Device and method capable of conducting whole-process capping and decapping on steel ladle

A technology of adding cover and ladle, which is applied in the direction of metal processing equipment, casting molten material container, casting equipment, etc., can solve the troubles of design technicians and steel factory technicians, high requirements on the space size of the production site, and gear-shaped structure Problems such as equipment production stoppage, to achieve the effect of good promotion and use value, compact structure, and elimination of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

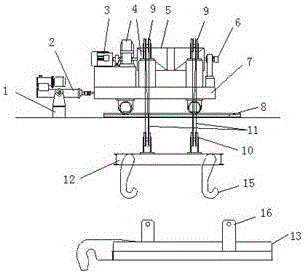

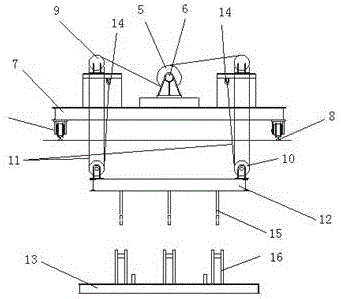

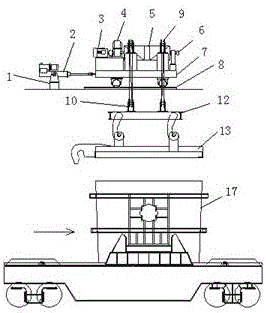

[0023] The invention provides a device and method for uncapping a steel ladle. Using the device and method, the ladle can be smoothly uncapped during transportation, thereby reducing the temperature drop of the molten steel process and lowering the tapping temperature of the converter.

[0024] The ladle adding and uncovering device of the present invention consists of a bracket 1, an electro-hydraulic push rod 2, a motor 3, a reducer 4, a reel 5, a limiter 6, a moving trolley 7, a track 8, a fixed pulley block 9, a movable pulley block 10, and a steel wire rope. 11, hanger 12, wire rope fixing point 14, suspension hook 15 are formed.

[0025] figure 1 , 2 It shows that the lower end of the bracket 1 is welded and fixed to the embedded plate on the upper platform of the workshop, the body of the electro-hydraulic push rod 2 is connected with the bracket 1, and the front joint of the electro-hydraulic push rod 2 is connected with the mobile trolley 7.

[0026] figure 1 , 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com