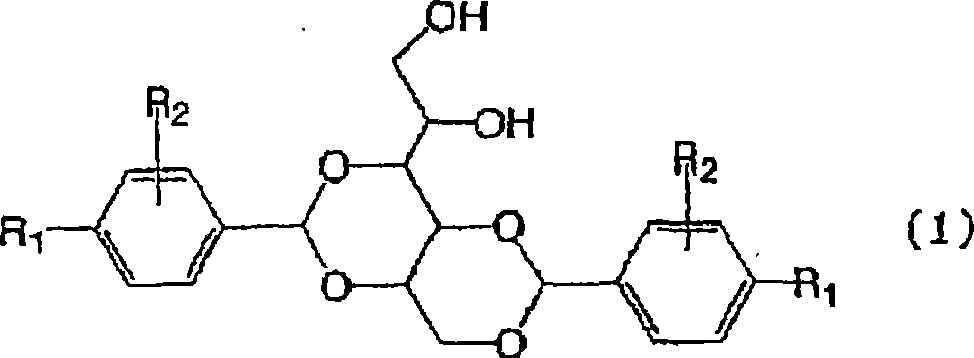

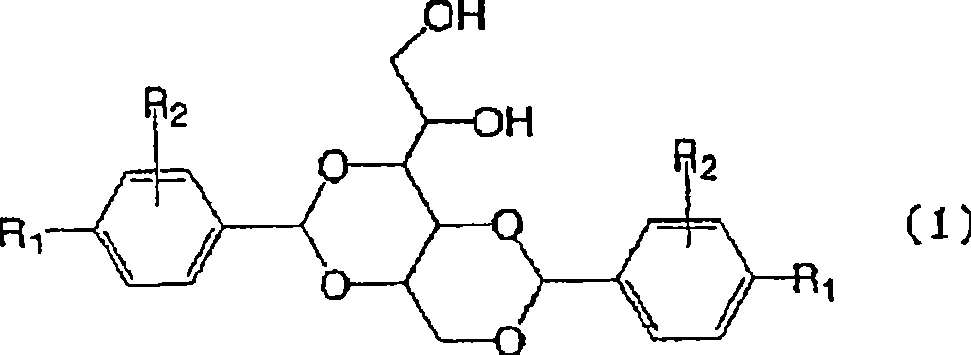

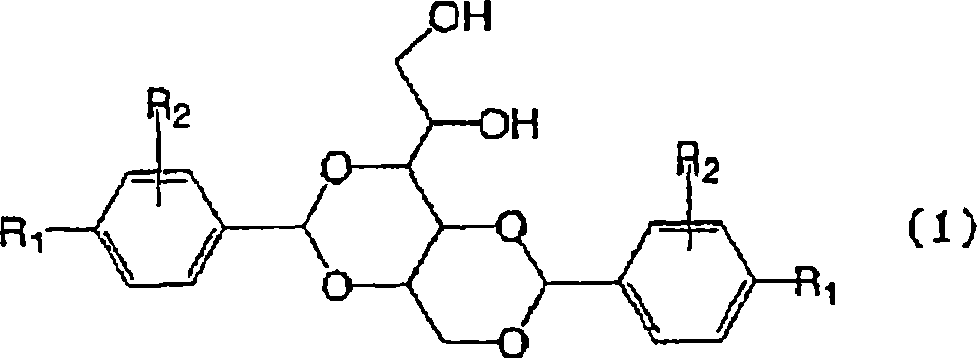

Biodegradable resin compositions and molded objects thereof

A technology of resin composition and biodegradability, which is applied in the field of biodegradable resin composition and its molded body, can solve the problem of not disclosing the processability and heat resistance of biodegradable plastics, and not being able to meet the requirements of biodegradability and resin combination things and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0205] (Manufacture example 1) [Manufacture of polyorganosiloxane latex (S-1)]

[0206] 1 part of tetraethoxysilane, 1.5 parts of γ-methacryloxypropyldimethoxymethylsilane, and 97.5 parts of octamethylcyclotetrasiloxane were mixed to obtain 100 parts of a siloxane mixture. Add 100 parts of the above-mentioned mixed siloxane to 200 parts of distilled water in which 1 part of sodium dodecylbenzenesulfonate and dodecylbenzenesulfonic acid have been dissolved, and pre-stir with a homomixer at 10000 rpm, then use Homogenizer at 300kg / cm 2 emulsification and dispersion under high pressure to obtain organosiloxane latex. Transfer the mixed solution to a separable flask with a condenser and a stirring blade, heat at 90° C. for 5 hours while stirring and mixing, then place it at 20° C. After 48 hours, use aqueous sodium hydroxide solution to the latex The pH was neutralized to 7.5, and the polymerization was terminated to obtain polyorganosiloxane rubber latex S-1. The polymerizatio...

manufacture example 2

[0207] (Manufacture example 2) [Manufacture of polyalkylacrylate latex (R-1)]

[0208] 200 parts of pure water, 1.5 parts of sodium citronellate, 0.4 parts of SFS, 0.01 parts of Disodium ethylenediaminetetraacetic acid (EDTA), 0.0025 parts of ferrous sulfate. While stirring the system, the temperature was raised to 40°C under a nitrogen flow. After reaching 40°C, a solution containing 100 parts of butyl acrylate (BA), 1 part of allyl methacrylate (A1MA), and 0.1 part of hydrogen peroxide was continuously added dropwise for 6 hours. Mixture of cumene oxide (CHP). After completion of the dropwise addition, stirring was continued at 40° C. for 1 hour to complete the polymerization. The polymerization conversion rate was 97%. The obtained latex had a pH of 8.2, a solid content concentration of 32%, an average particle diameter of 80 nm, and a gel content of 99%.

manufacture example 3

[0209] (Manufacture example 3) [manufacture of composite rubber]

[0210] (SR-1)

[0211]Take the above-mentioned polyorganosiloxane rubber latex S-1 with 10 parts of solid content, put it into a separable flask with a stirrer, add 180 parts of distilled water, carry out nitrogen replacement, heat up to 40 ° C, add 65 parts of acrylic acid After the mixed solution of butyl ester, 0.65 part of allyl methacrylate and 0.065 part of CHP was stirred for 30 minutes, the mixed solution was impregnated into the polyorganosiloxane rubber particles. Next, a mixed solution of 0.0025 parts of ferrous sulfate, 0.01 parts of EDTA, 0.3 parts of SFS and 5 parts of distilled water was charged to start free radical polymerization, and then kept at an internal temperature of 70°C for 2 hours to complete the polymerization to obtain a composite rubber latex. A part of this latex was collected, and the average particle diameter of the composite rubber was measured to be 0.22 μm.

[0212] (SR-2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com