Controlling method for reduction of four-strand slitting line differences and structure property differences

A control method and technology of tissue properties, applied in the control field of reducing the difference of the four-wire slicing line and the poor tissue properties, can solve the problems of uneven cooling and poor tissue properties of the four-wire, so as to reduce the poor mechanical properties of the tissue and improve the Stability, the effect of improving cooling uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

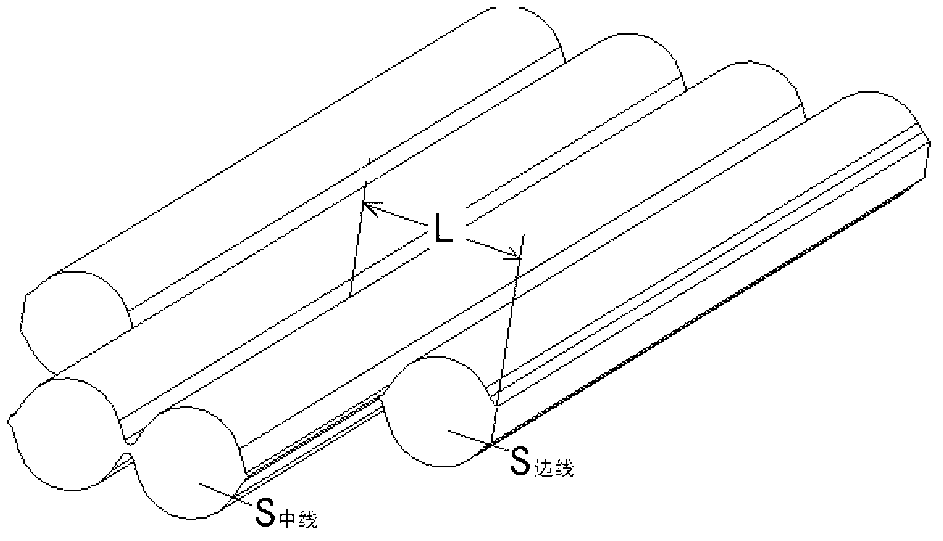

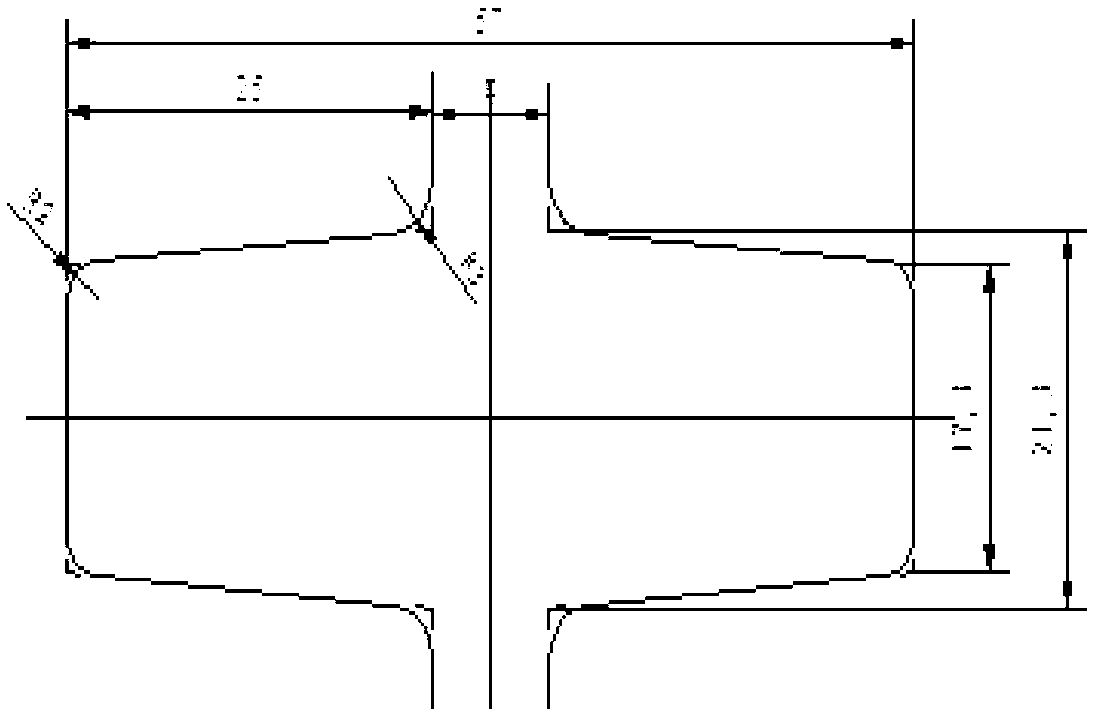

[0026] Attached figure 2 The parameters of the hole type, using the area method to calculate the line difference and K 3 The relationship of filling degree, as shown in Table 1, considers two different conditions of mill bounce of 0 and 0.2mm respectively. as attached image 3 As shown, using the DEFFORM finite element software to simulate and calculate the lower cutting hole K of the casing type 3 The actual fullness L value is 31.8mm. Compared with Table 1, the theoretical line difference at this time is 1523mm (rolling mill bounce is 0) and 1625mm (rolling mill bounce is 0.2). The calculation results show that the design of this set of passes is unreasonable. The line difference is large.

[0027] Table 1 Line difference and K 3 The relationship between the degree of filling (L value)

[0028]

Embodiment 2

[0030] in the attached figure 2 Based on the pass pattern shown, K 6 Hole height changed from 18.5mm to 17.5mm; fixed width hole K 5 Bore changed from 57mm to 58mm; pre-slit K 4 The half-wedge angle of the side walls of the two sidelines is changed from 36.0° to 37.5°; the split hole type K 3 The side wall wedge angle of the two side lines increased from 40.4° to 43.8°, and the line difference and K were calculated by using the area method 3 The relationship between the degree of fullness (L value) is shown in Table 2. Using DEFFORM finite element software to simulate and calculate the lower cutting hole K of the casing type 3 The actual fullness L value is 32.2mm, as attached Figure 4 shown. According to Table 2, the theoretical line difference at this time is -70mm (rolling mill bounce is 0) and -31mm (rolling mill bounce is 0.2).

[0031] Table 2 Line difference and K 3 The relationship between the degree of filling (L value)

[0032]

Embodiment 3

[0034] By adjusting the ring seam value of the cooler after rolling (the horizontal opening of the four-line ring seam is adjusted to 30mm, 38mm, 35mm, and 29mm respectively), the cooling intensity of the two sides is reduced, and the temperature of the upper cooling bed tends to be consistent. After adjustment, the fluctuation value of mechanical properties is significantly reduced. Grade HRB400E, specifications 14mm, the four wires are recorded as 1 # ,2 # 、3 # 、4 # .

[0035] Table 3 Corresponding four-line chemical composition w.t.% of a billet

[0036]

[0037] Table 4 Rolling process parameters

[0038]

[0039] Table 5 The annular gap value and mechanical properties of the four-wire controlled cooling cooler corresponding to a steel billet

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com