Pneumatic soft pole-climbing robot

A robot and robot body technology, applied in the field of pole-climbing robots, can solve problems such as low flexibility, slow operation, and robot damage, and achieve the effects of broad application prospects, reduced contact force, and good adaptability to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

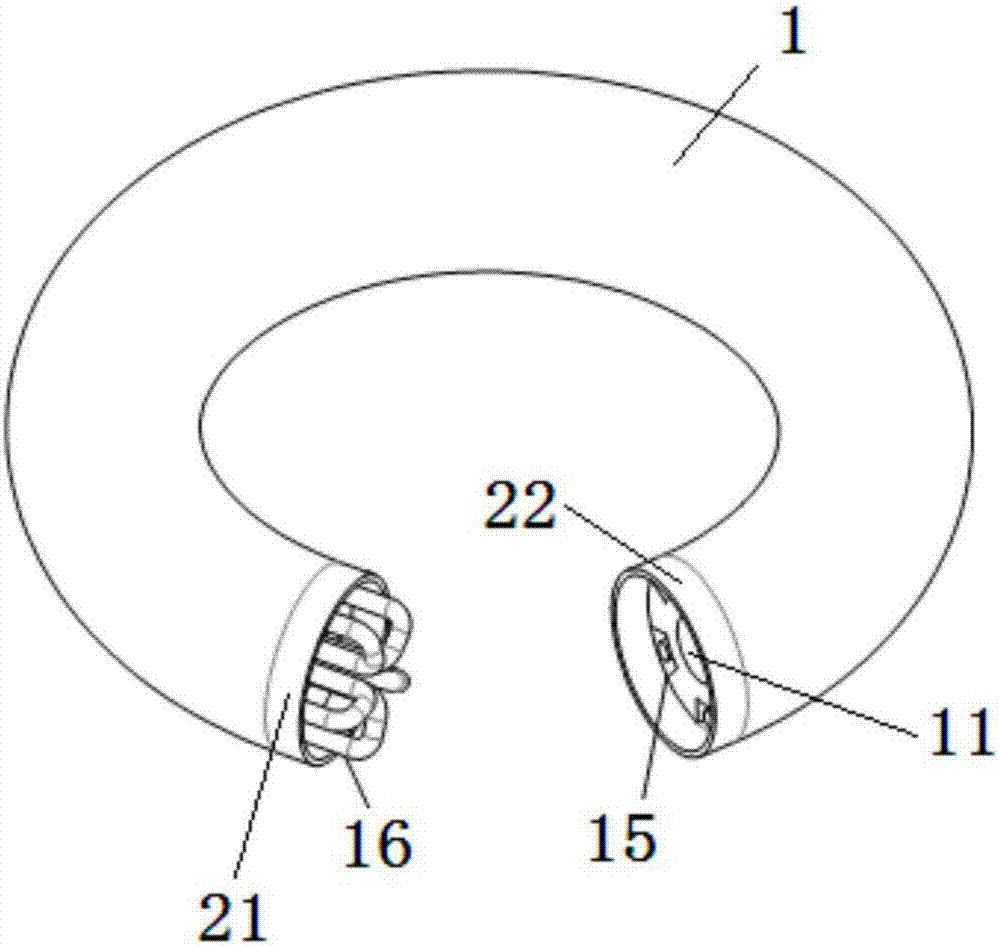

[0059] like figure 1 As shown, a pneumatic soft pole climbing robot includes a soft robot body 1 , an electromagnetic clamping device, a drive control system and a remote control device 4 .

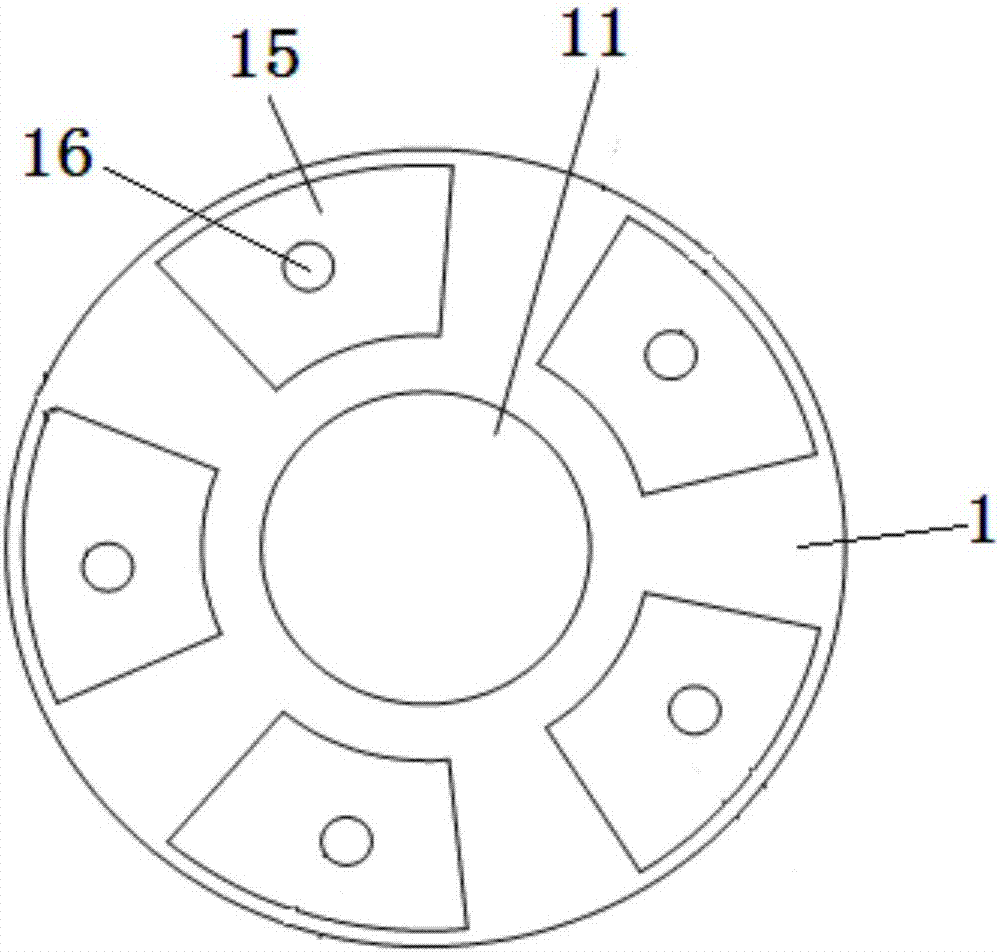

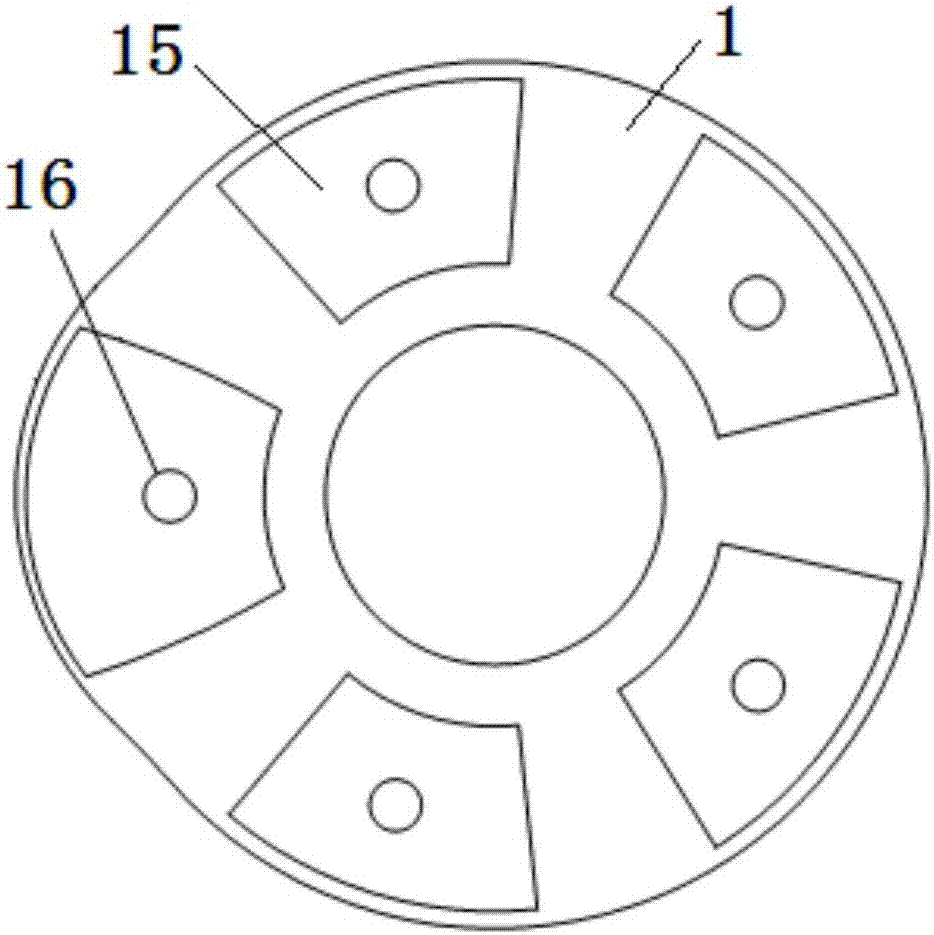

[0060] The soft robot body 1 is ring-shaped with openings, has two open end faces, and the cross section of the soft robot body is as follows: figure 2 circle shown.

[0061] When the ring-shaped soft robot body is straightened, the soft robot body takes on a cylindrical structure.

[0062] The soft silica gel or rubber of the soft robot body 1 is preferably EPDM.

[0063] A central accommodating cavity 11 is provided at the central loop line of the soft robot body, and the cross section of the central accommodating cavity is preferably circular.

[0064] Several airtight air cavities 15 are uniformly arranged on the body of the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com