Paper tube forming device

A forming device and paper tube technology, applied in the direction of paperboard winding articles, etc., can solve the problems of paper tube inner wall damage, paper tube forming shaft wear, raw material waste, etc., to improve the probability of damage, prolong the service life, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

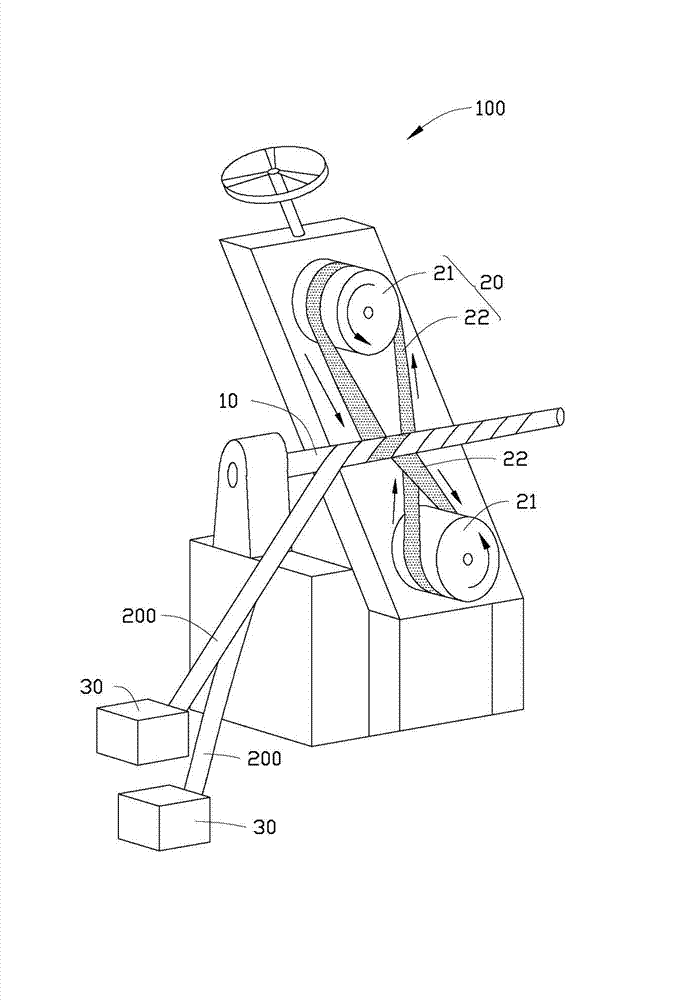

[0014] See figure 1 and figure 2 As shown, the paper tube forming device 100 provided by the embodiment of the present invention includes a paper tube forming shaft 10, a power device 20, and a paper tape conveying device 30, wherein the paper tape conveying device 30 is used to provide a paper tape 200, so The power device 20 is used to drive the paper tape 200 to rotate and wind on the paper tube forming shaft 10 to form a paper tube, and at the same time drive the paper tube to slide along the axis of the paper tube forming shaft 10 .

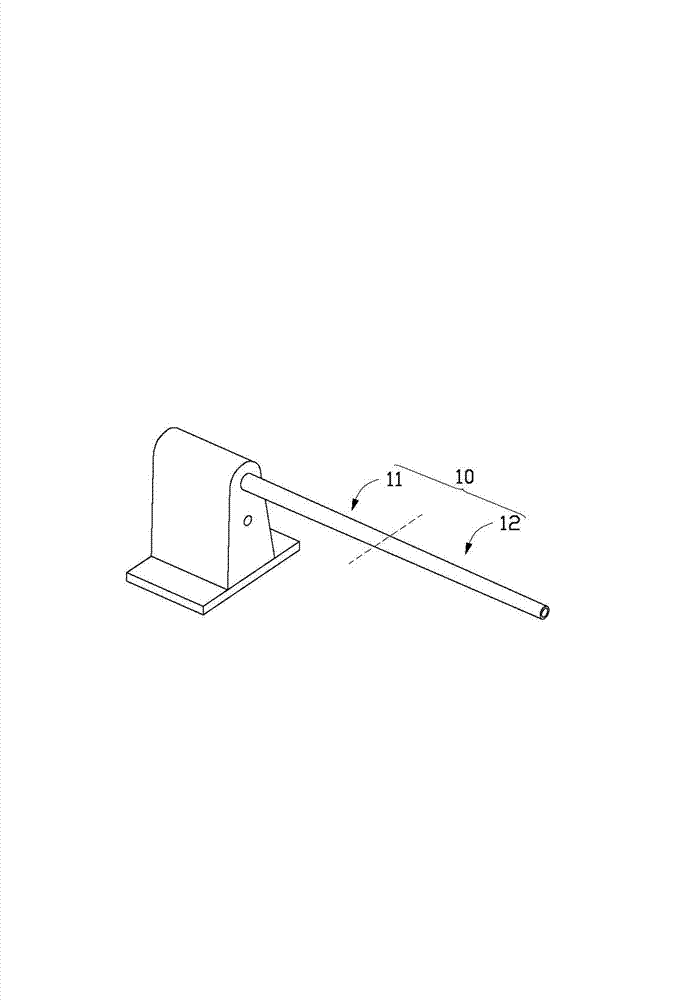

[0015] The paper tube forming shaft 10 includes a paper input forming section 11 and a paper output section 12 . In this embodiment, the paper input forming section 11 and the paper output section 12 are integrally structured. Of course, it can be understood that the paper-entry forming section 11 and the paper-out section 12 can also be detachably connected to each other by screw threads or the like.

[0016] In the present invention, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com