Weathering-resistant and permeable adhesive for paving a road and its constitutional body

An adhesive, water-permeable technology, used in adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve problems such as pure accumulation, affecting the natural circulation of rainwater, and resin yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

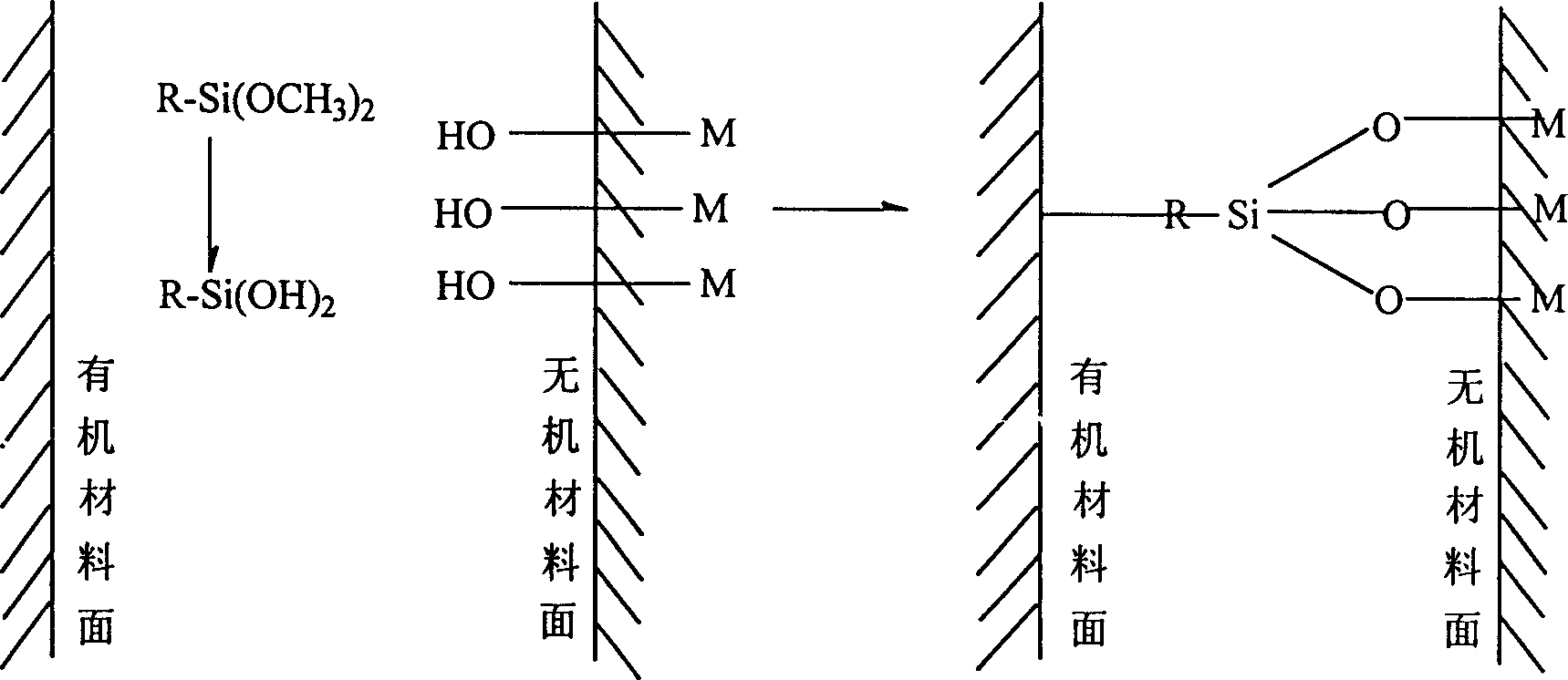

Method used

Image

Examples

experiment example

[0037] Preparation of weather-resistant fibrous epoxy resin adhesive and its structure:

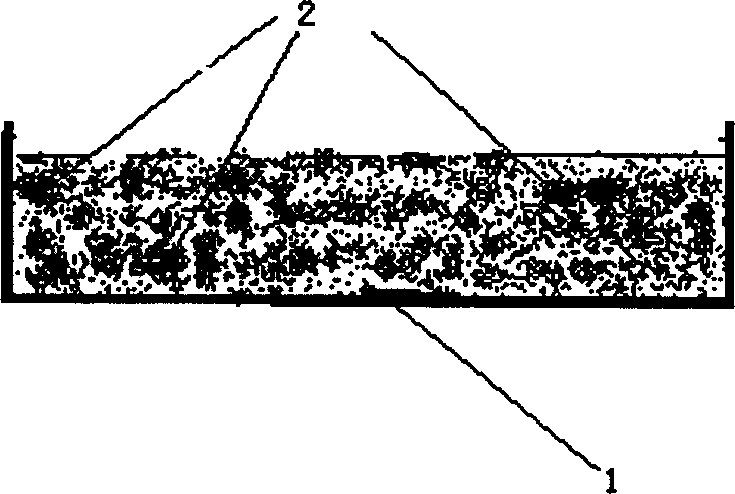

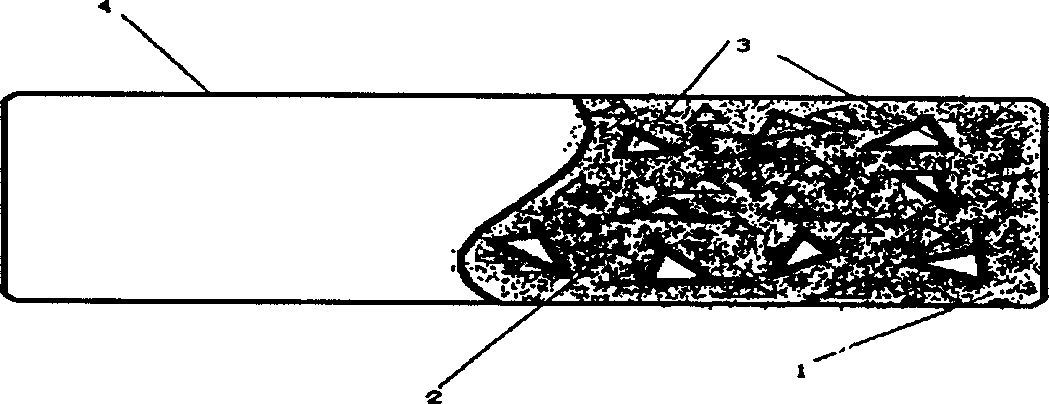

[0038] Add 30g of rock wool fiber, 100g of glass fiber, 40g of tackifier, and 15g of siliconized cement to 1000g of cycloaliphatic epoxy resin, stir and mix thoroughly at a temperature of 30-50°C to saturate and saturate various fiber resins to form Weather-resistant epoxy resin type fibrous resin. Add 500 g of non-yellowing and alicyclic polyamine to the above-mentioned fibrous resin, and mix uniformly to form a weather-resistant fibrous resin adhesive. Add 30Kg of light-colored sand grains (4-6mm) to the above-mentioned adhesive, mix evenly, and after a day of curing, a weather-resistant epoxy resin type fibrous resin adhesive structure is obtained. The bending strength of this structure is 113Kg / cm 2 , the compressive strength is 304Kg / cm 2 , porosity of 20 to 35%, with excellent strength performance and water permeability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com