Shot blasting auxiliary mechanism and shot blasting machine with same

An auxiliary mechanism and shot blasting machine technology, which is applied in the direction of manufacturing tools, abrasive jetting machine tools, used abrasive processing devices, etc., to achieve the effects of reducing friction, smooth rotation, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Before describing this embodiment in detail, first introduce the application scenario of the present invention. The present invention is conceived based on the technical problem of cleaning blind spots in the existing rotary table shot blasting machine when cleaning round workpieces, and is mainly used in the field of shot blasting machines, but it does not exclude the application of the technical solution of the invention to other technical fields possibility.

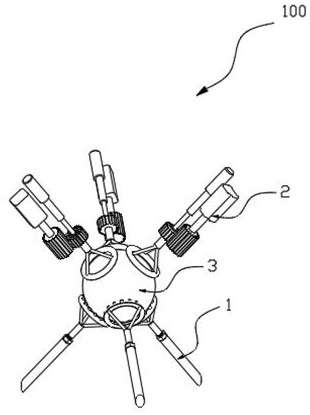

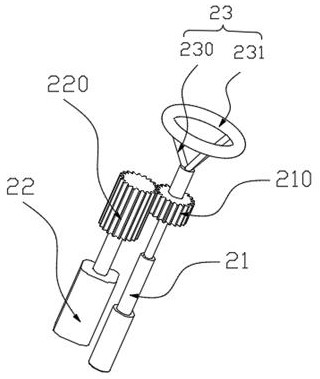

[0041] This embodiment will be described in detail below, according to Figure 1-Figure 8 As shown, a shot blasting auxiliary mechanism 100 according to the present application is used to assist the shot blasting of a spherical workpiece 3 , including: a support 1 for supporting the workpiece 3 and a driving assembly 2 for driving the workpiece 3 .

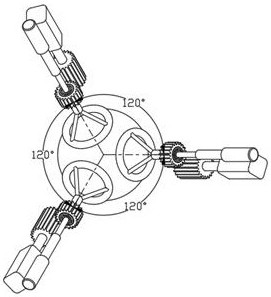

[0042] see figure 1, the support 1 surrounds the workpiece 3, and the spherical workpiece 3 can rotate in the space surrounded by the support 1; the drive assemb...

Embodiment 2

[0063] like Figure 1-Figure 9 As shown, a shot blasting machine 500 of the present application includes the shot blasting auxiliary mechanism 100 in Embodiment 1, the conical shot blasting chamber 5 and the shot blasting device 51 arranged in the shot blasting chamber 5 . The shot blasting machine 500 can realize 360° cleaning or strengthening of the spherical workpiece 3, eliminates the cleaning blind area caused by clamping, has a reasonable structure, and is easy to implement. The common parts of the prior art and this embodiment will not be repeated here. .

[0064] Wherein, the conical shot blasting chamber 5 can make the shot blasting collect by itself under the action of gravity, and the collection efficiency is high and easy to realize.

[0065] In addition, in order to ensure the effect of shot blasting, a plurality of shot blasting devices can be set in the shot blasting chamber 5, for example, three and three groups of shot blasting devices 51 coaxial with the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com