Vacuum thermal creep type forming method of titanium alloy skin and titanium alloy skin

A technology of titanium alloy and vacuum heating, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems that cannot meet the brazing requirements of titanium alloy honeycomb wallboard, the performance of the base material is reduced, and the precision of the shape is low. Meet structural brazing requirements, small residual stress, and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0028] A vacuum thermal creep forming method of a titanium alloy skin of the present invention comprises the following steps,

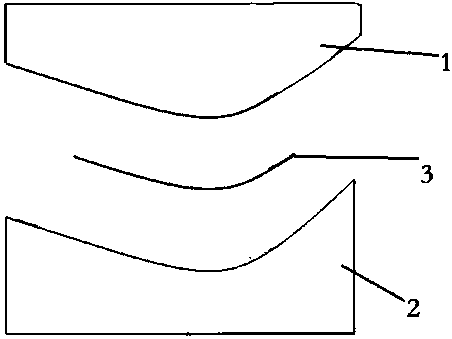

[0029] 1) Clamp and position the titanium alloy skin to be formed, such as TC4, TC1, TA18 or TA15, with a thickness of 0.5-2.0mm, between the matching upper and lower molds; figure 1 As shown, at the same time, a solder resist is provided on the surfaces of the upper mold and the lower mold, and the particle size of the solder resist is not greater than 19 μm, such as 13 μm. The solder resist is mainly to prevent the skin from sticking to the mold during the forming process. The solder resist is generally in the form of powder or paste, without volatile gas,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com