Water gas treatment device

A waste gas treatment device and waste gas technology are applied in the direction of climate sustainability, greenhouse gas capture, perfluorocarbon/hydrofluorocarbon capture, etc., which can solve the difficulties of semiconductor production efficiency reduction, cost and installation space constraints, etc. problem, to achieve the effect of preventing warming and excellent temperature correction correspondence ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, the best mode for carrying out the present invention will be described based on the drawings.

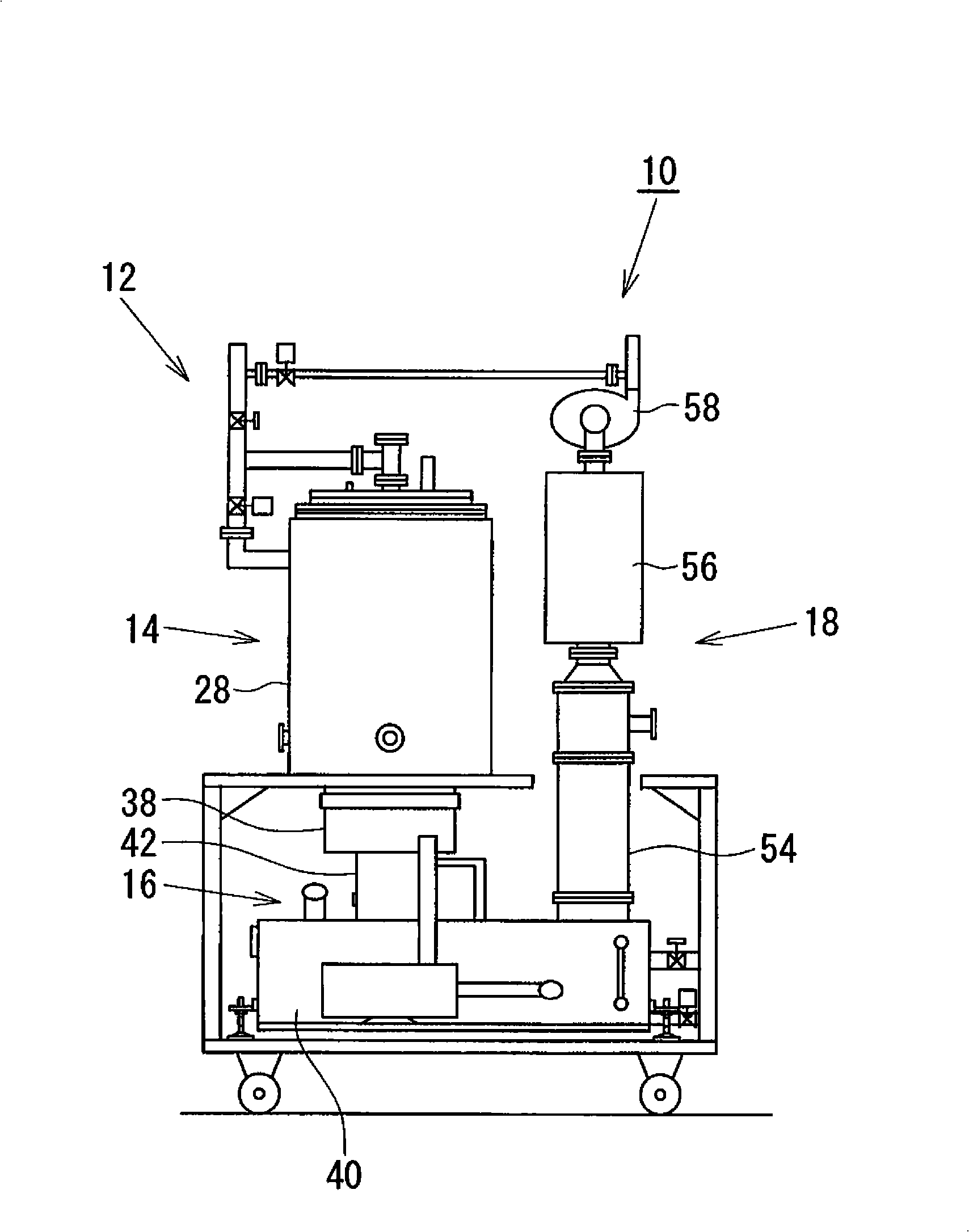

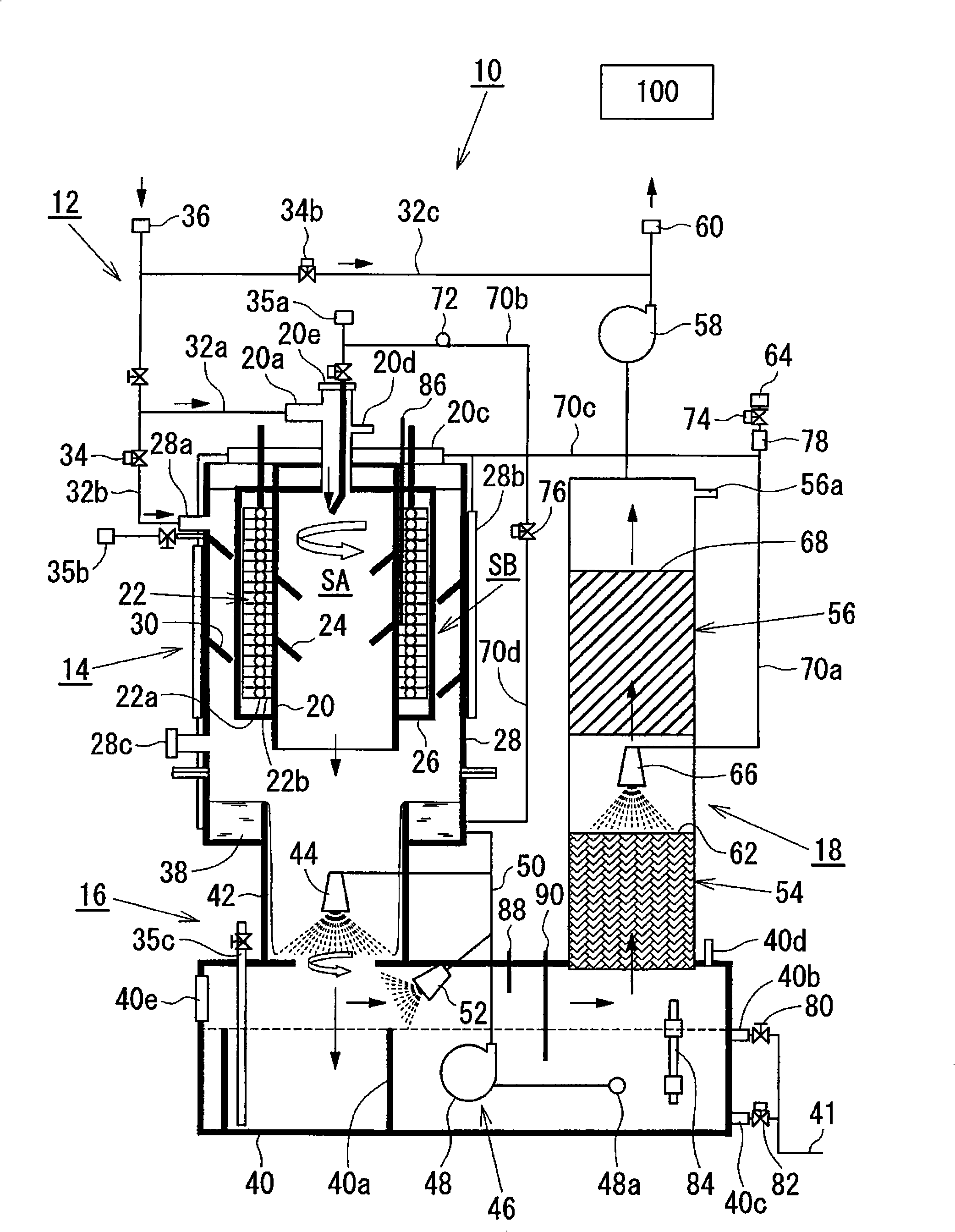

[0045] The exhaust gas treatment device 10 according to the embodiment of the present invention, such as figure 1 It includes an exhaust gas introduction part 12, a heat treatment part 14, a water treatment part 16, and a final treatment part 18, and has a width and depth of about 1 m and a height of about 2 m.

[0046] In the embodiment of the present invention, the waste gas introduction part 12 is provided with a circulation line of waste gas including toxic gas and warming effect gas such as PFC discharged in the semiconductor manufacturing process. In addition, the heat treatment part 14 is a part which heats exhaust gas. In addition, the water treatment part 16 is a part which cools the powder and gas produced|generated by heat-processing exhaust gas, and performs any one or all of hydrolysis, gas-liquid separation, and powder separation. In addition, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com