Patents

Literature

78results about How to "Increased wear and tear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

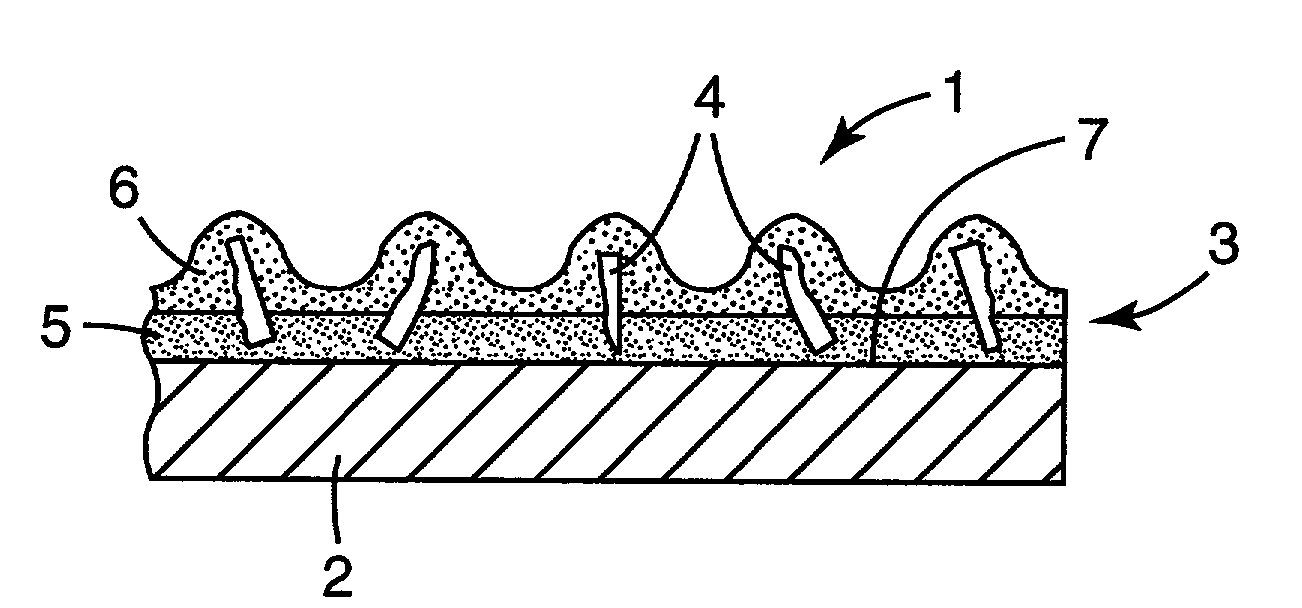

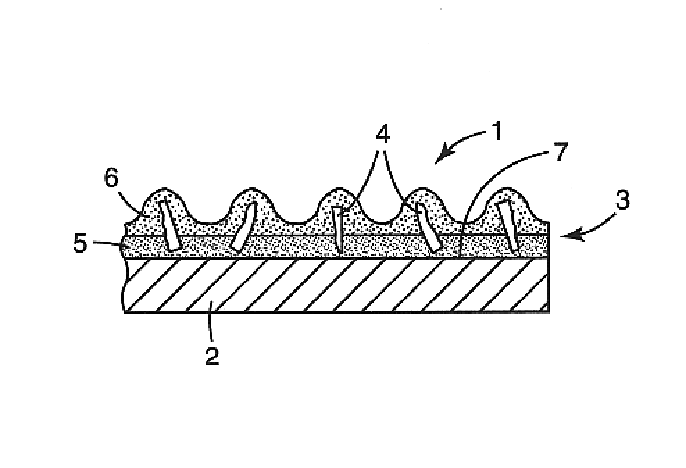

Coated abrasive article

InactiveUS20030176156A1Efficient mixingMinimize thermal expansionAbrasion apparatusMaterials scienceAbrasive

Owner:3M INNOVATIVE PROPERTIES CO

Coated abrasive article

InactiveUS6758734B2Reduce frizzIncreased wear and tearAbrasion apparatusMaterials scienceReaction product

Owner:3M INNOVATIVE PROPERTIES CO

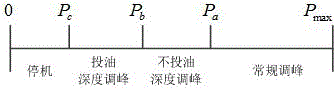

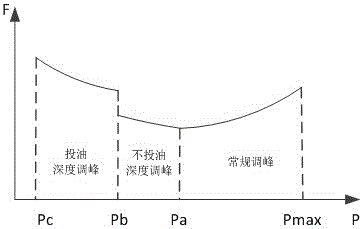

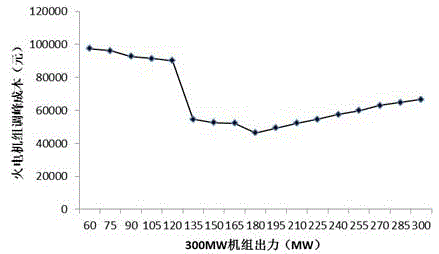

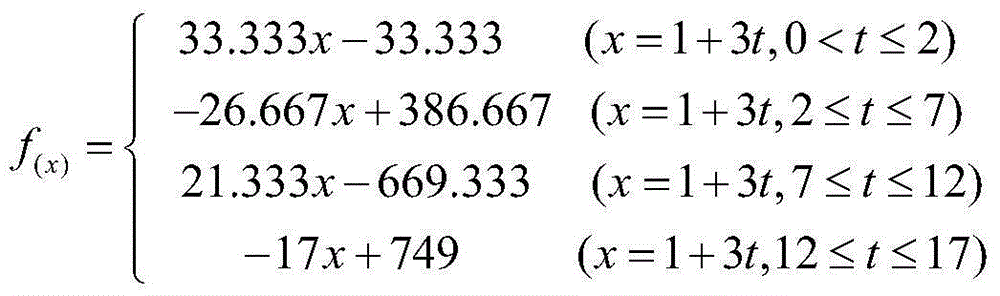

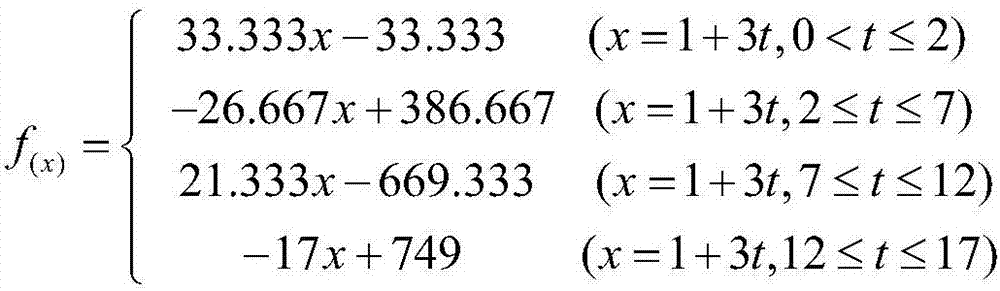

Piecewise calculation method for thermal power generating unit peak regulating energy consumption cost

InactiveCN106446404AImprove securityIncreased wear and tearDesign optimisation/simulationSpecial data processing applicationsThree stageEngineering

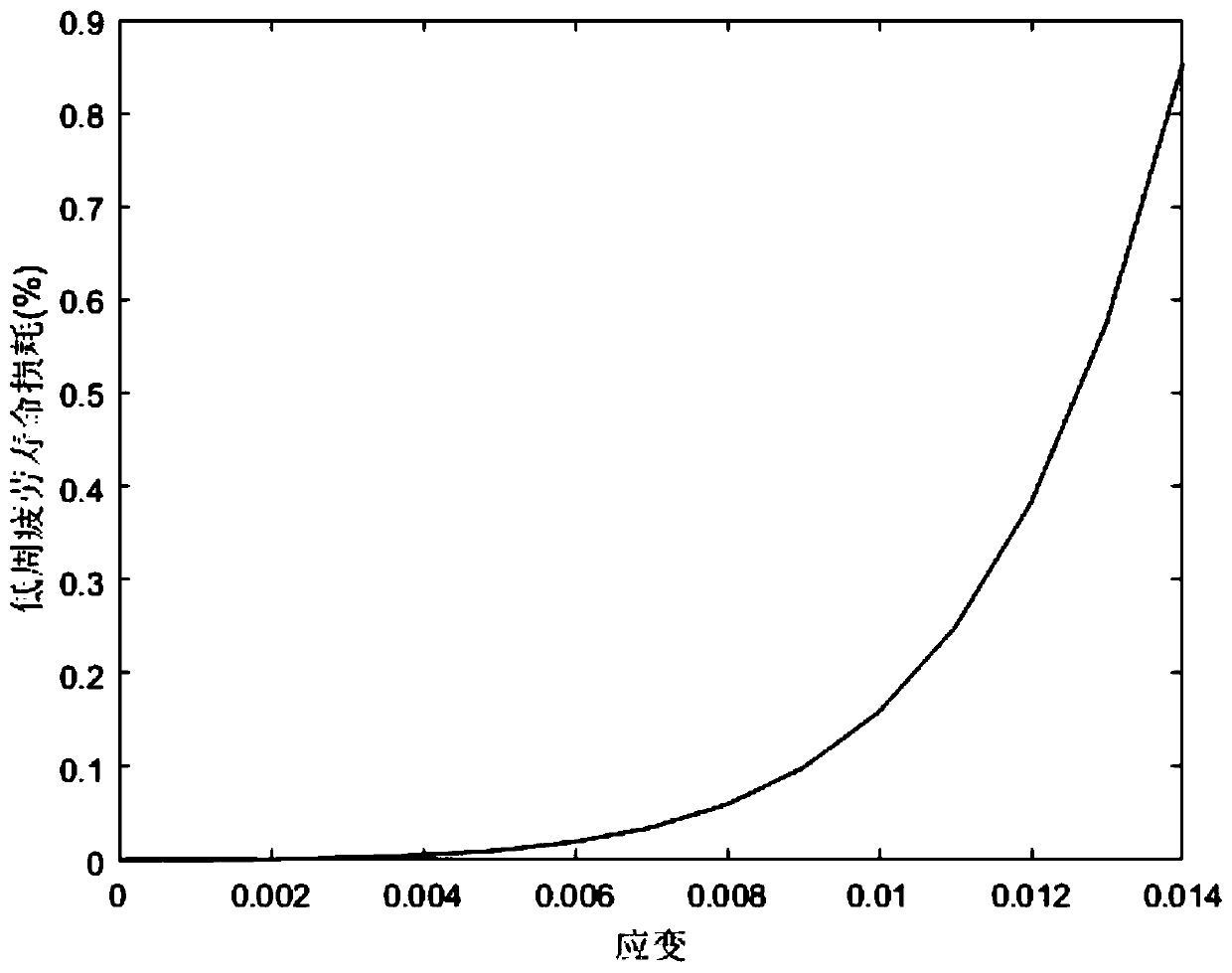

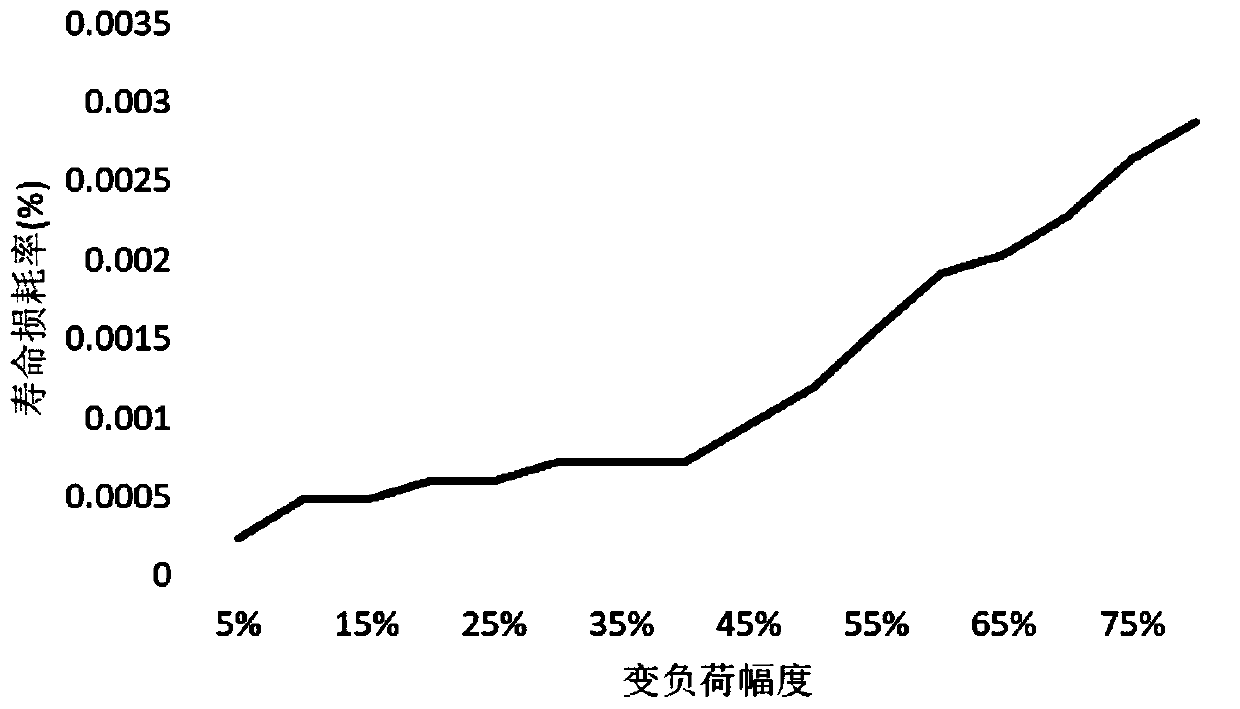

The invention relates to a piecewise calculation method for a thermal power generating unit peak regulating energy consumption cost. According to the method, force outputting threshold values at different pitch peak stages of the thermal power generating unit are determined according to a nameplate parameter and a unit performance testing of the thermal power generating unit. The peak regulating process of the thermal and power generating unit is divided into three stages based on a running state and an energy consumption character of the thermal power generating unit. Aiming at differences of the running state at different pitch peak stages of the thermal power generating unit and from a point view of benefits of a heat-engine plant, the cost of loss, the additional cost of environment and the cost of oil investment in the thermal power generating unit are calculated on the basis of considering a coal fired energy consumption character, a piecewise function of the thermal power generating unit pitch peak energy consumption cost is constructed, and further a curve of the thermal power generating unit pitch peak energy consumption cost is obtained. The piecewise calculation method for the thermal power generating unit pitch peak energy consumption cost can provide a basis for economic operations of the heat-engine plant.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

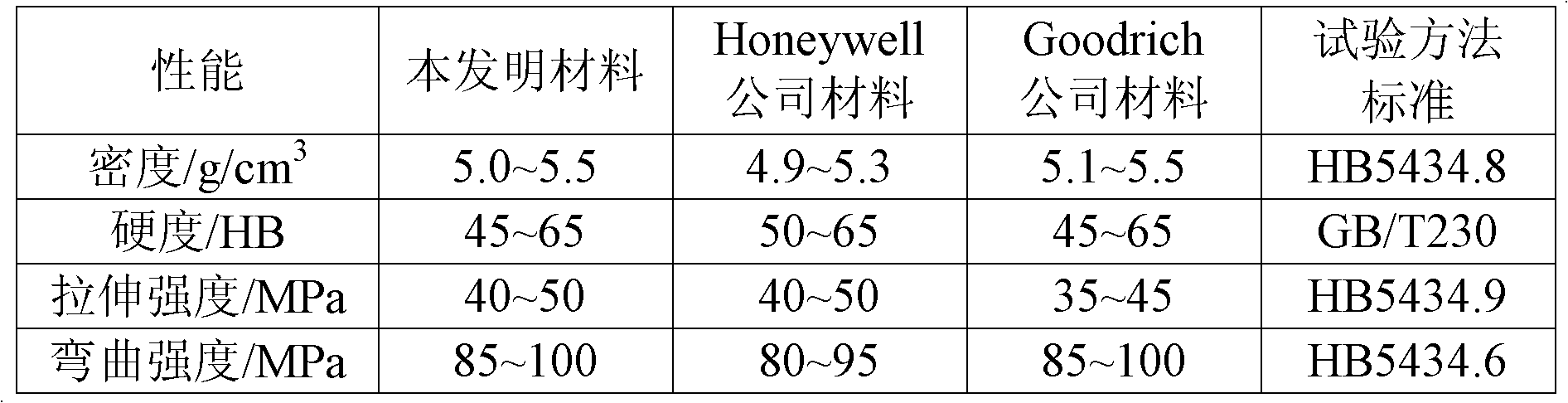

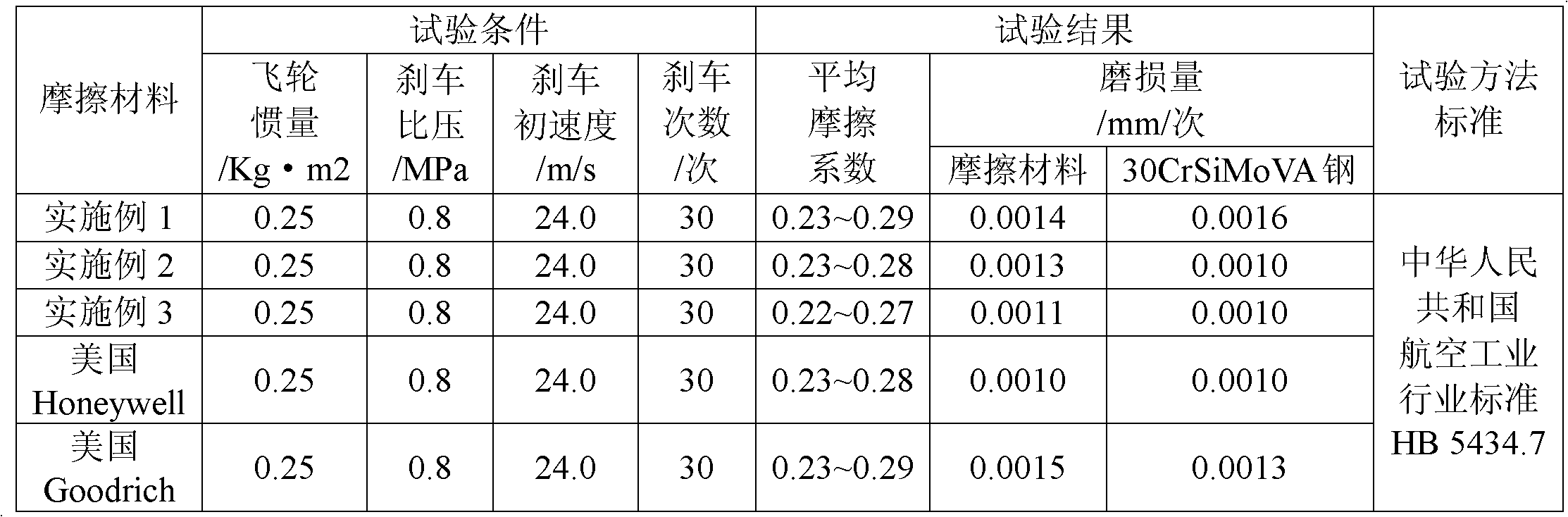

Friction material and process for manufacturing aircraft braking disc made from same

ActiveCN102604596AImprove heat resistanceImprove wear and tearOther chemical processesFriction liningAirplaneBoron nitride

The invention relates to a friction material which comprises the following components in percentage by weight: 62-72% of copper, 6-15% iron, 2-6% of aluminum, 3-8% of tin, 1-5% of nickel, 3-10% of cyanite (Al2O3.SiO2), 2-7% of boron nitride, 8-16% of graphite and 1-4% of molybdenum disulfide. The process for manufacturing an aircraft braking disc made from the friction material comprises the following steps: mixing a mixture of the friction material, pressing and moulding, preparing a steel back, and pressurizing and sintering the aircraft braking disc. Compared with the prior art, the mechanical performance, the physical performance, the friction and wear resistance, the use reliability and the service life of the aircraft braking disc made from the friction material reach or exceed those of the imported aircraft braking pair, and the aircraft braking disc made from the friction material can completely meet the use requirement of the Boeing 737 aircraft.

Owner:SHANTOU NORTHWEST AVIATION ARTICLES

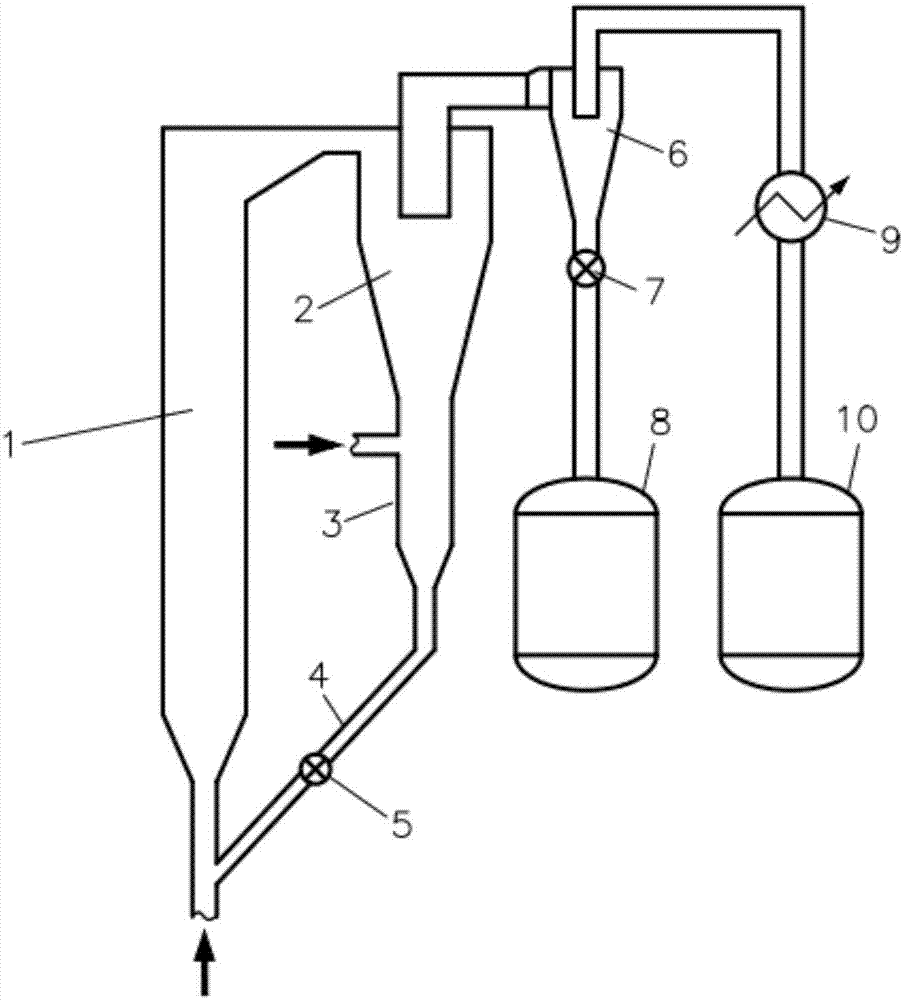

Circulating fluidized bed system and method for production of hydrogen fluoride from fluorite powder

ActiveCN107311109AFlow fastAvoid abnormal phenomena such as agglomeration and sticking to the wallHydrogen fluorideChemical/physical processesGas solidHydrogen fluoride

The invention discloses a circulating fluidized bed system and method for production of hydrogen fluoride from fluorite powder. The system comprises a reactor, a circulating part, a solid separation part and a gas condensation part, wherein the reactor is the place where a reaction takes place; the circulating part separates unreacted solids, allows the unreacted solids to settle and then returns the unreacted solids to the reactor for the reaction again; the solid separation part separates a gas-solid two-phase product and collects totally reacted solids as a solid product; and the gas condensation part liquefies and collects a gas product left after separation in the solid separation part. According to the invention, abnormal phenomena such as agglomeration and adhesion onto walls are avoided; mass transfer and heat transfer efficiency is improved; the circulation rate of a circulating fluidized bed is controlled by controlling the amount of gas and controlling the opening of a valve on an inclined tube, and the ratio of the separated solid product is controlled so as to control the reaction degree of the solids; liquid condensation is controlled via the temperature and amount of a condensate; and when the gas product contains other impurities, multi-stage condensers can be installed so as to control product quality.

Owner:ZHEJIANG UNIV

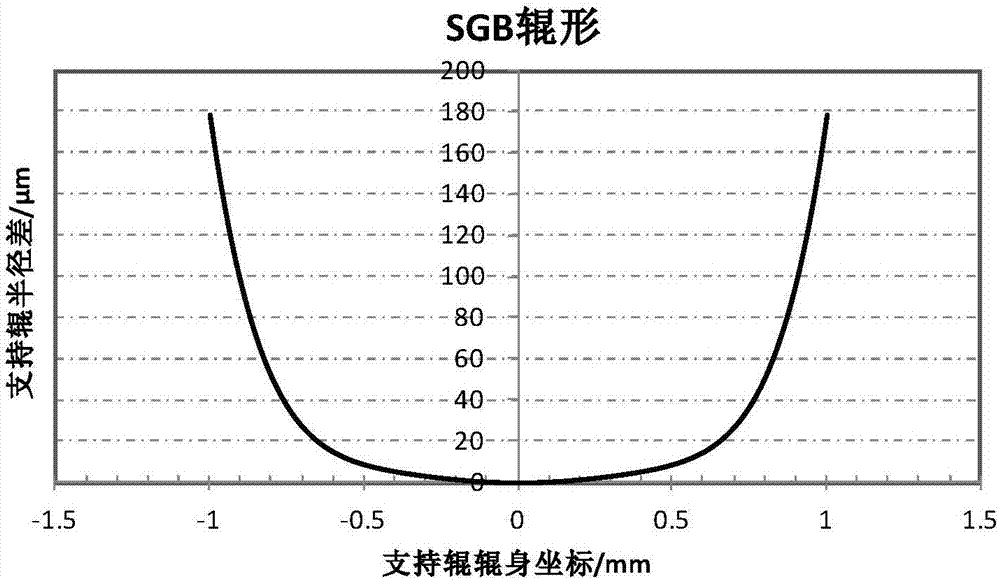

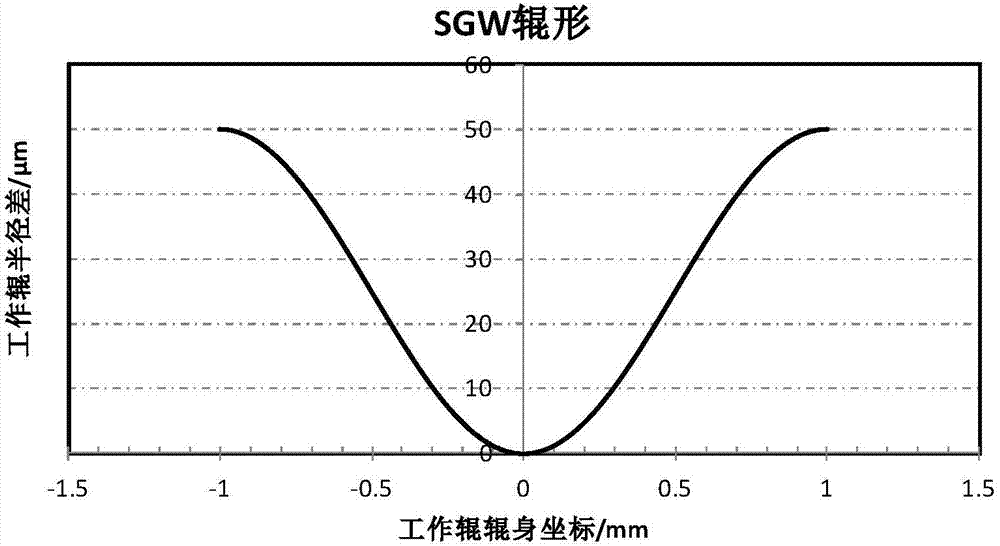

Method for controlling orange peel reticulate pattern defects on surface of strip steel

ActiveCN104998910AOrange Peel Defect ControlExtended service periodRollsProfile control deviceStrip steelMaterials science

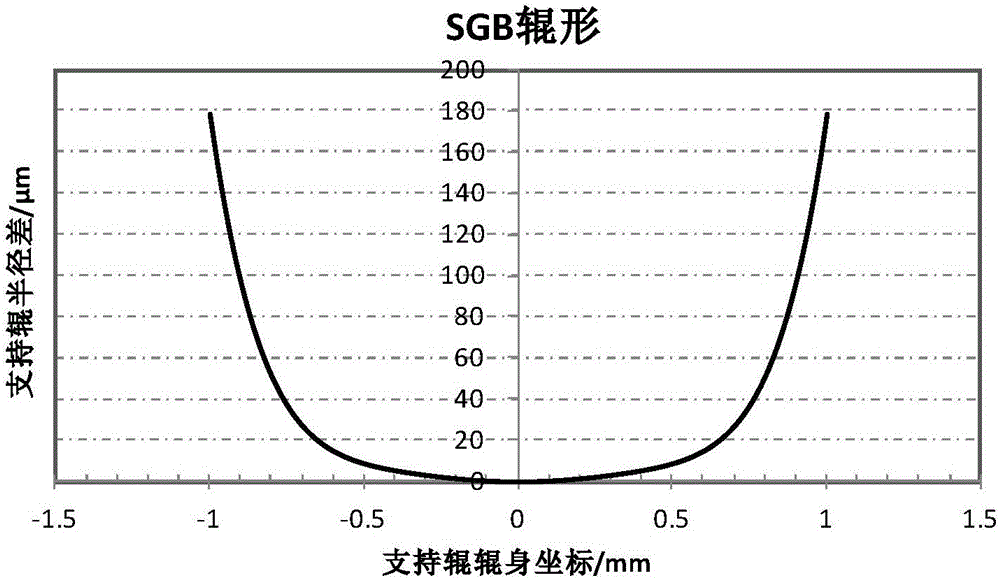

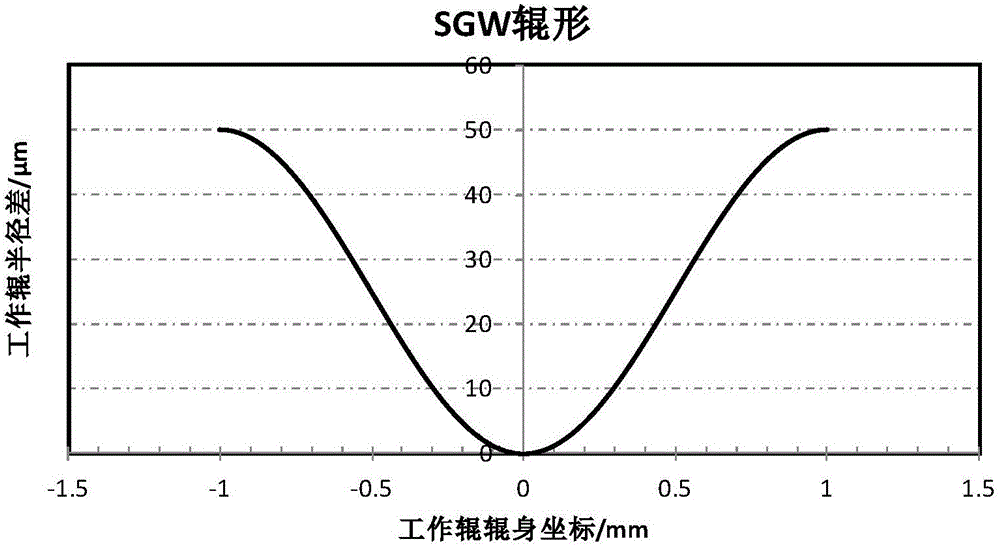

The invention belongs to the technical field of hot rolling, and discloses a method for controlling orange peel reticulate pattern defects on the surface of strip steel. The method is characterized by comprising the following steps: adopting an SGB roll profile curve on a supporting roller of a hot rolling temper mill; adopting an SGW roll profile curve on a working roller. The process parameters of the temper mill are set as the rolling force of 200-250 tons, the unwinding tension of 9-12 tons, and the winding tension of 20-23 tons, the rolling reduction of straightening rollers is used in a straightening machine group, and a roller shifting strategy with constant frequency, variable step sizes and variable stroke is adopted. According to the method, through the application of the SGB and SGW roll profile curves, a specific smoothing process and the roller shifting strategy, local wear of working rollers is greatly reduced, and orange peel reticulate pattern defects on the surface of the strip steel are effectively overcome.

Owner:SHOUGANG CORPORATION +1

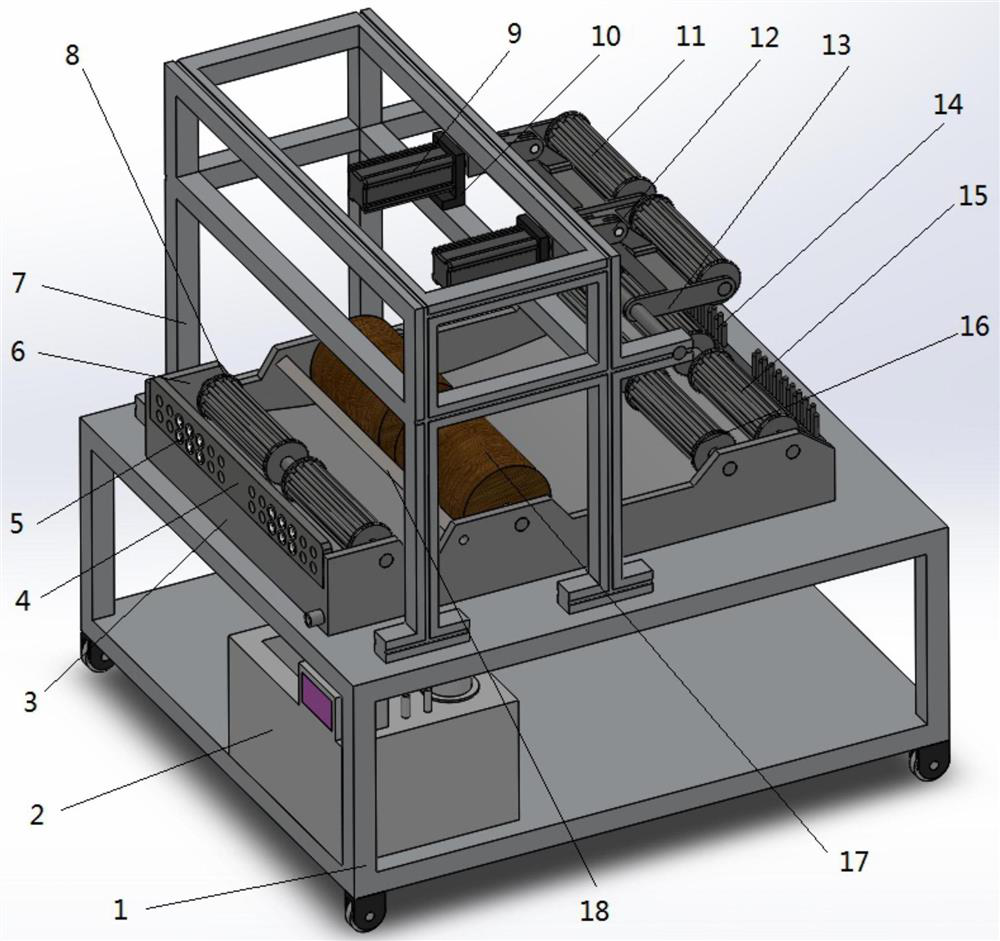

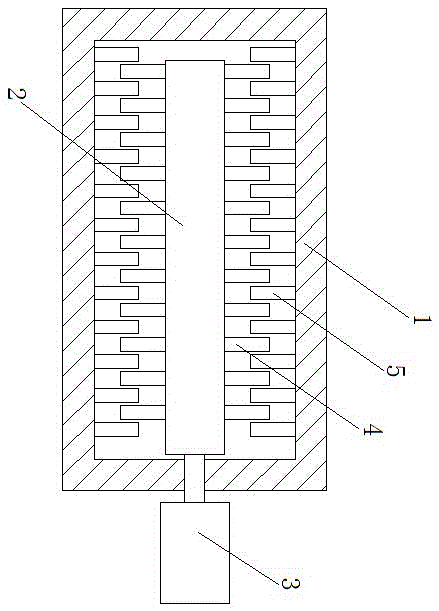

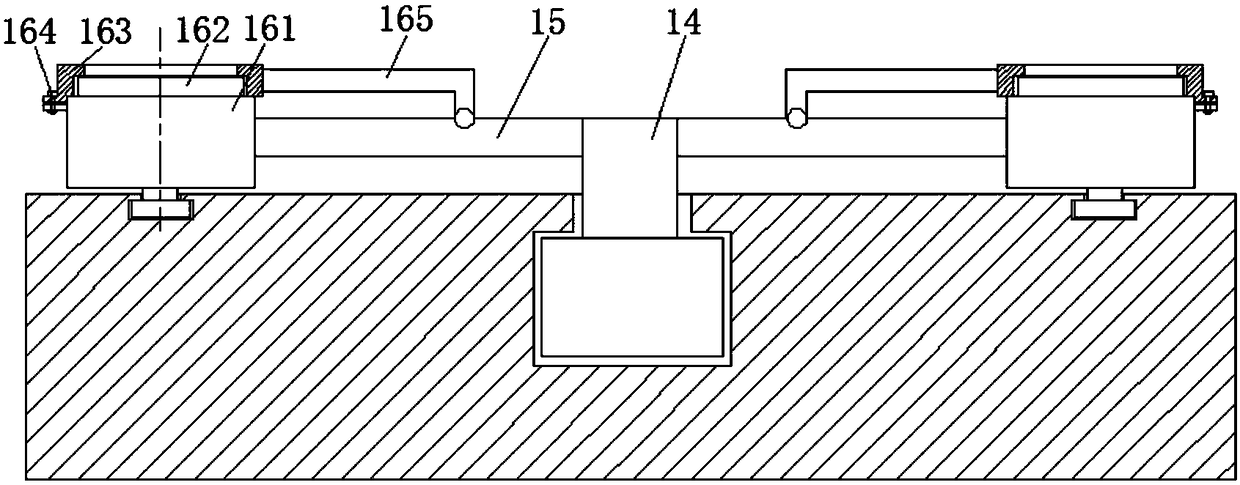

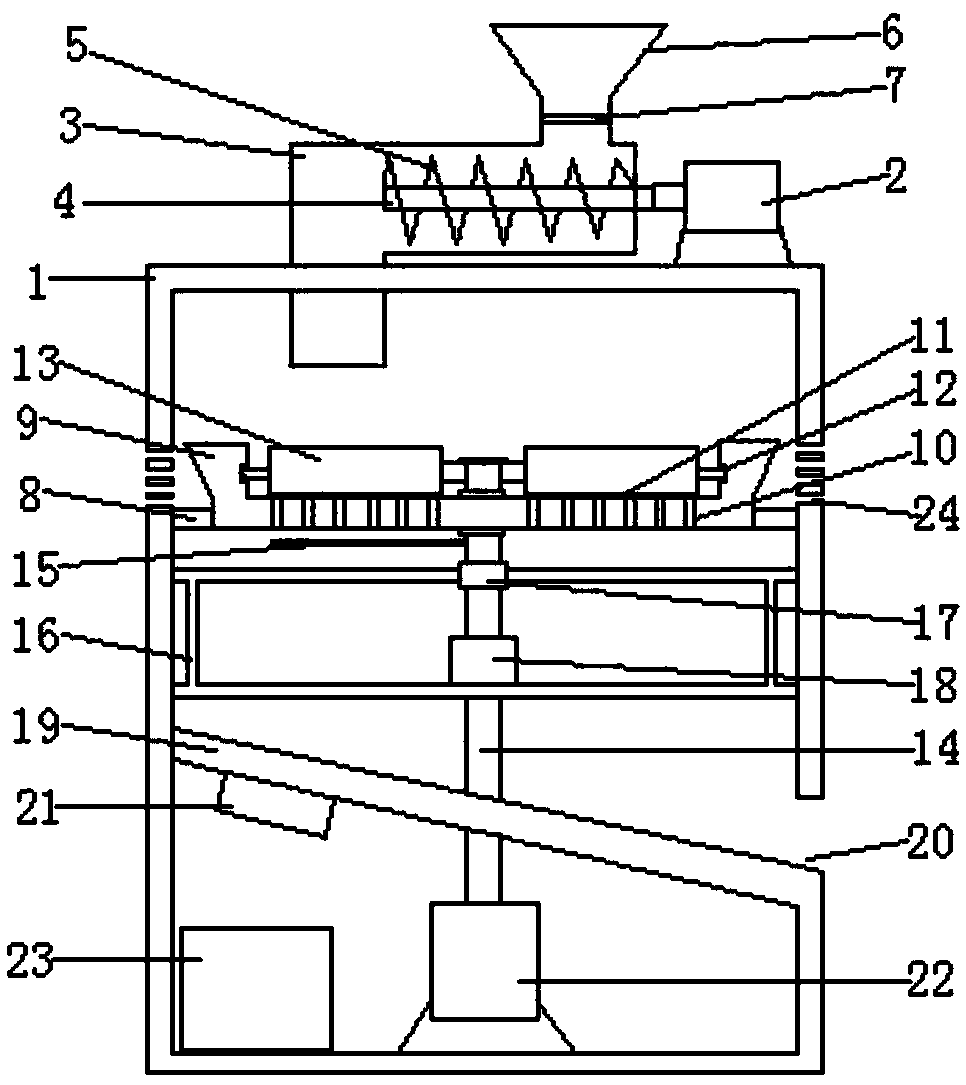

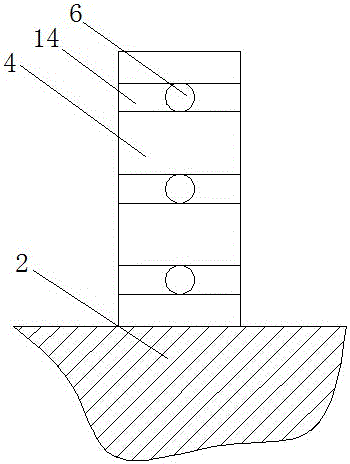

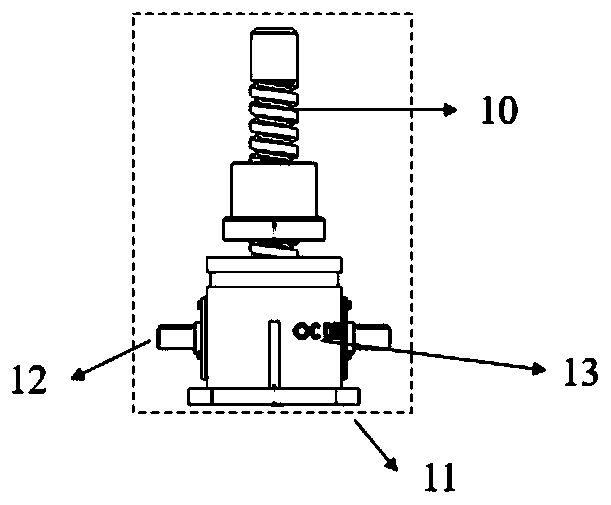

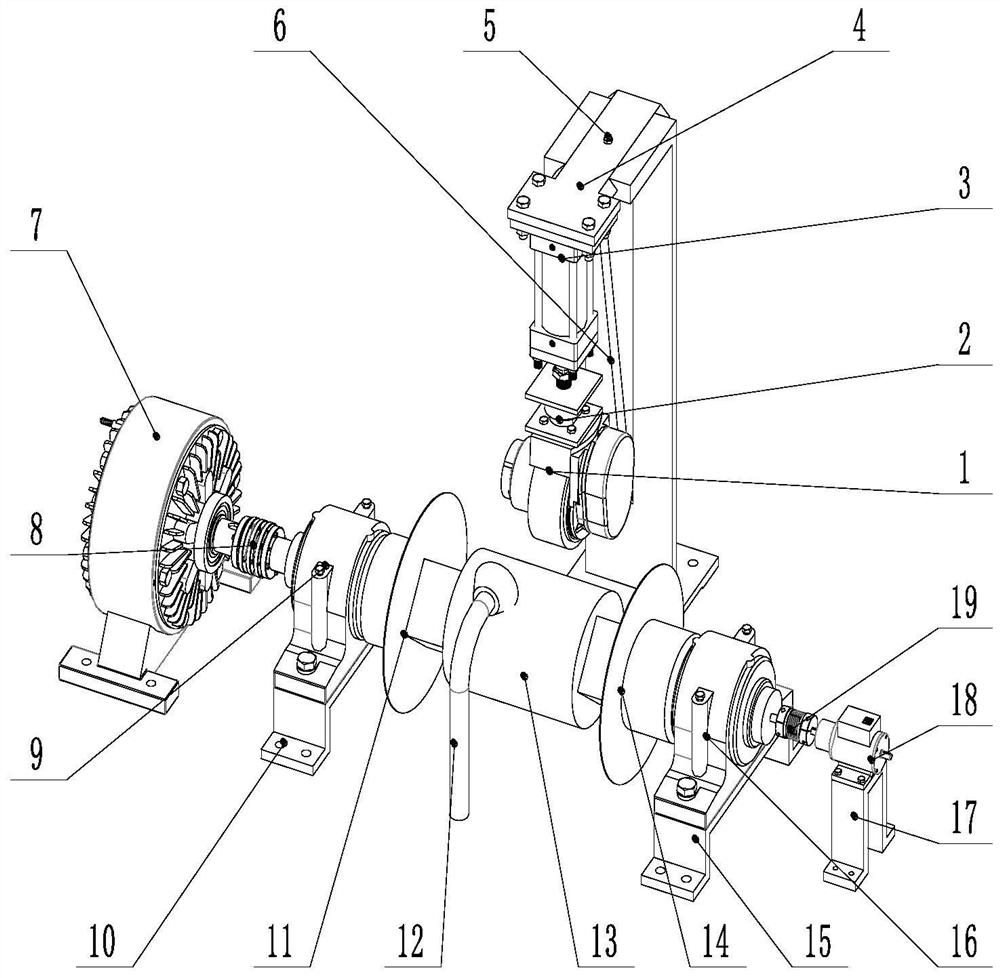

Constant-temperature impregnation device for composite fiber winding

The invention provides a constant-temperature impregnation device for composite fiber winding. The constant-temperature impregnation device for composite fiber winding is used for impregnating glass fiber and carbon fiber in the winding process and balancing fluctuation of the tension value during winding reversing and can be placed on a fiber winding tension control system to cooperate with a fiber winding mainframe to together complete processing of winding products. The constant-temperature impregnation device can be transversely and longitudinally moved according to the actual size of winding parts. The constant-temperature impregnation device is composed of a U-shaped impregnation tank, a constant-temperature device, a low-friction guide roll set, a fiber guiding device, a tension balancing device, an impregnation roll, an adjustable scraping knife and other components. Through the constant-temperature impregnation device for composite fiber winding, the technical problems that fiber is impregnated insufficiently and unevenly and fluffs due to dry friction, the constant-temperature effect of an adhesive solution is poor, the fiber is impregnated unevenly due to fluctuation ofthe fiber tension value and the quality of the winding products is affected through the existing fiber wet winding impregnation technology can be solved.

Owner:CHANGCHUN EQUIP TECH RES INST

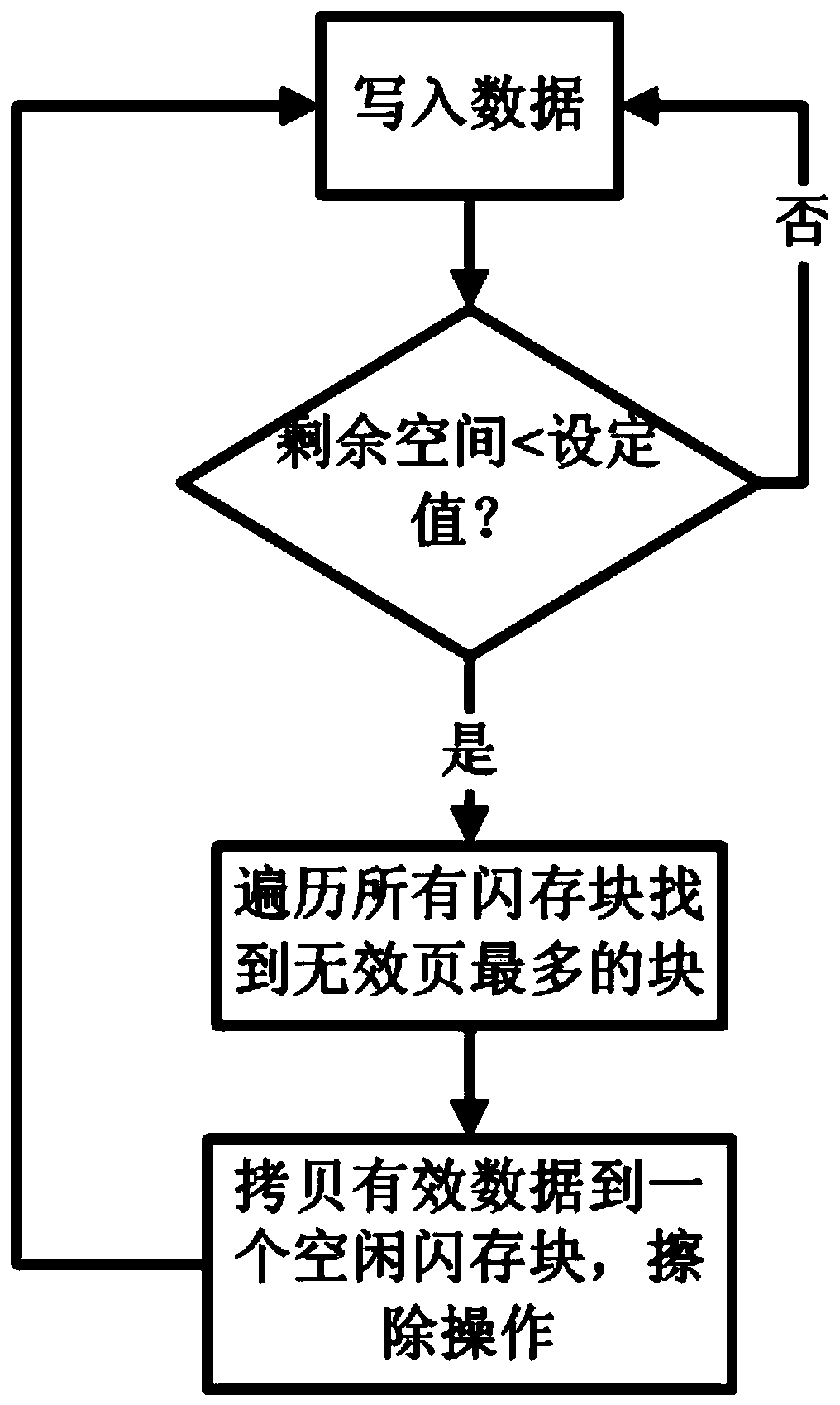

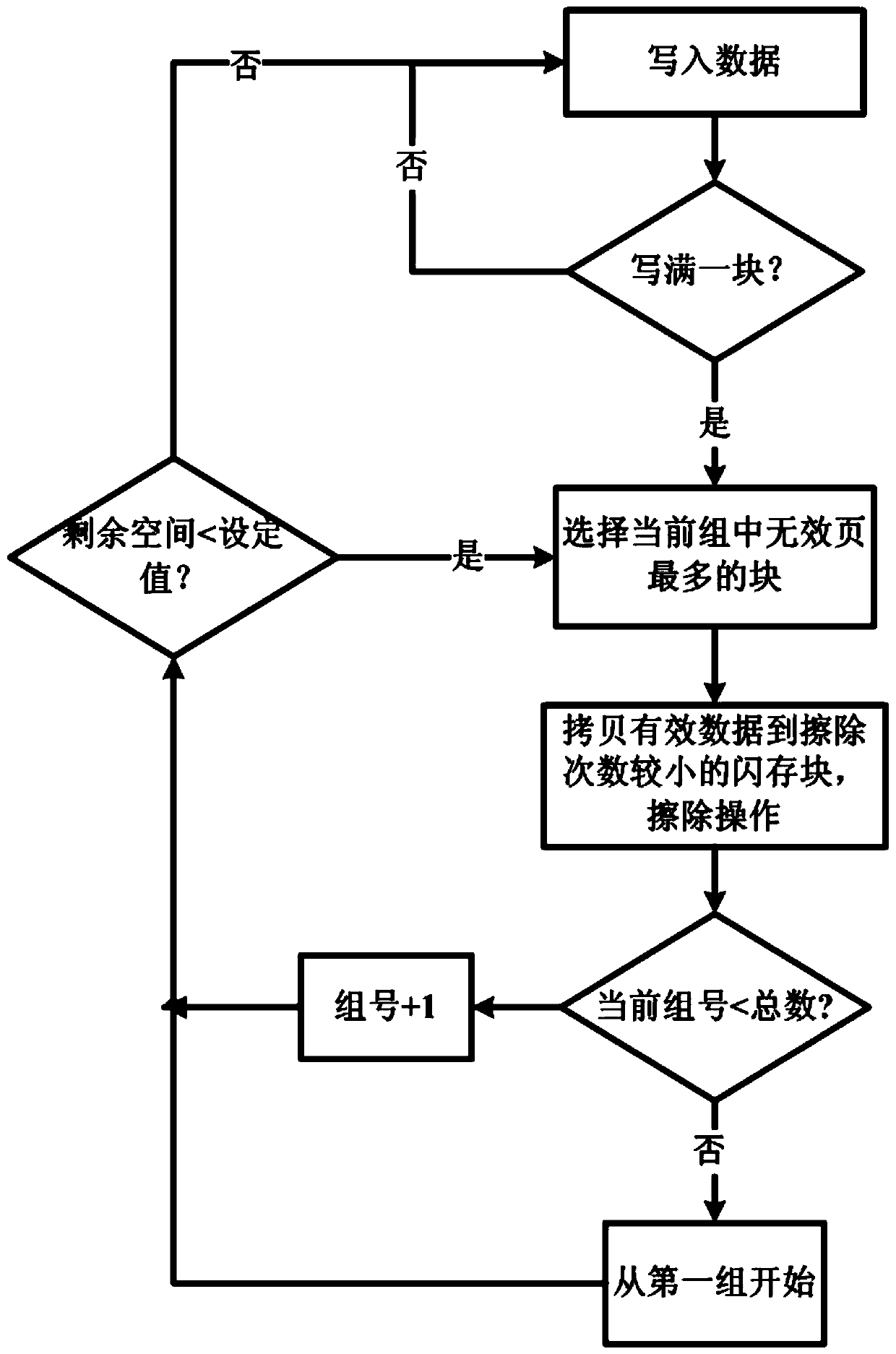

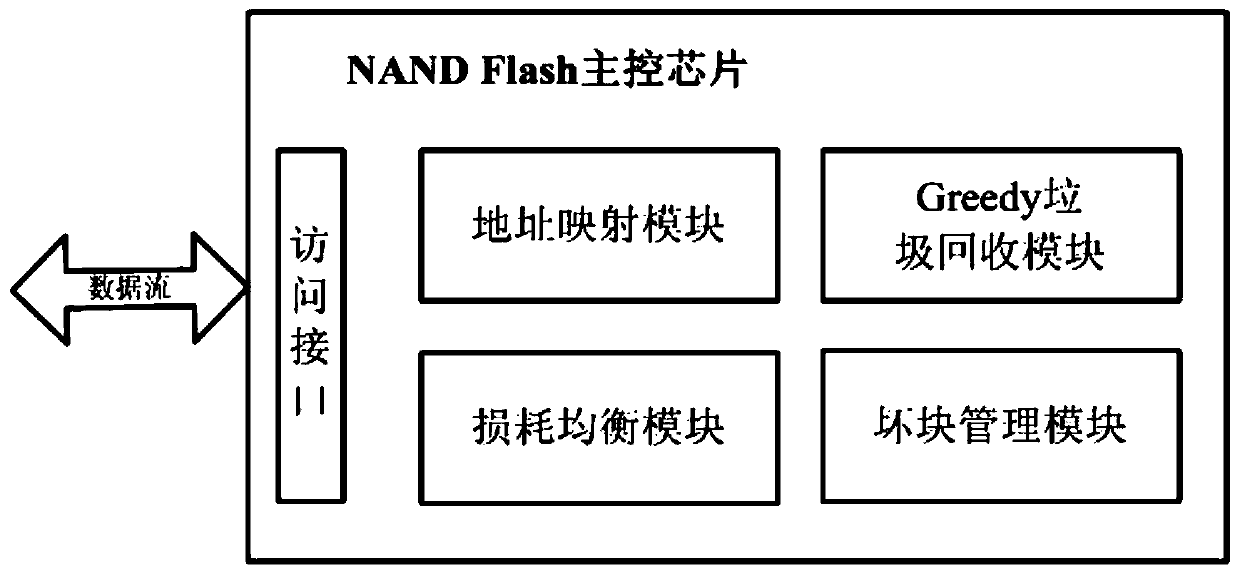

An optimization method aiming at NAND Flash main control chip Greedy garbage collection

ActiveCN109710541AAvoid centralized triggeringTimely releaseMemory adressing/allocation/relocationEnergy efficient computingControl systemGreedy algorithm

The invention belongs to the technical field of chips, and particularly relates to an optimization method aiming at NAND Flash main control chip Greedy garbage collection. Compared with the prior art,the method has the advantages that a 'one-full-one-erase 'trigger mode and a local retrieval search mechanism are added to the improved scheme to optimize the Greedy algorithm. Data is written into the last page of each flash memory block. Therefore, the NAND Flash control system can trigger the garbage collection algorithm, so that the storage space occupied by invalid data can be released in time, flash memory storage equipment can keep more available storage space for a long time as much as possible, and centralized triggering of the garbage collection algorithm is avoided.

Owner:TIANJIN JINHANG COMP TECH RES INST

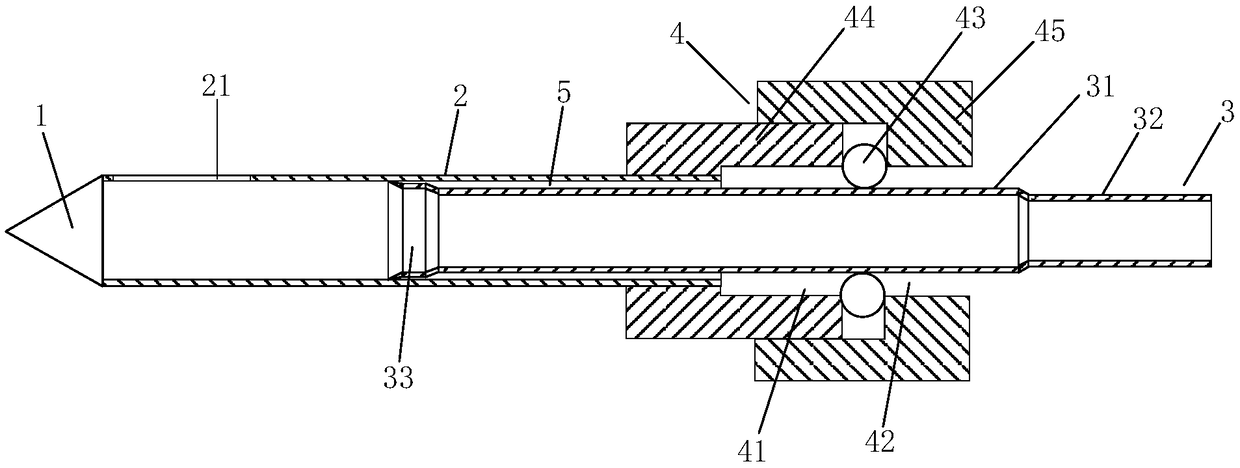

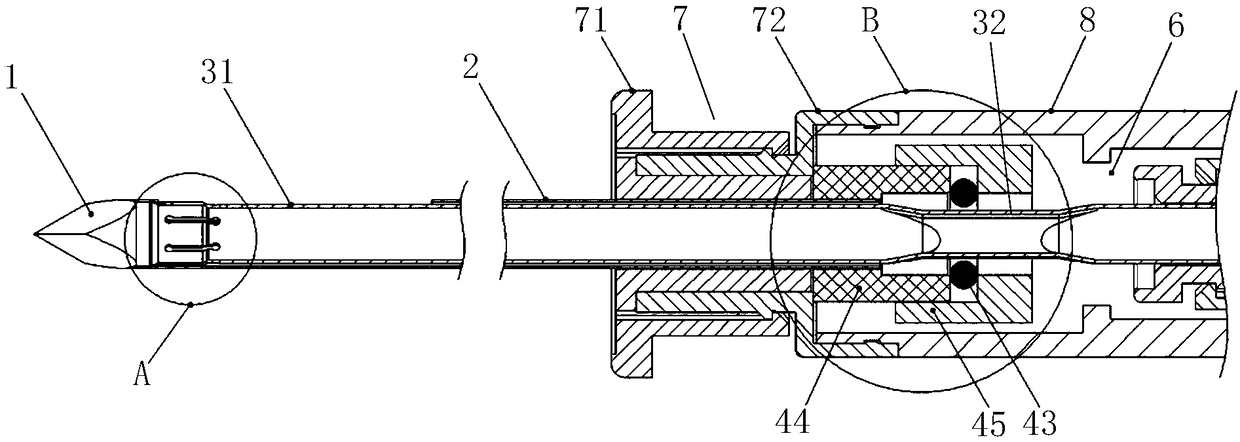

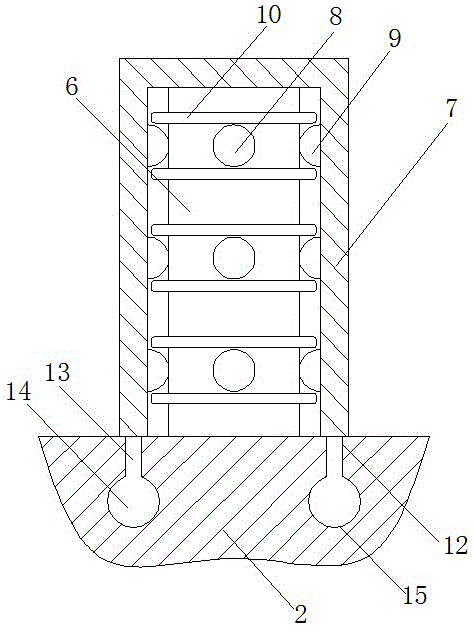

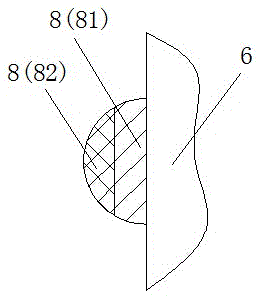

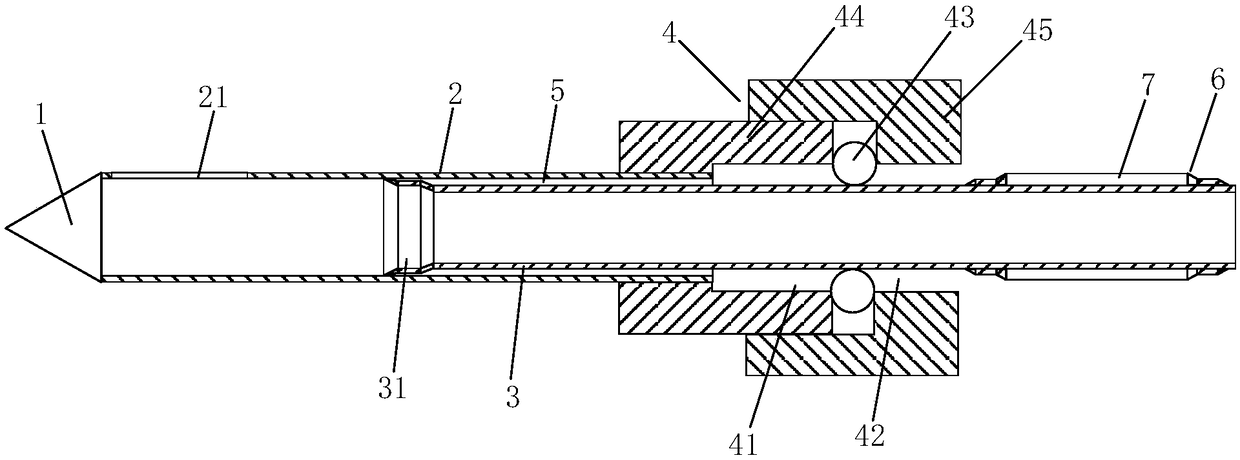

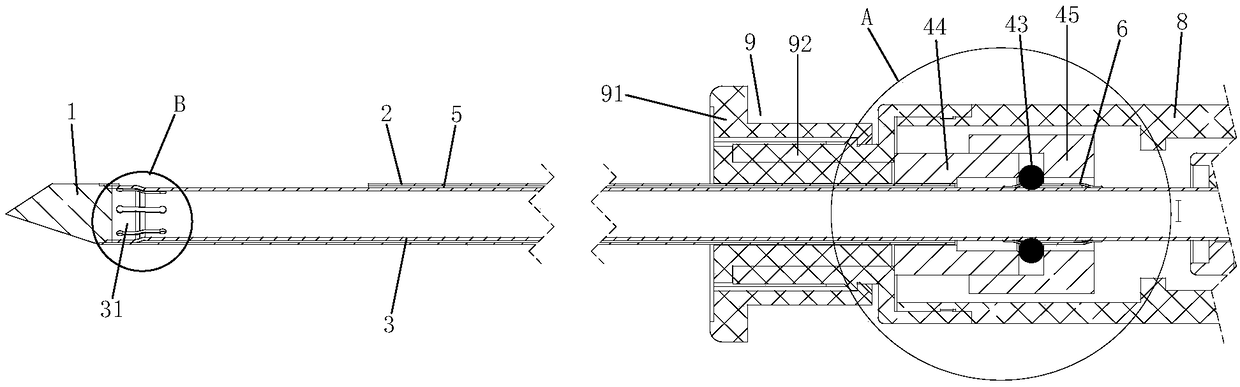

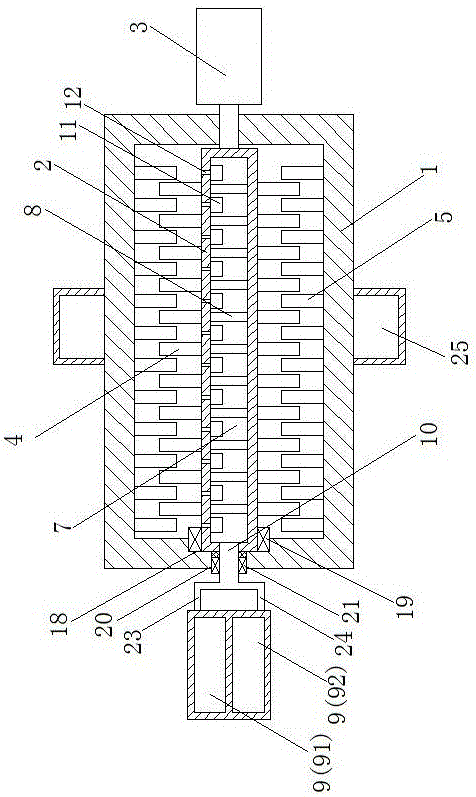

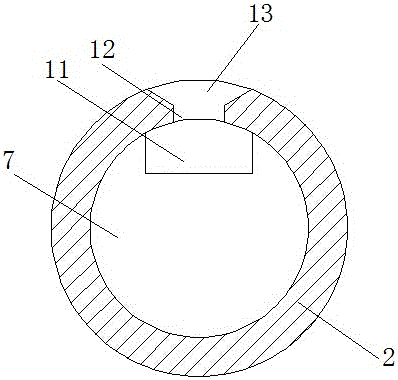

Biopsy rotary cutting device

ActiveCN109330632AEfficient suctionGood suction strengthSurgical needlesVaccination/ovulation diagnosticsUltimate tensile strengthBiopsy

The invention provides a biopsy rotary cutting device, which comprises a dynamic sealing structure arranged on the outer side of an inner cutter tube; the dynamic sealing structure forms a cavity outside the inner cutter pipe; the inner cutter pipe comprises a first pipe section and a second pipe section, wherein the outer diameter of the second pipe section is smaller than the outer diameter of the first pipe section; a sealing ring is arranged in the dynamic sealing structure; the cavity comprises a first cavity and a second cavity; when the inner cutter pipe moves to a first position alongthe axial direction of the inner cutter pipe, the sealing ring is positioned at the outer side of the second pipe section; an inter-cavity gap is formed between the sealing ring and the second pipe section so as to communicate the first cavity and the second cavity. According to the biopsy rotary cutting device, the atmosphere can be introduced to form the circulating airflow with better suction strength; the circulating airflow can more efficiently send the rotary-cut tissue of the corresponding position to a sample collector at the rear end, so that the sample yield is effectively improved.

Owner:ACCUTARGET MEDIPHARMA (SHANGHAI) CO LTD

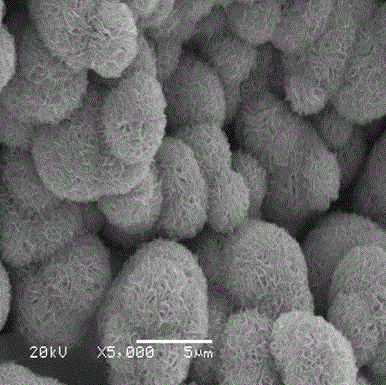

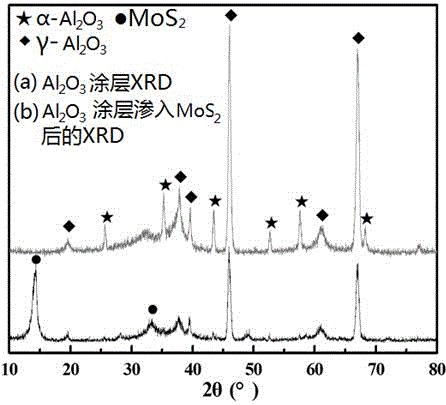

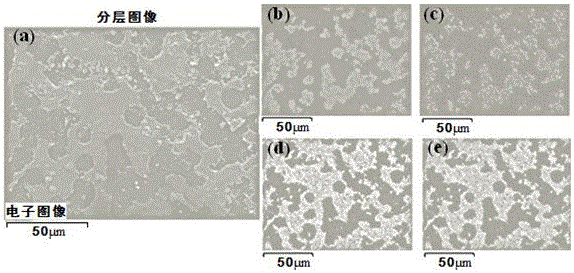

Method for improving friction and wear performance of thermal-sprayed Al2O3 ceramic coating

ActiveCN106048505AIncreased wear and tearReduce coefficient of frictionMolten spray coatingLiquid/solution decomposition chemical coatingWater useCoated surface

The invention discloses a method for improving friction and wear performance of a thermal-sprayed Al2O3 ceramic coating. The method comprises steps as follows: a metal transition coating and an Al2O3 ceramic coating are sprayed onto a metal substrate sequentially with an atmospheric plasma spraying technology; the prepared Al2O3 ceramic coating surface is ground; powdery thiourea and powdery sodium molybdate are weighed, are placed in deionized water used as a solvent and are fully stirred to be completely dissolved, and an MoS2 solution is obtained; a ground Al2O3 ceramic coating sample is immersed in the MoS2 solution, the solution is sealed and then placed in a drying oven, the drying oven slowly heats the solution to 220 DEG C at the heating rate smaller than or equal to 3 DEG C / min, and the solution is kept at the temperature and placed for 48-72 h; and after the drying oven is cooled to the room temperature, the Al2O3 ceramic coating sample is taken out, and redundant MoS2 powder which is produced through a self-reaction on the surface of the sample is completely removed. The wear degree of the coating obtained with the method is greatly improved; and meanwhile, holes in the Al2O3 ceramic coating surface are effectively sealed through filling of the holes in the coating surface with the MoS2 powder.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High-strength wear-resistant paint

ActiveCN103773227AIncrease the degree of cross-linkingHigh scratch resistanceCoatingsWear resistantSilicon oxide

The invention discloses a high-strength wear-resistant paint which is prepared from the following raw materials in parts by weight: 20-30 parts of tetraethoxysilane, 15-25 parts of methyl trimethoxysilane, 15-20 parts of calcium naphthenate, 3-5 parts of silica sol, 10-15 parts of crystallized silicon oxide, 7-13 parts of graphite powder and 15-20 parts of auxiliary material, wherein the particle size of the silica sol is 4-9 nm, the particle size of the crystallized silicon oxide is 25-35 mu m, the weight ratio of the silica sol to the crystallized silicon oxide is 2:(5-6), and the weight ratio of the tetraethoxysilane to methyl trimethoxysilane is (1-2):1. The high-strength wear-resistant paint is excellent in crocking resistance, good in adhesion property with a substrate, and lower in cost.

Owner:ANHUI JINDUN PAINT

Wear-resisting coating

The invention discloses a wear-resisting coating. The wear-resisting coating comprises the following raw materials in parts by weight: 20-30 parts of vinyl triisopropoxysilane, 3-5 parts of silicon dioxide aerogel, 15-20 parts of trioxane, 5-9 parts of water, 3-7 parts of acetic anhydride, 10-15 parts of acetylcholine, 0.1-0.3 part of polyoxyethylene anhydro-sorbit monoglyceride, 10-15 parts of crystallizing silicon oxide, and 7-13 parts of graphite powder, wherein the porosity of the silicon dioxide aerogel is 75-79%, and the weight ratio of silicon dioxide aerogel to vinyl triisopropoxysilane is 1:(5-7). The wear-resisting coating can improve the degree of crosslinking of a coating and enhance the resistance to scratching, and has low cost.

Owner:ANHUI JINDUN PAINT

Breaking part abrasion-resistance device suitable for hot mine machining device

The invention discloses a breaking part abrasion-resistance device suitable for a hot mine machining device. The breaking part abrasion-resistance device comprises breaking end teeth and auxiliary breaking end teeth, wherein the breaking end teeth and the auxiliary breaking end teeth are distributed in a staggered manner. The breaking end teeth and the auxiliary breaking end teeth comprise tooth cores and tooth sleeves. The tooth sleeves are arranged outside the tooth coress. A plurality of sets of first transmission end bodies are arranged on the side end faces of the tooth cores. A plurality of sets of second transmission end bodies are arranged on the inner walls of the tooth sleeves. Any set of first transmission end bodies correspond to one set of second transmission end bodies, wherein the first transmission end bodies and the corresponding second transmission end bodies are located in the same axial position of the corresponding tooth core. By means of the breaking part abrasion-resistance device suitable for the hot mine machining device, the impact force and the friction force which are borne by the breaking end teeth and the auxiliary breaking end teeth in the working process can be effectively controlled, and therefore in the long-term working process, the abrasion degree of the breaking end teeth and the auxiliary breaking end teeth is effectively reduced, and the abrasion-resistance performance of a whole breaking part is obviously improved.

Owner:常州坚鹏建材有限公司

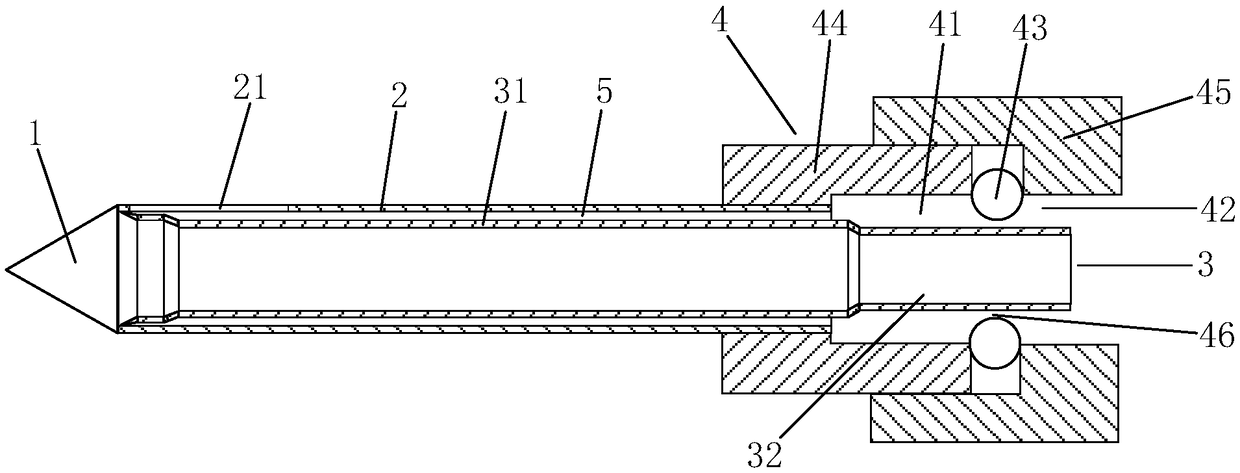

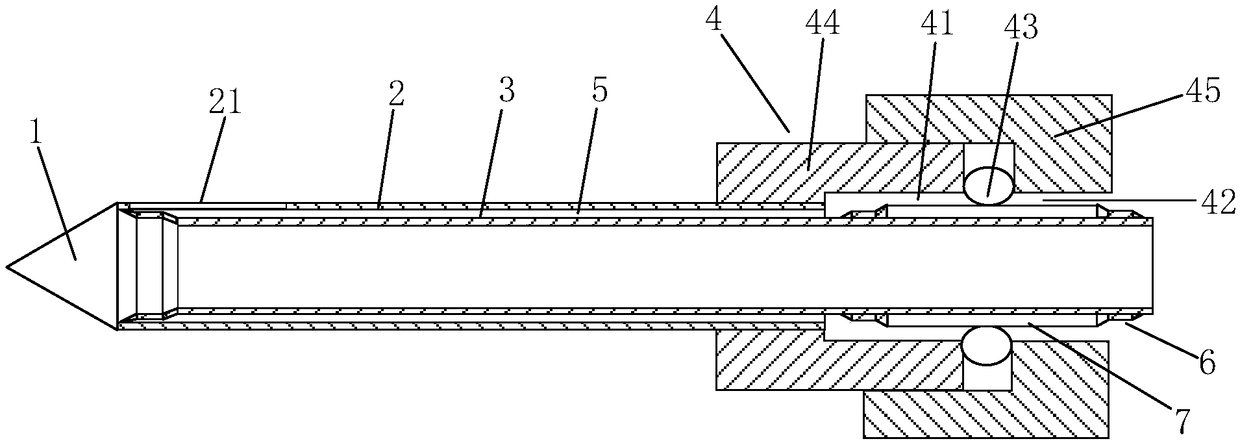

Biopsy rotary cutting device

PendingCN109330633AIncrease flow itineraryImprove delivery efficiencySurgical needlesVaccination/ovulation diagnosticsRing blockEngineering

The invention provides a biopsy rotary cutting device, which comprises a dynamic sealing structure arranged on the outer side of an inner cutter tube; the dynamic sealing structure forms a cavity outside the inner cutter pipe; a sealing ring is arranged in the dynamic sealing structure; the cavity comprises a first cavity and a second cavity; an auxiliary pipe is arranged outside the inner cutterpipe; the auxiliary pipe is provided with a circulation structure; when the inner cutter tube moves to a first position along the axial direction of the inner cutter tube, the sealing ring is positioned at the outer side of the auxiliary tube, and the first cavity and the second cavity are communicated through the circulation structure; when the inner cutter tube moves to a second position along the axial direction of the inner cutter tube, the sealing ring is positioned at the outer side of the inner cutter tube, and the sealing ring blocks the first cavity and the second cavity. According tothe biopsy rotary cutting device, the atmosphere can be introduced to form the circulating airflow with better suction strength; the circulating airflow can more efficiently send the rotary-cut tissue of the corresponding position to a sample collector at the rear end, so that the sample yield is effectively improved.

Owner:ACCUTARGET MEDIPHARMA (SHANGHAI) CO LTD

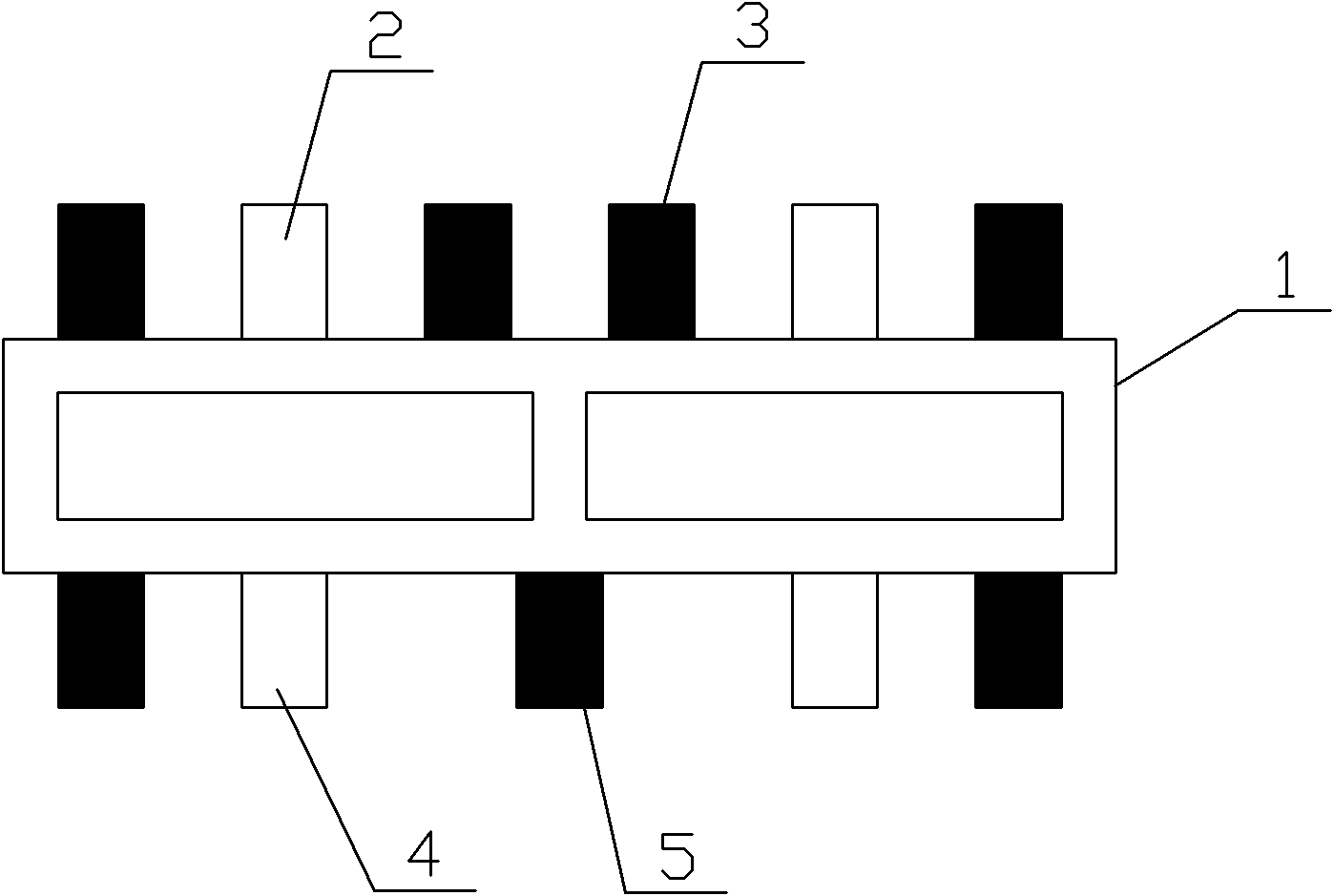

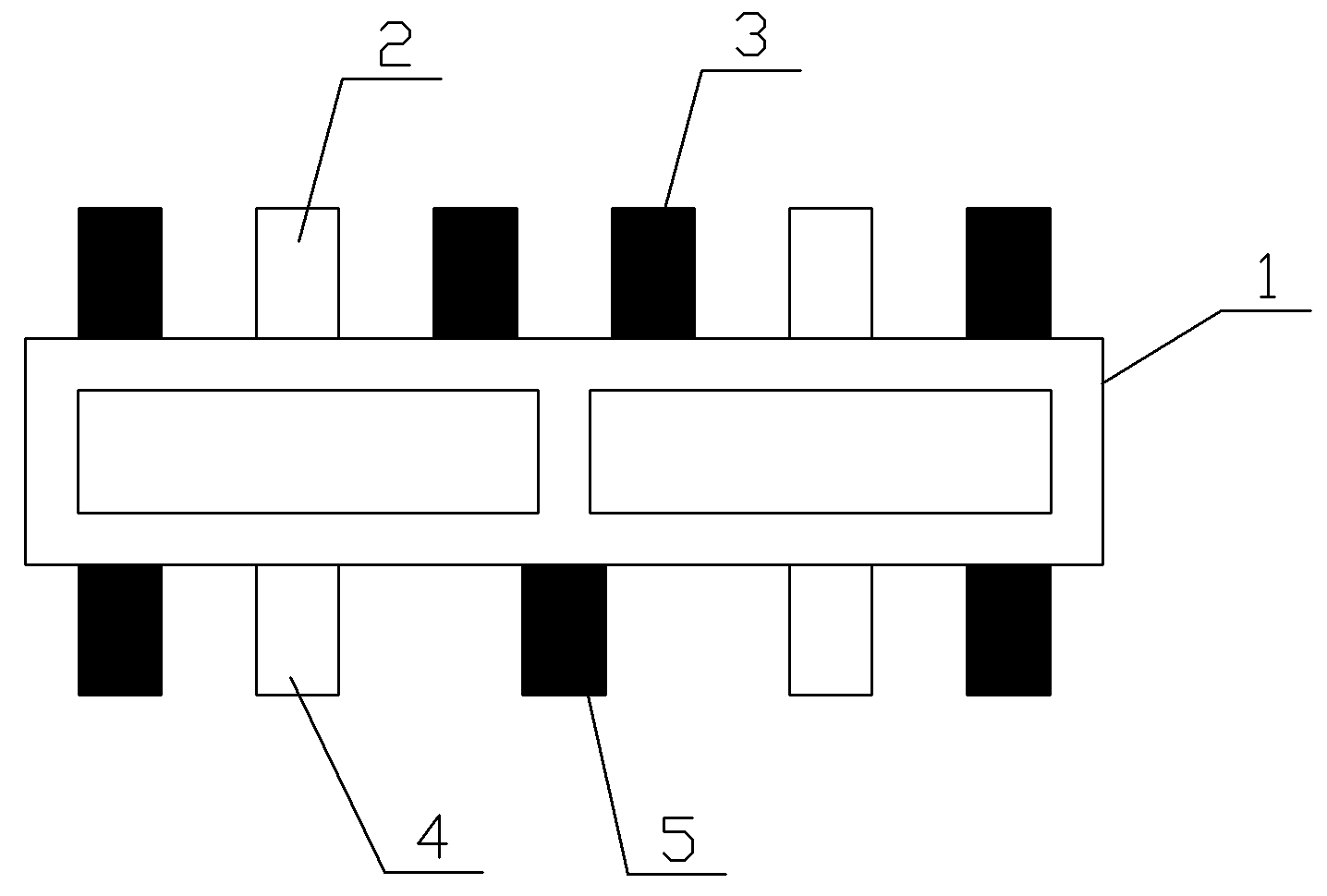

Crystallizer

The invention discloses a crystallizer, belonging to crystallizing devices, which structurally comprises a shell body of the crystallizer, wherein upper water outlets and upper water inlets are arranged on the upper part of the shell body of the crystallizer; lower water outlets and lower water inlets are arranged on the lower part of the shell body of the crystallizer; the upper water inlets and the lower water inlets are respectively two in quantity; the upper water inlets and the lower water inlets are symmetrically arranged; the amount of the upper water outlets is larger than the amount of the lower water outlets; and the lower water outlets and the lower water inlets are arranged in a staggered mode. Compared with the prior art, the crystallizer of the invention has the advantages that the temperature on the surface of cast ingots is reduced so that the tissues of the upper surfaces and the lower surfaces of the cast ingots are uniform; the cooling strength of a graphite plate on the crystallizer is enhanced, and the cooling strength on the lower surface of the crystallizer is reduced so that the upper and the lower cast ingots in the crystallizer can be simultaneously crystallized; the abrasion degree of the graphite plate on the lower surface of the crystallizer is improved to a certain extent; and the service life of the graphite plate is increased, and the like, therefore, the crystallizer has good popularization and application values.

Owner:CNMC ALBETTER ALBRONZE

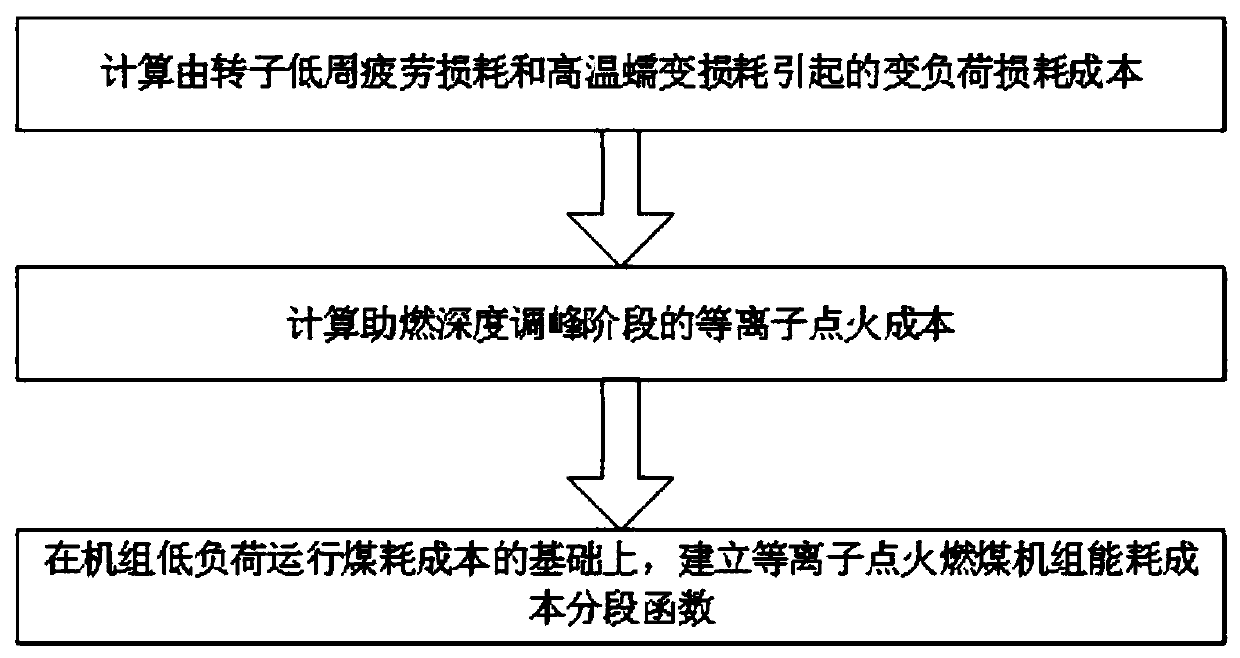

Method for calculating deep peak regulation energy consumption cost of coal-fired unit based on plasma ignition technology

PendingCN111144047AImprove securityIncreased wear and tearData processing applicationsDesign optimisation/simulationThermodynamicsEngineering

The invention provides a method for calculating the deep peak regulation energy consumption cost of a coal-fired unit based on a plasma ignition technology. The method comprises the following steps: (1) calculating the unit depth peak regulation variable load loss cost according to the operation state difference of the plasma ignition coal-fired unit in different depth peak regulation stages; (2)calculating the plasma ignition cost of the deep peak regulation combustion-supporting stage; and (3) on the basis of considering the coal consumption characteristics, constructing the deep peak regulation energy consumption cost piecewise function of the plasma ignition coal-fired unit. The patent achievements provide a basis for economic operation of a thermal power plant adopting a plasma ignition combustion-supporting technology.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

A high-strength wear-resistant coating

Owner:ANHUI JINDUN PAINT

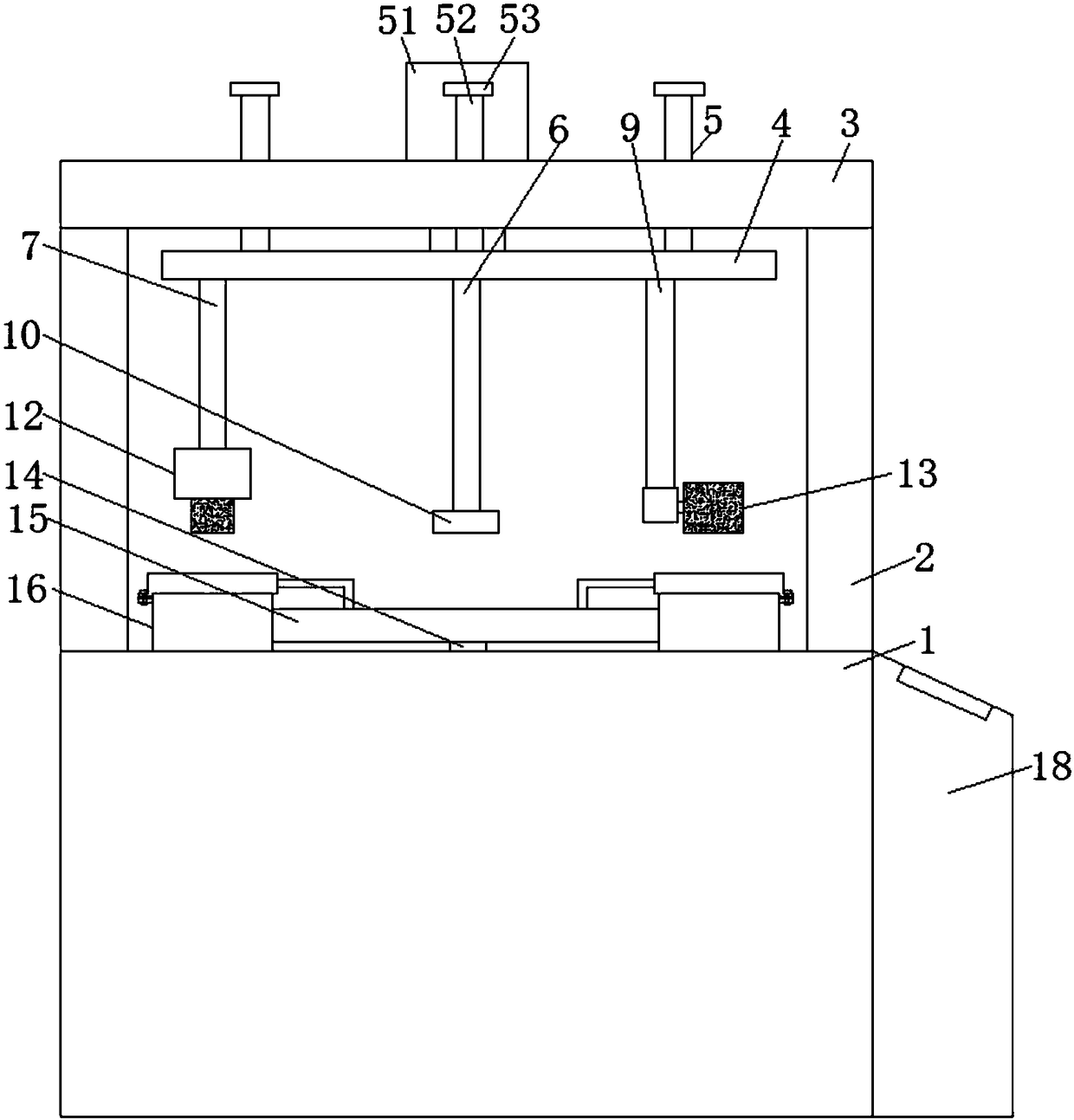

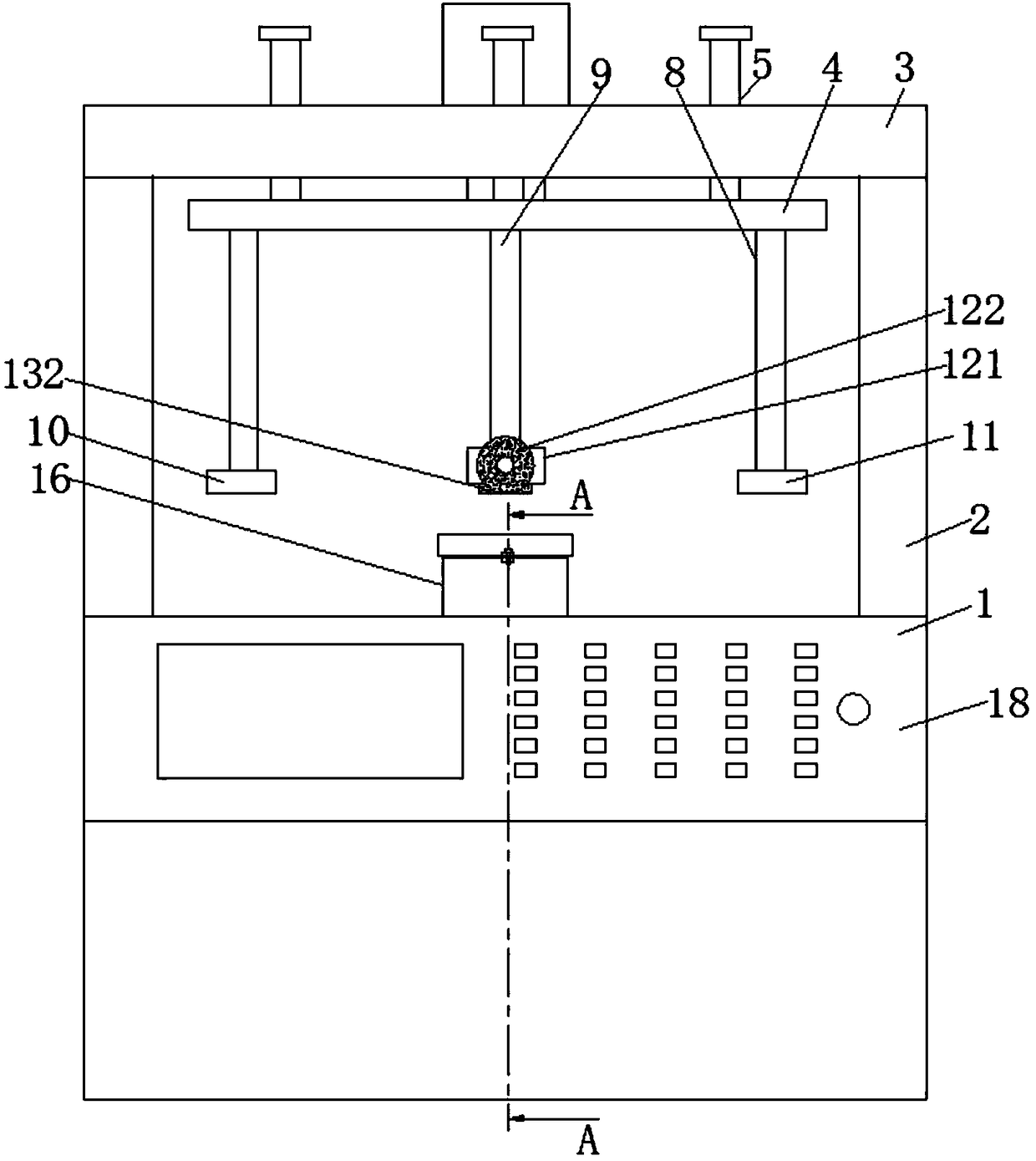

Abrasion resistant detection device of leather product

InactiveCN108225957AReliable test resultsEasy to fixInvestigating abrasion/wear resistanceWear patternWear resistance

The invention discloses an abrasion resistant detection device of a leather product. The abrasion resistant detection device comprises a detection table, wherein four groups of support rods are vertically arranged on the detection table; one ends, far away from the detection table, of the four groups of support rods are provided with a top plate; a lifting plate is arranged at one side, near the detection table, of the top plate; a lifting device is arranged between the lifting plate and the top plate; the lifting plate is vertically provided with a first hanging rod, a second hanging rod, a third hanging rod and a fourth hanging rod in a way of far away from the lifting device; one ends, far away from the lifting plate, of the first hanging rod and the third hanging rod are respectively provided with a first detection probe and a second detection probe. The abrasion resistant detection device has the advantages that the structure is simple; the design is novel; the leather sample piece fixation is firm and reliable; two groups of leather sample pieces can be sequentially subjected to abrasion tests in two grinding modes; the detection results, tested in the two grinding mode, of the leather sample pieces are more accurate; meanwhile, the abrasion mode with greater abrasion degree on the leather sample piece can also be judged; the comprehensive judgement on the abrasion resistance of the leather sample piece is facilitated.

Owner:苏州朦井纺织科技有限公司

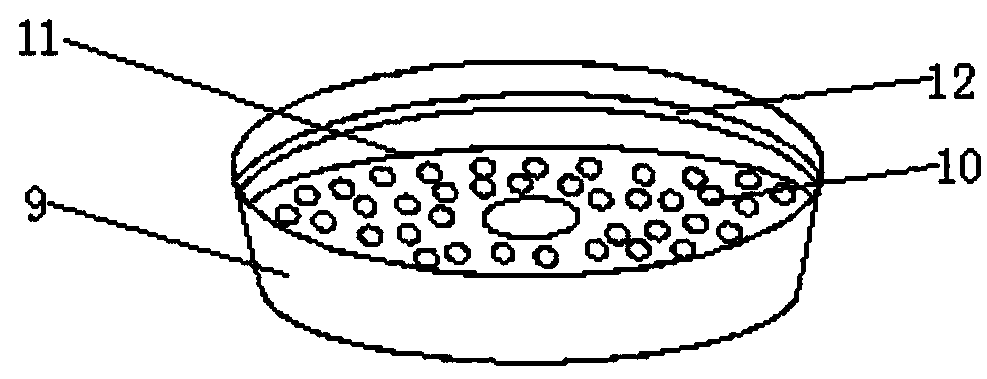

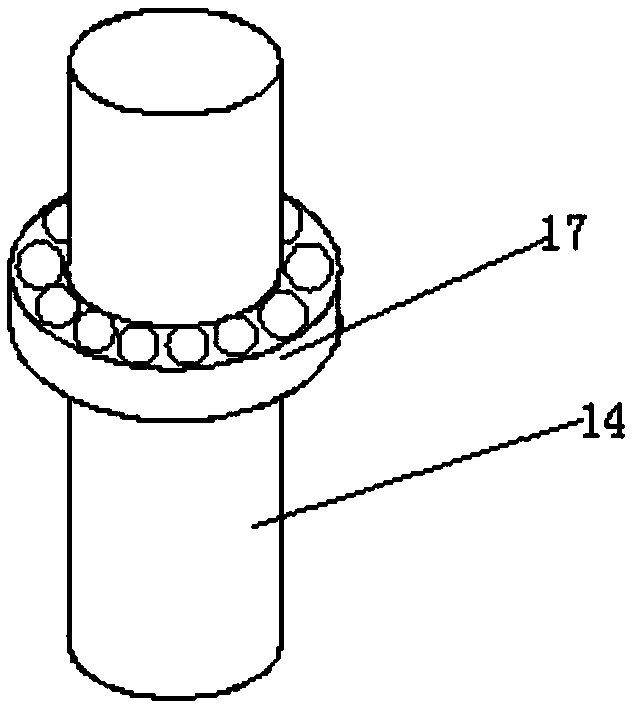

Novel biomass particulate fuel forming machine

The invention discloses a novel biomass particulate fuel forming machine comprising a case. A smashing motor is mounted at the top of the case; a feeding pipe is arranged on one side of the smashing motor; a transverse rotating shaft is arranged in the feeding pipe; a helical blade is arranged on the transverse rotating shaft, and the transverse rotating shaft is movably connected with the smashing motor in an engaged mode through a gear; a feeding hopper is arranged above the feeding pipe; a solenoid valve is arranged in the feeding hopper; a pressing disc is fixedly connected to an inner cavity of the case through a fixing rod; a plurality of forming through holes are formed in the bottom of the pressing disc; a circular groove is formed in the pressing disc, and a fixing sliding grooveis formed in the inner side of the circular groove; and two pressing rollers are arranged in the circular groove. The novel biomass particulate fuel forming machine is simple in structure, equipment overload can be effectively prevented, the mold abrasion degree is decreased, the production efficiency is improved, and the service life is prolonged, so that the novel biomass particulate fuel forming machine has wide application prospects.

Owner:RUGAO OUTONG MACHINERY FITTINGS

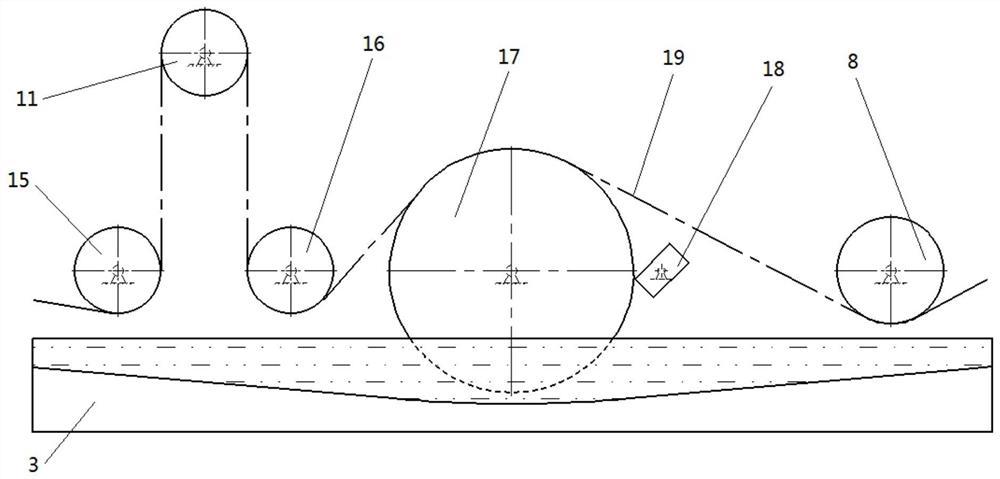

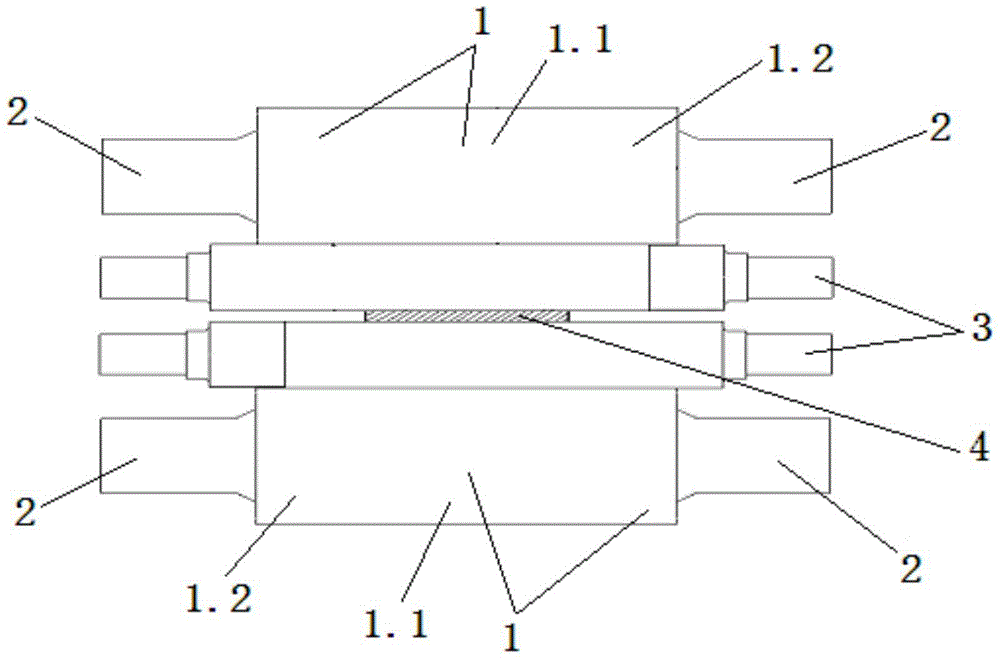

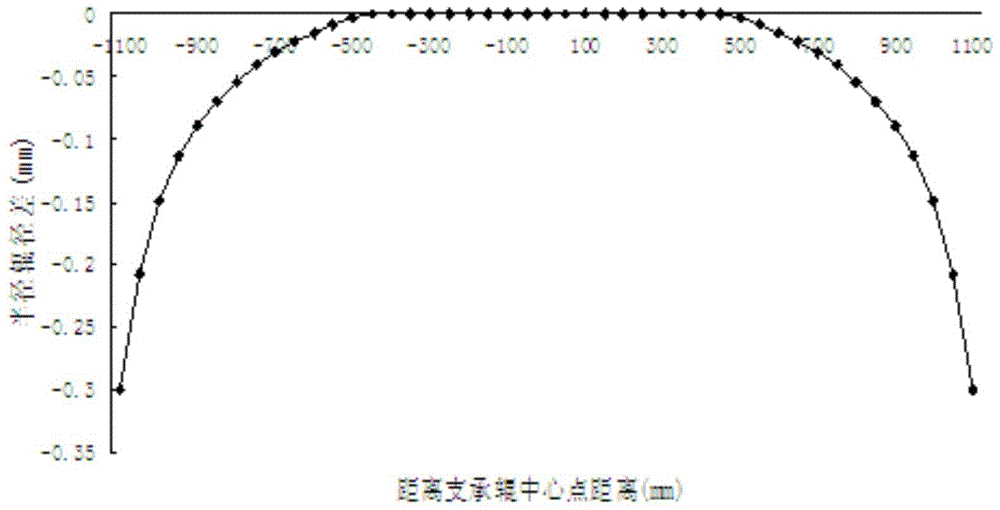

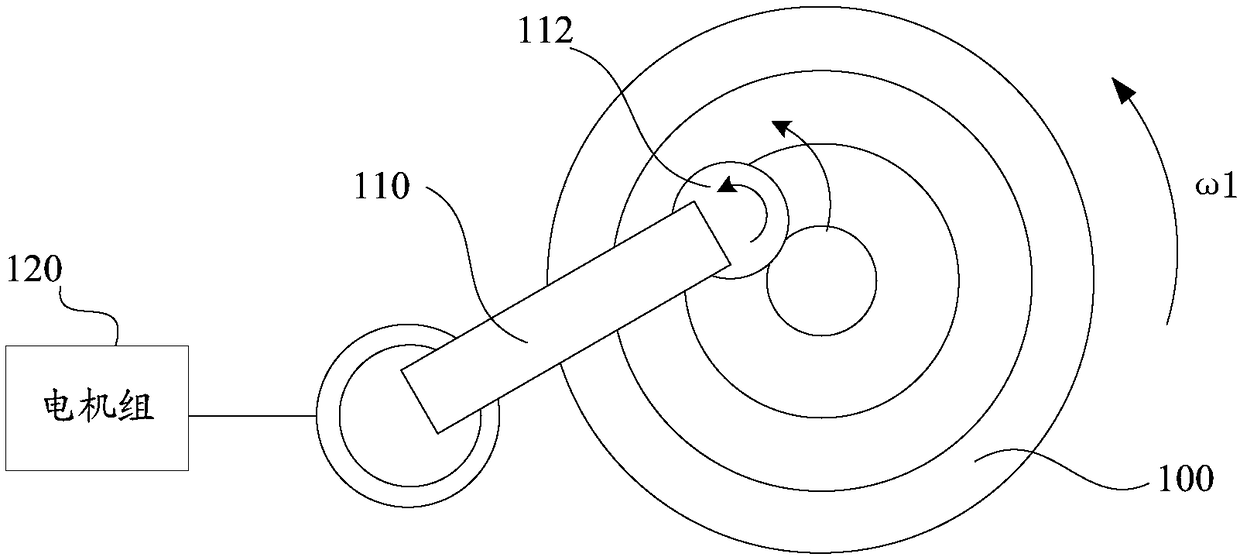

Supporting roll used for carrying out hot rolling on 2250 leveling unit and design method for roll barrel roll shape of supporting roll

InactiveCN103599939AIncreased wear and tearEasy to adjustRollsMetal rolling arrangementsEngineeringDesign methods

The invention discloses a supporting roll used for carrying out hot rolling on a 2250 leveling unit. The supporting roll comprises a roll barrel arranged in the middle and roll necks arranged at two sides, the roll barrel comprises a rolling area and harmful contact areas, the roll shape of the rolling area is a linear section, the rolling shapes of the harmful contact areas at the two sides are both VCR curves in the shape of a parabola, and the two VCR curves are arranged at the two ends of the roll barrel symmetrically by using the midpoint and the axis of the roll barrel as the original point and the X axis and using the Y axis as the symmetric axis. The design method for roll barrel roll shape of the supporting roll used for carrying out hot rolling on the 2250 leveling unit comprises the following steps that 1, a working roll is determined to be a plain-barrel roll; 2, the overall convexity of the roll barrel is determined; 3, the distance between the bending-starting position of the roll barrel and the midpoint is determined; 4, a VCR roll shape curve model of the harmful contact areas is determined; 5, the integrated shape of the roll barrel is determined. The supporting roll used for carrying out hot rolling on the 2250 leveling unit has the advantages of reducing the number of the harmful contact areas, improving the roll-bending effect, enabling contact pressure between rolls to be distributed evenly, improving strip shape quality and being small in working roll consumption, and can be widely applied to the technical field of hot rolling leveling.

Owner:武汉钢铁有限公司

Strong-strength abrasion-resistant coating

The invention discloses a strong-strength abrasion-resistant coating. The coating is characterized in that the coating is prepared from the following raw materials in parts by weight: 20 parts of tetraethyl orthosilicate, 15 parts of methyltrimethoxy silane, 15 parts of calcium naphthenate, 3 parts of silicon dioxide sol, 7 to 13 parts of graphite powder, 15 parts of auxiliary, 5 parts of carbon fiber powder and 6 parts of silicon carbide, wherein the particle size of the silicon dioxide sol is 5nm, the particle size of silicon oxide crystals is 25 mu m, the weight ratio of the silicon dioxide sol to the silicon oxide crystals is 2:3, and the weight ratio of the tetraethyl orthosilicate to the methyltrimethoxy silane is 2:1. The strong-strength abrasion-resistant coating disclosed by the method is high in abrasion resistance and lower in cost, and the adhesion performance of the strong-strength abrasion-resistant coating with a substrate is high.

Owner:李青玉

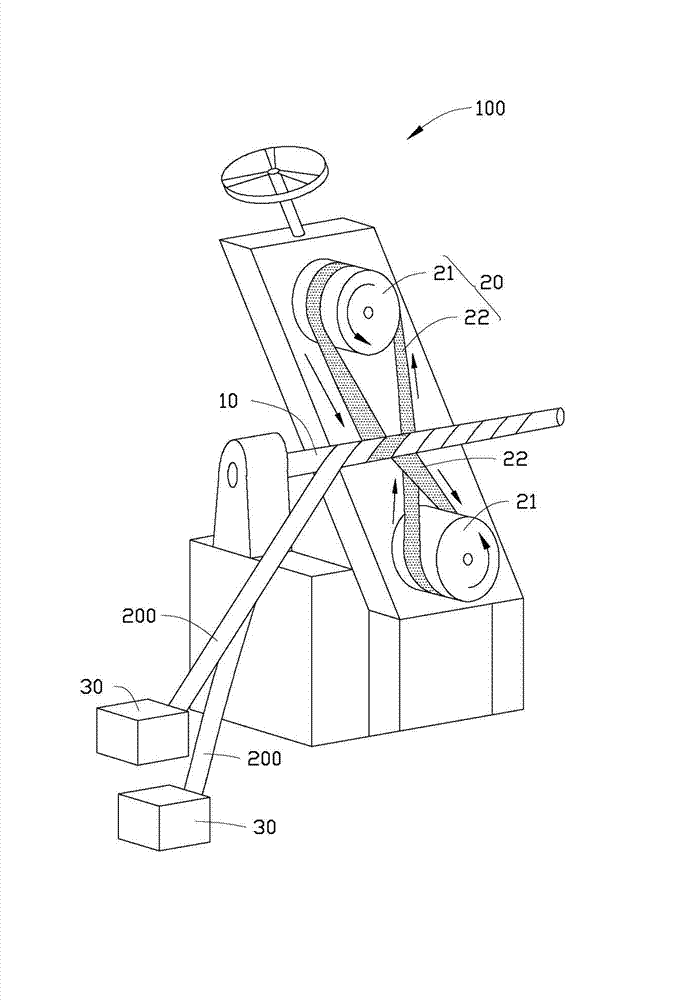

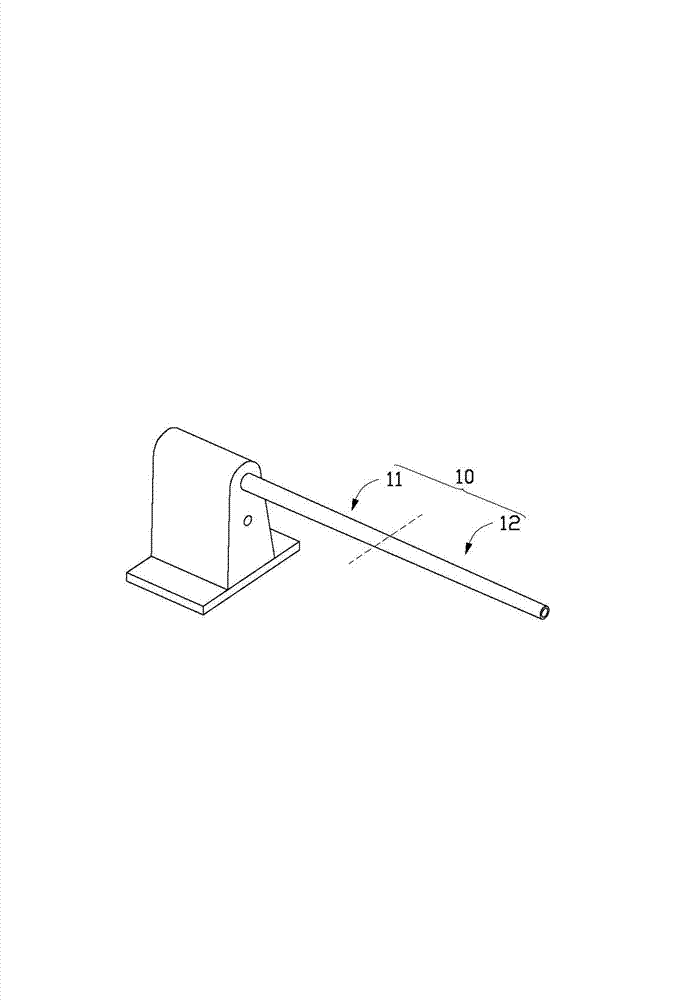

Paper tube forming device

ActiveCN102922779AIncrease productivityReduce manufacturing costPaper/cardboard wound articlesPaper tapePulp and paper industry

The invention relates to a paper tube forming device which comprises a paper tube forming shaft, a paper tape conveying device and a power device; the paper tape conveying device is used for supplying paper tapes to the paper tube forming shaft; the paper tube forming shaft comprises an inlet paper forming section and an outlet paper section; the power device is used for driving the paper tapes to be rotated and wound on the paper tube forming shaft so as to form paper tubes and simultaneously driving the paper tubes to slide from the inlet paper forming section to the outlet paper section along the axial line of the paper tube forming shaft; and the diameter of the paper tube forming shaft decreases gradually from the inlet paper forming section to the outlet paper section. Compared with the prior art, the paper tube forming device provided by the invention can effectively reduce the probability of damage caused by friction force of the inner walls of the paper tubes during the winding process and prolongs the service life of the paper tube forming shaft at the same time.

Owner:GOLD HONG YE PAPER

Liquid auxiliary treatment-based hot ore crushing equipment

ActiveCN105728104AImprove crushing effectImprove impact performanceGrain treatmentsEngineeringHigh pressure

The invention discloses liquid auxiliary treatment-based hot ore crushing equipment. The equipment comprises a crusher body, wherein a crushing roll shaft is arranged in the crusher body; a plurality of crushing end teeth which extend along a direction vertical to an axis of the crushing roll shaft are arranged on the crushing roll shaft; a plurality of auxiliary crushing end teeth are arranged on the inner wall of the crusher body; a plurality of pressure sensors are arranged on the crushing end teeth and the auxiliary end teeth; a plurality of liquid injection chambers are arranged in the crushing roll shaft; a cutting liquid slot which is communicated with the liquid injection chamber is formed outside the crusher body; a pressure pump is arranged in each liquid injection chamber; and auxiliary cutting nozzles are connected with the pressure pumps. According to the liquid auxiliary treatment-based hot ore crushing equipment, high-pressure liquid flow injection can be carried out on ores through the liquid injection chambers in the crushing roll shaft in the working process of the hot ore crushing equipment, so that the ores can be crushed under the cutting of the liquid flows, and then the ore crushing efficiency and precision can be effectively improved.

Owner:NANTONG ZHENQIANG MACHINERY MFG

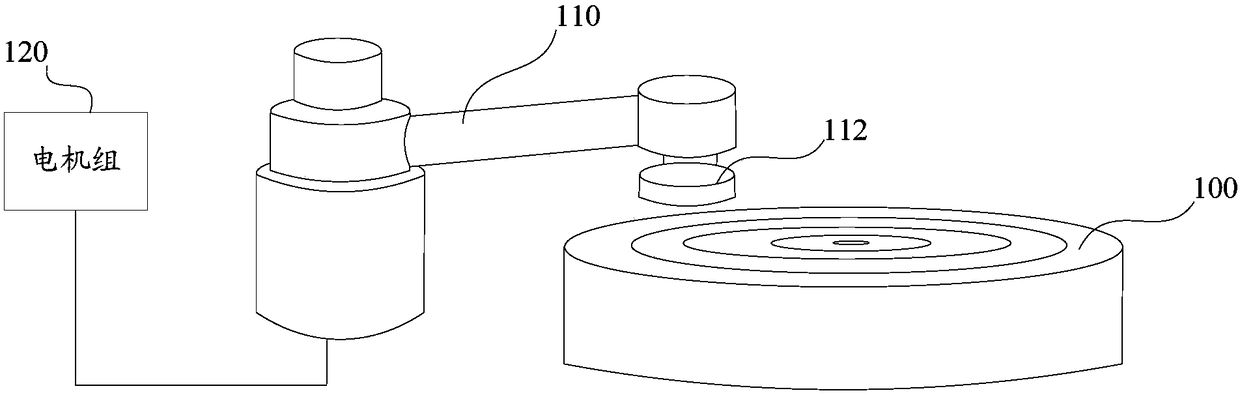

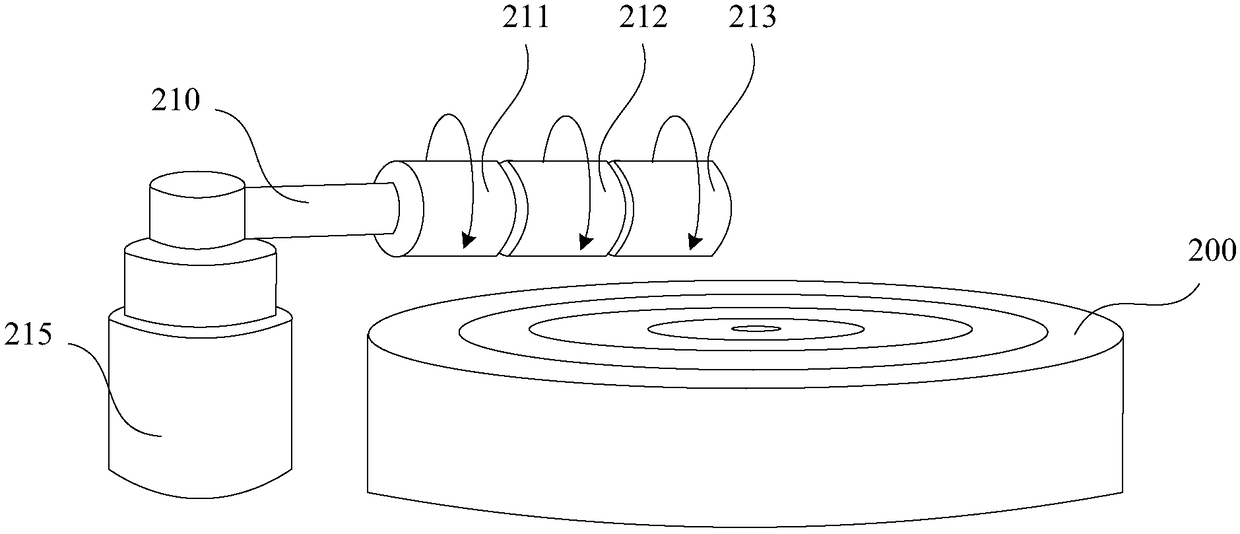

Polishing pad trimmer and polishing system

InactiveCN108214306AIncrease speedIncreased wear and tearAbrasive surface conditioning devicesControl theoryTopography

The invention relates to a polishing pad trimmer and a polishing system. The polishing pad trimmer comprises a trimming arm and a rotating speed control component, the trimming arm comprises a plurality of rollers connected end to end, and the total length of the multiple rollers is larger than or equal to the radius of a polishing pad; and the rotating speed control component is connected with the multiple rollers and controls the rotating speed of each roller, and the rotating speed of the roller close to the center of the polishing pad is larger than the rotating speed of the roller close to the edge of the polishing pad. According to the scheme, the coincidence of the center zone height and the edge zone height of the polishing pad can be improved, and the surface topography is optimized.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

A method for controlling the orange-peel reticulate defect on the surface of steel strip

ActiveCN104998910BOrange Peel Defect ControlExtended service periodRollsProfile control deviceConstant frequencyStrip steel

The invention belongs to the technical field of hot rolling, and discloses a method for controlling orange peel reticulate pattern defects on the surface of strip steel. The method is characterized by comprising the following steps: adopting an SGB roll profile curve on a supporting roller of a hot rolling temper mill; adopting an SGW roll profile curve on a working roller. The process parameters of the temper mill are set as the rolling force of 200-250 tons, the unwinding tension of 9-12 tons, and the winding tension of 20-23 tons, the rolling reduction of straightening rollers is used in a straightening machine group, and a roller shifting strategy with constant frequency, variable step sizes and variable stroke is adopted. According to the method, through the application of the SGB and SGW roll profile curves, a specific smoothing process and the roller shifting strategy, local wear of working rollers is greatly reduced, and orange peel reticulate pattern defects on the surface of the strip steel are effectively overcome.

Owner:SHOUGANG CORPORATION +1

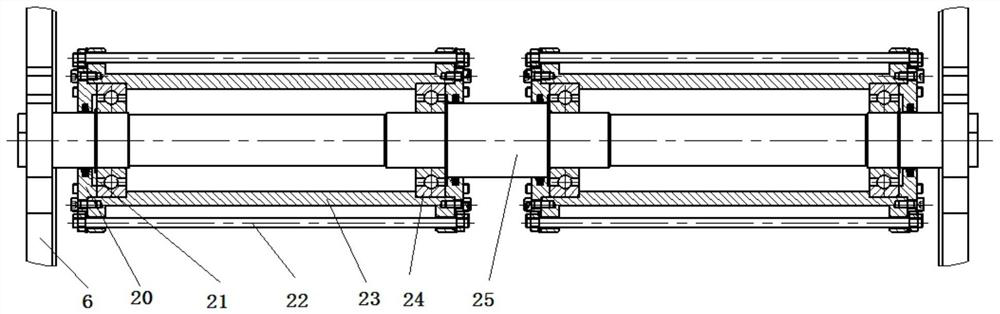

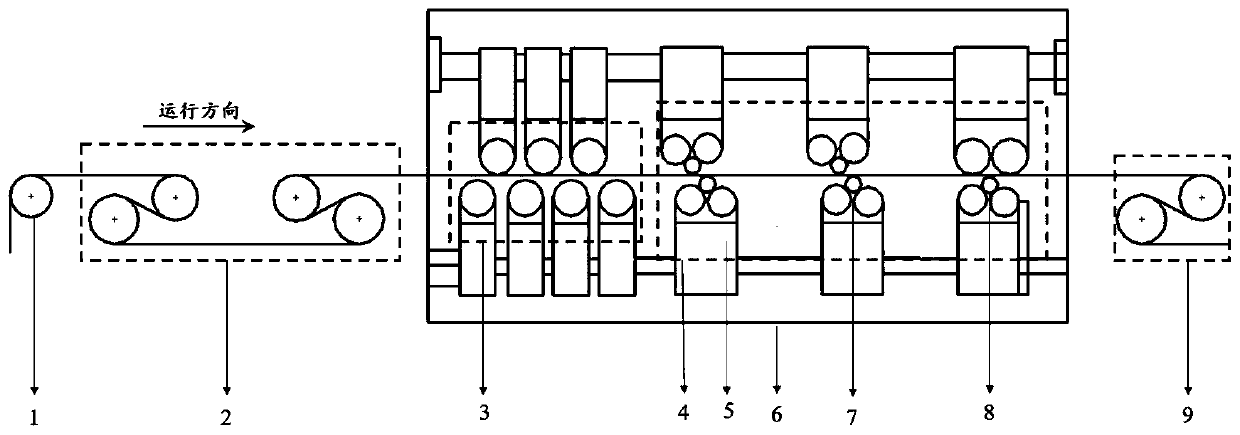

Combined type cold-rolled stretching-bending straightener

ActiveCN111185481AImprove scale breaking effectImprove flatnessWork treatment devicesMetal rolling arrangementsStructural engineeringStrip steel

The invention provides a combined type cold-rolled stretching-bending straightener, and belongs to the technical field of withdrawal and straightening equipment. The combined type cold-rolled stretching-bending straightener comprises a turning roller, an inlet tensioning roller set, a multi-roller straightening system, a stretching and straightening roller system, roller boxes, a machine frame, abending roller set, a straightening roller set, an outlet tensioning roller set and an elevator. The turning roller, the inlet tensioning roller set, the multi-roller straightening system, the stretching and straightening roller system, the bending roller set, the straightening roller set and the outlet tensioning roller set are sequentially arranged in the conveying direction of strip steel, themulti-roller straightening system, the stretching and straightening roller system, the bending roller set and the straightening roller set are installed on the machine frame, and the multi-roller straightening system, the stretching and straightening roller system, the bending roller set and the straightening roller set are provided with the roller boxes and the lower parts of the multi-roller straightening system, the stretching and straightening roller system, the bending roller set and the straightening roller set are connected with the elevator through lifting synchronous connecting rods.The combined type cold-rolled stretching-bending straightener can improve the scale breading effect on the surface of the strip steel, improve the acid pickling efficiency, reduce the acid consumptionamount in an acid pickling technology, can effectively improve the wear degree, reduce the risk of excessive withdrawal and straightening of welding lines, reduce the enterprise cost, and improve thesafety of equipment operation.

Owner:UNIV OF SCI & TECH BEIJING

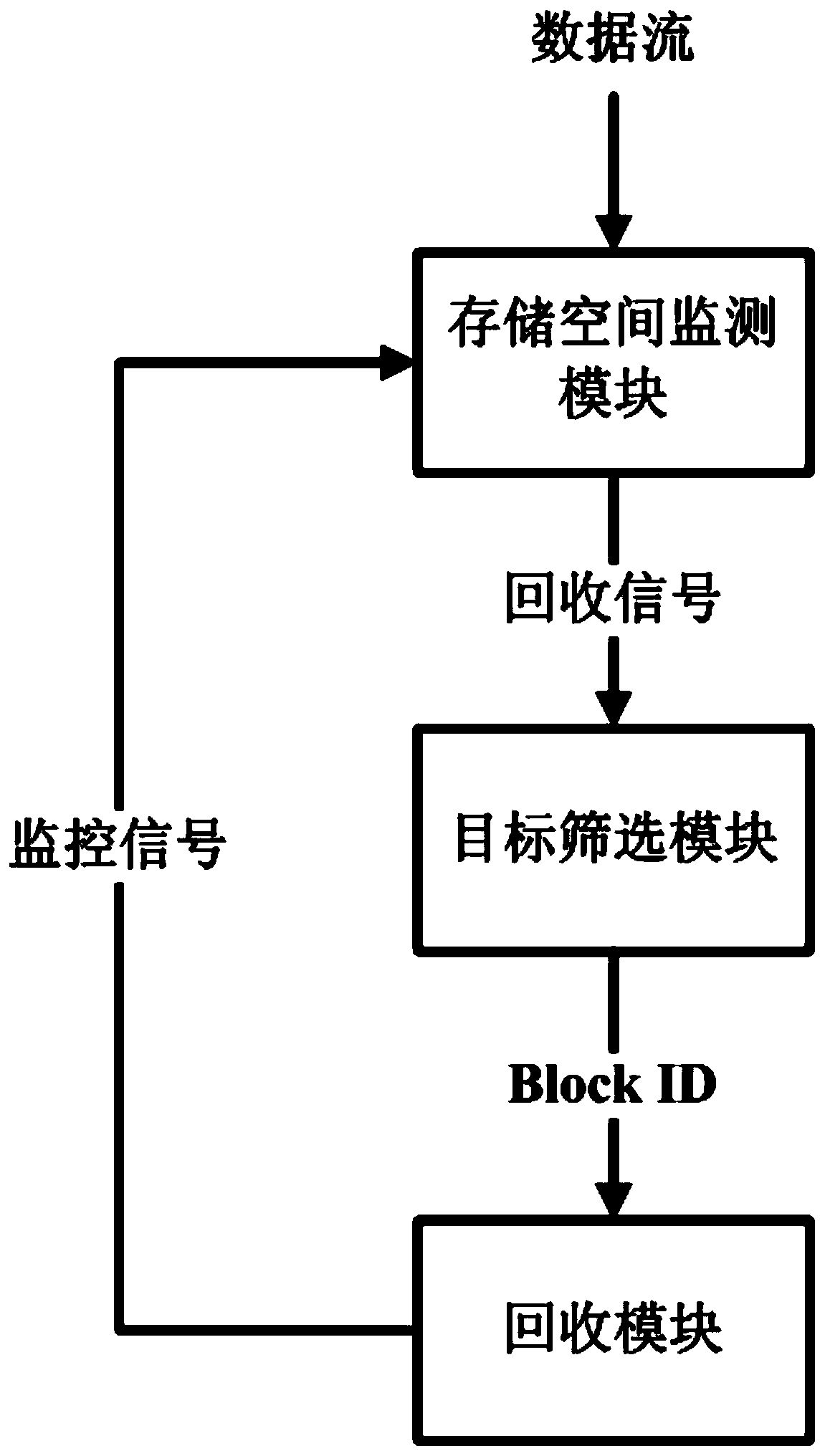

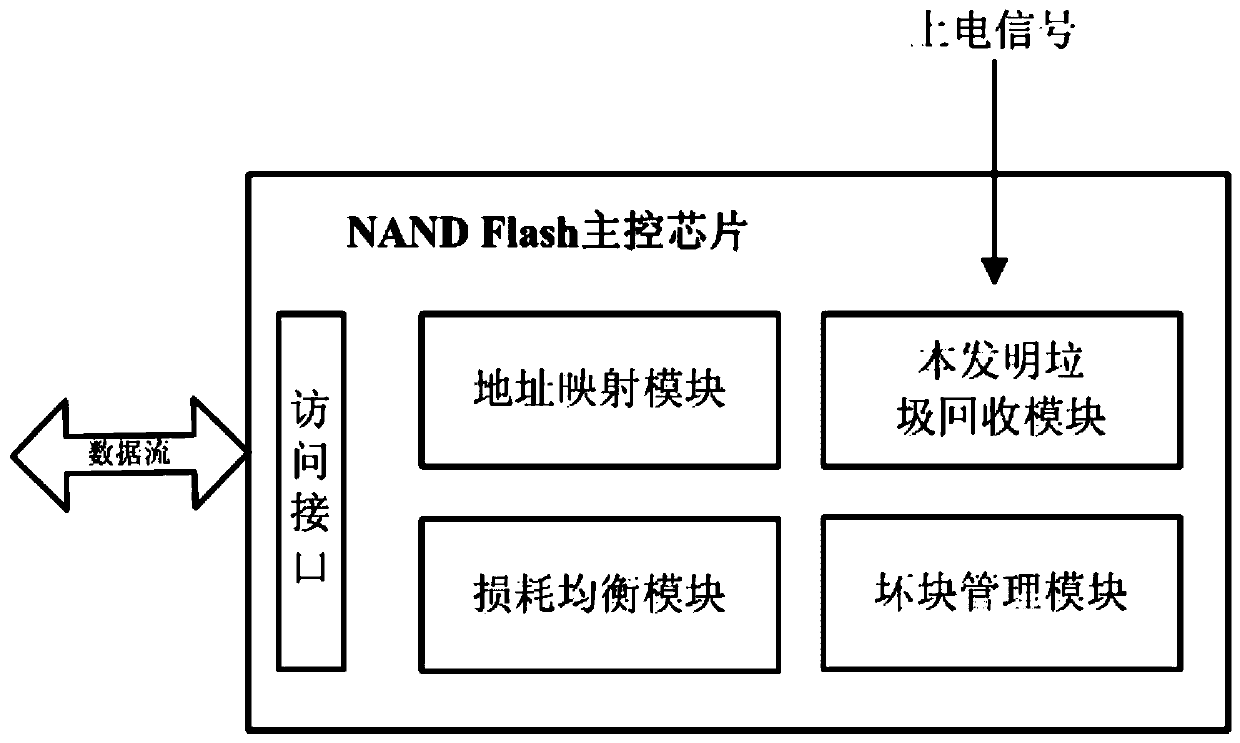

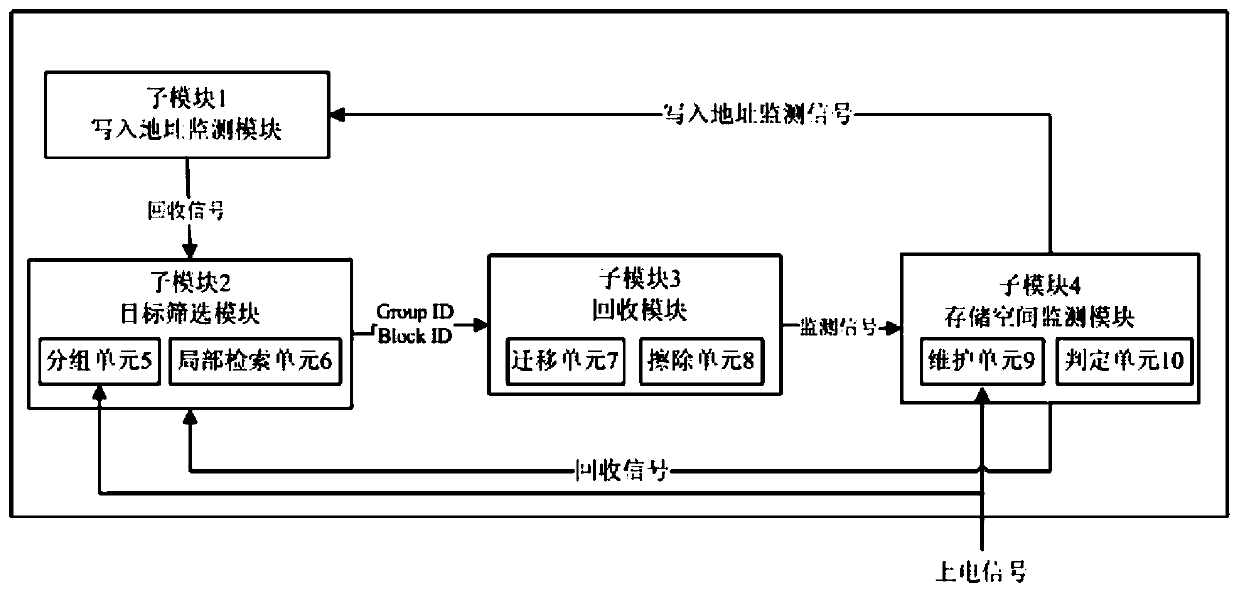

Greedy garbage collection system for an NAND Flash main control chip

ActiveCN109739776AImprove reliabilityImprove recycling efficiencyMemory adressing/allocation/relocationEnergy efficient computingEmbedded system

The invention belongs to the technical field of chips, and particularly relates to a Greedy garbage collection system for an NAND Flash main control chip. Compared with the prior art, the garbage collection system provided by the invention is high in reliability, simple to implement and high in collection efficiency, and is embedded into a main control chip of the NAND Flash. Compared with a general garbage collection module adopting a Greedy collection strategy, the main control chip embedded with the high-reliability and high-efficiency garbage collection system has the advantage that the working efficiency can be greatly improved on the premise that the high reliability is ensured.

Owner:TIANJIN JINHANG COMP TECH RES INST

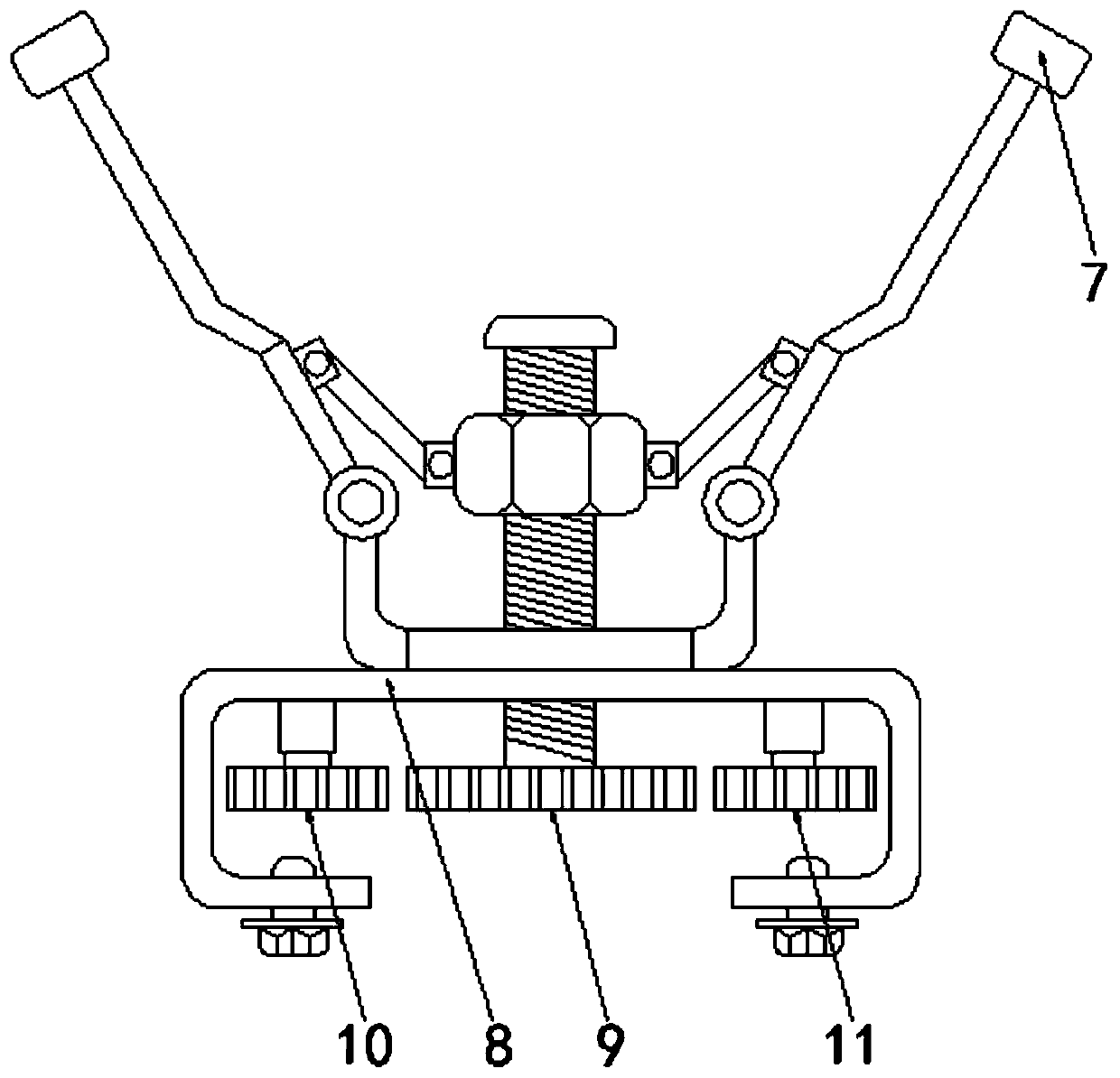

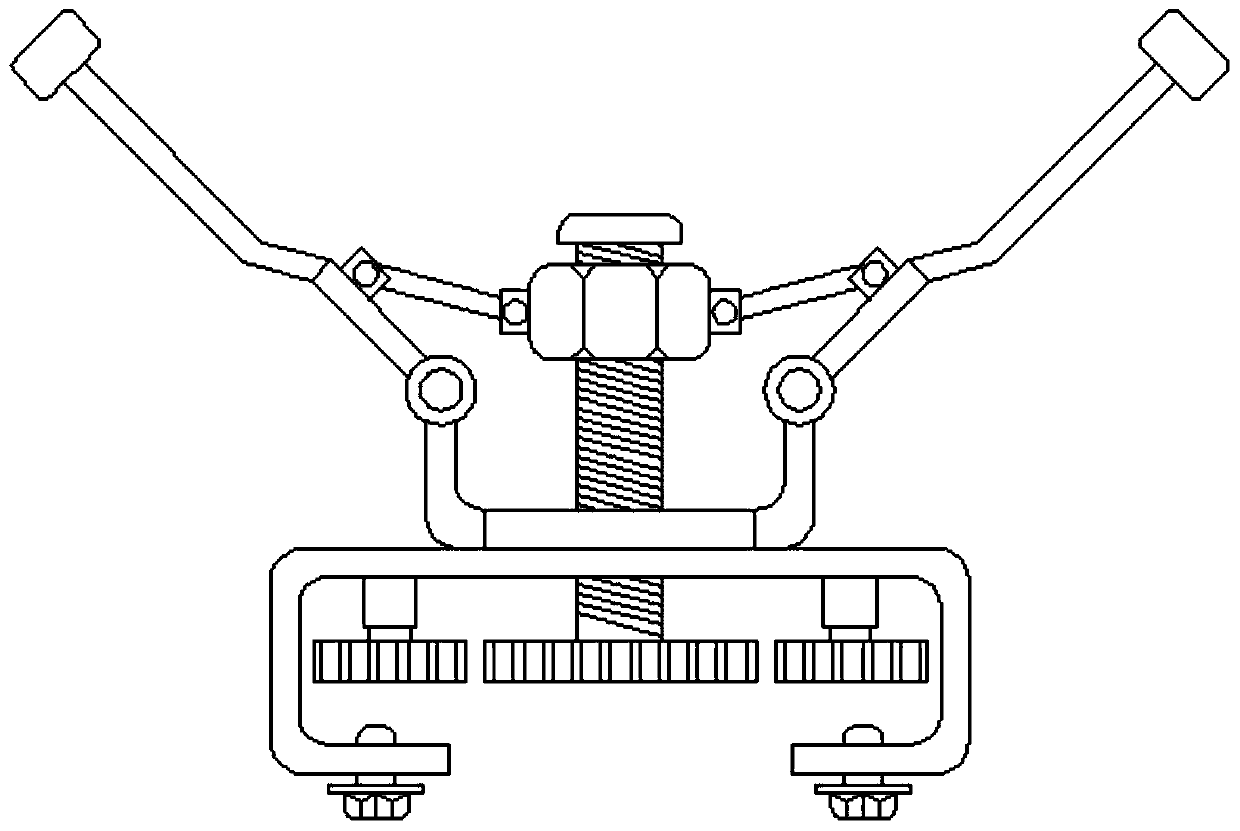

Driving wheel road holding force and life detection device and road holding force and life detection method

PendingCN111721550AReal gripIncreased wear and tearVehicle tyre testingCell controllerControl circuit

The invention discloses a driving wheel road holding force and life detection device and a and road holding force and life detection method. The detection device comprises a driving wheel unit which comprises a supporting device, a pushing device, and a driving wheel assembly; a road surface simulation unit which is arranged below the driving wheel unit and comprises a first supporting part, a second supporting part and a roller assembly; and a control unit which comprises a main controller, a driving wheel control circuit, a brake unit controller and a pushing device controller; the road holding force and service life detection method comprises the following steps: adjusting the position of the driving wheel assembly to enable the driving wheel assembly to be in close contact with the rolling surface for simulating close contact between a driving wheel and a simulated road surface; and then the road holding force and the service life are measured by adjusting the brake unit. The device has the beneficial effects that different pavement conditions can be simulated; the effects of different anti-skid patterns can be inspected; the service life of the driving wheel can be tested; when the driving wheel starts to slip can be detected; and the error-tolerant rate of the system is improved.

Owner:ZHEJIANG UNIV OF TECH

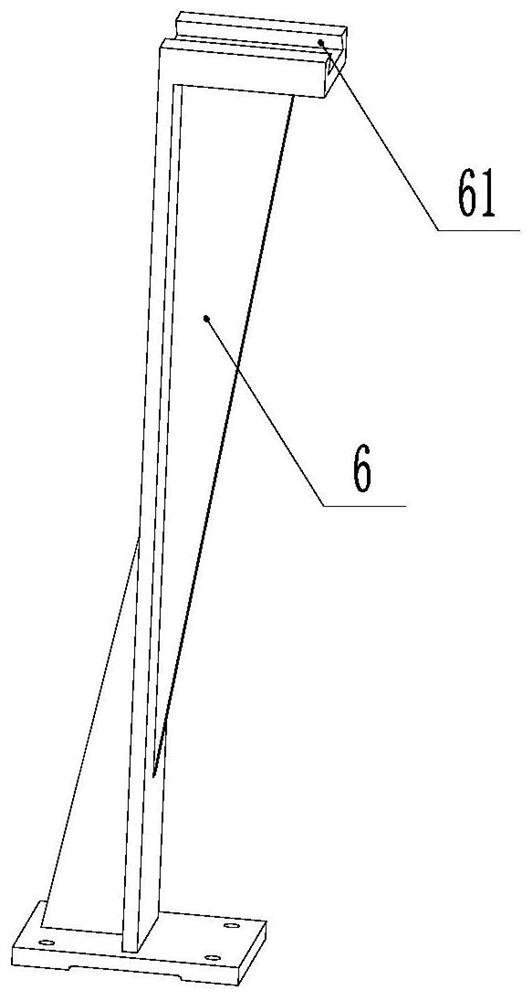

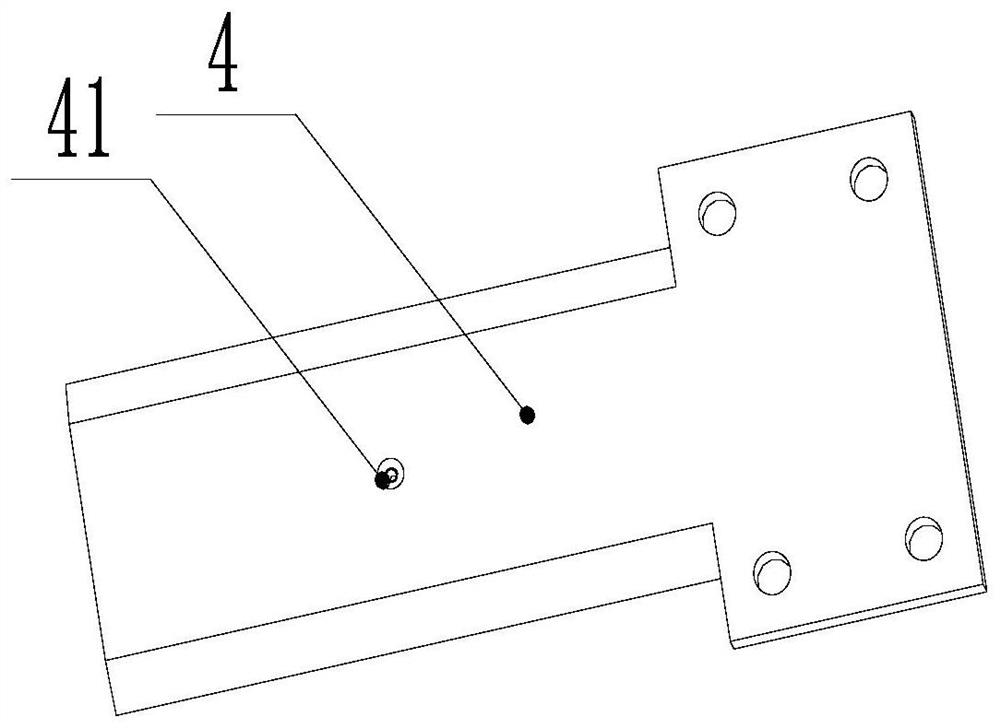

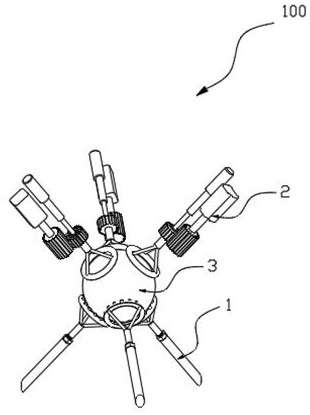

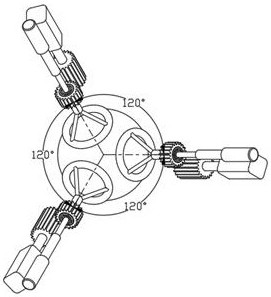

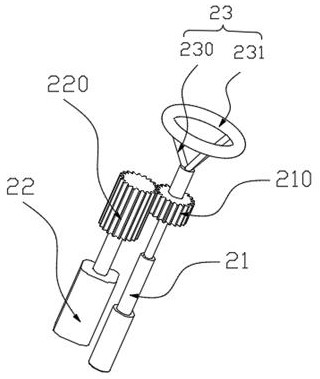

Shot blasting auxiliary mechanism and shot blasting machine with same

ActiveCN113103157AEliminates the problem of cleaning blind spotsEasy to cleanAbrasive machine appurtenancesAbrasive blasting machinesGear wheelDrive by wire

The invention provides a shot blasting auxiliary mechanism and a shot blasting machine with the shot blasting auxiliary mechanism, which are used for assisting shot blasting of a spherical workpiece. The shot blasting auxiliary mechanism comprises a supporting piece, the supporting piece surrounds a part of the spherical workpiece, and the spherical workpiece can rotate in a space defined by the supporting piece; driving components comprising a linear driving device and a rotary driving device, and at least three groups of driving components are uniformly distributed in the circumferential direction; and the rotary driving device comprises a driving gear, the driving gear is meshed with a driven gear, and the rotary driving device is used for driving the driving gear to rotate, so that the spherical workpiece rotates along with a friction piece. A part of the spherical workpiece is surrounded by the supporting piece, and the spherical workpiece is sequentially driven by the three groups of driving devices which are uniformly distributed in the circumferential direction, so that all surfaces of the spherical workpiece can be treated, and the problem of cleaning blind areas is solved.

Owner:南京汇恒机电有限公司

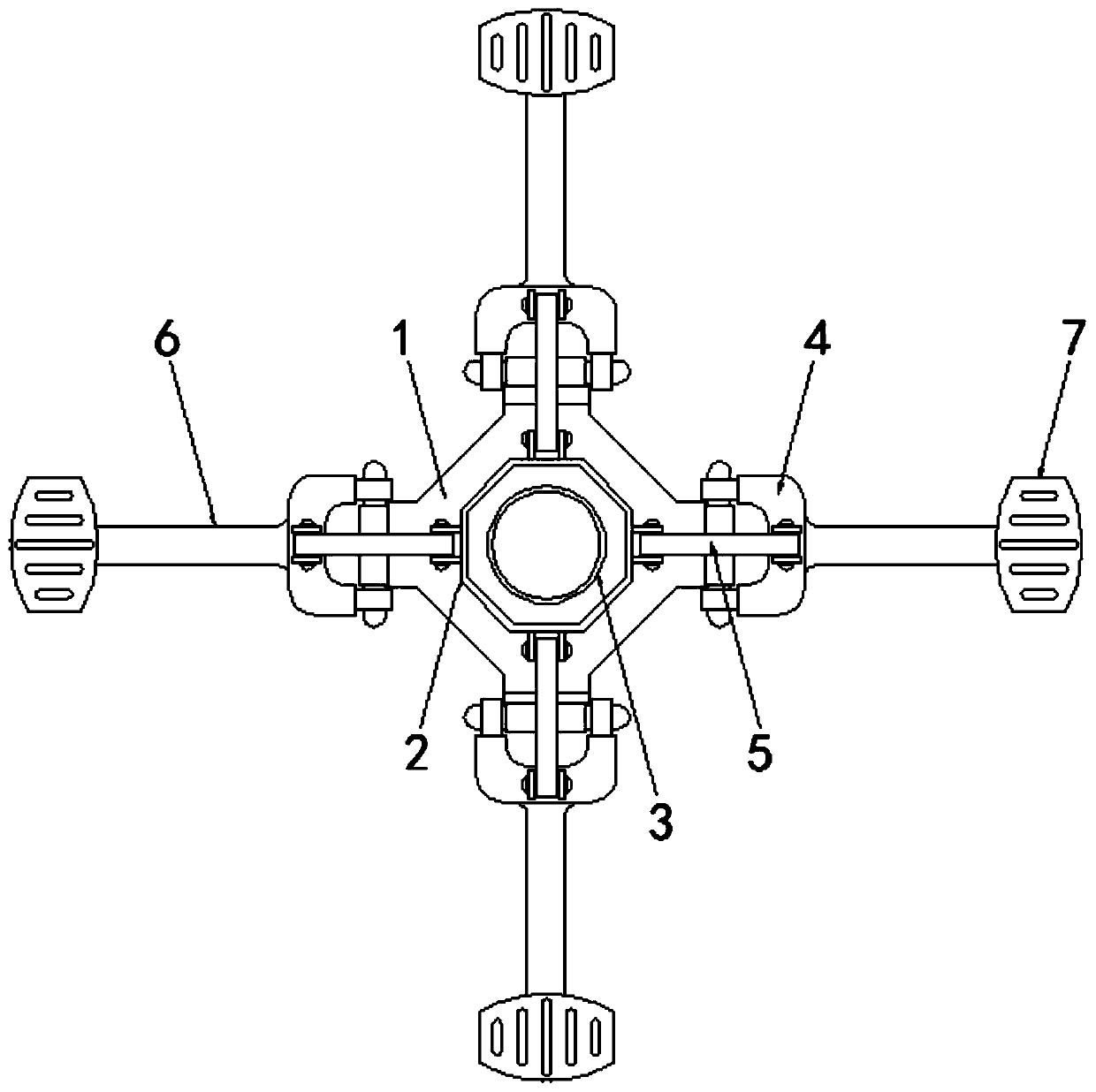

Wheel flaw detector auxiliary device based on gear linkage principle

The invention relates to the technical field of automobile detection auxiliary equipment, provides a wheel flaw detector auxiliary device based on a gear linkage principle. The auxiliary device comprises a bottom plate; a movable screw group is connected to the front side of the bottom plate; a fixed screw is connected to the movable screw group and penetrates the bottom plate; and the bottom of the fixed screw is fixedly connected with a driven gear. The central axes of the bottom plate, the movable screw group and the fixed screw are arranged at the same straight line. Four limiting seats are fixedly connected to the outer side of the bottom plate. According to the auxiliary device, when the movable screw group moves upward, the distance between clamp blocks is reduced to clamp a tyre; when the movable screw group moves downward, the distance between clamp blocks is increased to take out the tyre after detection completion. On the basis of the structure and process, the tyre can be clamped and fixed by the device; the operation becomes convenient and thus certain working time is saved; the accuracy of the detection result is improved and the work efficiency is enhanced.

Owner:阮晓媚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com