Crawler maglev vehicle and conveyor

A magnetic levitation and crawler technology, which is applied to tracked vehicles, motor vehicles, electric vehicles, etc., can solve the problems of energy consumption of compressed air, large dust pollution, dust, etc., and achieve high power utilization efficiency, comprehensive cost reduction, and driving energy consumption low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

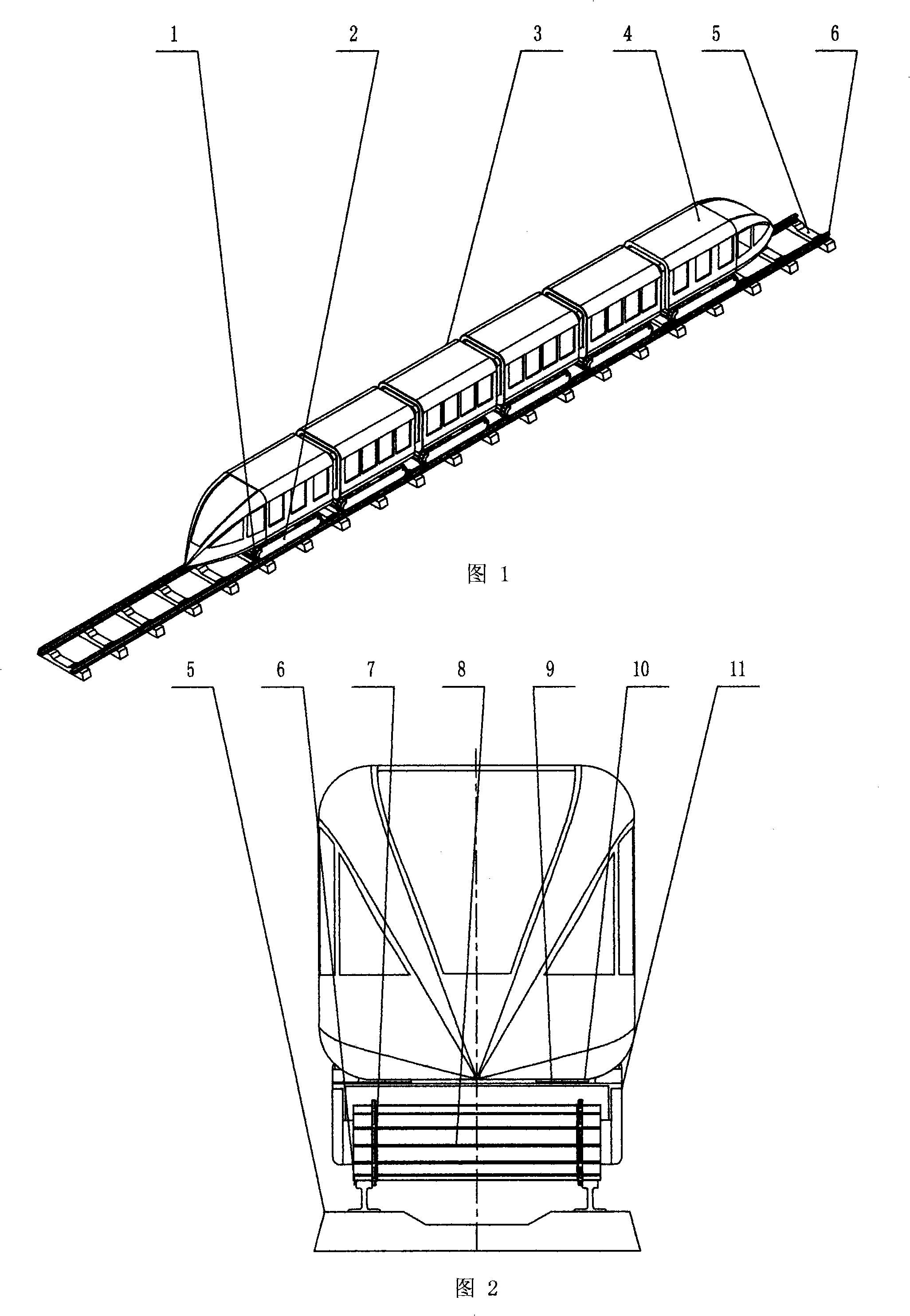

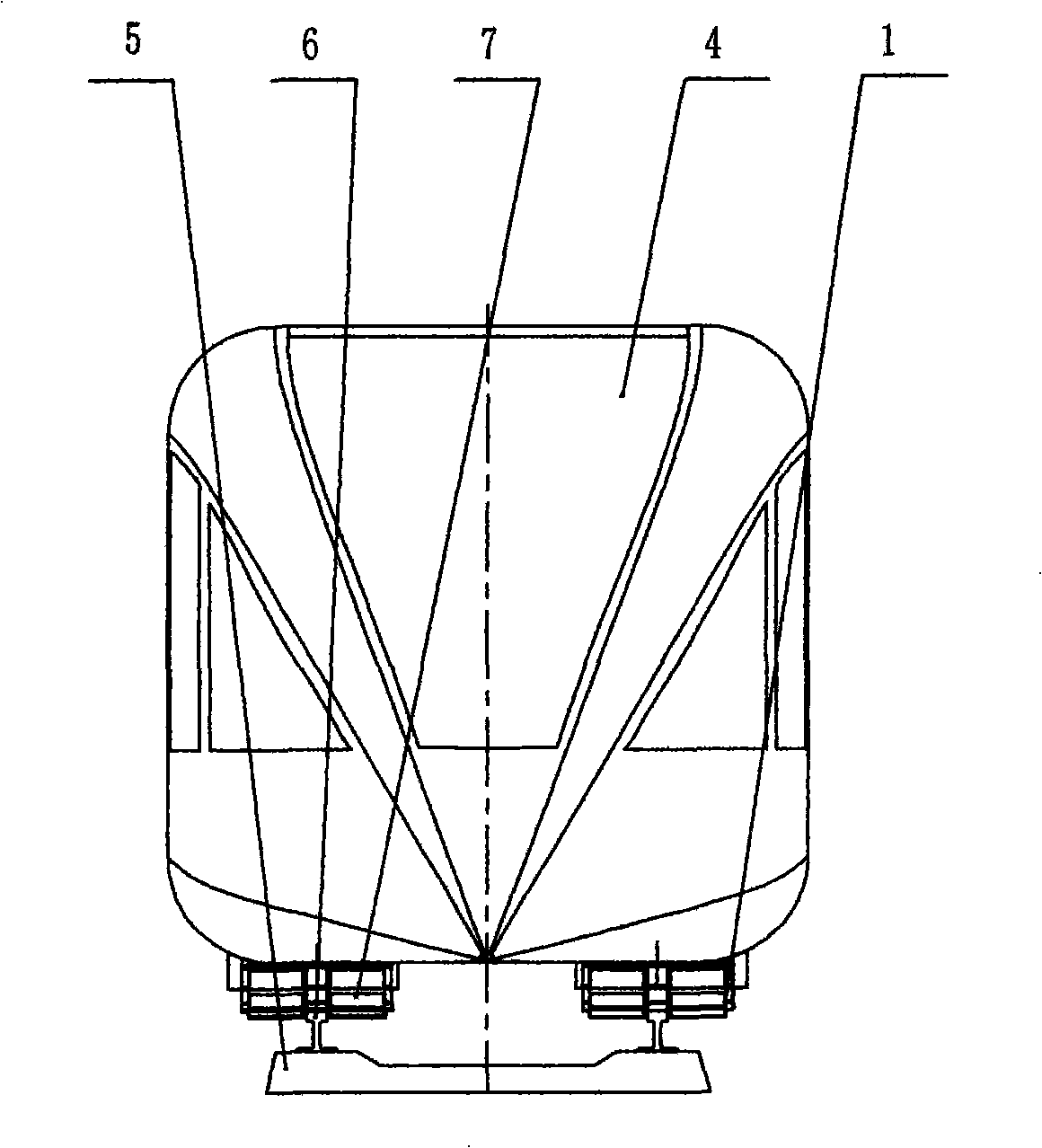

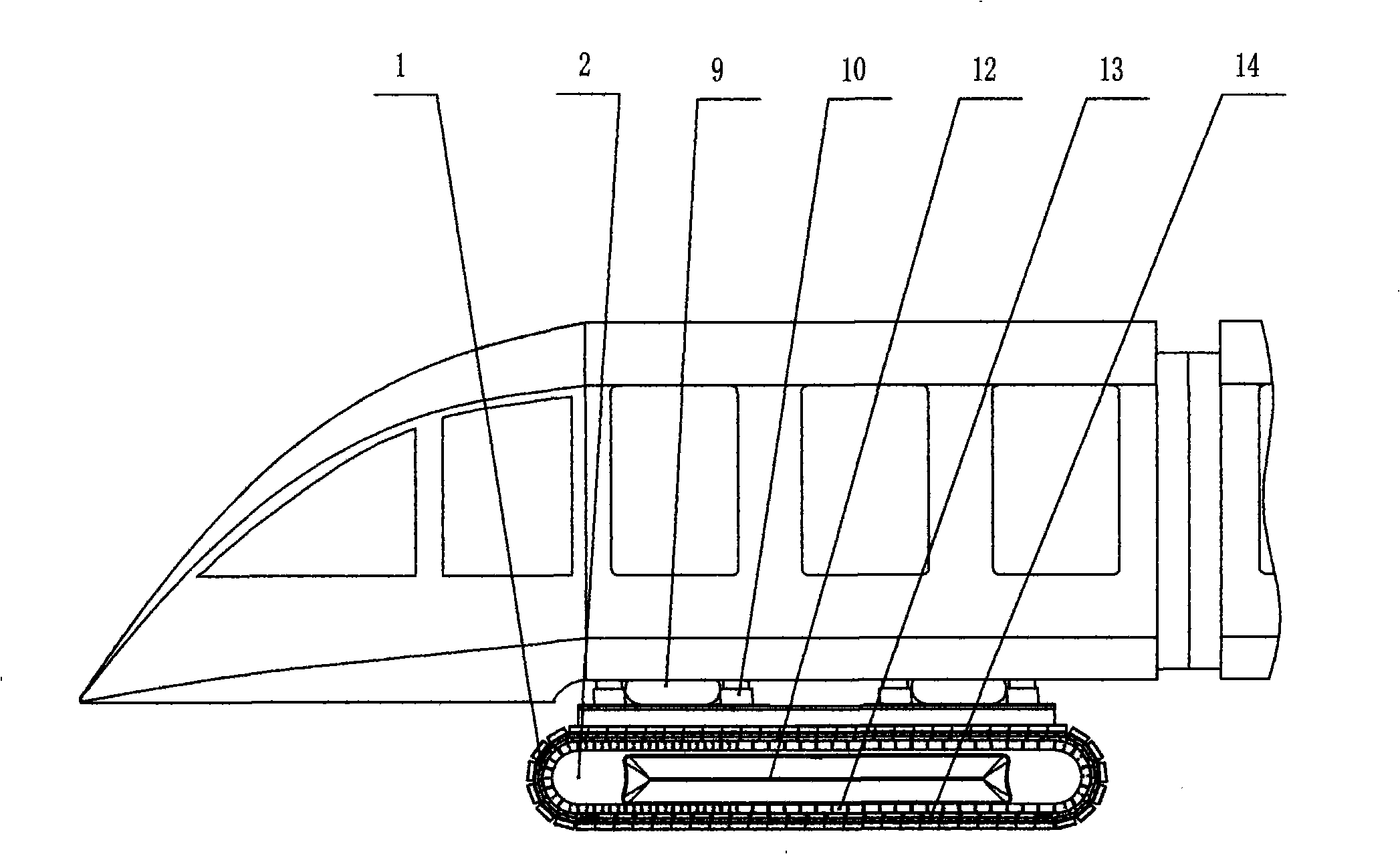

[0065] As shown in Figures 1, 2, 3, and 4, a crawler-type maglev train is mainly composed of a crawler belt 1, a suspension seat 2, a train car 3, a locomotive 4, a permanent magnet 14, a spring 9 and a suspension formed by a damper 10. 11 compositions.

[0066] As shown in Figure 1, existing railway system mainly is made up of rail 6 and road sleeper 5 and connection and damping pad at present, and crawler-type maglev train of the present invention can run on existing railway system, so can save To eliminate the construction cost of laying the maglev railway, and only need to manufacture the tracked maglev train to open to traffic.

[0067] As shown in Figures 2, 3, and 4, the suspension of the tracked magnetic levitation train can use the current gas spring damping suspension system (11). The crawler belt 1 on two rails 6 can be one, and as shown in Figure 2, crawler belt 1 is provided with two guide blocks 7, and the position is as the flange of existing train wheel. The ...

Embodiment 2

[0076] As shown in Figures 9, 10, 11, 12, 13, and 14, a crawler-type magnetic levitation vehicle mainly consists of a crawler belt 1, a suspension seat 2, a vehicle body 22, a suspension system 11 formed by a spring 9 and a damper 10.

[0077] The tire of wheeled vehicle is replaced with magnetic levitation track and just becomes crawler type magnetic levitation vehicle.

[0078] The number of magnetic levitation tracks can usually be 4, two at the front and rear, and the two at the front can be turned to control the direction.

[0079] The number of magnetic levitation tracks can also be 1, 2 or more.

[0080] The driving mode can adopt the transmission mode of the sprocket 23 driving the chain generally adopted at present, and the auxiliary wheel 27 can be arranged above the chain link 15 or the chain plate 8, and the auxiliary wheel 27 is separated from the chain link 15 at ordinary times. When the auxiliary wheel 27 is in contact with the chain link 15 or the chain plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com