Method and device for global warming prevention

A greenhouse and earth technology, applied in chemical instruments and methods, separation methods, greenhouse gas capture, etc., can solve problems such as a large amount of heat of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0161] For the composition and flow rate shown in Table 1, discharged from adipic acid manufacturing equipment, containing nitrous oxide gas (N 2 O) Nitrous oxide gas (N) in the gas to be treated (raw material gas) 2 O) Carry out thermal decomposition reaction.

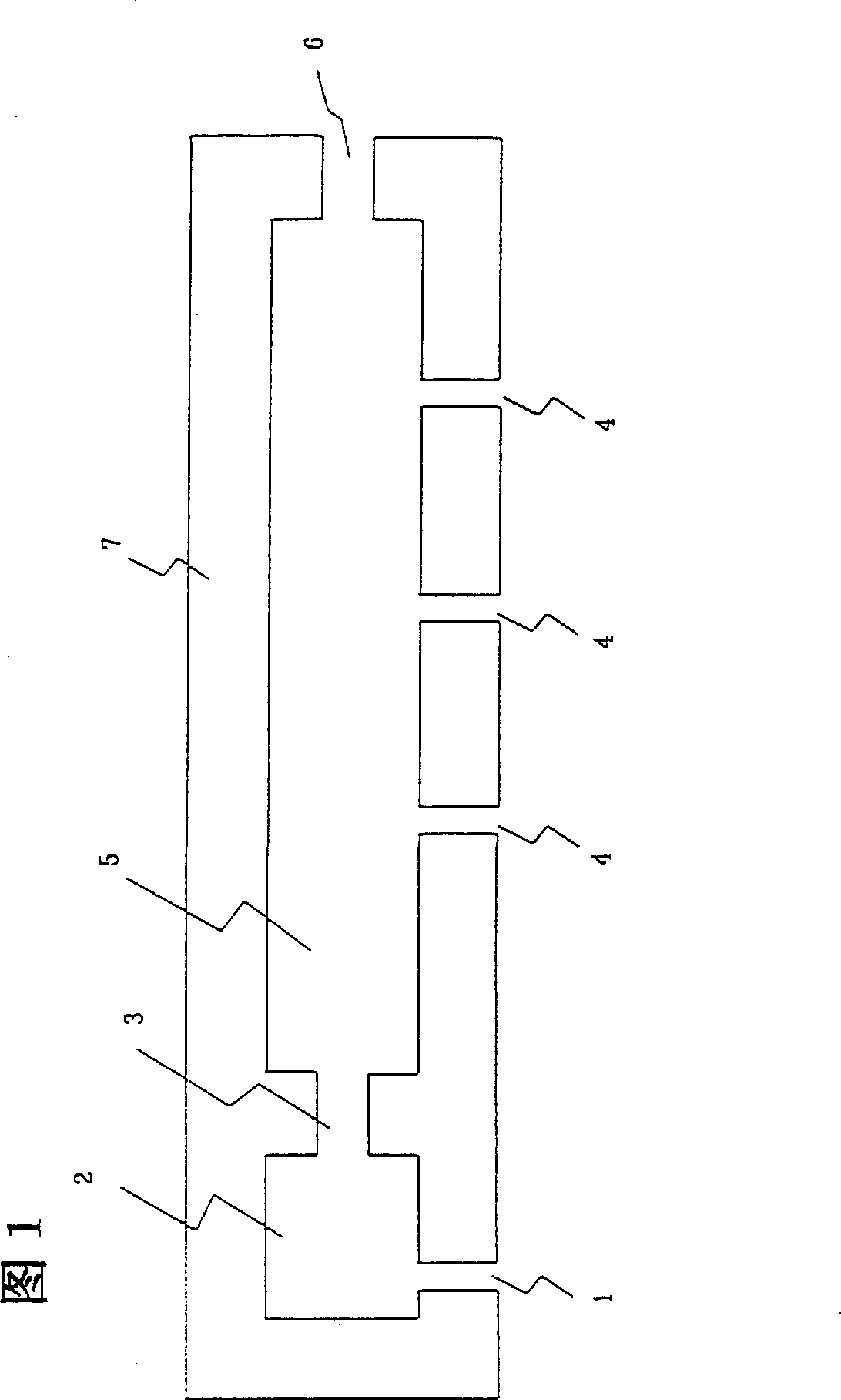

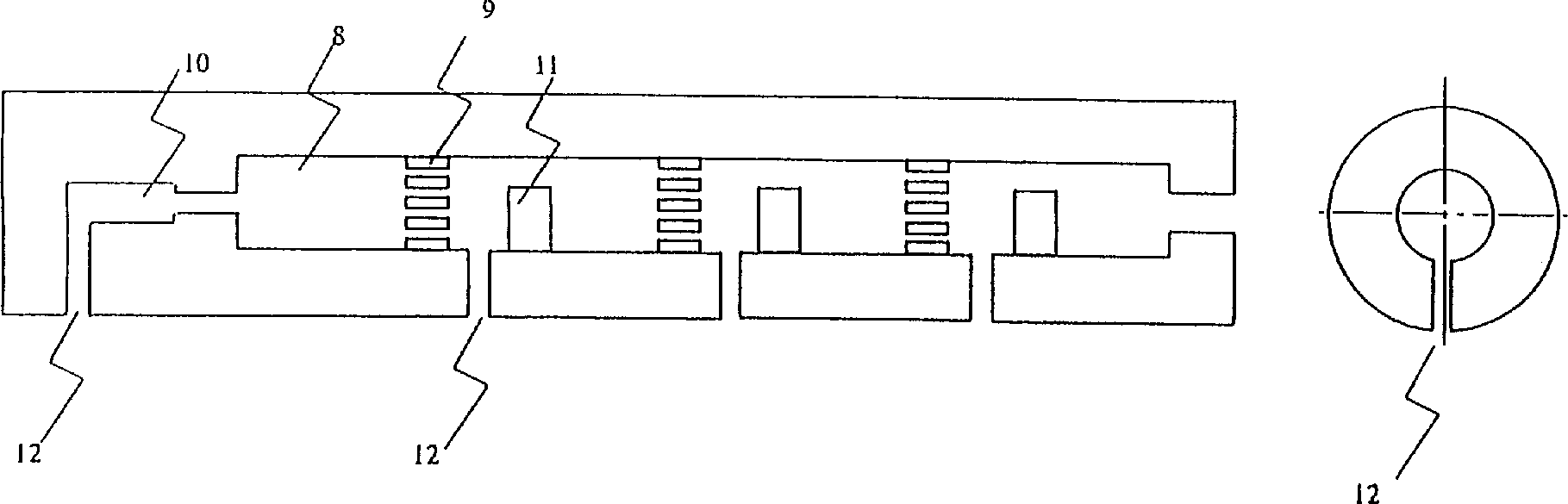

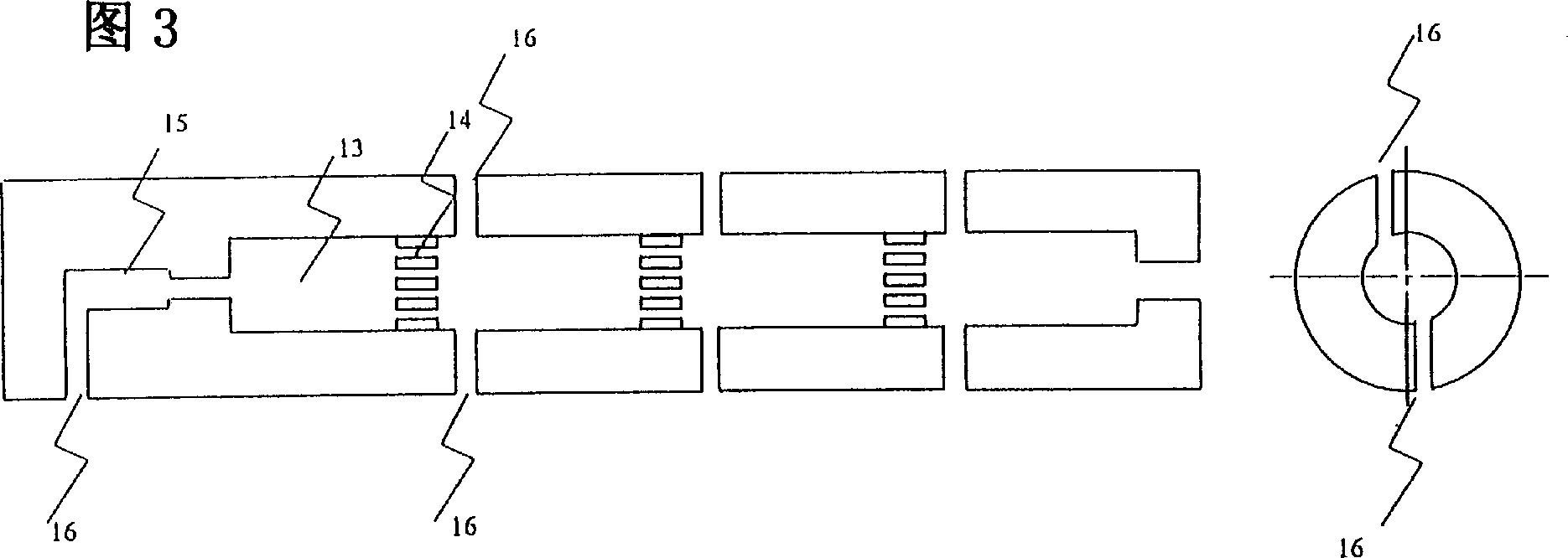

[0162] figure 2 It is a schematic explanatory diagram showing such a thermal decomposition device.

[0163] This pyrolysis reaction furnace (pyrolysis part 8) can be a kind of internal diameter be 450 millimeters, length be the cylindrical heat-resistant brick furnace of 4750 millimeters, the thickness of furnace wall is 300 millimeters. In the furnace, four thermal decomposition reaction chambers (nitrous oxide gas (N 2 O) with a decomposition reaction zone). The number of staged supply of the gas to be processed is four. The divided and preheated gas to be processed is introduced into the first reaction chamber, and the remaining divided gas to be processed is introduced into the second, third and fourth reacti...

Embodiment 2

[0166] Except that the supply temperature of the gas to be treated is 300°C and the flow rate of hydrogen gas supplied to the preheating part is 7.2 standard cubic meters per hour (Nm 3 / hr), the flow rate of the gas to be treated supplied to the preheating part, the second, the third, and the fourth reaction chamber is 55.7 standard cubic meters / hour (Nm 3 / hr), 60.0 standard cubic meters / hour (Nm 3 / hr), 72.9 standard cubic meters / hour (Nm 3 / hr), 91.4 standard cubic meters / hour (Nm 3 / hr), are the same as in Example 1, and under this condition, the nitrous oxide gas (N 2 O) Carrying out thermal decomposition.

[0167] At this time, the pressure in the pyrolysis furnace is 1.25 kg / cm2 (kg / cm 2 ), the temperature of the mixed airflow located at the entrance of the preheating part, the second, the third, and the fourth reaction chamber is 830°C respectively, and the temperature of the airflow discharged from the thermal decomposition furnace is 1027°C, so in the supplied t...

Embodiment 3

[0169] Except that the supply temperature of the gas to be treated is 700°C and the flow rate of hydrogen gas supplied to the preheating part is 0.1 standard cubic meter / hour (Nm 3 / hr), the flow rate of the gas to be treated supplied to the preheating part, the second, the third, and the fourth reaction chamber is 3 standard cubic meters / hour (Nm 3 / hr), 12.0 standard cubic meters / hour (Nm 3 / hr), 50.6 standard cubic meters / hour (Nm 3 / hr), 214.4 standard cubic meters / hour (Nm 3 / hr), are the same as in Example 1, and under this condition the nitrous oxide gas in the gas to be treated (N 2 O) Carrying out thermal decomposition.

[0170] At this time, the pressure in the pyrolysis furnace is 1.25 kg / cm2 (kg / cm 2 ), the temperature of the mixed airflow located at the entrance of the preheating part, the second, the third, and the fourth reaction chamber is 830°C respectively, and the temperature of the airflow discharged from the thermal decomposition furnace is 1263°C, so ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com