Method for improving friction and wear performance of thermal-sprayed Al2O3 ceramic coating

A ceramic coating, friction and wear technology, applied in the coating, metal material coating process, fusion spraying, etc., can solve the problem of coating quality decline, poor wettability, ceramic coating tribological properties can not be greatly improved, etc. problems, achieve the effect of improving the degree of wear and reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

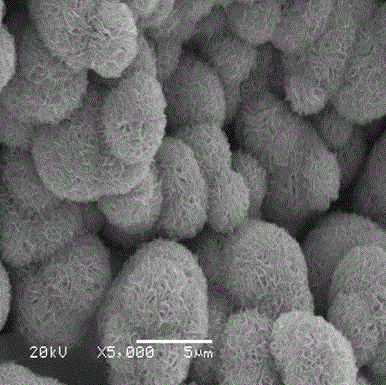

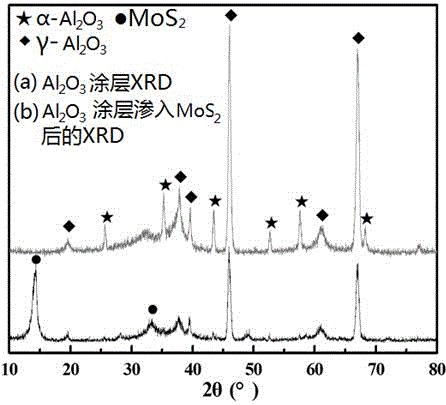

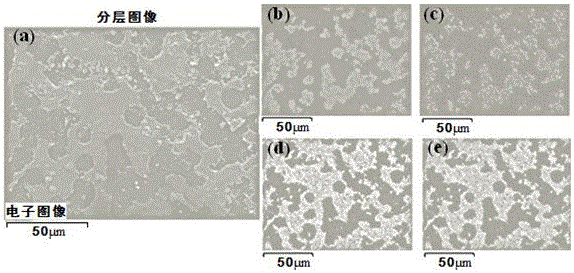

[0021] A: Use the atmospheric plasma spraying process to spray NiAl transition coating on the stainless steel substrate with a thickness of about 60 μm, and then spray to prepare Al 2 o 3 Ceramic coating, the coating thickness is 180~200μm.

[0022] B: Prepared Al 2 o 3 After the ceramic coating surface is polished and polished, the surface roughness of the ceramic coating R a ≈2.2 μm.

[0023] C: Weigh: Thiourea (CN 2 h 4 S) is 3.2g, sodium molybdate (Na 2 MoO 4 ) was 2.3g, and 100g of ionized water were mixed uniformly and fully dissolved, then poured into a reaction kettle with a volume of 200ml.

[0024] D: the Al prepared in step B 2 o 3 The ceramic coating sample is immersed in the solution prepared in step C in the reactor. After sealing the reactor, place the reactor in an oven. The oven is slowly heated to 220°C (heating rate: 2.5°C / min), and kept for 48 Hour.

[0025] E. After the heat preservation is over, when the temperature of the oven drops to room ...

Embodiment 2

[0028]A: Use the atmospheric plasma spraying process to spray NiCrAl transition coating on the stainless steel substrate with a thickness of about 70 μm, and then spray to prepare Al 2 o 3 Ceramic coating, the coating thickness is 160~180μm.

[0029] B: Prepared Al 2 o 3 After the ceramic coating surface is polished and polished, the surface roughness of the ceramic coating R a ≈2.0 μm.

[0030] C: Weigh: Thiourea (CN 2 h 4 S) is 3.5g, sodium molybdate (Na 2 MoO 4 ) was 2.5g, and 100g of ionized water were mixed uniformly and fully dissolved, then poured into a reaction kettle with a volume of 200ml.

[0031] D: the Al prepared in step B 2 o 3 The ceramic coating sample is immersed in the solution prepared in step C in the reaction kettle. After sealing the reaction kettle, place the reaction kettle in an oven. The oven is slowly heated to 220°C (heating rate: 2.5°C / min), and kept for 72 Hour.

[0032] E. After the heat preservation is over, when the temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com