Oil shale dry distillation system

A technology of oil shale and dry distillation, which is applied in special forms of dry distillation, direct heating dry distillation, petroleum industry, etc., can solve the problems of reducing the dust content of dry distillation gas, reducing operating costs, etc., and achieves low operating cost, improved utilization rate, and technical performance reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

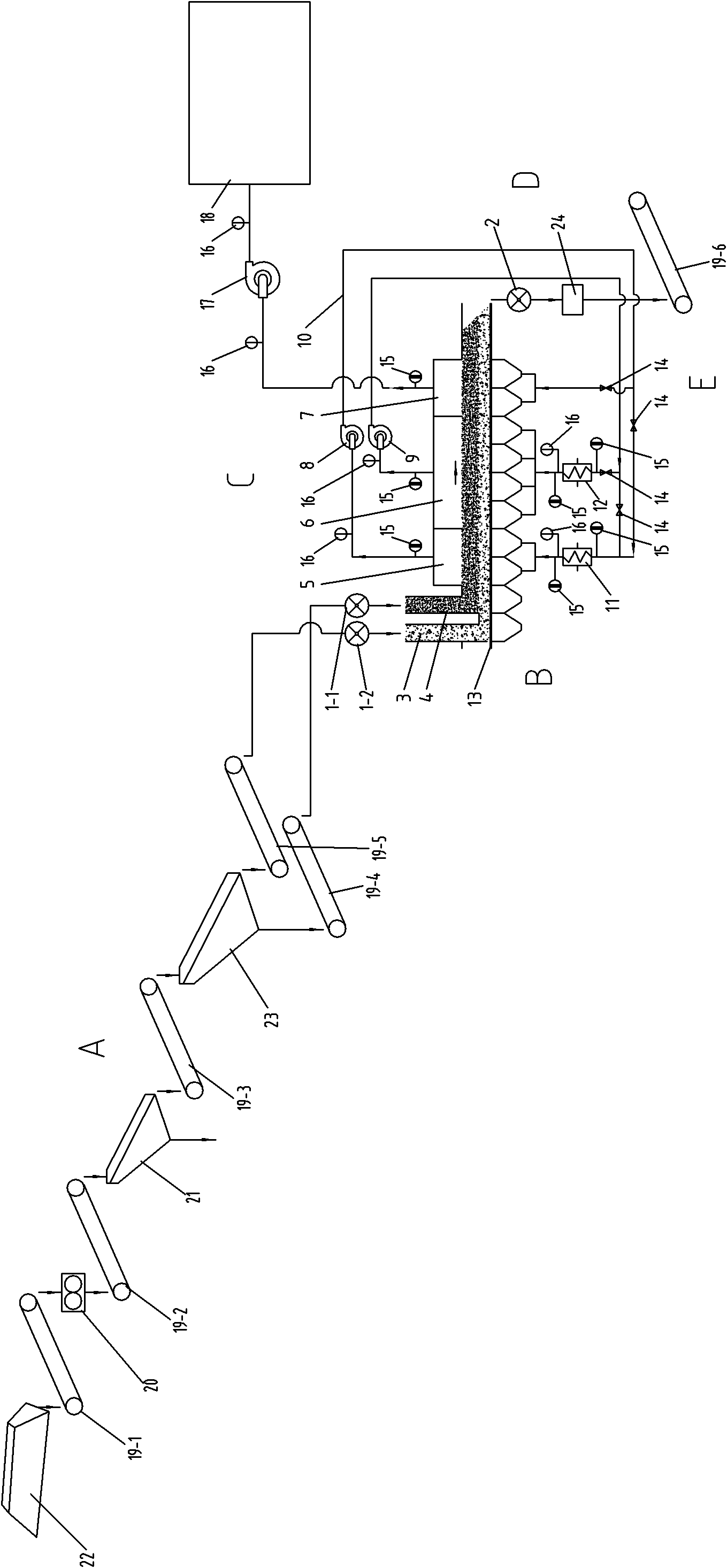

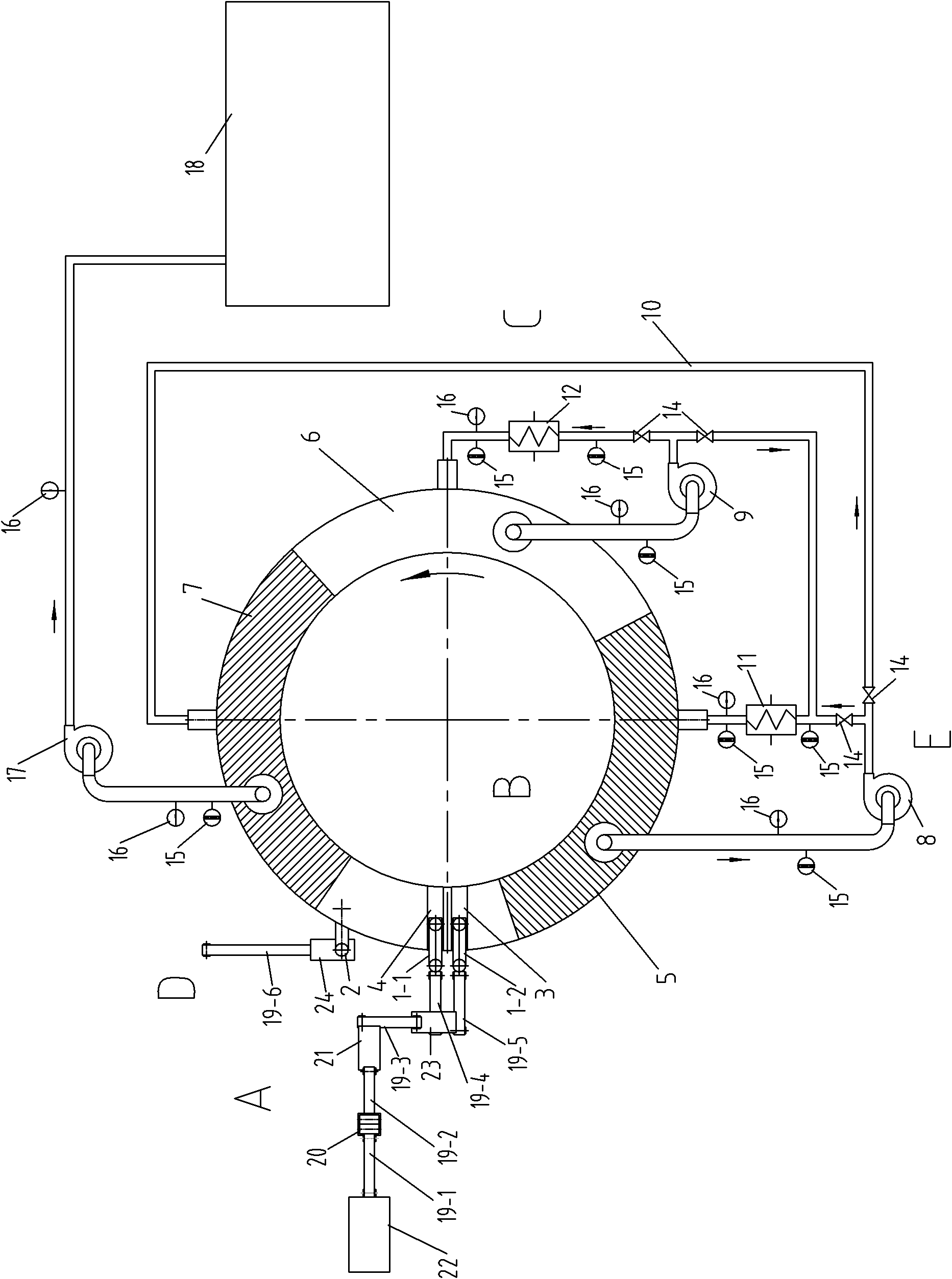

[0032] refer to figure 1 , figure 2 As shown, an oil shale retort system mainly includes a distributing system A, a reaction furnace B, a retort gas circulation system C, a cooling system D, a control system E and related conveying and output pipelines, related control circuits, etc.; its distributing system A The reaction furnace B is connected to the reaction furnace B through the relevant delivery and output pipelines, and the reaction furnace B is connected to the retort gas circulation system C through the control system E and the relevant delivery and output pipelines. Oil shale retort system for shale crushing, screening, furnace loading, heating, collection of shale retort gas, cooling and collection of shale semi-coke.

[0033]The material distribution system A mainly includes a sealed feeder 1, a large-size oil shale feed bin 3 for the reaction furnace, a small-size oil shale feed bin 4 for the reaction furnace, a conveyor belt conveyor 19, and a crusher 20 , vibr...

Embodiment 2

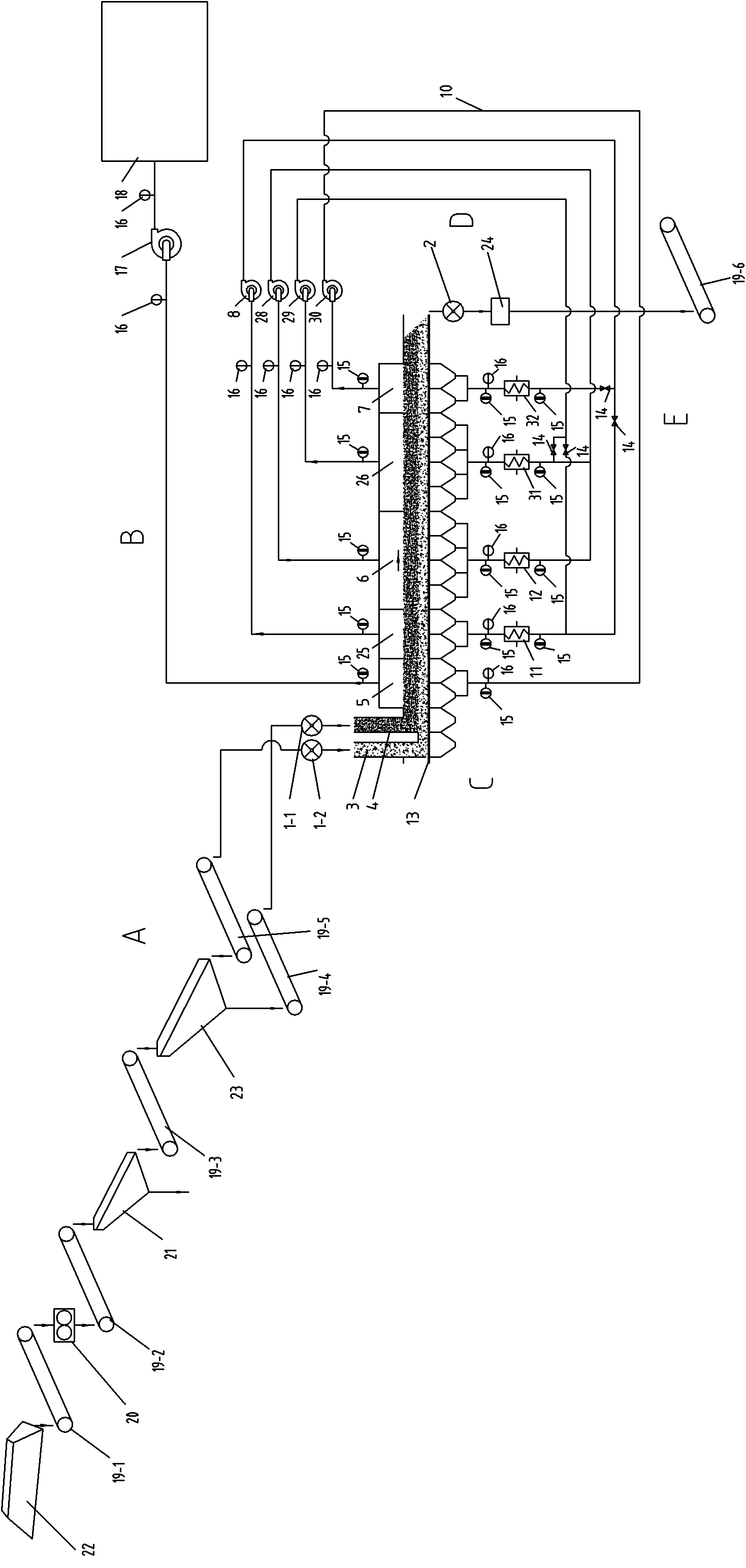

[0040] refer to image 3 , Figure 4 As shown, the reaction furnace B mainly includes a heating section 5, a heating section 25, a reaction section 6, a reaction section 26, and a cooling section 7. The retort gas circulation system C also includes a retort gas circulation fan 28 in the reaction section. , 29, and the retort gas circulation fan 30 in the cooling section, the retort gas heater 31 in the reaction section, the retort gas heater 32 in the cooling section, etc.; the retort gas circulation fan 8 in the heating section is connected to the retort gas heater in the heating section through the retort gas circulation pipeline 10 11. The second heating section 25 and the retort gas heater 32 and cooling section 7 in the cooling section; the retort gas circulation fan 28 in the reaction section is connected to the reaction section heater 12 and the reaction section 6 through the retort gas circulation pipeline 10, and is connected to the reaction section retort gas heating...

Embodiment 3

[0043] refer to Figure 5 , Figure 6 As shown, the reaction furnace B mainly includes a heating section 5, a heating section 25, a reaction section 6, a reaction section 26, a cooling section 7, and a cooling section 27. The retort gas circulation system C includes a heating section Retort gas circulation fan 8, retort gas circulation fan 28, 29 in the reaction section, retort gas circulation fan 30, fan 17 in the cooling section, retort gas heater 31 in the reaction section, retort gas heater 32 in the cooling section, condensate collection device 33, etc. The retort gas circulation fan 8 in the heating section is connected to the heating section 5, the condensate collecting device 33, and the second cooling section 27 through the retort gas circulation pipeline 10; The gas heater 11 and the second section of heating 25 are connected to the retort gas heater 32 of the cooling section and the first section of cooling 7; The dry distillation gas heater 31 in the reaction sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com