Liquid auxiliary treatment-based hot ore crushing equipment

A technology of auxiliary processing and crushing equipment, applied in grain processing and other directions, can solve problems such as slow processing efficiency and impact on equipment service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

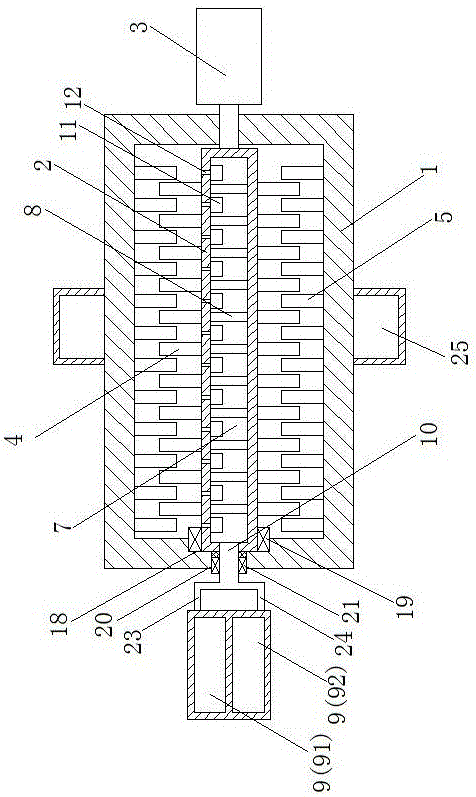

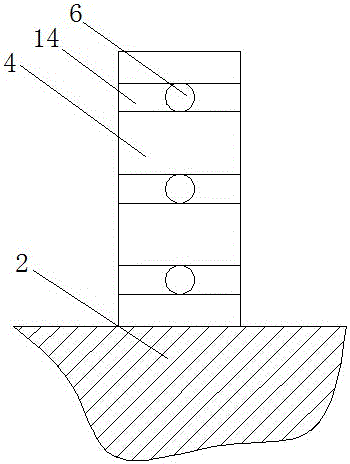

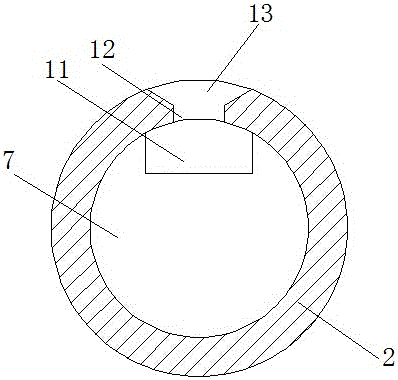

[0027] Such as figure 1 The shown hot ore crushing equipment based on liquid auxiliary treatment includes a crushing body 1, and a crushing roller shaft 2 is arranged inside the crushing body 1, which is driven by a drive motor 3 arranged outside the crushing body 1; the crushing roller A plurality of crushing end teeth 4 extending perpendicular to the axis of the crushing roller shaft 2 are arranged on the shaft 2, and a plurality of auxiliary crushing end teeth 5 are arranged on the inner wall of the crushing body 1, and the crushing end teeth 4 and the auxiliary crushing end The teeth 5 are distributed alternately with each other. Each crushing end tooth 4 and auxiliary crushing end tooth 5 are respectively provided with a plurality of pressure sensors 6; the crushing roller shaft 1 adopts a hollow structure, and a plurality of injection chambers 7 are arranged inside it, and a plurality of injection chambers 7 It is evenly distributed in the axial direction of the crushin...

Embodiment 2

[0032] As an improvement of the present invention, such as Figure 4 and Figure 5 As shown, among the crushing end teeth 4 and the auxiliary crushing end teeth 5, the corresponding position of each group of pressure sensors 6 is provided with a circularly extending detection tank 14, and the pressure sensors 6 are all arranged in the detection tank 14; the inside of the detection tank 14 is provided with a rubber protection layer 15, which extends annularly along the detection tank 14, and the pressure sensor 6 is arranged between the rubber protection layer 15 and the detection tank 14; the rubber In the protective layer 15 , a plurality of detection port holes 16 extending from the end surface of the pressure sensor 6 to the outer end surface of the rubber protective layer 15 are provided at corresponding positions of each pressure sensor 6 .

[0033] By adopting the above technical scheme, it can prevent the pressure sensor from protruding from the surface of the crushing...

Embodiment 3

[0036] As an improvement of the present invention, such as Figure 5 As shown, each detection port hole 16 is provided with an air storage chamber 17 extending perpendicular to the axial direction of the detection port hole 16, which can increase the air inside the detection port hole, so that the air pressure formed by it is more effective. Obviously, the detection accuracy of the pressure sensor is further improved.

[0037] The remaining features and advantages of this embodiment are the same as those of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com