Polishing pad trimmer and polishing system

A polishing pad and dresser technology, applied in the field of polishing pad dressers and polishing systems, can solve the problems of poor surface morphology uniformity, decreased polishing effect and the like, and achieve the effect of improving the degree of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

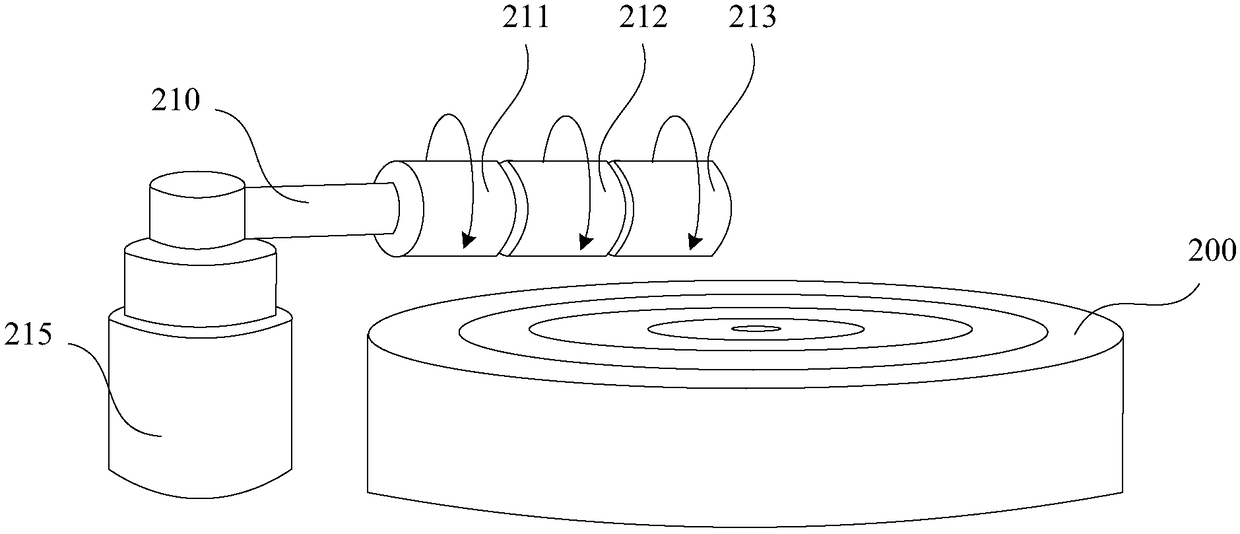

[0028] In the prior art, the surface of the polishing pad will become smooth or hardened due to the accumulation of debris from the abrasive slurry and the continuous friction of the wafer surface, resulting in a decline in the polishing effect. Therefore, it is necessary to use a dresser to dress the polishing pad to increase The roughness of the polishing pad surface.

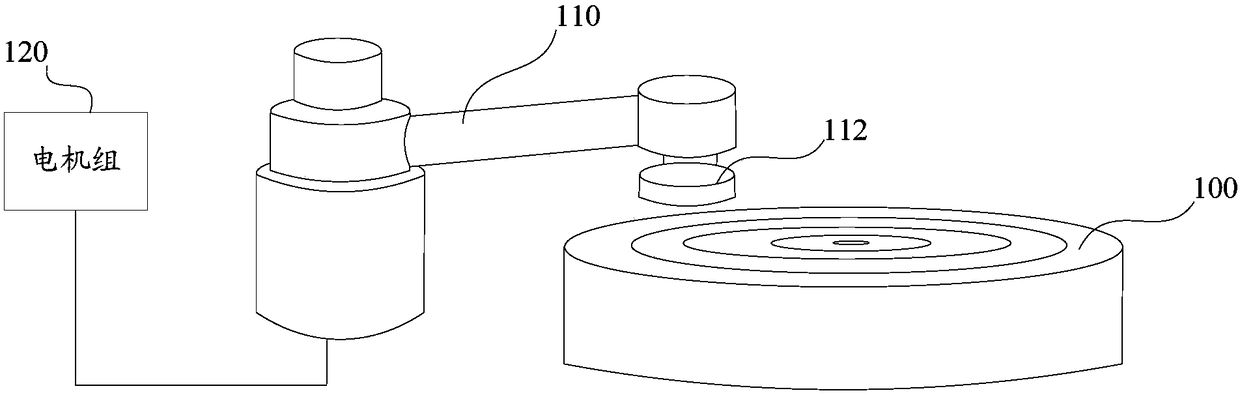

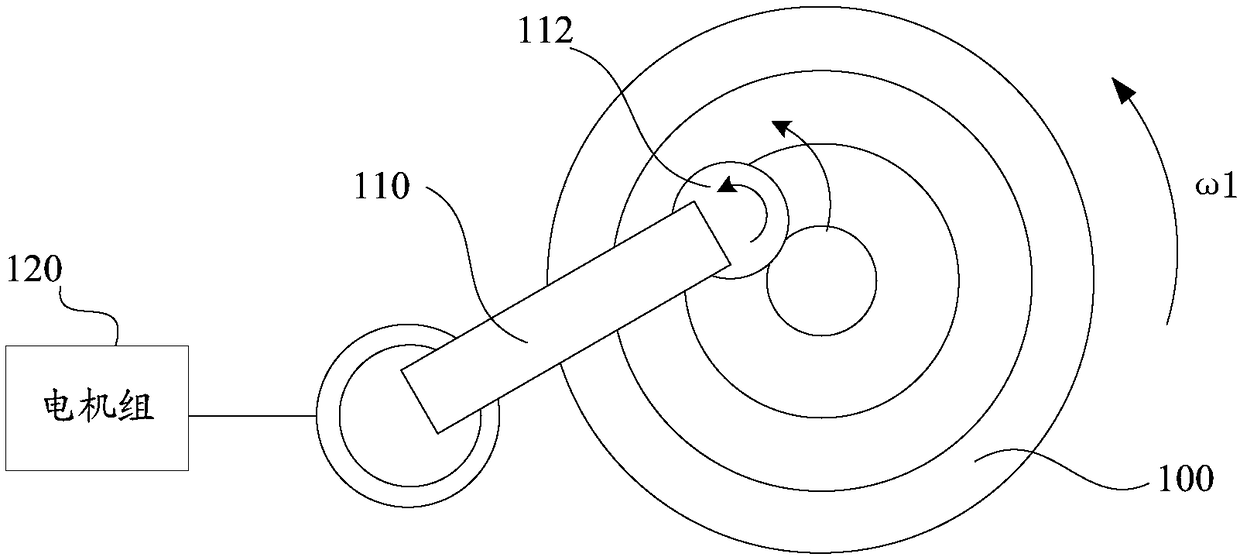

[0029] combined reference figure 1 as well as figure 2 , figure 1 It is a structural schematic diagram of a dresser for a polishing pad in the prior art, figure 2 yes figure 1 A top view of the trimmer is shown.

[0030] The conditioner for the polishing pad may include a conditioner arm 110 , a conditioner disc 112 and a motor unit 120 .

[0031] Wherein, the trimming disc 112 is fixed on one end of the trimming arm 110 and is in contact with the surface of the polishing pad 100 , and the trimming arm 110 can drive the trimming disc 112 to swing horizontally above the polishing pad 100 .

[0032] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com