Supporting roll used for carrying out hot rolling on 2250 leveling unit and design method for roll barrel roll shape of supporting roll

A design method and back-up roll technology, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of work roll 3 wear, affect the coil, improve the quality of the plate shape, etc., achieve the improvement of wear degree and prolong the service life , The effect of improving the leveling amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments, but the embodiments should not be construed as limiting the present invention.

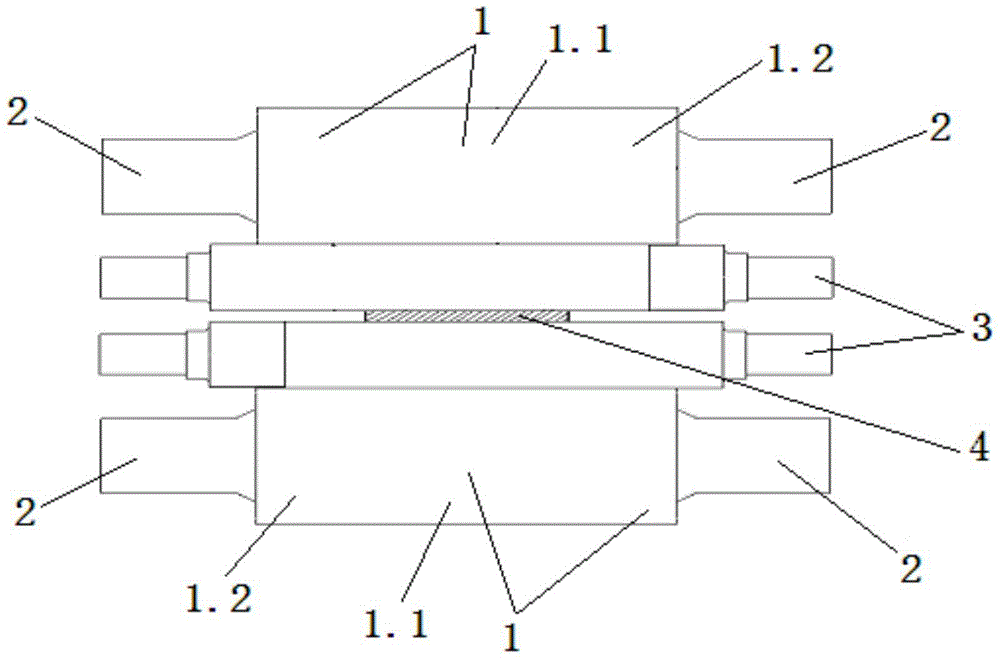

[0021] The backup roll of the present invention for hot rolling 2250 temper mill comprises a roll body 1 in the middle and roll necks 2 on both sides, the roll body 1 includes a rolling zone 1.1 in the middle and harmful contact zones 1.2 on both sides, The roll shape of the rolling zone 1.1 is a straight section, and the axial length of the roll body 1 is 2200 mm.

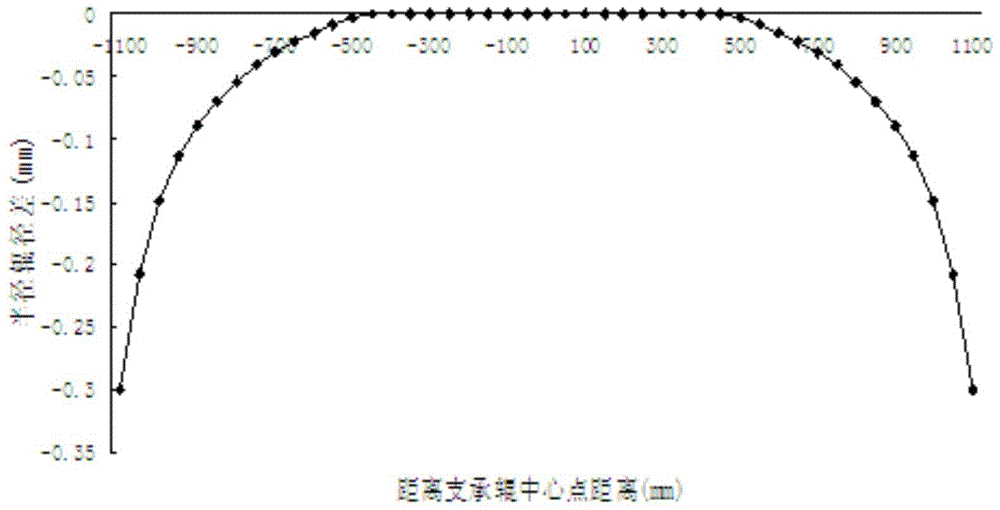

[0022] see figure 2 , the roll shapes of the harmful contact areas 1.2 on both sides are parabolic VCR curves. The two VCR curves are symmetrically distributed on the roll body with the midpoint and axis of the roll body 1 as the origin and the X axis, and the Y axis as the symmetrical axis. 1 ends. The roll shape equation of the VCR curve is P=b 1 X 2 +b 2 X 4 +b 3 X 8 , where b 1 The value is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com