Friction material and process for manufacturing aircraft braking disc made from same

A friction material and manufacturing process technology, applied in friction linings, mechanical equipment, and other chemical processes, can solve problems such as wear or damage, short service life, and poor wear matching of brake pairs, so as to improve the degree of wear and increase the use of The effect of improving life and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

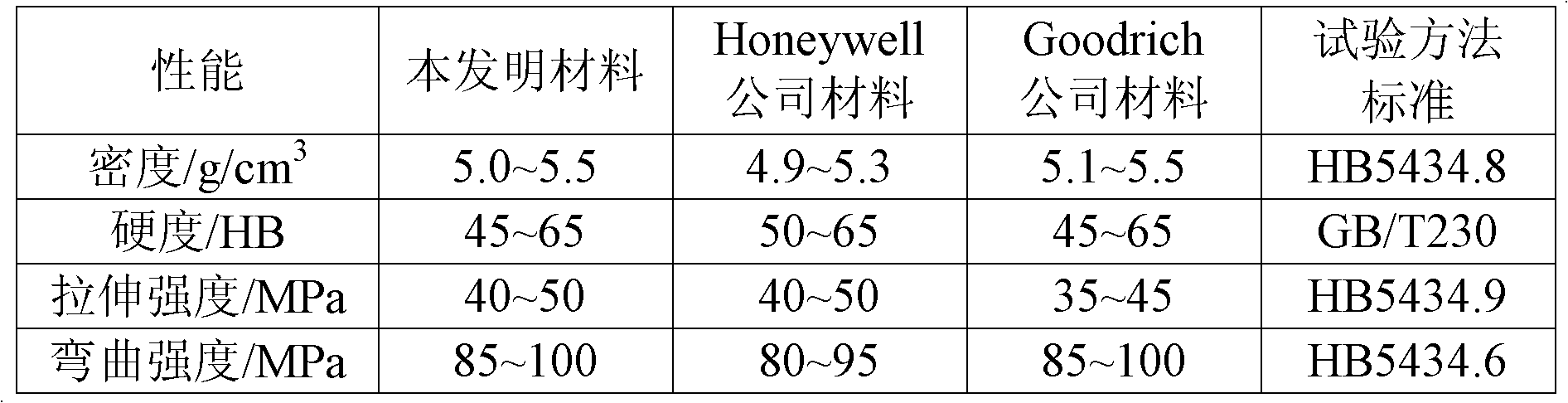

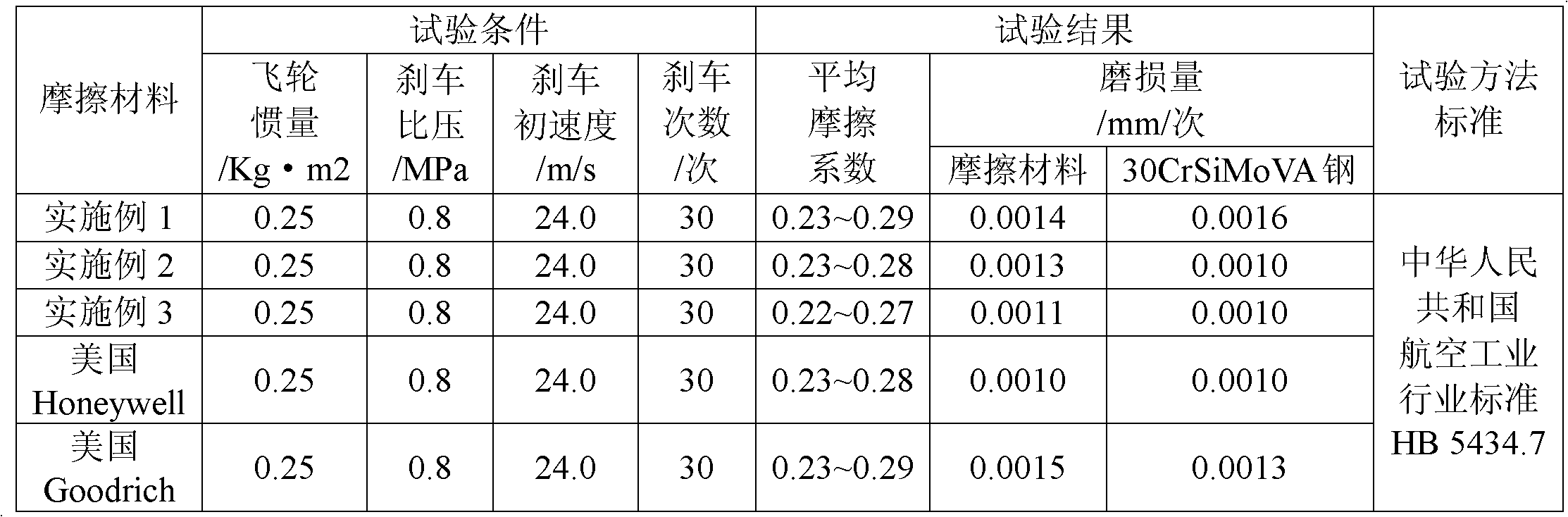

[0032] A kind of friction material used for aircraft brake pads in the present embodiment, the percentage by weight of each component is: copper 72%, iron 6%, aluminum 2%, tin 3%, nickel 1%, kyanite 3%, Boron nitride 2%, graphite 8%, molybdenum disulfide 3%.

[0033] The manufacturing process of brake pads is as follows:

[0034] After weighing the above-mentioned components according to the percentage of the formula, put the powders of copper, iron, aluminum, tin, nickel and molybdenum disulfide into the V-shaped mixing cylinder. After first machine mixing for 1 hour, then kyanite and boron nitride powder were poured into the mixing cylinder, and machine mixing was continued for 1 hour, and then 0.7% of the total weight of ingredients was added to the mixture. # machine oil, then machine-mix for 1 hour, then pour the graphite powder into the V-shaped mixing barrel, and machine-mix for 4 hours; press the evenly mixed mixture to form a powder compact with a pressing pressure o...

Embodiment 2

[0036] A kind of friction material used for aircraft brake pads in this embodiment, the weight percent of each component is: copper 68%, iron 7%, aluminum 2%, tin 3%, nickel 1%, kyanite 4%, Boron nitride 3%, graphite 10%, molybdenum disulfide 2%.

[0037] The manufacturing process of brake pads is as follows:

[0038] After weighing each component according to the formula percentage, put the powders of copper, iron, aluminum, tin, nickel and molybdenum disulfide into the V-shaped mixing barrel, first mix by machine for 1 hour, then add kyanite and boron nitride powder Pour into this mixing cylinder and continue machine mixing for 1 hour, then add 0.5% of the total weight of ingredients in the mixture after 10 # machine oil, and then machine-mixed for 1 hour, then pour graphite powder into the V-shaped mixing barrel, and machine-mix for 4 hours; press the uniformly mixed mixture to form a powder compact with a pressing pressure of 370MPa; use 30CrMoA with a thickness of 1.5-1....

Embodiment 3

[0040] A kind of friction material used for aircraft brake pads in the present embodiment, the percentage by weight of each component is: copper 62%, iron 10%, aluminum 3%, tin 3%, nickel 1%, kyanite 6%, Boron nitride 2%, graphite 12%, molybdenum disulfide 1%.

[0041] The manufacturing process of brake pads is as follows:

[0042] After each component is weighed according to the formula percentage, put the copper, iron, aluminum, tin, nickel and molybdenum disulfide powders into the V-shaped mixing cylinder, first mix by machine for 1 hour, then pour the kyanite and boron nitride powder Put into this mixing cylinder and continue machine mixing for 1 hour, then add 0.6% of the total weight of ingredients in the mixture after 10 # machine oil, and then machine-mixed for 1 hour, then pour the graphite powder into the V-shaped mixing barrel, and machine-mix for 4 hours; the uniformly mixed powder is formed into a powder compact with a pressing pressure of 350MPa; the thickness i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com