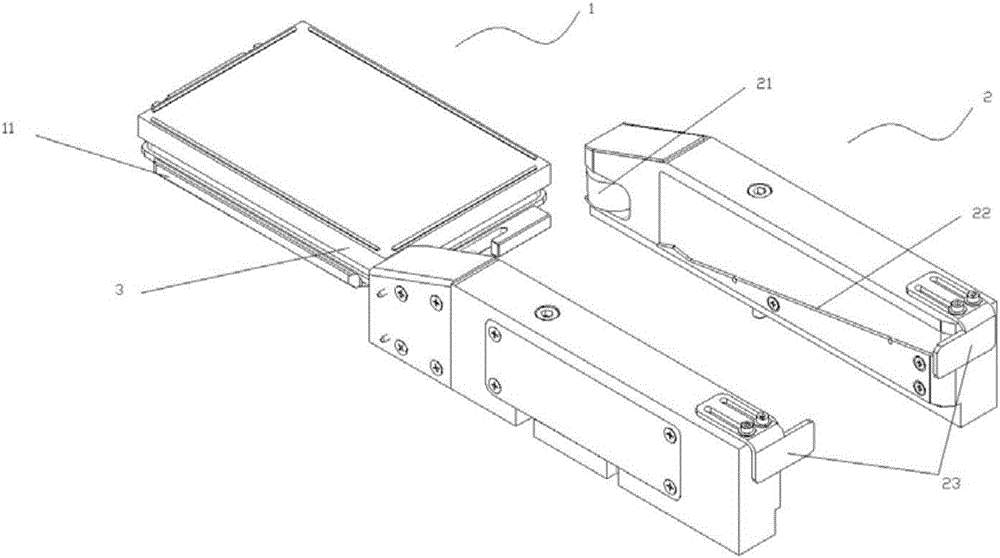

Organic light-emitting display apparatus and method of manufacturing the same

ActiveUS10090484B1Reduce manufacturing costSimple manufacturing processVacuum evaporation coatingSolid-state devicesEngineeringDecapping

A method of manufacturing an organic light-emitting display apparatus includes the step of forming a first pixel electrode and a second pixel electrode on a substrate, forming a pixel-defining film on the first pixel electrode and the second pixel electrode, the pixel-defining film having an opening through which each of the first pixel electrode and the second pixel electrode is exposed, forming a first masking pattern on the pixel-defining film having a first opening portion through which the first pixel electrode is exposed, sequentially forming a first intermediate layer including a first emission layer, a first counter electrode, a first protective layer, and a first anti-decapping layer on the first pixel electrode and the first masking pattern, and removing the first masking pattern along with the first intermediate layer, the first counter electrode, the first protective layer, and the first anti-decapping layer disposed on the first masking pattern.

Owner:SAMSUNG DISPLAY CO LTD

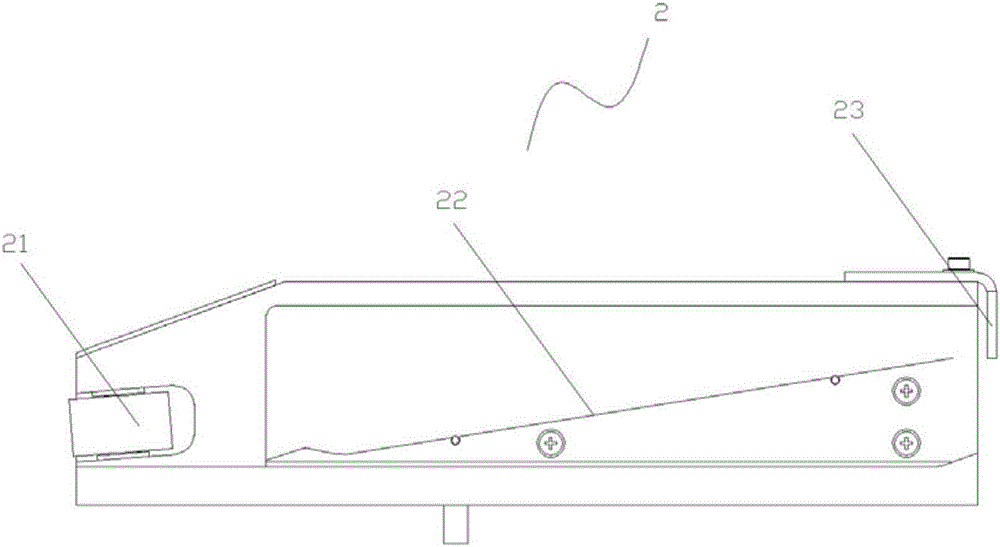

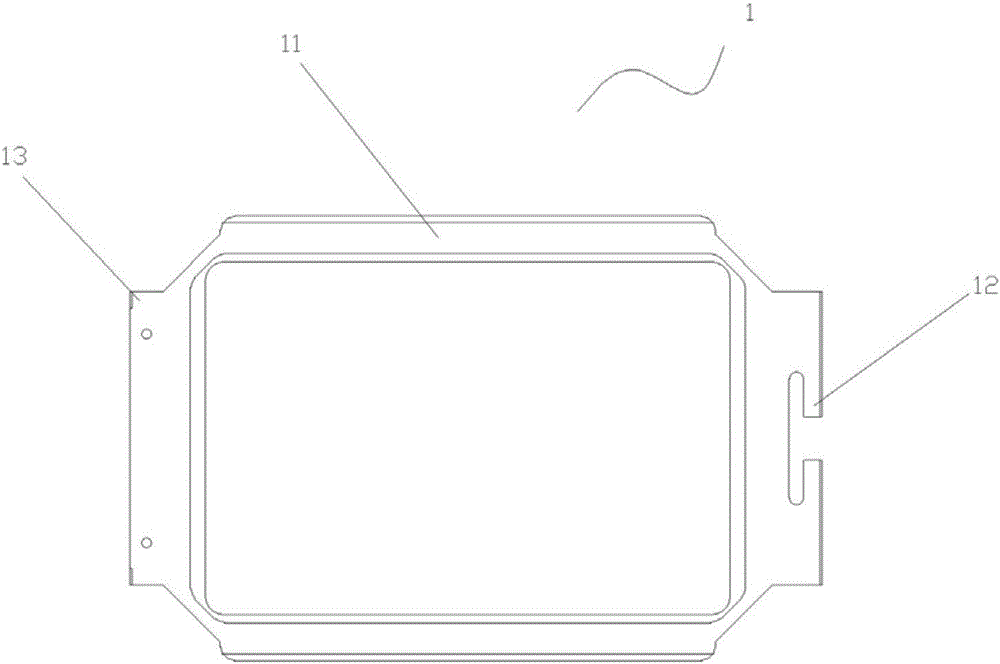

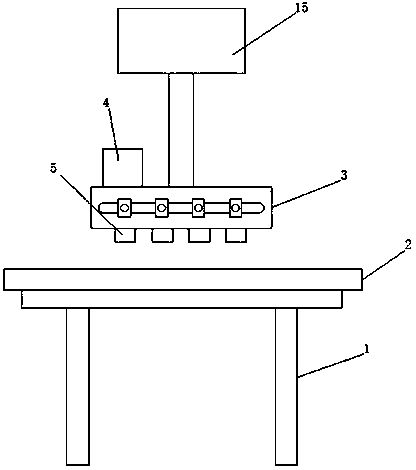

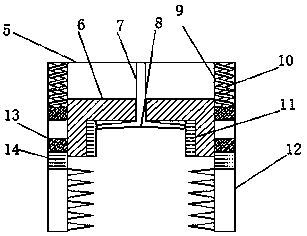

Automatic capping and decapping device

ActiveCN105818091AAchieve stampingRealize uncappingMetal-working hand toolsSterile environmentRelative motion

The invention relates to the technical field of machinery, and particularly discloses an automatic capping and decapping device. The automatic capping and decapping device is used for capping and decapping of a combined cap. The combined cap comprises an upper cap body and a lower cap body. The capping and decapping device comprises a bracket and a matching part. The bracket comprises a bracket body, a pulling part and a stop block. The matching part comprises two opposite pier blocks. The inner side faces of the two pier blocks are each provided with a guiding wheel and an oblique rail. Baffles are arranged on the front end faces of the pier blocks. Through matching of the bracket and the matching part, capping and decapping of the combined cap can be achieved through relative motion of the bracket and the matching part, and the device can be suitable for various laboratory sterile environments and factory small platforms.

Owner:GUANGZHOU INST OF BIOMEDICINE & HEALTH CHINESE ACAD OF SCI

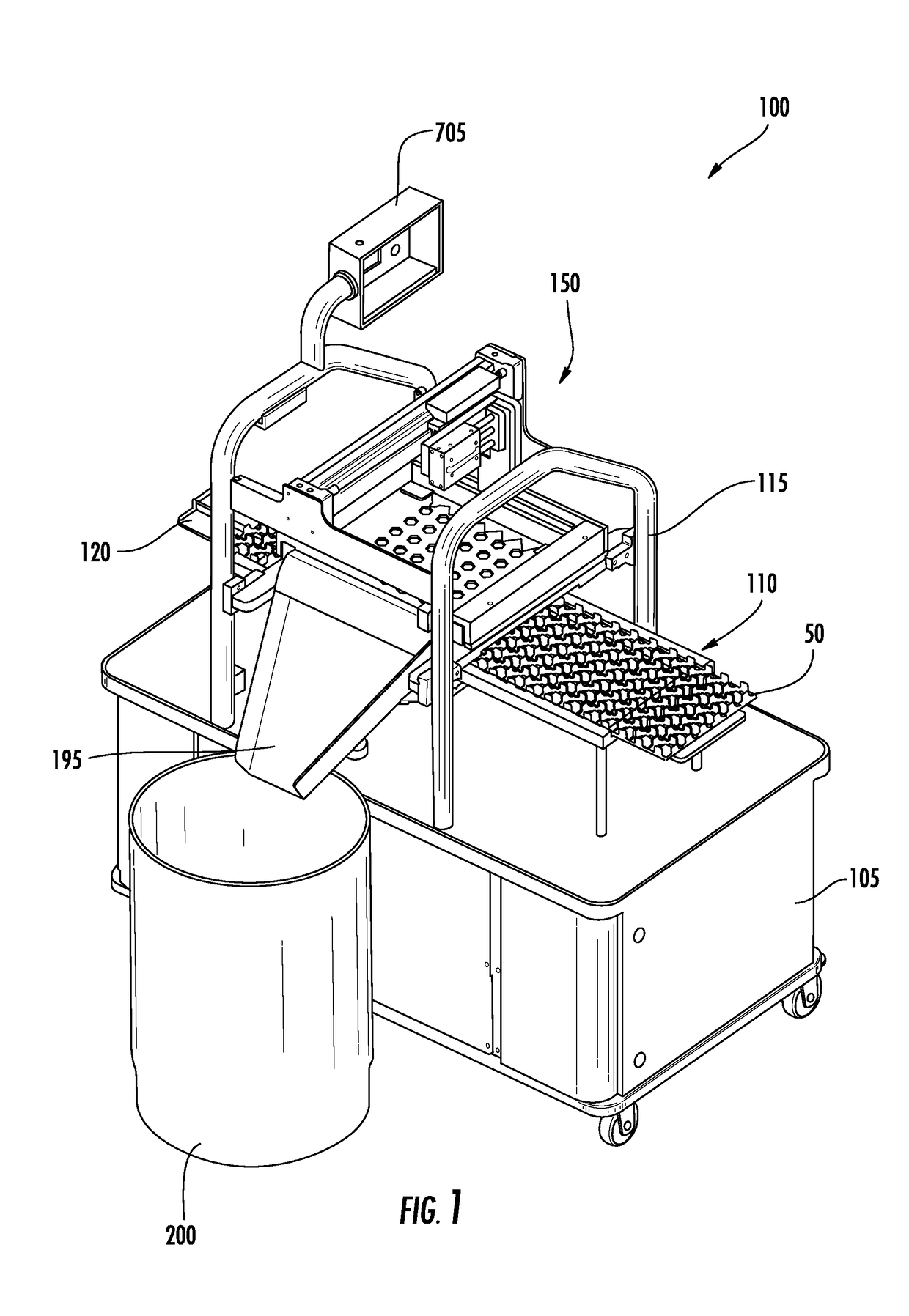

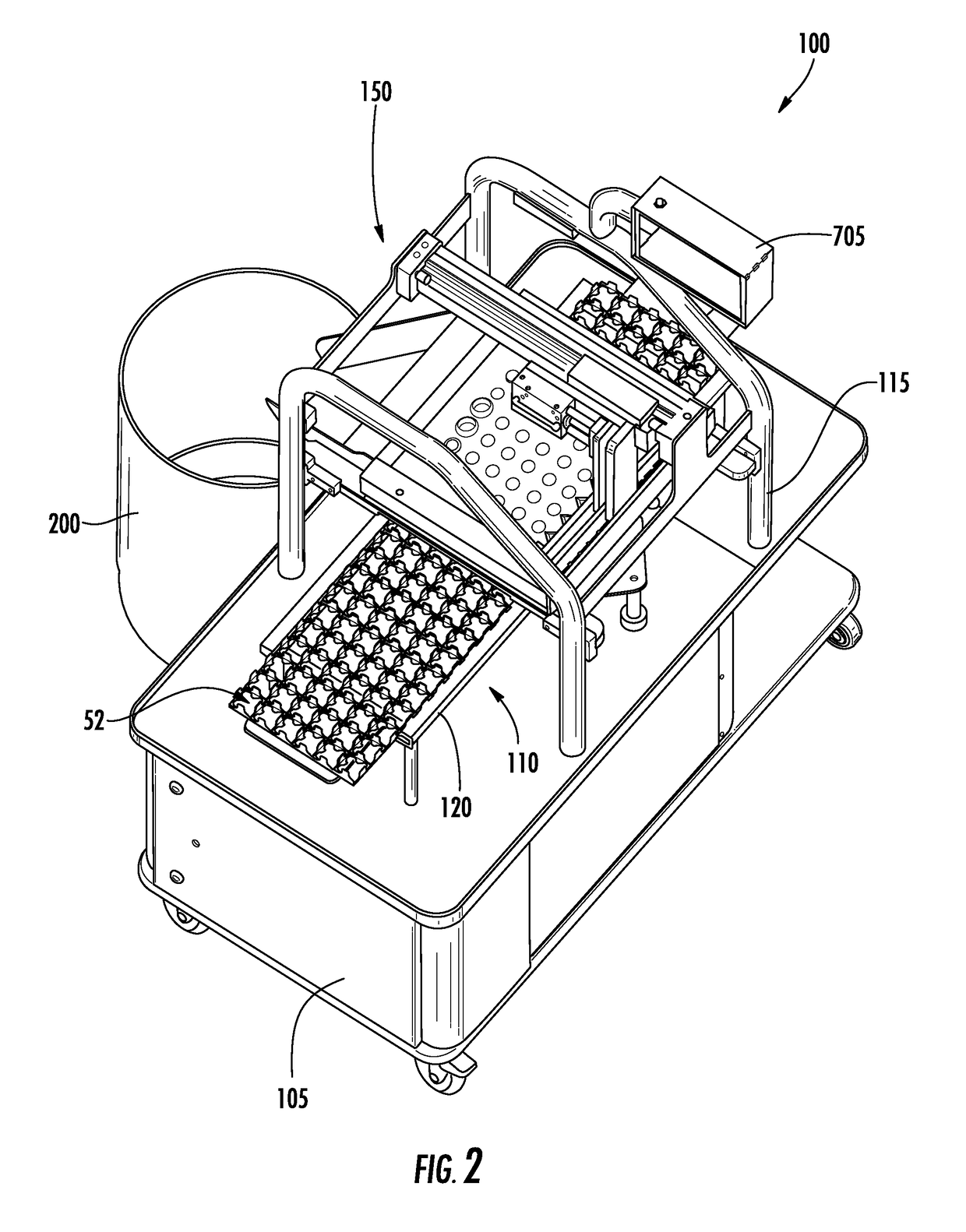

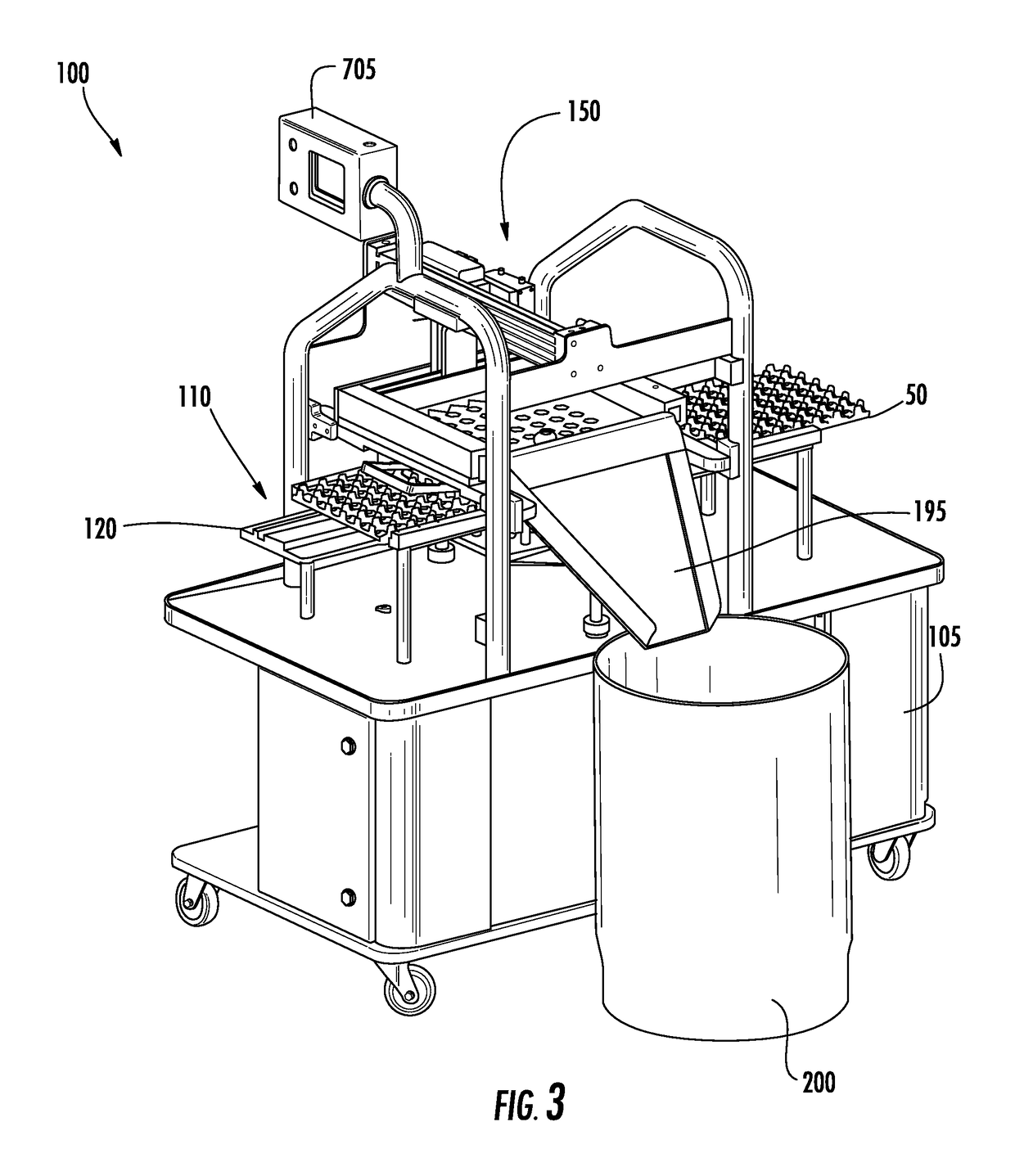

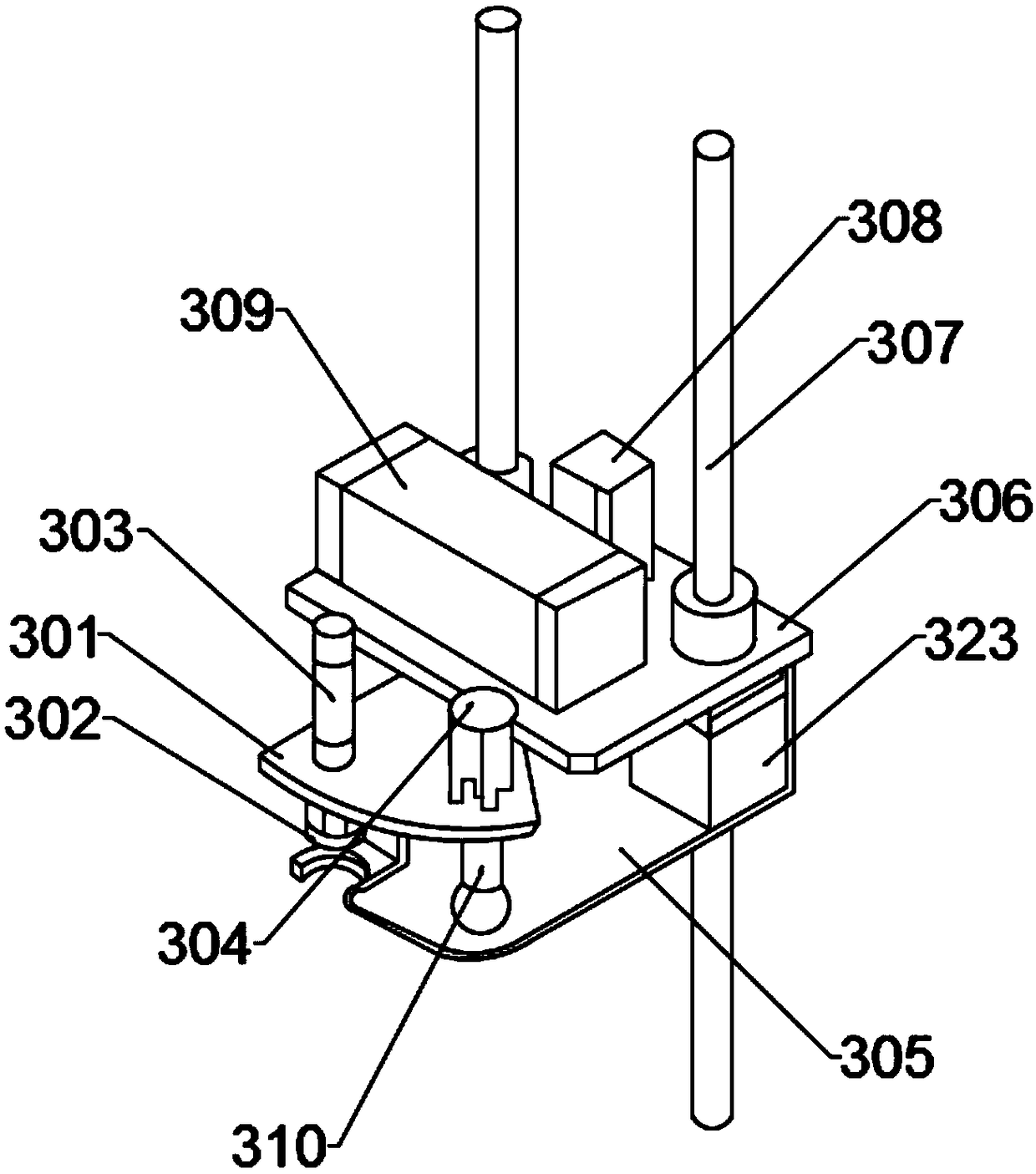

Egg decapping apparatus, and associated method

An egg decapping apparatus is provided. Such an apparatus includes a reference plate defining a plurality of reference openings therethrough. Each reference opening is adapted to receive an avian egg therein from a lower side of the reference plate and to stop further upward movement of the avian egg within the reference opening when an upper egg section to be cut extends from the reference opening above the reference plate. A cutter member is positioned above the reference plate. The cutter member is moveable across the reference plate and the reference openings from a precut position to a post cut position for creating an opening in the upper egg section. A cleaning member is moveable with the cutter member across the reference plate. The cleaning member is actuatable at the post cut position so as to remove debris from the upper egg section accumulated on the cutter member. Associated methods are also provided.

Owner:ZOETIS SERVICE LLC

Dual Barcode Labeling Facilitating Automated Decapping

A specimen collection assembly and method for detecting the same are disclosed. The specimen collection assembly includes a specimen collection container having an open top end, a closed bottom end, and a sidewall extending therebetween defining an interior adapted to receive a biological specimen. The specimen collection container also includes first indicia containing information. The assembly further includes a cap having thereon second indicia, the cap being removably engagable with the open top end of the container. The second indicia contains the same information as the first indicia.

Owner:BECTON DICKINSON & CO

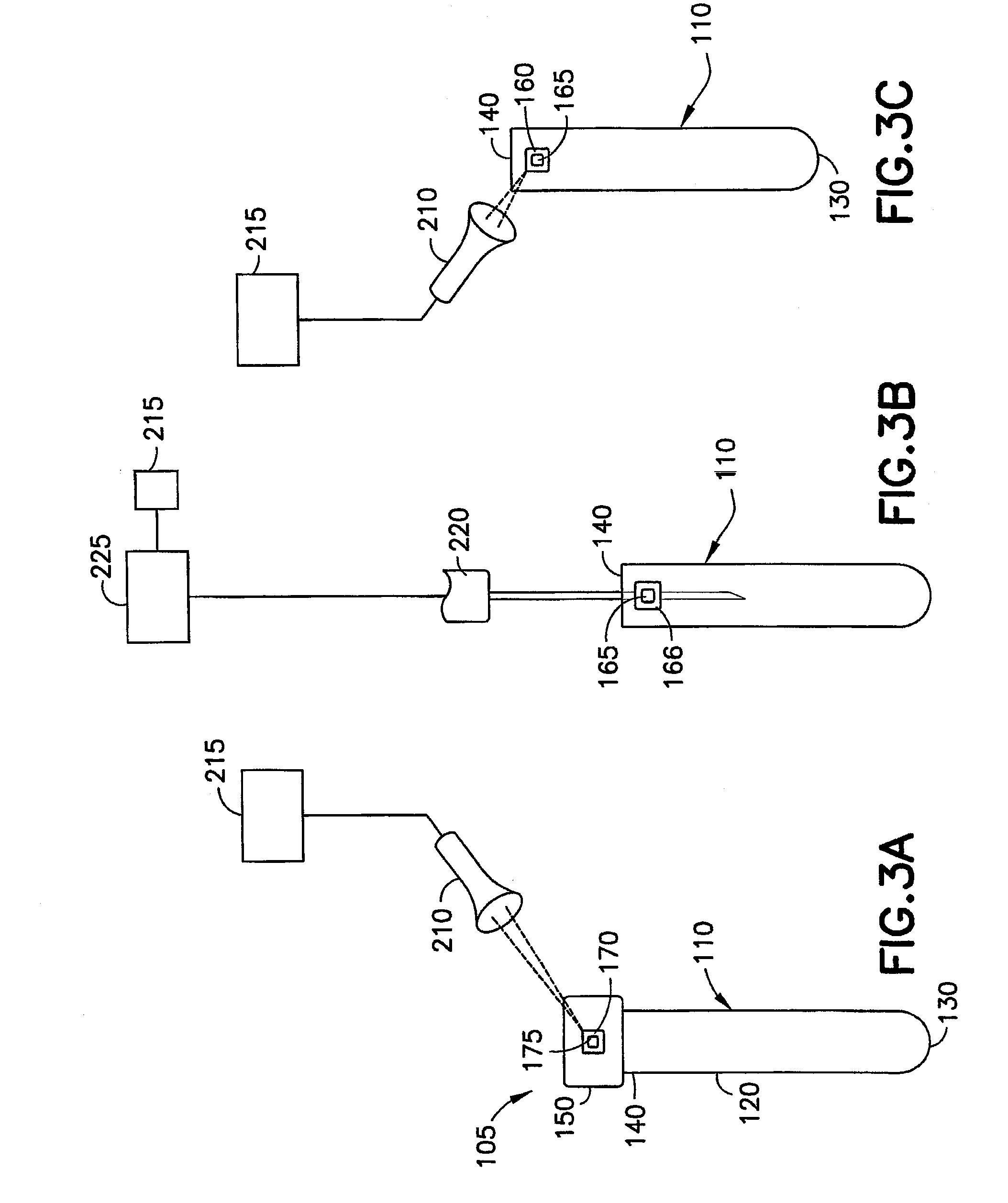

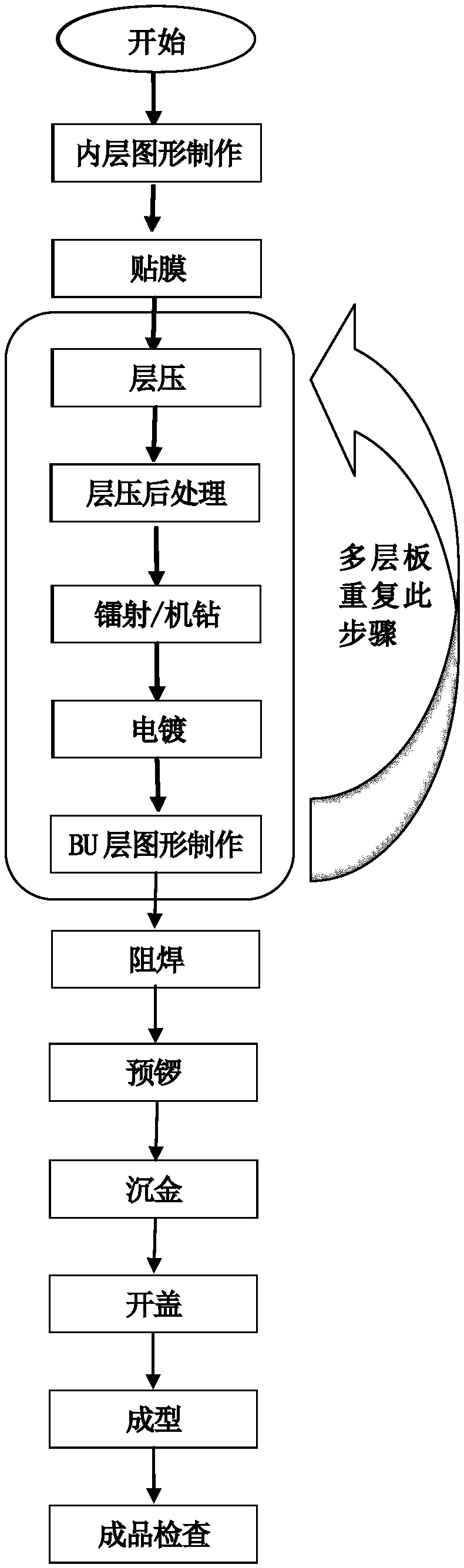

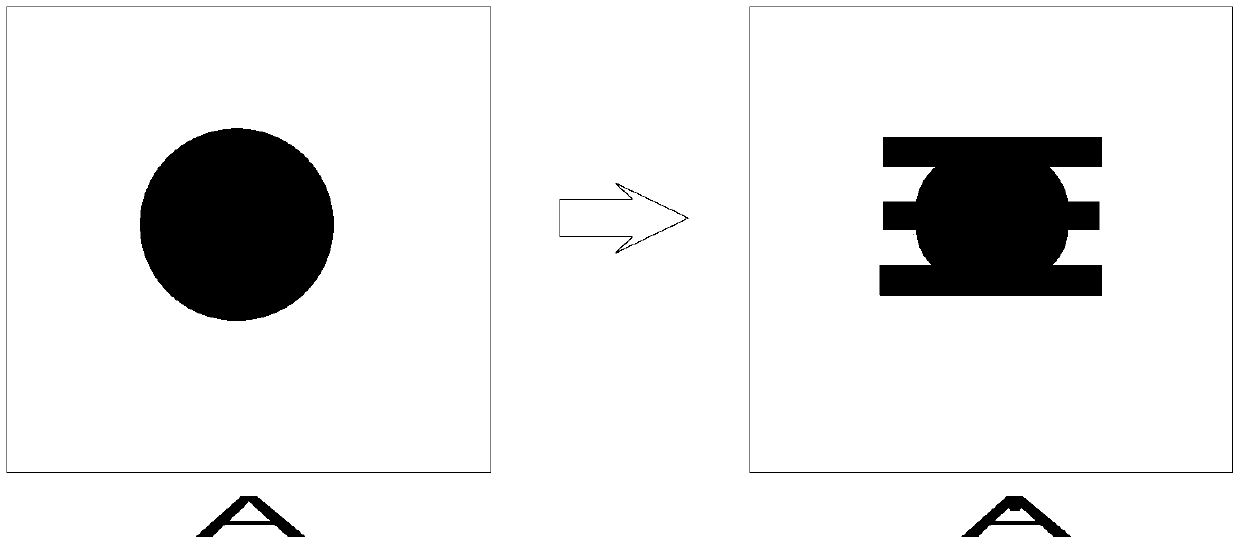

Fool-proofing method for UV laser decapping of PCB

InactiveCN108684147AAvoid damagePrinted circuit manufactureLaser beam welding apparatusEngineeringDecapping

The invention discloses a fool-proofing method for UV laser decapping of a PCB. The method comprises the steps of setting a positioning target, adding a fool-proofing target, adding a cutting position, setting fool-proofing target cutting parameters, grabbing a fool-proofing target and performing cutting stopping and alarming. Through setting the fool-proofing target, in decapping, after all targets are burndown, a laser machine cannot grab the target, and a problem of PCB damage caused by repeated cutting is prevented.

Owner:GUANGZHOU MEADVILLE ELECTRONICS

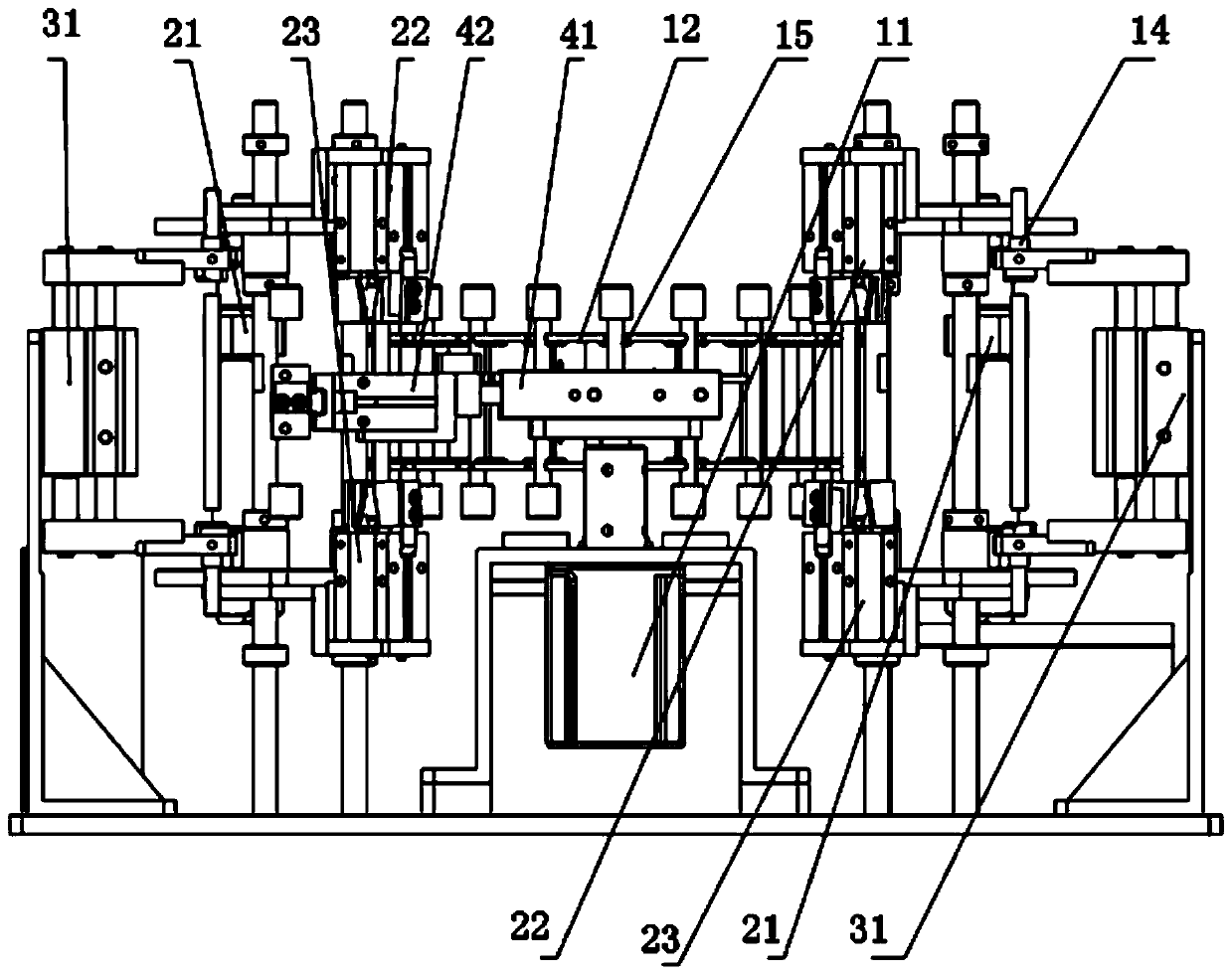

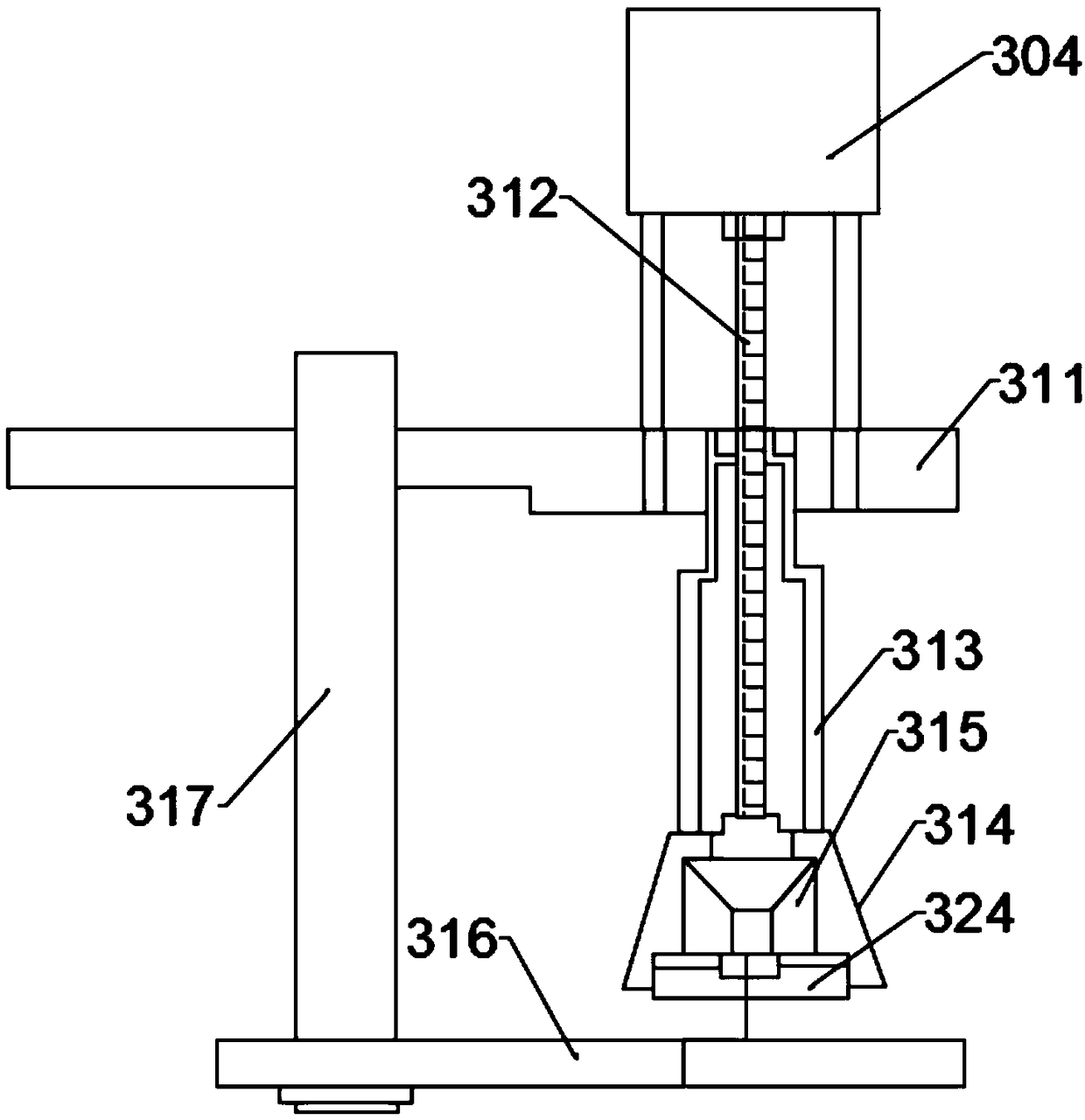

High-efficiency decapping machine

ActiveCN107804813AImprove efficiencyInhibitory activityTight-fitting lid removalThreaded caps removalEngineeringDecapping

The invention discloses a high-efficiency decapping machine. The high-efficiency decapping machine comprises a supporting frame. A conveying table is arranged on the supporting frame. A decapping device is arranged above the conveying table. Four positioning cavities are formed in the decapping device. The positioning cavities movable penetrate through the side face, close to the conveying table,of the decapping device. The four positioning cavities are connected into the decapping device through fixing shafts. The side faces, close to the conveying table, of the positioning cavities are provided with openings. Cleaning brushes are connected with the openings. Each positioning cavity is of a hollow cylindrical structure. According to the high-efficiency decapping machine, by forming the positioning cavities and arranging the cleaning brushes capable of cleaning caps on the outer sides of the positioning cavities, dust on the surfaces of the caps can be removed, then decapping treatment is conducted, the caps are sucked through a suction cup, thus, the caps are prevented from moving, after the caps are completely opened, degassing treatment is conducted, the opened bottle caps canbe collected more completely, and by forming the four positioning cavities, the multiple sets of bottle caps can be opened in one effort, so that the caps are opened more efficiently.

Owner:安徽康乐机械科技有限公司

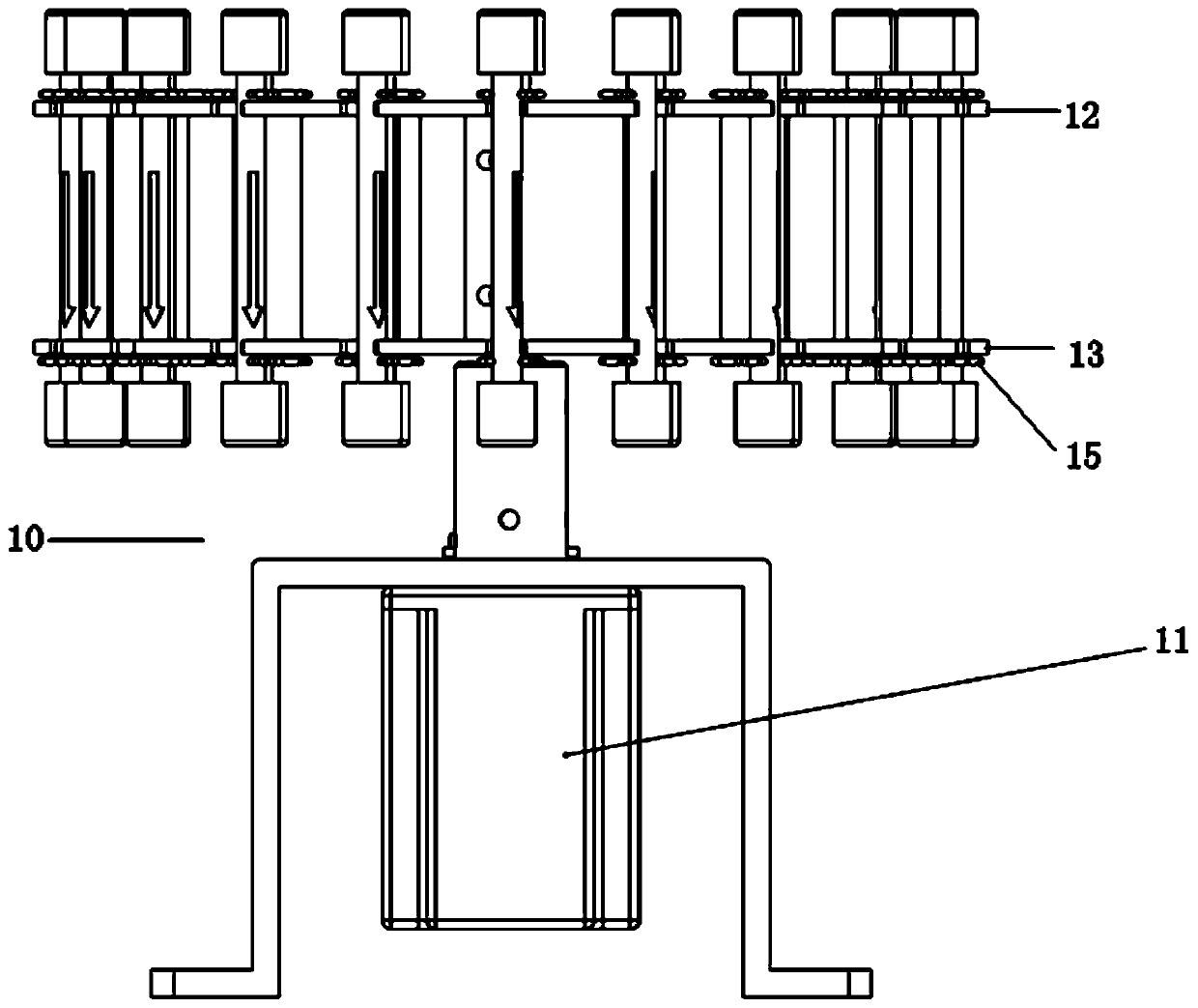

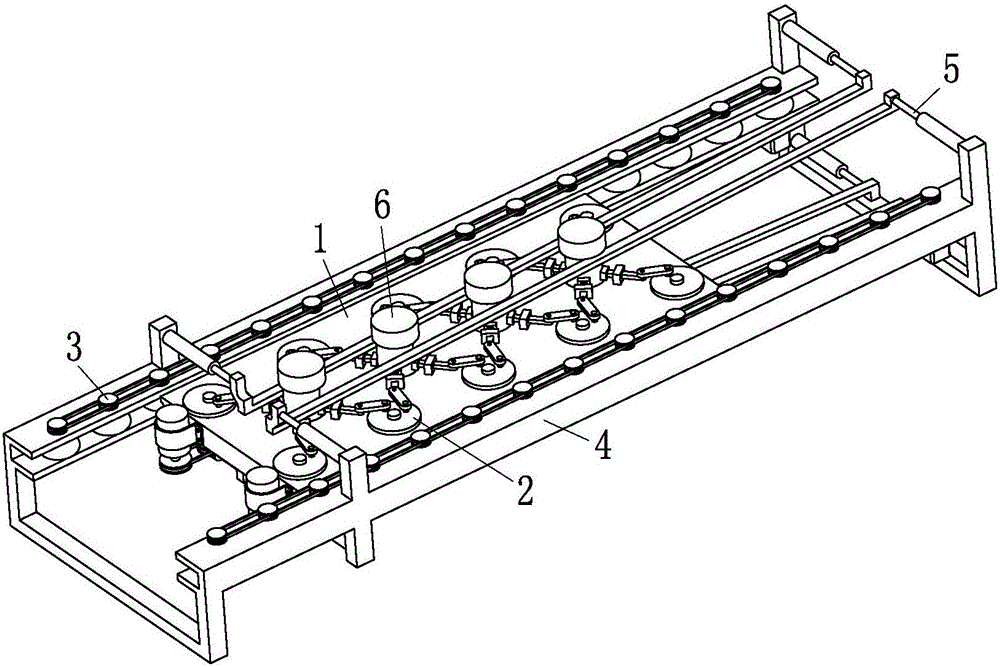

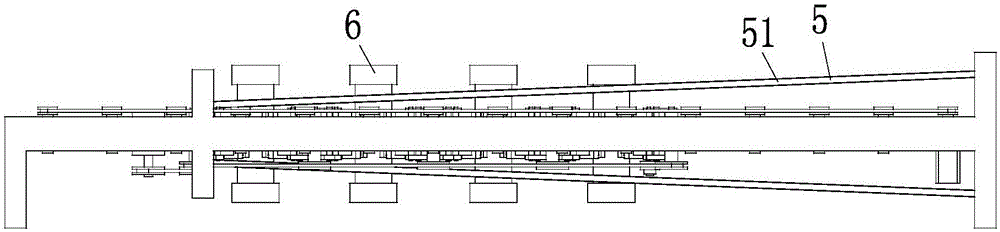

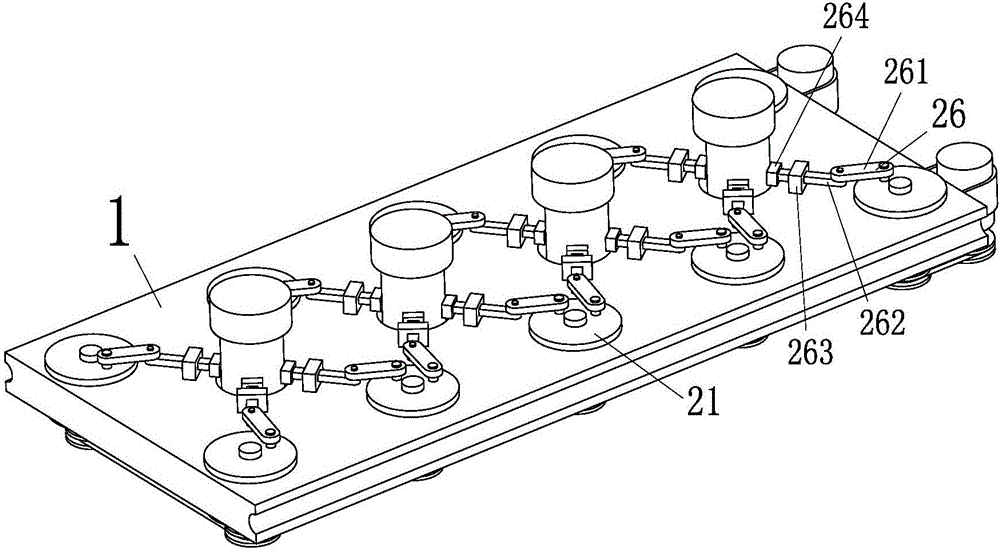

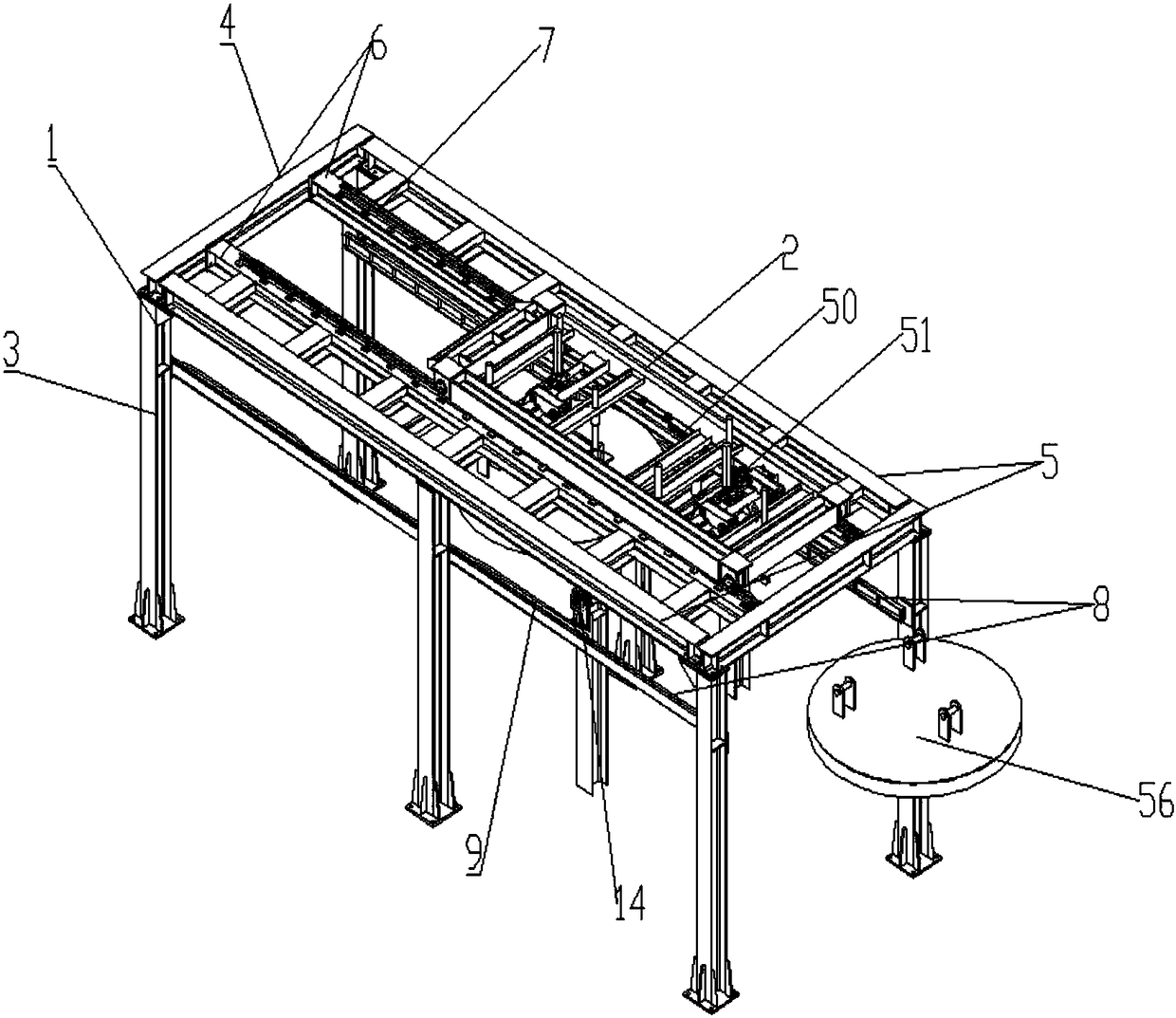

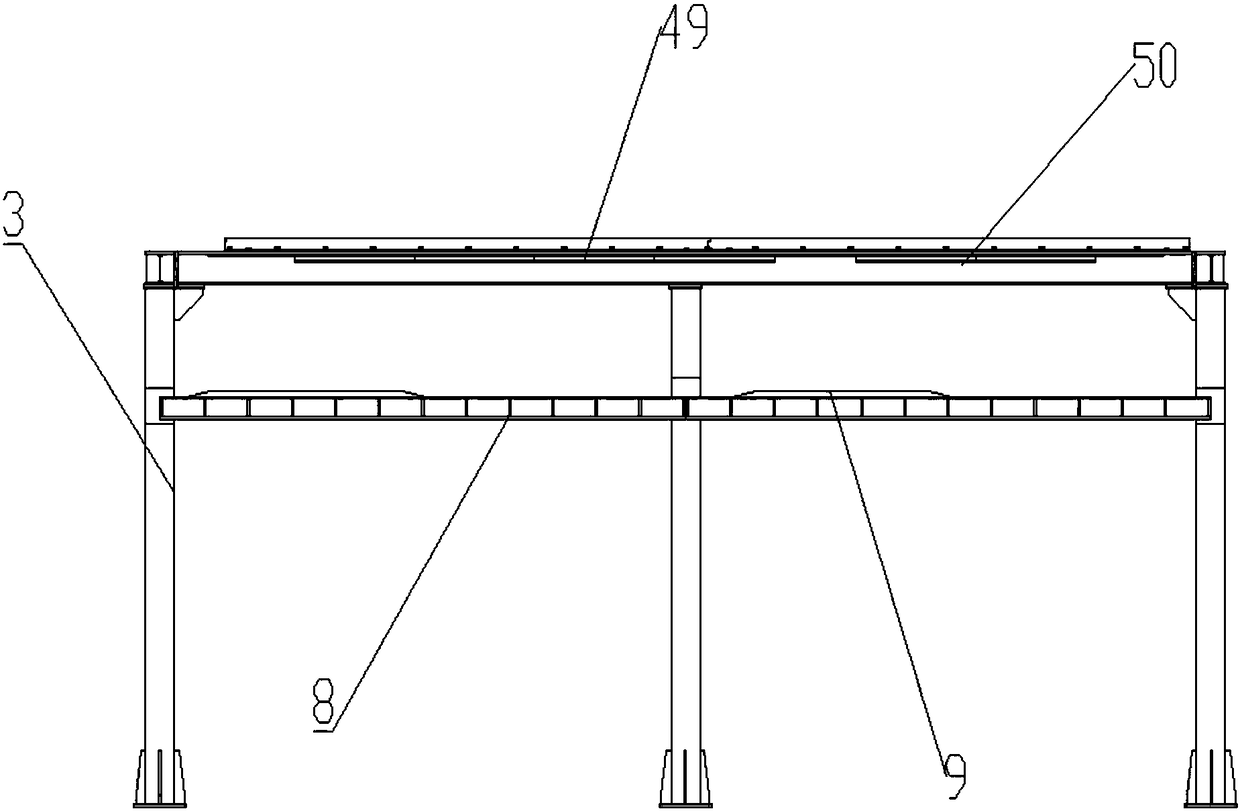

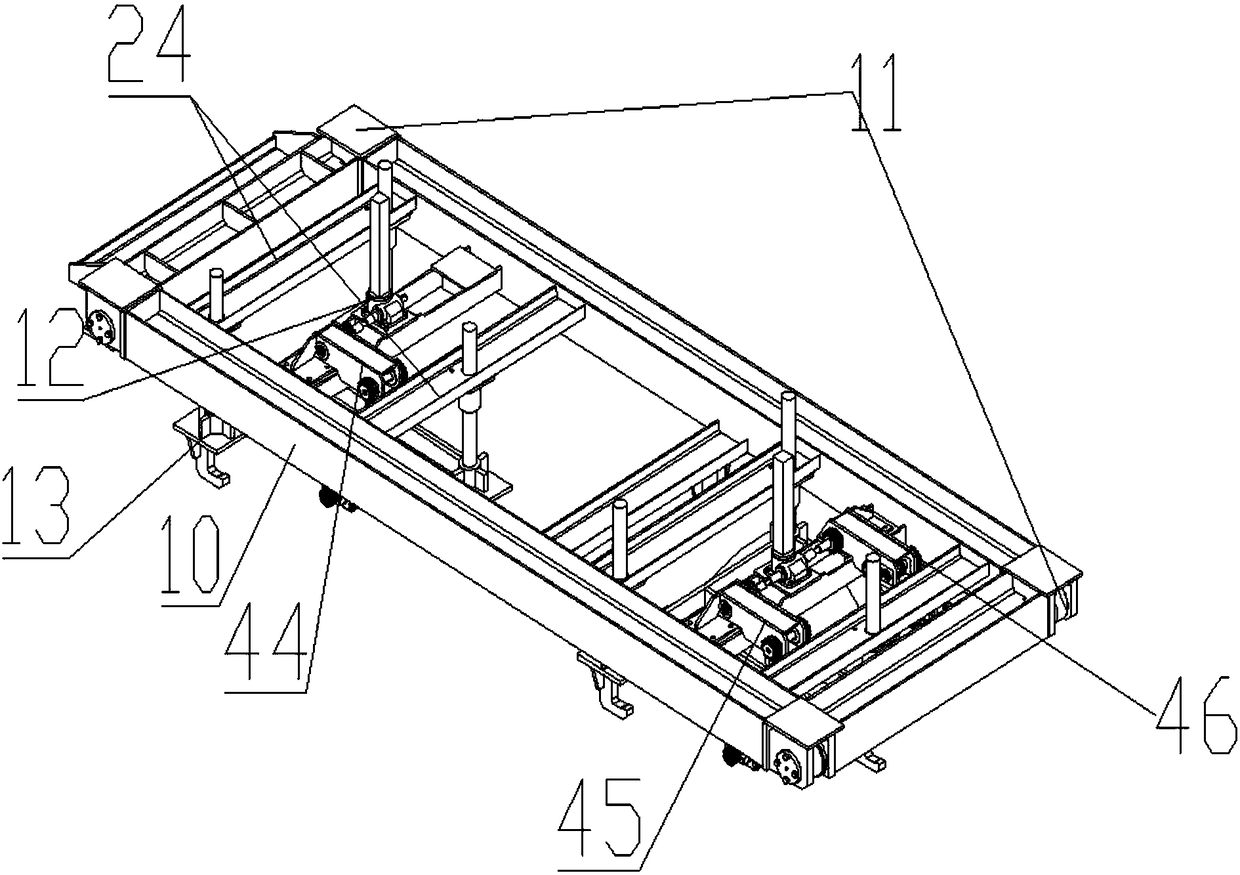

Automatic resistor decapping production line

ActiveCN106816244AAchieving Pipeline OperationsHigh decap efficiencyResistor manufactureProduction lineEngineering

The invention relates to the field of resistors, in particular to an automatic resistor decapping production line. The automatic resistor decapping production line comprises a resistor holding plate, a resistor clamping device, a resistor conveying device and a cap pulling device. The resistor holding plate is uniformly provided with round holes to hold resistors, the resistor clamping device is mounted on the resistor holding plate and used for clamping the resistors different in diameter, the resistor conveying device is used for conveying the resistor holding plate to translate, and the cap pulling device is used for supporting a body of the resistor conveying device and mounted on the body to pull resistor caps at upper and lower ends of the resistors. Conveying chains can be arranged at both left and right ends of the resistor conveying device, the resistor clamping device comprises clamping ends in contact with resistor surfaces, and the cap pulling device comprises two pairs of horizontal cap pulling rods. The automatic resistor decapping production line can be used with external conveying chains to realize automatic resistor decapping operations, and high decapping efficiency is realized; in addition, automatic decapping of the resistors difference in diameter is realized, and structural simplicity, wide application range and high practicality are realized.

Owner:山东润蒙应急救援装备有限公司

Filling mechanism of tea filling machine

InactiveCN109178374ASolve the problem of lax valve closingSolve the problem of pinched tea leavesSolid materialForeign matterSurface type

Owner:芜湖市春满壶茶业有限公司

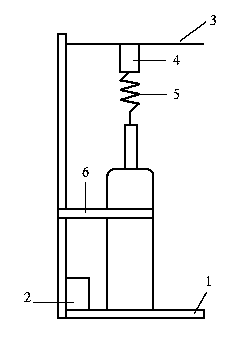

Steel ladle decapping system

The invention discloses a steel ladle decapping system, and belongs to steel ladle decapping systems suitable for steel ladle vehicle decapping in the field of steelmaking operation equipment, and aims at providing an unpowered decapping device. According to the technical scheme, the device comprises a portal frame and a lifting truck arranged at the upper end of the portal frame, the portal framecomprises a beam and a track beam connected with the beam, the lower end of the track beam is provided with a driving rack, the lower end of a track is provided with a driving track bracket, and theupper end of the driving track bracket is connected with a driving track; the lifting truck comprises a worm and gear spiral lifting device, and the lower end of the worm and gear spiral lifting device is connected with a ladle cover lifting hook; and the lifting truck is provided with a truck driving device. The invention provides a steel ladle decapping device with an automatic decapping function, the steel ladle decapping device drives the lifting truck to remove a steel ladle cover by adopting the conversion of the driving force of a molten steel vehicle, thereby greatly reducing the floorspace and energy consumption of equipment of steel works.

Owner:德阳峰瑞机械科技有限责任公司

Vacuum blood collection tube cap removal device

InactiveCN104692307BQuick connectionTight-fitting lid removalThreaded caps removalBlood Collection TubeDecapping

The invention discloses a decapping device for a vacuum blood collection tube. The decapping device comprises a rack, a group of gears, a group of end-surface helical disks, pressure heads, a test tube rack and a decapping power component, wherein the test tube rack is provided with at least one row of vacuum blood collection tube positioning units, the number of each column of vacuum blood collection tube positioning units is the same as that of the gears, a non-return part is formed in each vacuum blood collection tube positioning unit after the vacuum blood collection tube is inserted; the decapping power component is connected with the test tube rack and drives the test tube rack to move up and down. With the adoption of the decapping device, decapping can be realized safely, reliably and quickly through reduction of the decapping force.

Owner:QIANFOSHAN HOSPITAL OF SHANDONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com