Method for controlling orange peel reticulate pattern defects on surface of strip steel

A control method and strip steel technology, applied in the direction of contour control, metal rolling, manufacturing tools, etc., can solve problems such as orange-peel reticulate defects on the surface of strip steel, reduce orange-peel reticulate defects and prolong roll change Cycle, eliminate the effect of severe wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiment of the present application provides a method for controlling the orange-peel reticulate defect on the surface of the strip steel, which solves the problem in the prior art that the edge of the work roll of the temper mill is excessively worn, resulting in an orange-peel reticulate defect on the surface of the strip steel. Technical problems have been solved, and the technical effect of effectively controlling the orange-peel-like texture defects on the surface of the strip steel has been achieved.

[0031] In order to solve the above technical problems, the general idea of the technical solution provided by the embodiment of the present application is as follows:

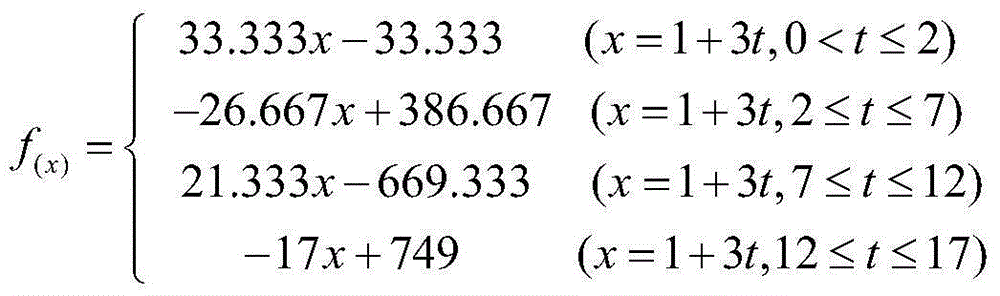

[0032] A method for controlling the orange-peel-like texture defect on the surface of strip steel, characterized in that it comprises the following steps:

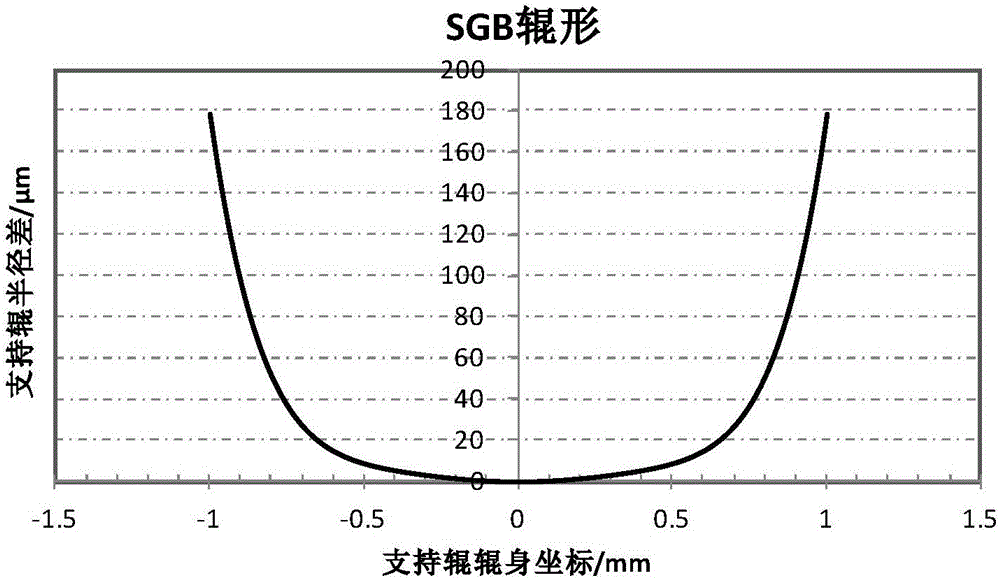

[0033] Adopt SGB roll shape curve on the backup roll of the hot rolling tempering mill;

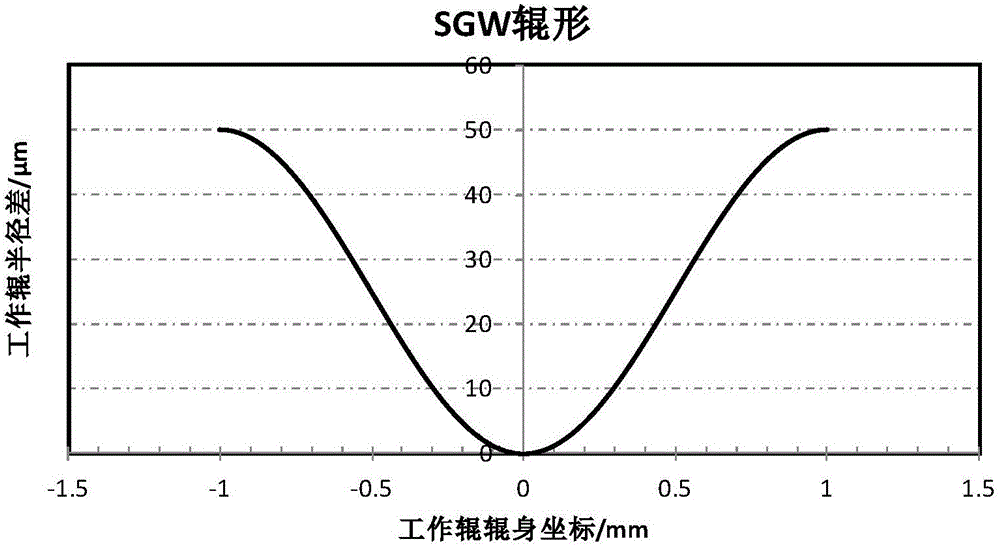

[0034] SGW roll shape curve is adopted on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com