Teapot nodulizing packet

A teapot and spheroidizing chamber technology, which is applied in casting molten material containers, metal processing equipment, casting equipment, etc., can solve problems such as inconvenient use, large contact area, and rapid temperature drop of molten iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing.

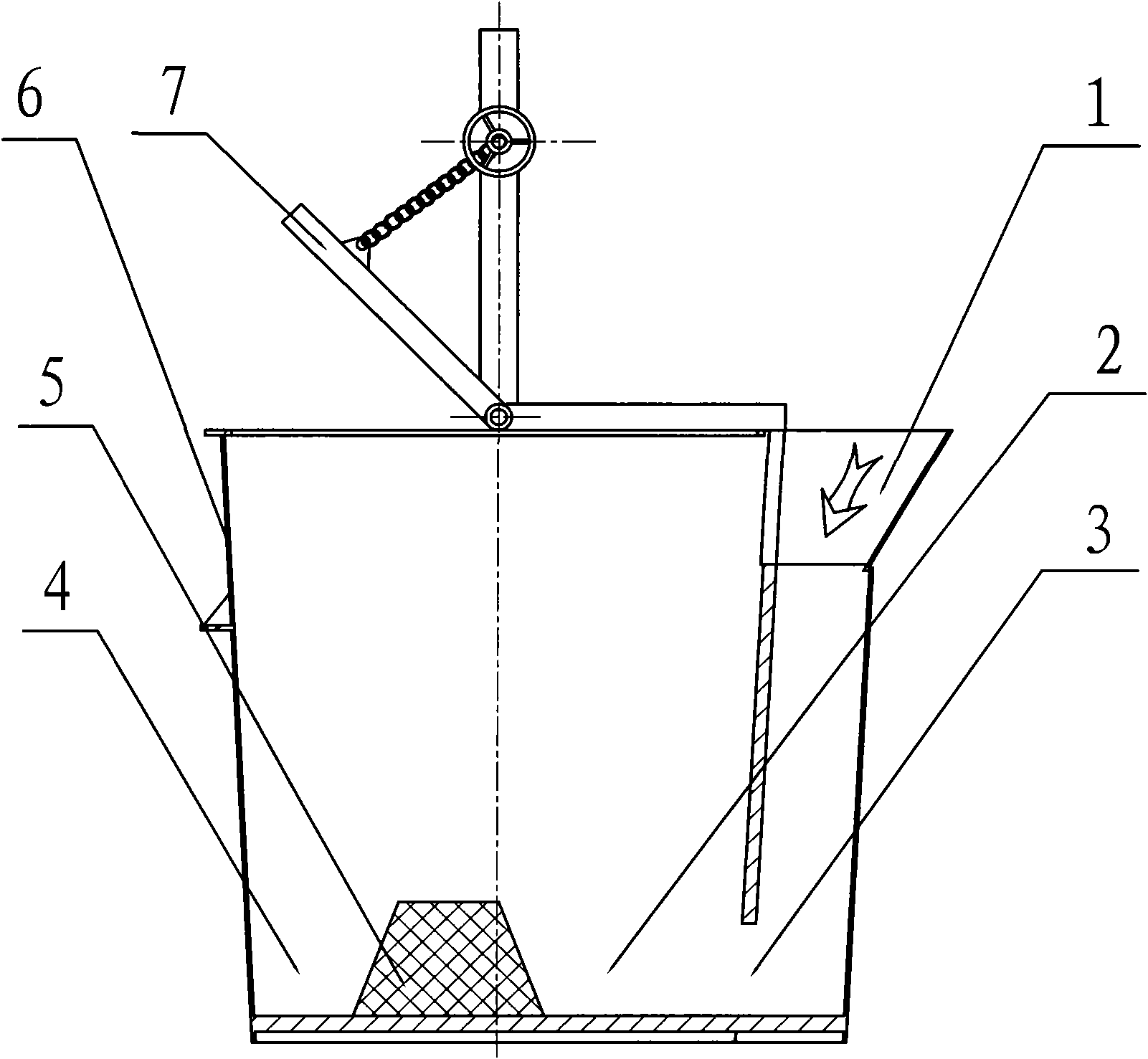

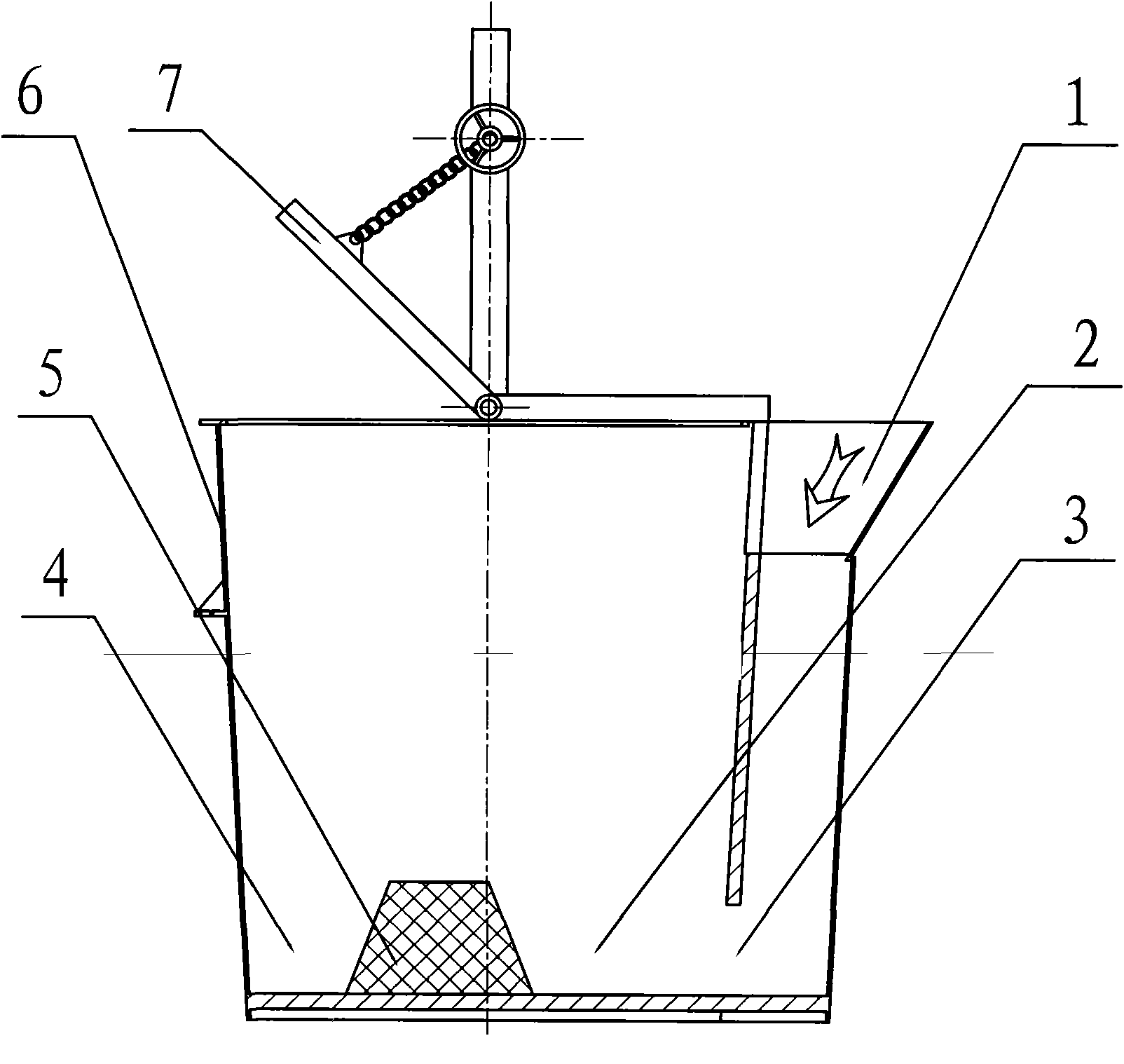

[0012] Depend on figure 1 It can be known that a teapot-type spheroidizing bag includes a bag body 6, the bottom of the bag body 6 is provided with a dam 5, and the bottom of the bag body 6 is divided into a feeding chamber 2 and a spheroidizing chamber 4, and the top of the bag body 6 is provided with a dam 5. There is a single sealing side cover 7, one side of the package body 6 is provided with a spout 1, and the lower part of the package body 6 is provided with a molten iron inlet and outlet 3 connected to the spout 1, and the feeding chamber 2 is connected to the spout through the molten iron inlet and outlet 3. 1 connected.

[0013] The kettle spout 1 of the present invention is a funnel tube type kettle spout, and the diameter of its molten iron inlet and outlet channel is 100mm-120mm (120mm in this embodiment).

[0014] The height of the embankment 5 of the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com