Cellulose derivative, thermoformed material, molded body, production method therefor, and casing for electrical and electronic equipment

A technology of cellulose derivatives and thermoforming materials, applied in the fields of cellulose derivatives, thermoforming materials, shaped bodies and their preparations, as well as casings for electrical equipment and electronic equipment, to achieve excellent thermoplasticity, good impact resistance , the effect of preventing global warming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

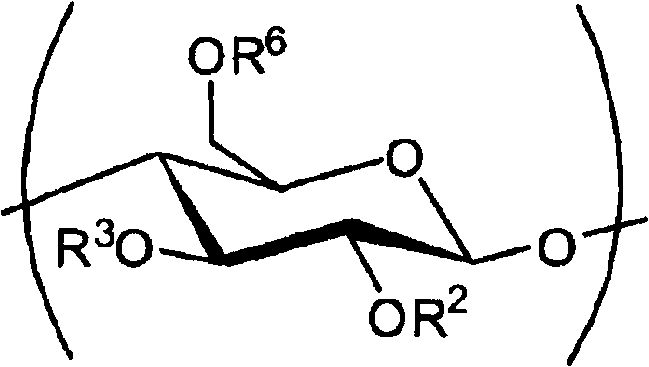

[0142] 2. Preparation method of cellulose derivatives

[0143] The production method of the cellulose derivative in the present invention is not particularly limited, and the cellulose derivative of the present invention can be produced by using cellulose as a raw material and performing etherification and esterification of the cellulose. Any cellulosic source can be used including, for example, cotton, linters, pulp, and the like.

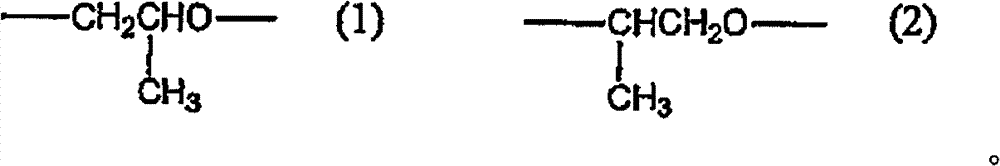

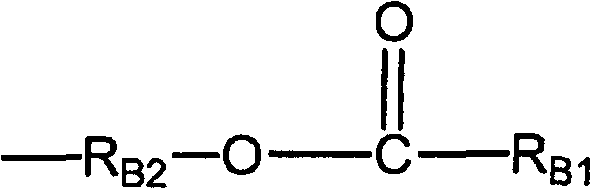

[0144] A preferred embodiment of the production method of the cellulose derivative in the present invention is carried out by a method comprising: reacting hydroxypropyl cellulose ether having a hydrocarbon group and a hydroxypropyl group with an acid chloride or an acid anhydride to perform esterification ( acylation) process.

[0145] In addition, as another embodiment, a method comprising a process of etherification of cellulose such as methyl cellulose and ethyl cellulose with propylene oxide or the like, or making alkyl chlorides such as met...

Embodiment

[0215] Although the present invention will be described in detail with reference to the following examples and comparative examples, the scope of the present invention is not limited to the following examples.

Synthetic example 1

[0216]

[0217]30 g of hydroxypropylmethylcellulose (trade name: Marpolose 60MP-4000; manufactured by Matsumoto Yushi-Seiyaku Co., Ltd.; H-1) and 2,250 mL of N,N-dimethylacetamide were weighed and juxtaposed into a 5-liter three-necked flask equipped with a mechanical stirrer, a thermometer, a cooling tube, and a dropping funnel, followed by stirring at room temperature. After confirming that the reaction system became transparent and completely dissolved, 84 mL of acetyl chloride was slowly added dropwise, and then the temperature of the system was increased to 80°C to 90°C. Stirring was continued for 3 hours, after which time the reaction was cooled to room temperature. The reaction solution was added to 10 L of water while vigorously stirring, whereby a white solid was precipitated. The white solid was isolated by suction filtration and washed three times with copious amounts of water. The obtained white solid was dried under vacuum at 100° C. for 6 hours to obtain the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com