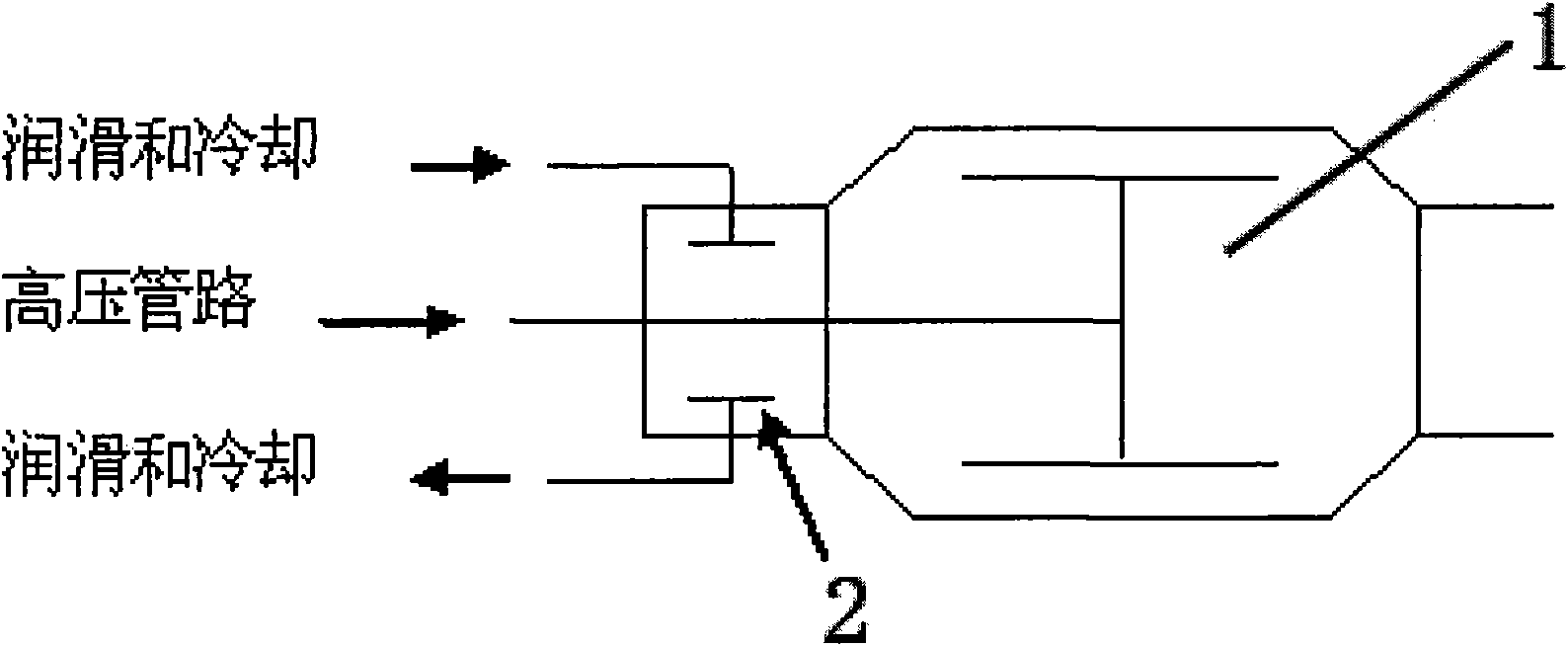

Method for forming variable crown working (VCW) roll shape for strip steel plate shape control

A technology of strip shape and work roll, applied in the direction of contour control, etc., which can solve the problems of same-slab difference and thickness tolerance, limited service period of rolls, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

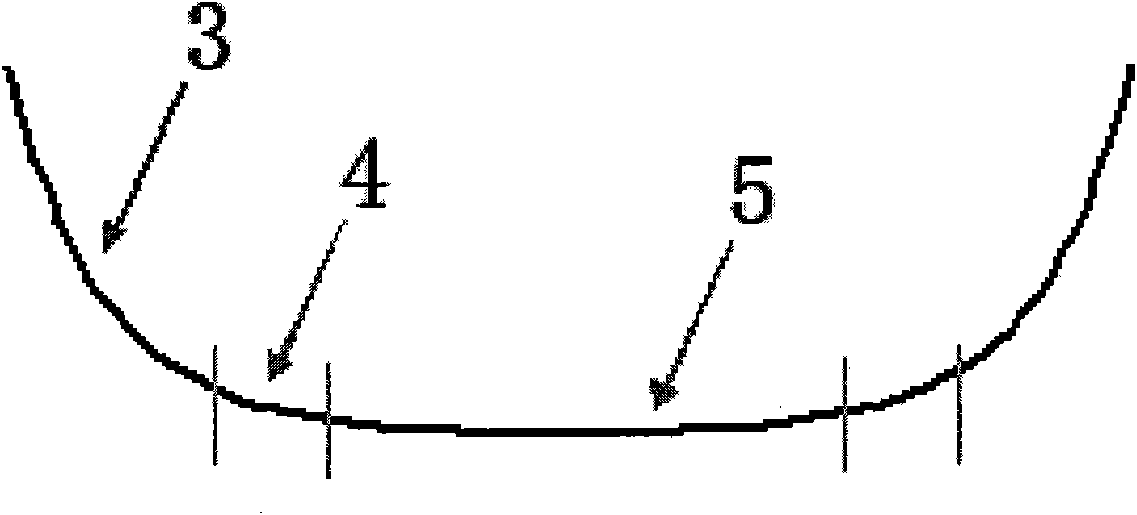

[0060] The VCW work roll shape design was carried out for Baosteel 1550 continuous tempering machine, and the VCW roll shape for 1550 continuous tempering machine was designed by using the off-line simulation method according to the design goal of the roll shape curve. The specific parameters are as follows:

[0061] A 12 = 20A 14 = 10A 16 =90A 18 =580

[0062] A 20 = 0A 22 = 2A 24 = 4A 26 =564A 28 =0

[0063] A 30 = 0A 32 = 20A 34 =59A 36 =88A 38 =551

[0064] When calculating B=1430mm, L B =1620mm, L W =1850mm, then normalize the x coordinates, that is, [-L W / 2,L W / 2] is converted to [-1, 1].

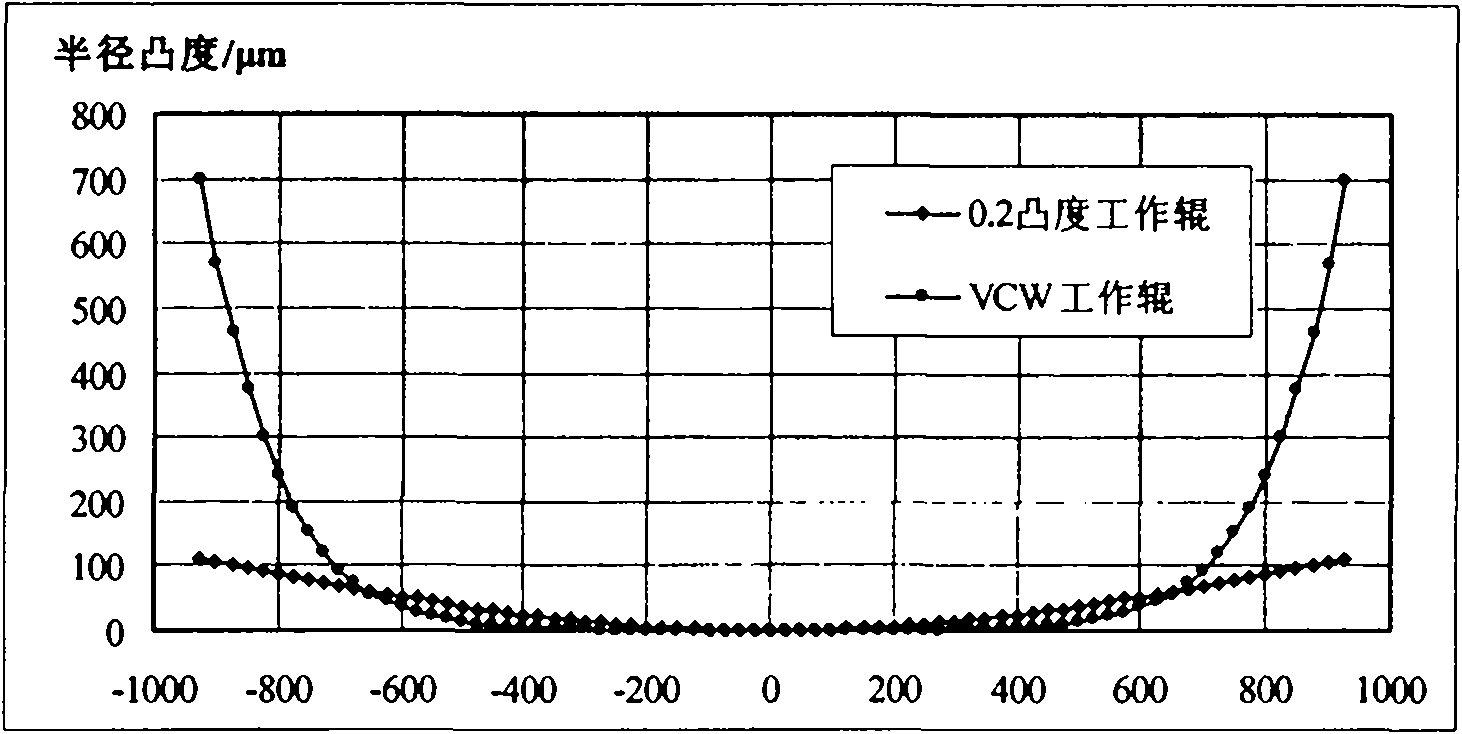

[0065] At the end of 2007, the roll profile of VCW work rolls was tested on Baosteel 1550 continuous tempering machine. The VCW work roll has a certain effect on controlling the edge wave of the refrigerator plate. Compared with the 0.2mm crown work roll, it can significantly reduce the rolling force and improve the shape of the unit outlet (as shown in Table 2)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com