Direct reduction iron cooling device

A cooling device and reduced iron technology, which is applied in the direction of processing discharged materials, furnace components, lighting and heating equipment, etc., can solve the problems of high cooling intensity, which cannot meet the needs of rotary hearth furnaces, and low cooling intensity, and achieve accurate frequency conversion speed regulation Adjustable, precise and adjustable cooling water volume, avoiding the effect of pulverization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

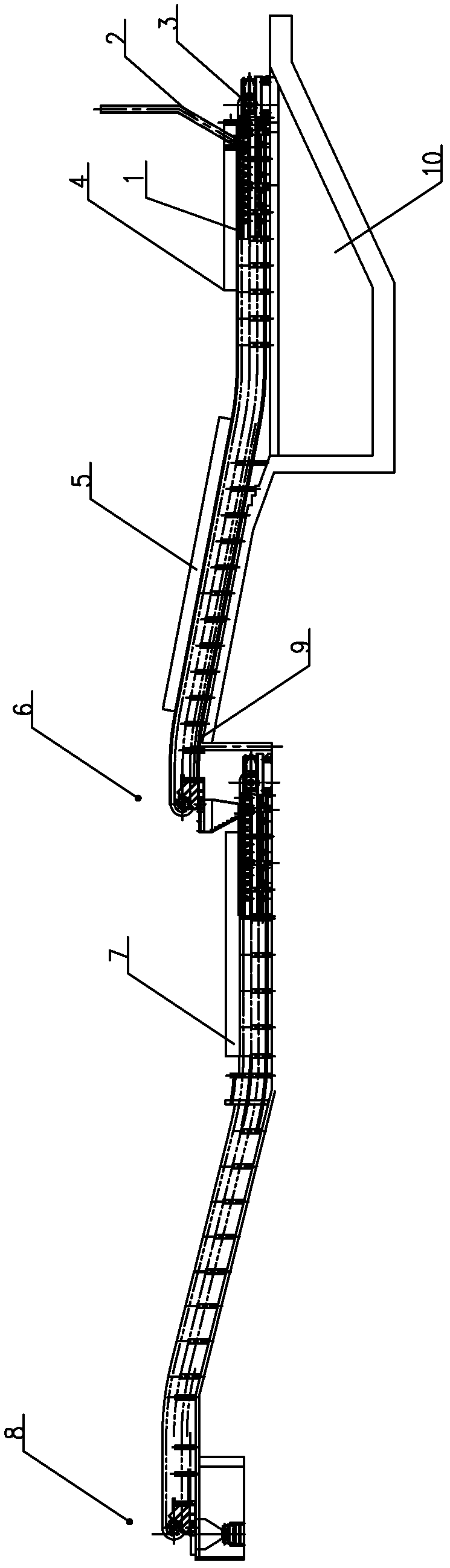

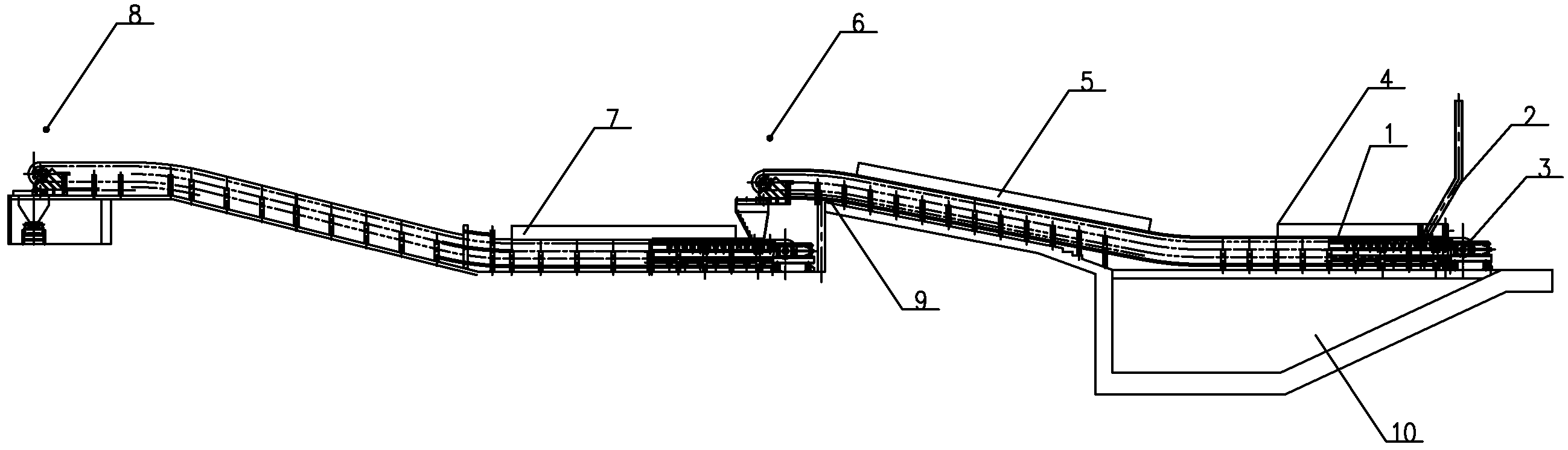

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] Such as figure 1 As shown, the direct reduced iron cooling device of the present invention includes a high temperature chain plate machine 3, a cooling section 4, a cooling section 5 and a cooling section 7 arranged according to the conveying direction, a cooling section 4, a cooling section 5 and a cooling section 3 7 Set the flow meter and valve, and the high-temperature chain plate machine 3 is equipped with an infrared thermometer.

[0019] Among them, the first cooling section 4 is a cooling section using spray cooling, the second cooling section 6 and the third cooling section 7 are cooling sections using spray cooling, the cooling section 4 cools the high-temperature direct reduced iron to 1000°C-500°C, and the second cooling section 5 is 500°C-300°C, and the third section of cooling 7 is 300°C-150°C. A slag pool is arranged at the head of the chain pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com