Vinyl modified polyester polyatomic alcohol, two-part curable paint composition and condensate

A technology of polyester polyol and modified polyester, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of reduced water resistance, wear resistance, hardness and weather resistance of coating films, etc. To achieve the effect of preventing global warming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

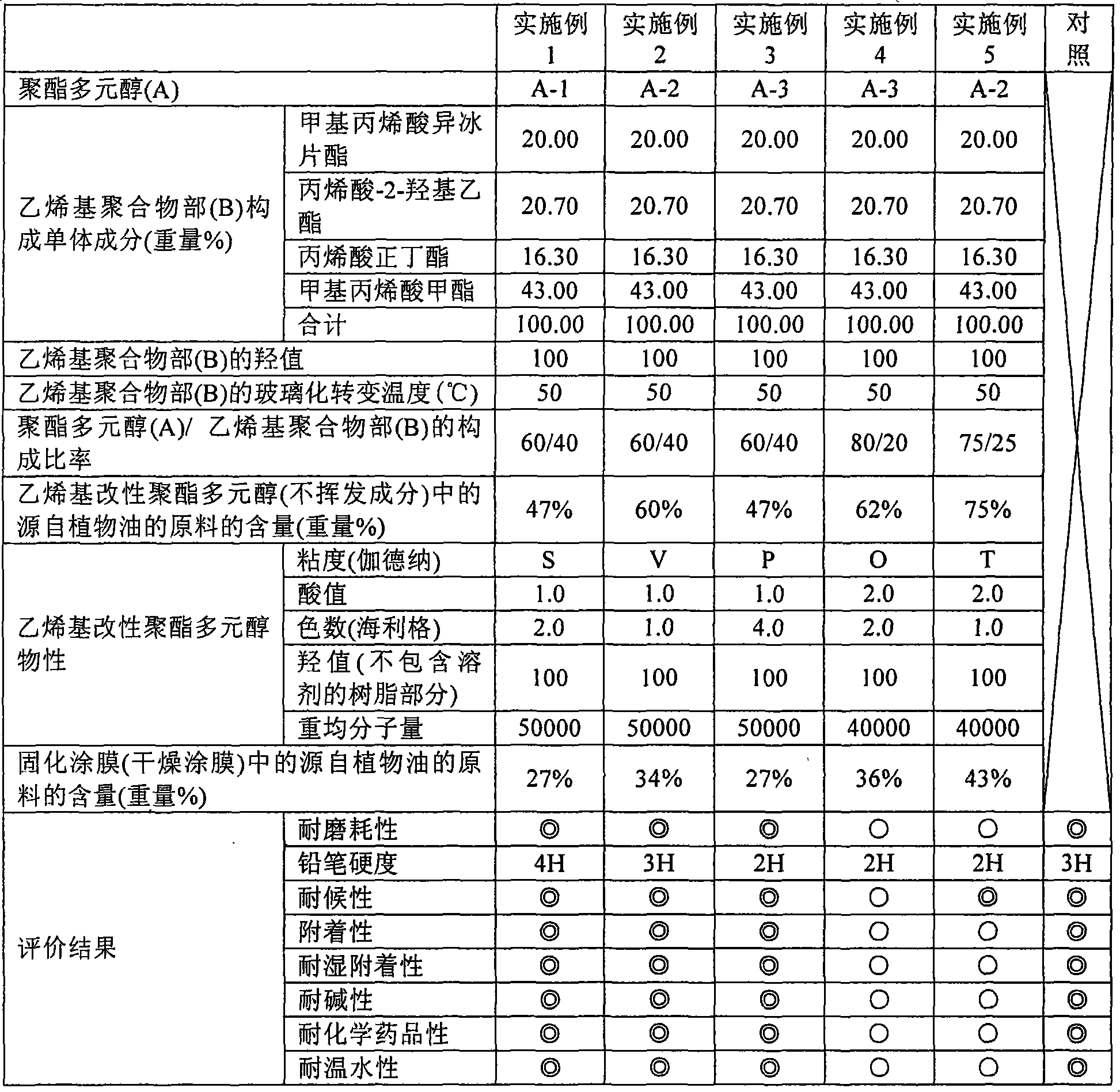

[0084] The present invention will be described in more detail through examples below, but the present invention is not limited to these examples.

[0085] Here, the measurement of various physical properties in Examples and Comparative Examples was performed by the following methods.

[0086]

[0087] The measurement was carried out in accordance with JIS-K5600 using a Gardner bubble viscometer.

[0088]

[0089] Measurement was performed in accordance with JIS-K5601.

[0090]

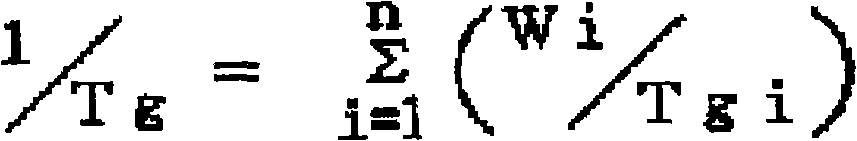

[0091] Measurement was performed in accordance with JIS-K0070. However, the hydroxyl value of the vinyl polymer part (B) is calculated based on the composition of the monomer component (the monomer component constituting the vinyl polymer part) constituting the vinyl polymer part (B).

[0092]

[0093] Measured using a Heilig colorimeter.

[0094]

[0095] Determined by gel permeation chromatography.

[0096]

[0097] Measurement was performed in accordance with JIS-K5601.

manufacture example 1-

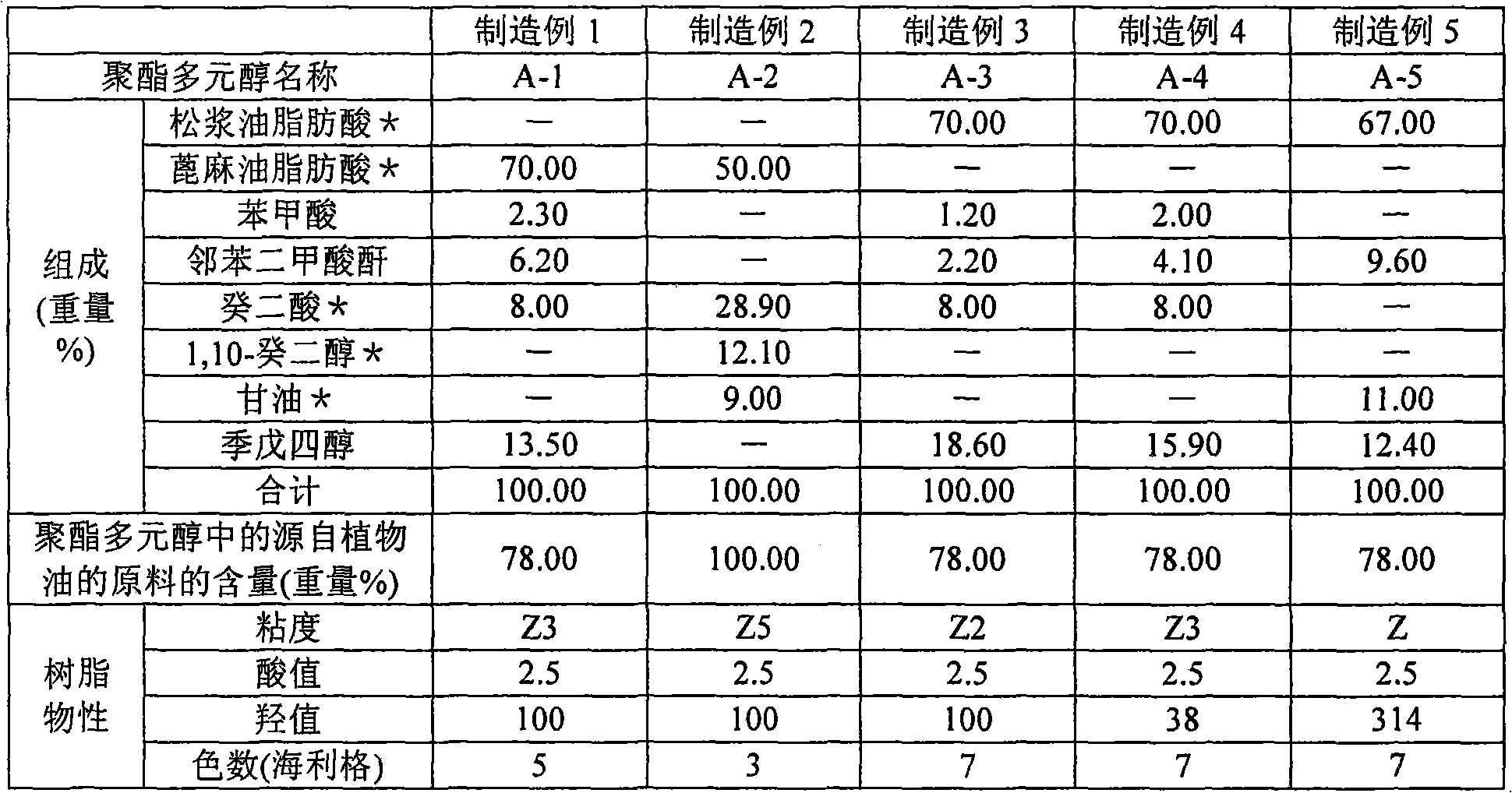

[0098] (Production Example 1 - Synthesis of polyester polyol (A) using vegetable oil-derived raw material)

[0099]In the reactor, add 700 parts by weight of castor oil fatty acid (raw material derived from vegetable oil), 23 parts by weight of benzoic acid, 62 parts by weight of phthalic anhydride, 80 parts by weight of sebacic acid (raw material derived from vegetable oil), 135 parts by weight of pentaerythritol parts by weight and 30 parts by weight of xylene as a reflux solvent, the temperature is raised to 240° C., and when the acid value is below 5, the pressure is reduced, and the xylene is distilled off, and then cooled to obtain polyester polyol (A-1 ). Various physical properties (viscosity, acid value, hydroxyl value, color number (Heilig)) of this polyester polyol are shown in Table 1.

manufacture example 2-

[0100] (Production Example 2 - Synthesis of polyester polyol (A) using vegetable oil-derived raw material)

[0101] In the reactor, add 500 parts by weight of castor oil fatty acid (raw material derived from vegetable oil), 289 parts by weight of sebacic acid (raw material derived from vegetable oil), 121 parts by weight of 1,10-decanediol (raw material derived from vegetable oil) , 90 parts by weight of glycerin (raw material derived from vegetable oil) and 30 parts by weight of xylene as a reflux solvent, the temperature was raised to 240° C., and the pressure was reduced when the acid value was 5 or less, and the xylene was distilled off, and then cooled. , to obtain polyester polyol (A-2). Various physical properties (viscosity, acid value, hydroxyl value, color number (Heilig)) of this polyester polyol are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com