Drying oven

A technology of drying furnace and drying chamber, which is applied in the directions of drying, drying machine, drying gas arrangement, etc., and can solve the problem of high energy consumption of drying furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

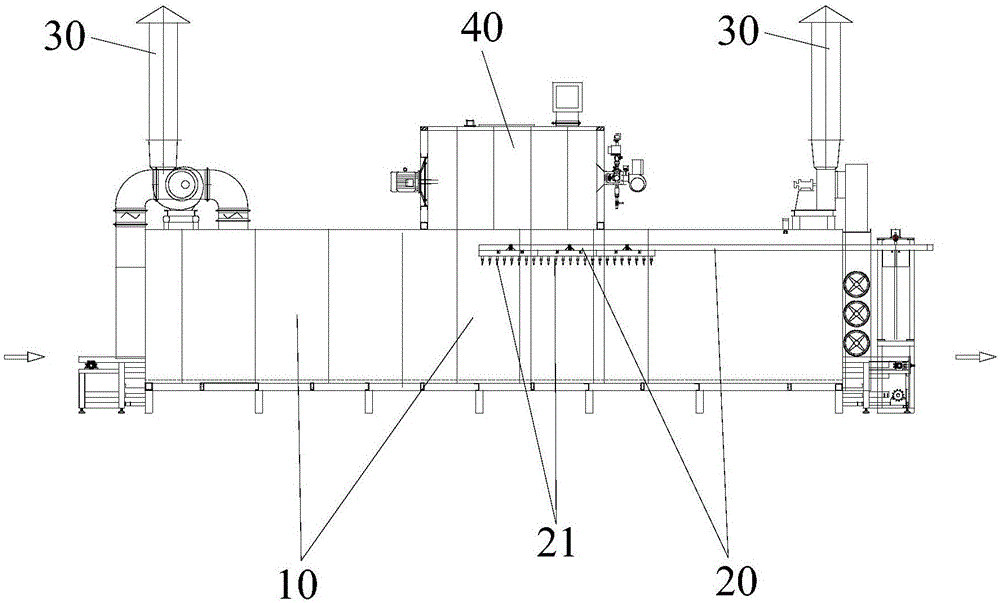

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0016] The drying furnace of the prior art is explained by theoretical analysis and experimental data: the volatile lubricating oil remaining after the air conditioner is mainly left in the inner wall of the fins and copper tubes, the lubricating oil on the fins is easy to volatilize, and the drying The circulating fan in the drying furnace drives the air flow, so the volatilization of the fin drying requires only a small amount of heat energy. The copper tube is a long U-shaped semi-closed structure, and the residual volatile oil therein is difficult to remove.

[0017] According to the above situation, according to an embodiment of the present invention, a drying furnace is provided for drying and degreasing air conditioner components, the air conditioner components include fins and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com