Manufacturing technology for continuously casting and rolling aluminum alloy plate strips

A technology of aluminum alloy strip, continuous casting and rolling, applied in metal rolling and other directions, can solve the problems of poor performance of strip products, low casting speed, small equipment investment, etc., to achieve stable product quality, improve organizational performance, production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

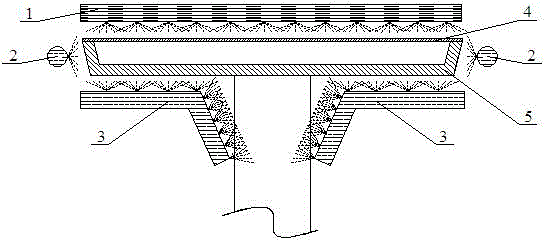

Image

Examples

Embodiment 1

[0022] A preparation process for continuous casting and rolling of 1100 aluminum alloy strips, comprising smelting, continuous casting and rolling and winding, specifically comprising the following steps:

[0023] (1) The production of 1100 aluminum alloy strips adopts electrolytic aluminum liquid to add remelted aluminum ingots to cool down, add Fe and Cu additives to the ingredients, and melt and stir at 750 ° C to obtain the aluminum melt composition: Si 0.067%, Fe 0.36%, Cu 0.087 %; use argon to blow the powder refining agent into the aluminum melt, the amount of powder refining agent is 2 kg per ton of aluminum liquid, at the same time, pass argon gas for refining treatment and slag removal, and the pressure of argon gas is 0. 08Mpa; then stand at 735°C for 30 minutes, countercurrently add AlTiB wire at a speed of 200 cm / min to carry out online grain refinement treatment on the aluminum melt, and then through online degassing and filter residue removal, the online degassin...

Embodiment 2

[0031] A preparation process for continuous casting and rolling of 5052 aluminum alloy strips, comprising smelting, continuous casting and rolling and winding, specifically comprising the following steps:

[0032] (1) Production of 5052 aluminum alloy plates and strips: use electrolytic aluminum liquid to add remelted aluminum ingots to cool down, add Mg metal ingots and Cr additives to the ingredients, melt and stir at 750°C, and obtain aluminum melt compositions: Si 0.045%, Fe 0.18% , Mg 2.46%, Cr 0.22%; the powder refining agent is blown into the aluminum melt with argon gas, the amount of powder refining agent is 2 kg per ton of aluminum liquid, and at the same time, the argon gas is introduced for refining treatment and slag removal. The argon gas pressure was 0.08 Mpa; then after standing at 742°C for 30 min, the Al-Ti-B wire was added countercurrently at a speed of 200 cm / min to conduct online grain refinement treatment on the aluminum melt, and then through online degas...

Embodiment 3

[0040] A preparation process for continuous casting and rolling of 6063 aluminum alloy strips, comprising smelting, continuous casting and rolling and winding, specifically comprising the following steps:

[0041] (1) Production of 6063 aluminum alloy strips: use electrolytic aluminum liquid to add remelted aluminum ingots for cooling treatment, add Mg metal ingots and 20% aluminum-silicon master alloy as ingredients, melt and stir at 750°C, and obtain the aluminum melt composition: Si 0. 45%, Fe 0.18%, Mg 0.63%; the powder refining agent is blown into the aluminum melt with argon gas, the amount of powder refining agent is 2 kg per ton of aluminum liquid, and at the same time, argon gas is introduced for refining treatment and slag removal , the pressure of argon gas was introduced at 0.07 Mpa; then after standing at 735°C for 27 minutes, AlTiB wire was added countercurrently at a speed of 200 cm / min to refine the aluminum melt online, and then degassed and filtered on-line F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com