Crystallizer

A crystallizer and water outlet technology, which is applied in the field of crystallization devices, can solve the problems of increasing the internal defects of the billet, uneven ingot structure, and upper crystallization center, etc., so as to reduce dummy resistance, uniform ingot structure, and wear degree Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

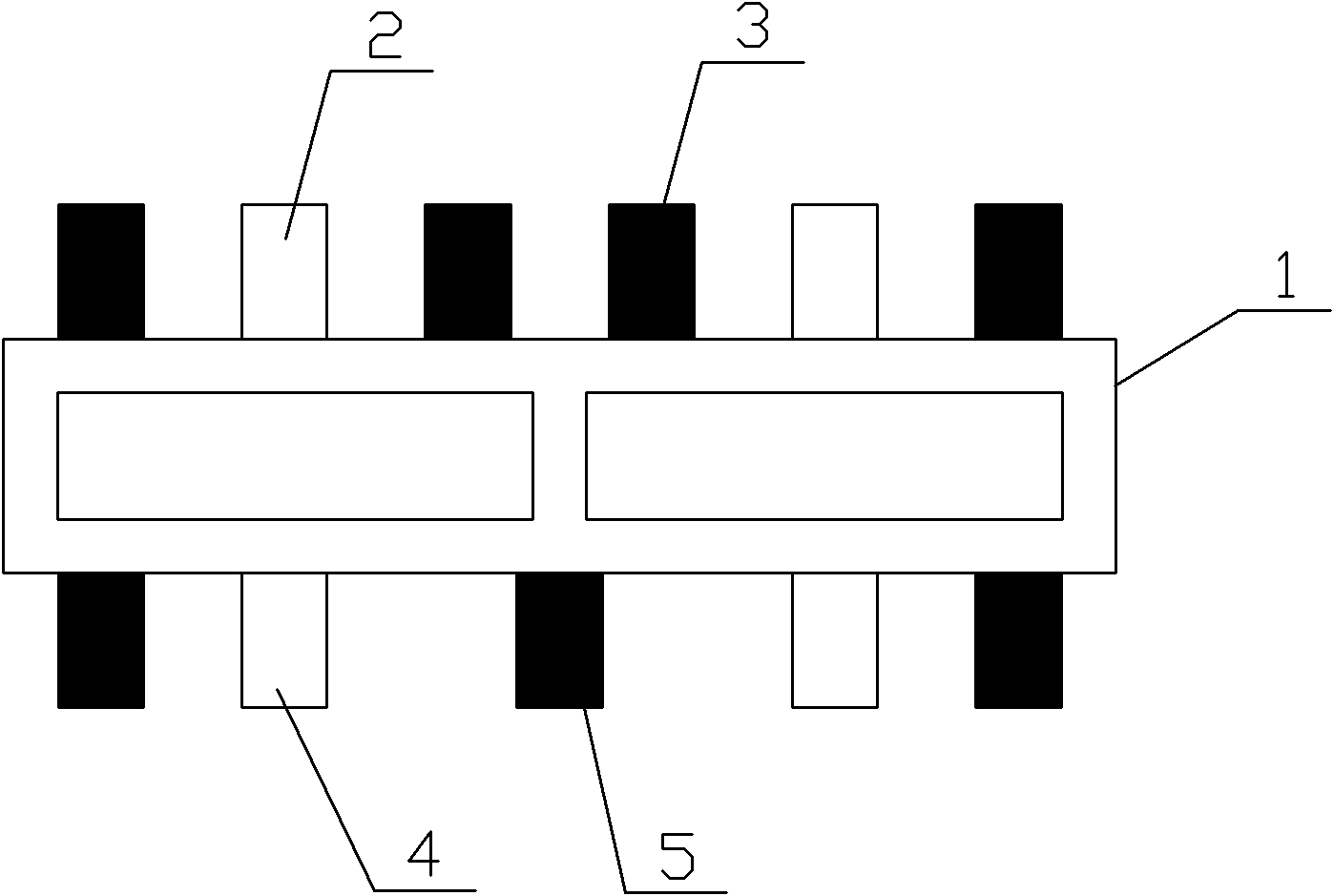

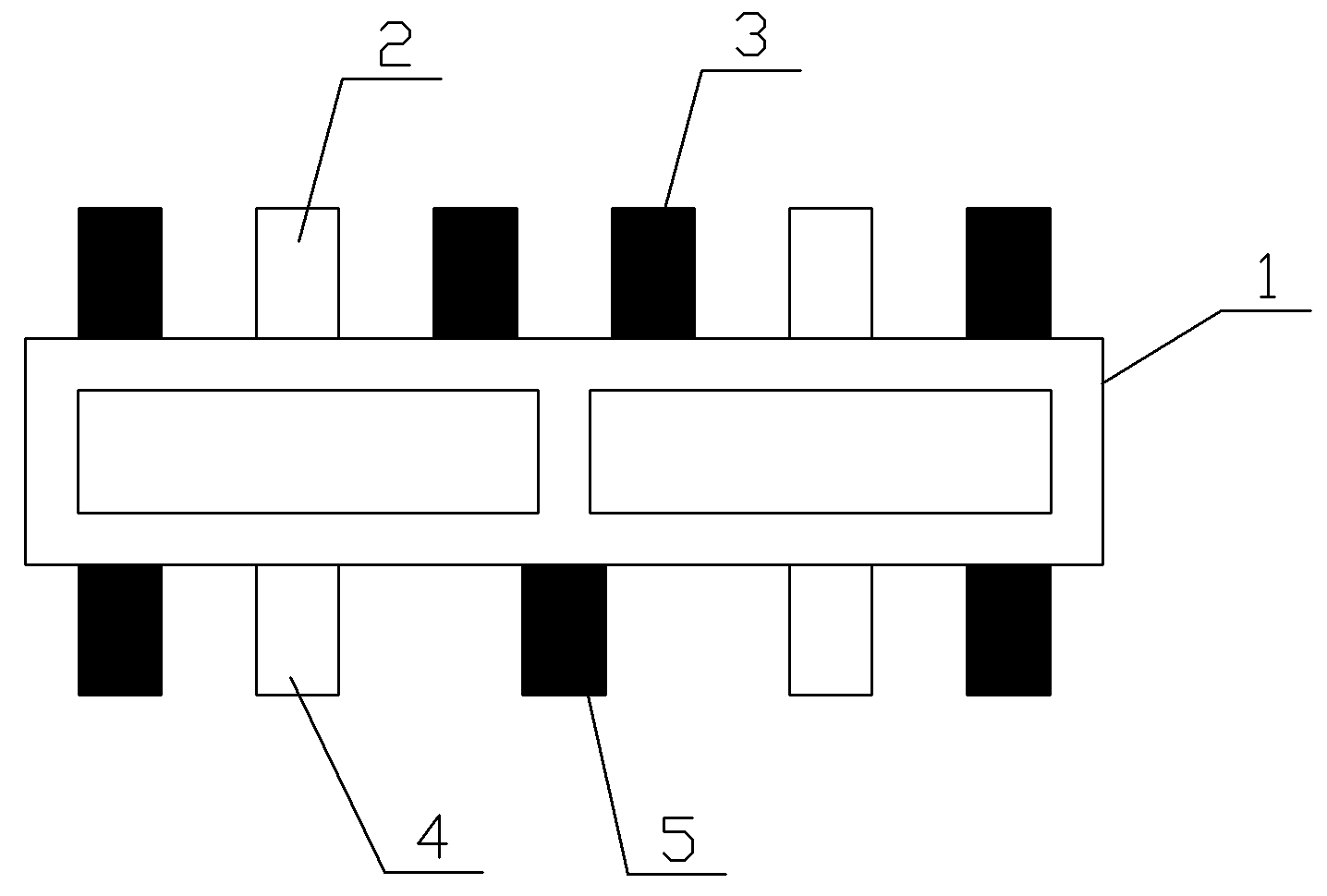

[0011] Refer to the attached figure 1 A crystallizer of the present invention is described in detail below.

[0012] A crystallizer of the present invention, its structure includes a crystallizer shell 1, the upper part of the crystallizer shell 1 is provided with an upper water outlet 3 and an upper water inlet 2, and the lower part of the crystallizer shell 1 is provided with a lower outlet The water inlet 5 and the lower water inlet 4, the upper water inlet 2 and the lower water inlet 4 are respectively two, the upper water inlet 2 and the lower water inlet 4 are arranged symmetrically, and the number of the upper water outlets 3 is large According to the number of the lower water outlets 5, the lower water outlets 5 and the lower water inlets 4 are arranged in a staggered arrangement.

[0013] There are four upper water outlets 3 and three lower water outlets 5 .

[0014] Since the design adopts four upper water outlets 3 and three lower water outlets 5, the cooling stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com